Active black K-BR and nonpolluting production technology thereof

A production process, K-BR technology, applied in the field of dyes, can solve the problems of complex production process, low solubility, high unit cost, etc., achieve low production cost, high product yield, and reduce printing and dyeing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

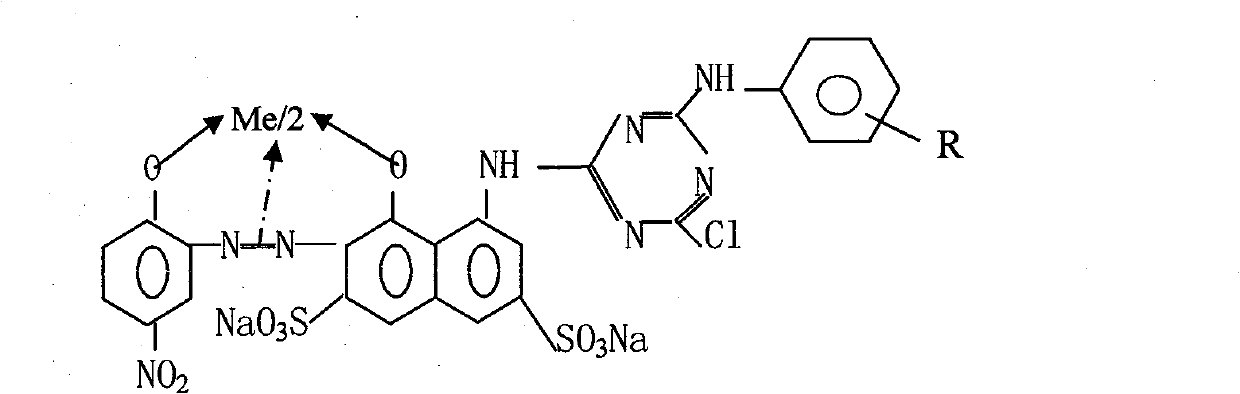

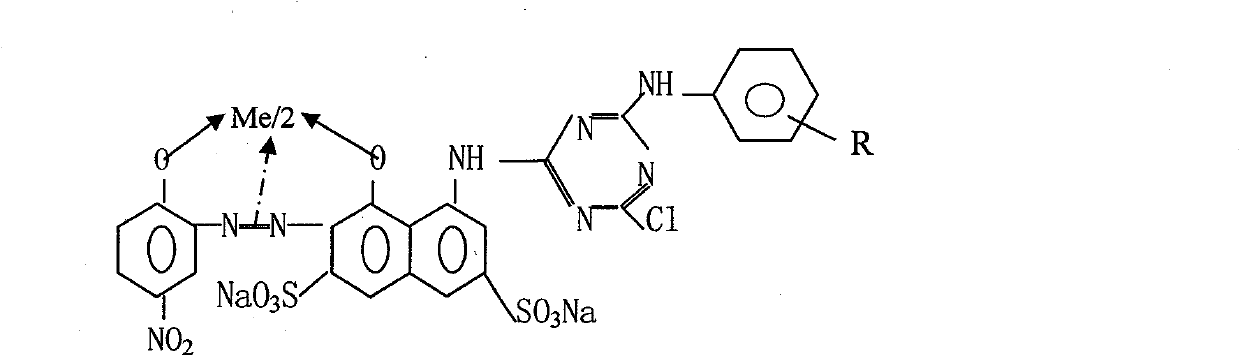

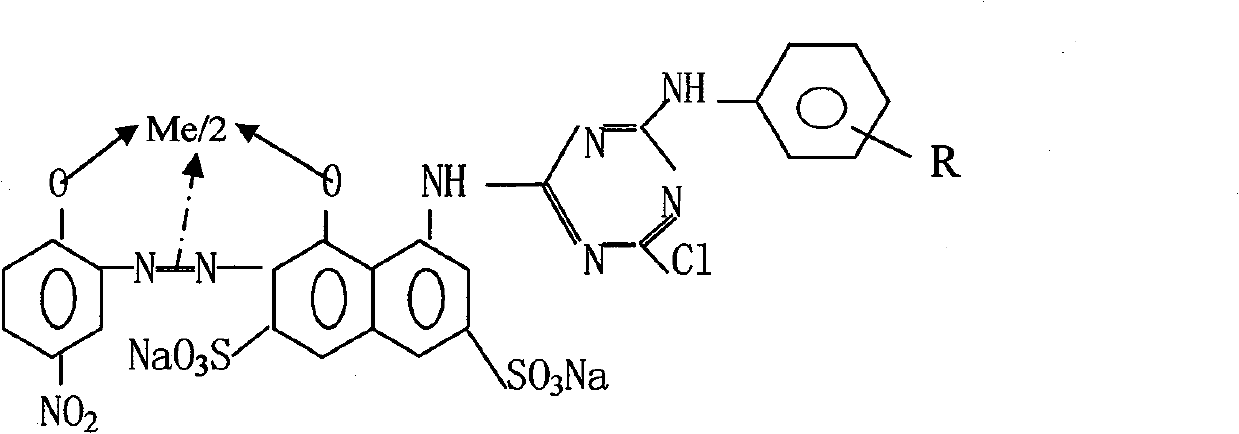

[0013] Embodiment 1, a kind of reactive black K-BR is characterized in that general structural formula is:

[0014]

[0015] Among them, Me=Cr or Co

[0016] R = right / inter / ortho SO 3 Na, COONa

[0017] The clean production process of this active black K-BR is:

[0018] 1) The diazotization of 4-nitro-2 amino-phenol with hydrochloric acid and sodium nitrite is carried out at 0-10°C, and the diazonium salt is neutralized with sodium acetate to PH=3.5-4, and then carried out with H acid solution Alkaline coupling, pH is 6.5-7.5, temperature is 5-10°C, and the coupling solution is the chromophore;

[0019] 2) The obtained coupling solution, that is, the chromophore is metal-complexed with chromium sulfate and sodium acetate or cobalt sulfate and liquid caustic soda. The complexation temperature is 90-110°C. neutral;

[0020] 3) Carry out primary condensation with sulfonic acid or formic acid derivatives of cyanuric chloride and aniline to free ammonia mass concentration≤...

Embodiment 2

[0024] Embodiment 2, referring to Example 1, the pH=6.5-8 during the two shrinkages, and the temperature is between 40-55°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| solubility (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com