Garlic sprout leaf fiber

A technology of garlic seedling leaves and fibers, applied in the field of materials, can solve the problems of poor fiber length uniformity, long fiber degumming time, and low fiber strength, and achieve the effects of improving strength, reducing degumming time, and improving degumming rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

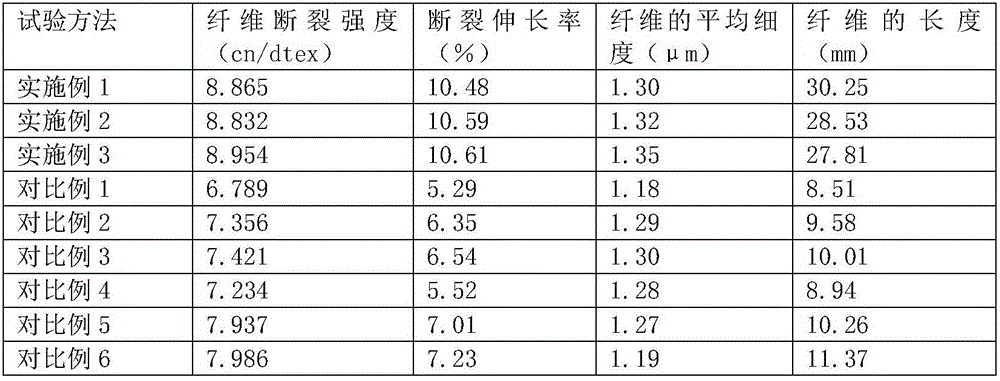

Examples

Embodiment 1

[0027] A preparation method of garlic sprout leaf fiber, the steps are as follows:

[0028] (1) Preprocessing:

[0029] Garlic leaves are picked, washed and dried, mechanically beaten to remove impurities, and then pretreated with compound acid. The treatment time is 10 minutes, the temperature is 50°C, and the bath ratio is 1:20. The formula of the compound acid is: citric acid 4g / L, oxalic acid 2g / L, malic acid 1g / L, tartaric acid 1g / L;

[0030] (2) Low temperature plasma treatment:

[0031] Wash the pretreated garlic leaf fiber twice, dry it, place it in the reaction chamber of the plasma generator, close the reaction chamber, evacuate it, connect it to oxygen, and turn on the radio frequency power supply after the airflow is stable, with a power of 300W. Time 3min, deflate, open the vacuum chamber, take out the garlic leaf fiber;

[0032] (3) Microwave irradiation and compound enzyme alternate treatment:

[0033] Put the low-temperature plasma-treated garlic leaf fiber...

Embodiment 2

[0035] Embodiment 2: a kind of preparation method of garlic leaf fiber, the steps are as follows:

[0036] (1) Preprocessing:

[0037] Garlic leaves are picked, washed and dried, mechanically beaten to remove impurities, and then pretreated with compound acid, the treatment time is 20 minutes, the temperature is 60°C, and the bath ratio is 1:20. The formula of the compound acid is: citric acid 4g / L, oxalic acid 2g / L, malic acid 1g / L, tartaric acid 1g / L;

[0038] (2) Low temperature plasma treatment:

[0039] Wash the pretreated garlic leaf fiber twice, dry it, place it in the reaction chamber of the plasma generator, close the reaction chamber, evacuate, insert oxygen, and turn on the radio frequency power supply after the air flow is stable, with a power of 350W. Time 4min, deflate, open the vacuum chamber, take out the garlic leaf fiber;

[0040] (3) Microwave irradiation and compound enzyme alternate treatment:

[0041] Put the garlic seedling fiber after low-temperatur...

Embodiment 3

[0044] A preparation method of garlic sprout leaf fiber, the steps are as follows:

[0045] (1) Preprocessing:

[0046] Garlic leaves are picked, washed and dried, mechanically beaten to remove impurities, and then pretreated with compound acid, the treatment time is 30 minutes, the temperature is 70°C, and the bath ratio is 1:20. The formula of the compound acid is: citric acid 4g / L, oxalic acid 2g / L, malic acid 1g / L, tartaric acid 1g / L;

[0047] (2) Low temperature plasma treatment:

[0048] Wash the pretreated garlic leaf fiber twice, dry it, place it in the reaction chamber of the plasma generator, close the reaction chamber, evacuate, connect oxygen, and turn on the radio frequency power supply after the air flow is stable, the power is 400W, and the treatment Time 5min, deflate, open the vacuum chamber, take out the garlic leaf fiber;

[0049] (3) Microwave irradiation and compound enzyme alternate treatment:

[0050] Put the garlic leaf fiber after low-temperature pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com