Dyeing method for improving reactive dye fabric tray dyeing color strength

A technology of reactive dyes and color depth, which is applied in dyeing methods, textiles and papermaking, etc., can solve the problems of insufficient dyeing depth of reactive dyes, large discharge volume, and excessive dye consumption, so as to reduce pollutant discharge and save dyes, with obvious effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

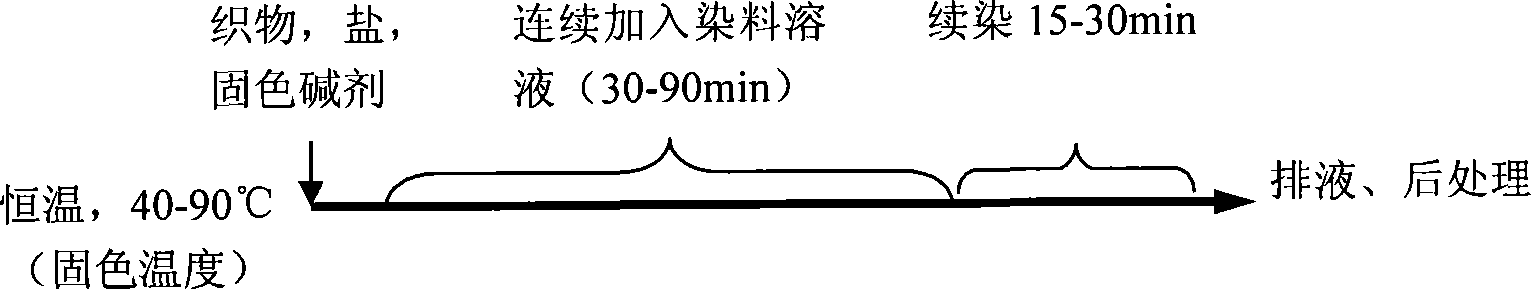

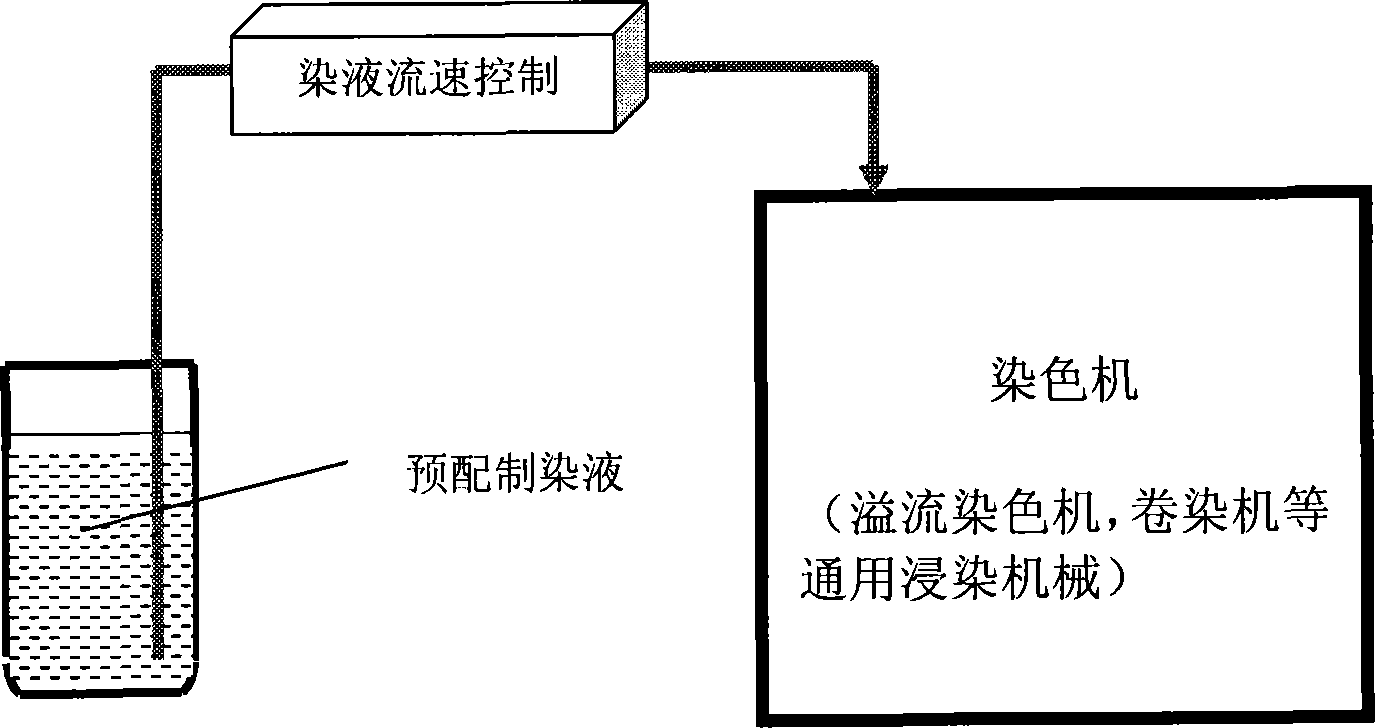

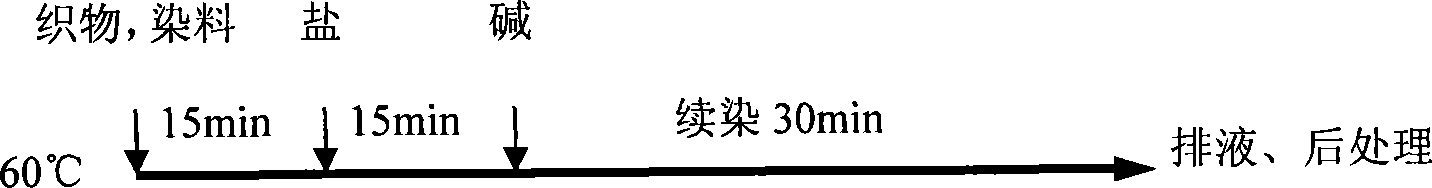

Method used

Image

Examples

Embodiment 1

[0082] When examining the dyeing of woven fabrics, when the same color depth is used, the percentage of dyestuffs can be saved by using the process of the present invention.

[0083] Dye: Levafix CA three-color reactive dye, Remazol black reactive dye (Dystar Company).

[0084] Woven fabric: khaki bleached semi-finished product, yarn count 20 / 16, density 128 / 60; poplin semi-finished product, yarn count 40 / 40, density 133 / 72.

[0085] Table 1 Saving rate of reactive dyes in woven fabric dyeing

[0086]

[0087]

[0088] By table 1, when Levafix CA three primary colors and black reactive dyestuff are dyeing poplin fabric, application process dyestuff saving rate of the present invention is 20~35%, and dyestuff consumption can reduce 27.2% on average; When khaki fabric is dyed, dyestuff saving rate is 16~28% , The average amount of dye can be reduced by 25.5%.

Embodiment 2

[0090] Investigate the dyeing of knitted fabrics, when the same color depth, using the process of the present invention can save the percentage of dyestuffs.

[0091] Dye: Levafix CA three-color reactive dye, Remazol black reactive dye (Dystar Company).

[0092] Knitted fabric: bleached semi-finished cotton sweater cloth, 250 g / m 2 .

[0093] Table 2 Saving rate of reactive dyes in knitted fabric dyeing

[0094]

[0095] Black N

[0096] By table 2, when Levafix CA three primary colors and black reactive dyestuff are dyed in knitted fabric (cotton sweater cloth), apply the process dyestuff saving rate of the present invention 16-38%, dye dark color saving rate higher, dyestuff consumption can reduce 25.5% on average %.

Embodiment 3

[0098] Investigate the change of color fastness of Levafix CA reactive dyes. Because in the new process of the present invention, the fixation mechanism of the dyestuff on the fabric has no difference with the conventional dyeing process, but the fixation concentration of the dyestuff on the fabric surface is improved. Therefore, the impact of the new process on color fastness may be mainly in terms of rubbing resistance. This example illustrates the changes in the color fastness to rubbing of fabrics dyed with similar depths of color by the conventional process and the new process.

[0099] Dye: Levafix three primary color reactive dye, Remazol black reactive dye (Dystar company).

[0100] Fabric: Semi-bleached poplin, count 40 / 40, density 133 / 72.

[0101] Table 3 Color fastness to rubbing of dyed fabrics

[0102]

[0103] According to the above test data, the color depth (K / S value) of the fabrics dyed by the two processes is very close (color di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com