Method for dyeing rayon fiber by using reduced dye

A cotton fiber and dye technology, applied in the field of fiber dyeing, to achieve the effect of improving the utilization rate, improving the dispersion performance, and no white core

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

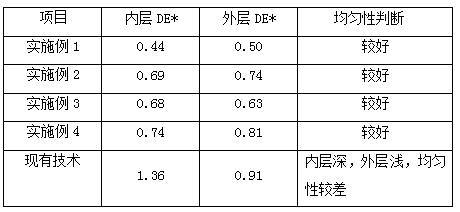

Examples

Embodiment 1

[0041] A method for dyeing rayon fibers with vat dyes, comprising the steps of:

[0042] A. Preprocessing

[0043] Transport the rayon yarn to the bathtub, add water, dyes and flattened o, keep it for 9 minutes, then add caustic soda, then add bone glue, triethanolamine and water, keep it for 9 minutes, then add hydrosulfite;

[0044] B. Dyeing

[0045] After raising the temperature of the bathtub to 60°C, keep it warm for 45 minutes, and then add 5% of the total amount of hydrosulfite in step A; keep it for 15 minutes;

[0046] C.Washing

[0047] Wash the dyed fiber 4 times with water, each time for 9 minutes;

[0048] D. Oxidation

[0049] Add glacial acetic acid and hydrogen peroxide into the bathtub, keep it for 27 minutes, and wash with water;

[0050] E. Soaping

[0051] Add soda ash and soaping agent into the bathtub, raise the temperature to 95°C, keep it for 18 minutes, then drain and wash to obtain dyed yarn;

[0052] F. Post-processing

[0053] After the soa...

Embodiment 2

[0069] A method for dyeing rayon fibers with vat dyes, comprising the steps of:

[0070] A. Preprocessing

[0071] Transport the rayon yarn to the bathtub, add water, dyes and flattened o, keep it for 8 minutes, then add caustic soda, then add bone glue, triethanolamine and water, keep it for 8 minutes, then add hydrosulfite;

[0072] B. Dyeing

[0073] After raising the temperature of the bathtub to 65°C, keep it warm for 40 minutes, and then add 5% of the total amount of hydrosulfite in step A; keep it for 20 minutes;

[0074] C.Washing

[0075] Wash the dyed fiber twice with water, each time for 8 minutes;

[0076] D. Oxidation

[0077] Add glacial acetic acid and hydrogen peroxide into the bathtub, keep it for 25 minutes, and wash with water;

[0078] E. Soaping

[0079] Add soda ash and soaping agent into the bathtub, raise the temperature to 90°C, keep it for 15 minutes, then drain and wash to obtain dyed yarn;

[0080] F. Post-processing

[0081] After the soape...

Embodiment 3

[0095] A method for dyeing rayon fibers with vat dyes, comprising the steps of:

[0096] A. Preprocessing

[0097] Transport the rayon yarn to the bathtub, add water, dyes and flat additives, keep it for 12 minutes, then add caustic soda, then add bone glue, triethanolamine and water, keep it for 12 minutes, then add hydrosulfite;

[0098] B. Dyeing

[0099] After raising the temperature of the bathtub to 60°C, keep it warm for 45 minutes, and then add 10% of the total amount of hydrosulfite in step A; keep it for 18 minutes;

[0100] C.Washing

[0101] Wash the dyed fiber 3 times with water, each time for 12 minutes;

[0102] D. Oxidation

[0103] Add glacial acetic acid and hydrogen peroxide into the bathtub, keep it for 30 minutes, and wash with water;

[0104] E. Soaping

[0105] Add soda ash and soaping agent into the bathtub, raise the temperature to 100°C, keep it for 20 minutes, then drain and wash to obtain dyed yarn;

[0106] F. Post-processing

[0107] After...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com