Degumming method of rice bran oil

A degumming method and rice bran oil technology, which are applied in the direction of fat oil/fat refining, fat production, etc., can solve the problems of decolorization of rice bran oil, adverse effects of refining processes, complicated equipment operation, and high residual phosphorus content in oil, and are beneficial to removing, Simple process and low residual phosphorus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

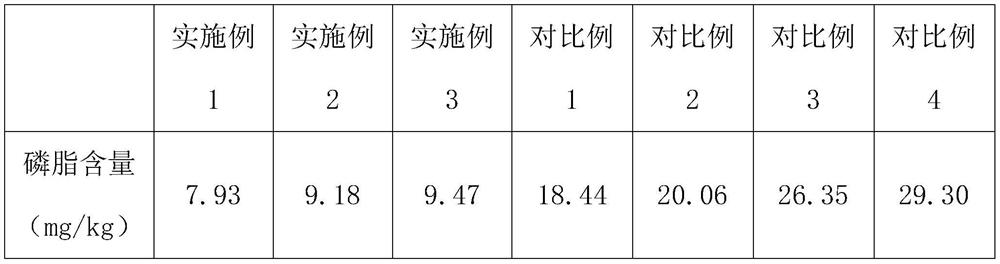

Examples

Embodiment 1

[0019] A degumming method for rice bran oil, comprising the following steps:

[0020] S1. Mix the acid solution of carboxymethyl cellulose and rice bran crude oil in a volume ratio of 0.2:100, heat to 65°C, and then keep stirring for 20 minutes. The acid solution of carboxymethyl cellulose is made of carboxymethyl cellulose It is obtained by uniformly dispersing in an aqueous phosphoric acid solution with a concentration of 85%, and in the acid solution of carboxymethyl cellulose, the content of carboxymethyl cellulose is 1% by weight;

[0021] S2, the aqueous solution of the hydroxypropyl guar gum that concentration is 0.4wt% is heated to 65 ℃, then adds in the material that step S1 obtains, first under the condition of 300W supersonic treatment 8min, then insulated and stirred for 20min, through rotating speed is 3500r / Centrifuge for 15 minutes under the condition of 1 min, and take the upper layer of oil to obtain the degummed rice bran oil, wherein the volume ratio of the...

Embodiment 2

[0023] A degumming method for rice bran oil, comprising the following steps:

[0024] S1. Mix the acid solution of carboxymethyl cellulose and crude rice bran oil in a volume ratio of 0.25:100, heat to 70°C, and then keep stirring for 25 minutes. The acid solution of carboxymethyl cellulose is made of carboxymethyl cellulose Obtained by uniform dispersion in an aqueous solution of oxalic acid with a concentration of 20%, and in the acid solution of carboxymethyl cellulose, the content of carboxymethyl cellulose is 1.5wt%;

[0025] S2, the aqueous solution of the hydroxypropyl guar gum that concentration is 0.5wt% is heated to 70 ℃, then adds in the material that step S1 obtains, first ultrasonic treatment 5min under 400W condition, then insulation and stirring 25min, through rotating speed is 4500r / Centrifuge for 10 minutes under the condition of 1 min, and take the upper layer of oil to obtain the degummed rice bran oil, wherein the volume ratio of the aqueous solution of hy...

Embodiment 3

[0027] A degumming method for rice bran oil, comprising the following steps:

[0028] S1. Mix the acid solution of carboxymethyl cellulose and crude rice bran oil in a volume ratio of 0.3:100, heat to 80°C, and then keep stirring for 30 minutes. The acid solution of carboxymethyl cellulose is made of carboxymethyl cellulose It is uniformly dispersed in an aqueous solution of citric acid with a concentration of 50%, and in the acid solution of carboxymethyl cellulose, the content of carboxymethyl cellulose is 2wt%;

[0029] S2. Heating the aqueous solution of hydroxypropyl guar gum with a concentration of 0.6wt% to -80°C, then adding it to the material obtained in step S1, first ultrasonically treating it at 500W for 4min, then insulated and stirring for 30min, and passing through at a speed of 5000r Centrifuge and separate for 5 minutes under the condition of 1 / min, take the upper layer of oil, and obtain the degummed rice bran oil, in which the volume ratio of the aqueous sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com