Reverse micelle system and application thereof in acid dye dyeing

An acid dye, reverse micelle technology, applied in dyeing, textile and papermaking, etc., can solve the problems of limited reverse micelle system, harm to human health, difficult to recycle and reuse, etc., to reduce the amount of water and reduce the cost of dyeing , the effect of water saving and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

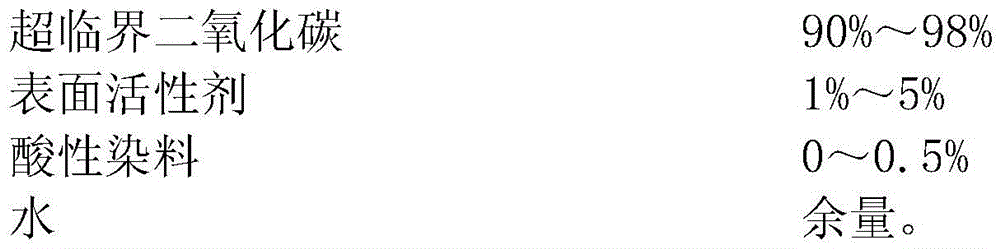

Method used

Image

Examples

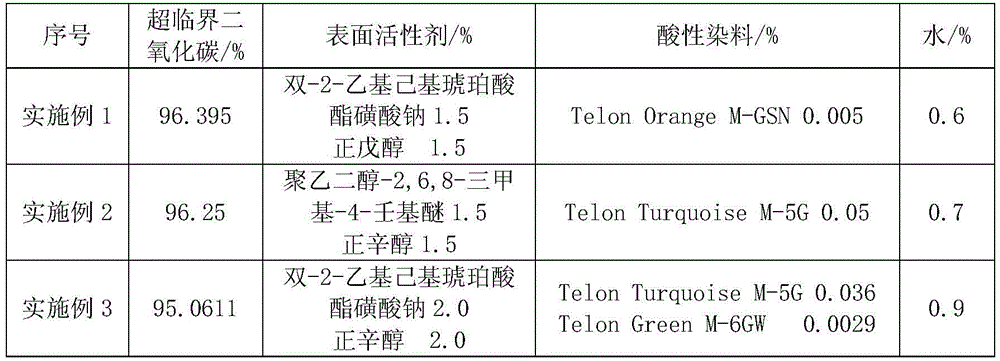

Embodiment 1

[0025] (1) join in the dissolving tank of supercritical carbon dioxide dyeing equipment according to the tensio-active agent of table 1 formula consumption and acid dyestuff aqueous solution;

[0026] (2) Put the wool fabric into the dyeing tank of the supercritical carbon dioxide dyeing equipment according to the mass ratio of 1:20 (wool: supercritical carbon dioxide);

[0027] (3) The dyeing temperature is 80°C, the dyeing pressure is 25MPa, and the dyeing time is 20min;

[0028] (4) Lower the dyeing temperature, remove the pressure, take out the dyed fabric, and reclaim the surfactant in the supercritical dyeing equipment;

[0029] (5) High-efficiency detergent 2g / L, bath ratio 1:50, soap at 90°C for 20 minutes, then wash with water and dry.

Embodiment 2

[0033] (1) join in the dissolving tank of supercritical carbon dioxide dyeing equipment according to the tensio-active agent of table 1 formula consumption and acid dyestuff aqueous solution;

[0034] (2) Put the mulberry silk fabric into the dyeing tank of supercritical carbon dioxide dyeing equipment according to the mass ratio mass ratio of 1:20 (mulberry silk: supercritical carbon dioxide);

[0035] (3) The dyeing temperature is 80°C, the dyeing pressure is 20MPa, and the dyeing time is 40min;

[0036] (4) Lower the dyeing temperature, remove the pressure, take out the dyed fabric, and recover the surfactant in the supercritical dyeing equipment.

[0037] (5) High-efficiency detergent 2g / L, bath ratio 1:50, soap at 90°C for 20 minutes, then wash with water and dry.

Embodiment 3

[0041] (1) join in the dissolving tank of supercritical carbon dioxide dyeing equipment according to the tensio-active agent of table 1 formula consumption and acid dyestuff aqueous solution;

[0042] (2) Put the nylon fabric into the dyeing tank of the supercritical carbon dioxide dyeing equipment according to the mass ratio mass ratio of 1:20 (nylon: supercritical carbon dioxide);

[0043] (3) The dyeing temperature is 95°C, the dyeing pressure is 25MPa, and the dyeing time is 30min;

[0044] (4) Lower the dyeing temperature, remove the pressure, take out the dyed fabric, and recover the surfactant in the supercritical dyeing equipment.

[0045] (5) High-efficiency detergent 2g / L, bath ratio 1:50, soap at 90°C for 20 minutes, then wash with water and dry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical point | aaaaa | aaaaa |

| critical point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com