Dyeing process monitoring method

A dyeing process and data monitoring technology, applied in textile and papermaking, textile processing machine accessories, textile material processing and other directions, can solve the problem of inability to monitor dyeing process data, and achieve the effect of improving dyeing process and dyeing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A kind of dyeing process monitoring method of the present embodiment comprises the following steps:

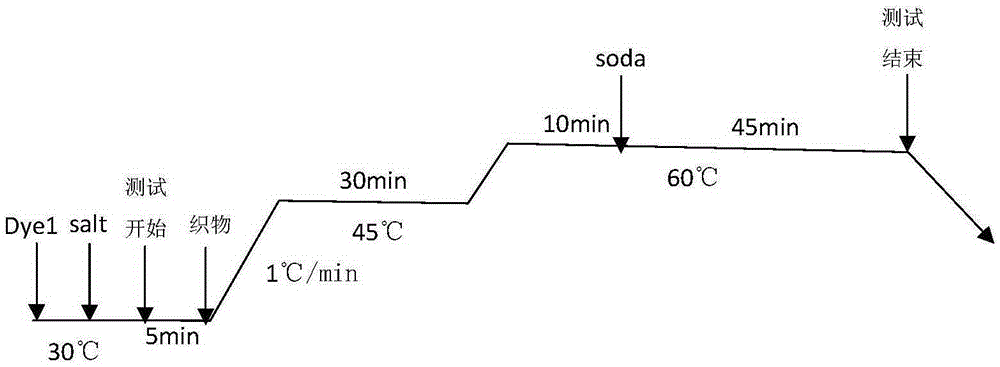

[0034] (1) The dyeing formula used is Dye1:2.0%Salt:50g / LSoda:15g / L, liquor ratio 1:10, and the process curve is as follows figure 1 shown;

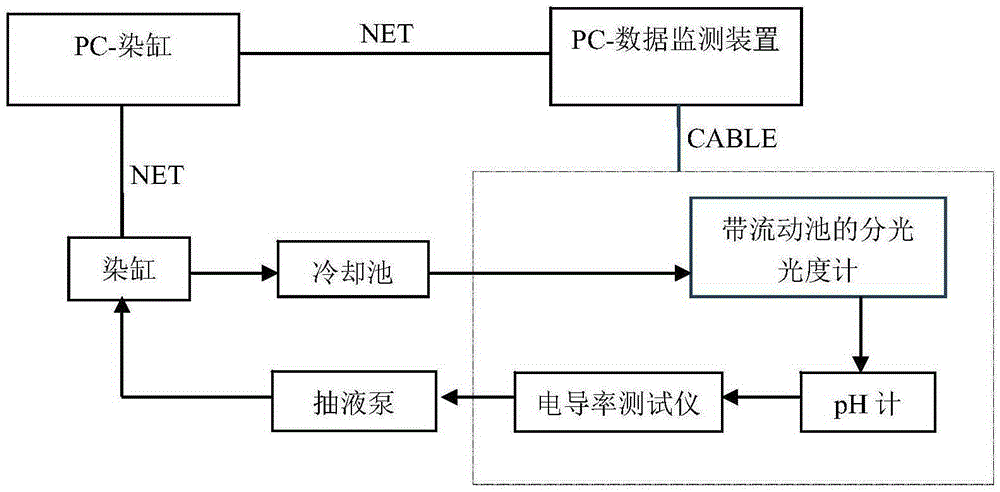

[0035] (2) if figure 2 As shown, the dye vat with temperature sensor, the dye solution cooling pool, the spectrophotometer (dual-wavelength UV-visible spectrophotometer) with quartz glass flow cell, pH meter, conductivity tester (liquid medium conductivity test) are connected through the pipeline. Apparatus) and liquid suction pump are connected in turn to form a loop. A water circulation pipeline is arranged outside the dye liquor cooling pool, and flowing cold water is passed through the pipeline to rapidly cool the dye liquor. At the same time, a data acquisition device is set, and the data The acquisition device includes a computer (PC)-dyeing vat and a PC-data monitoring device, the temperature sensor is wirelessly connect...

Embodiment 2

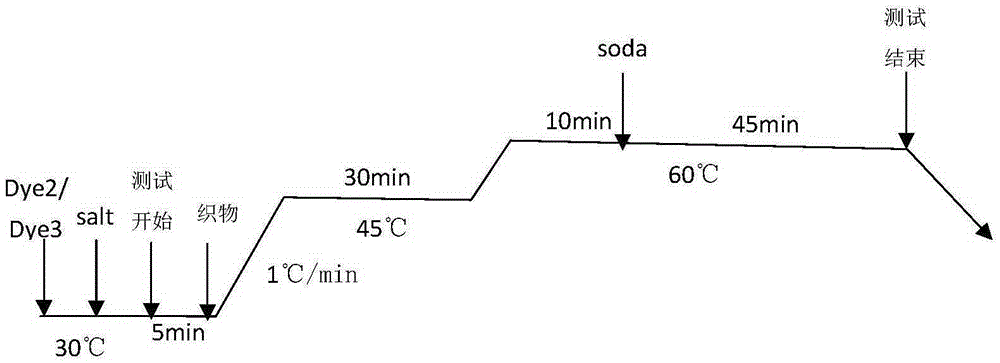

[0043] A kind of dyeing process monitoring method of this embodiment, the dyeing formula that adopts is Dye2:1.0%Dye3:1.0%Salt:50g / LSoda:15g / L, liquor ratio 1:10, process curve is as follows image 3 As shown, its steps are the same as in Example 1, and the difference is: in the uninterrupted circulation flow described in step (3), the flow velocity of the control dye liquor is 0.7m / s, and the temperature of the dye liquor after being cooled by the dye liquor cooling pool is is 28°C.

[0044] After repeated monitoring three times, the average value of each data was taken, and the results are shown in Table 2. The average deviation of the three results was 0.01, and the test was highly repeatable and the results were accurate.

[0045] Table 2

[0046]

[0047]

Embodiment 3

[0049] This embodiment is a kind of dyeing process monitoring method. The dyeing formula and steps adopted are the same as those in Embodiment 1, the difference is that in the uninterrupted circulation flow described in step (3), the flow velocity of the dyeing solution is controlled to be 0.8m / s, and the The temperature of the dye liquor after cooling in the dye liquor cooling pool is 30°C.

[0050] After repeated monitoring three times, the average value of each data was taken, and the results are shown in Table 3. The average deviation of the three results was 0.01, and the test was highly repeatable and the results were accurate.

[0051] table 3

[0052]

[0053]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com