Blanket dyeing device and dyeing method

A dyeing device and dyeing method technology, applied in the processing of textile material equipment configuration, textile and papermaking, liquid/gas/steam textile processing, etc. High operability, overcoming color flower, simple and practical effect of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

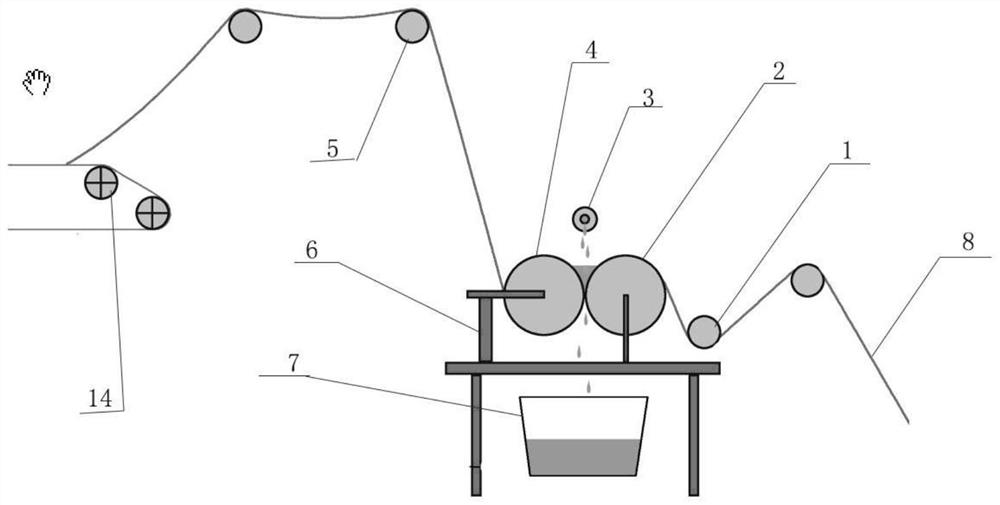

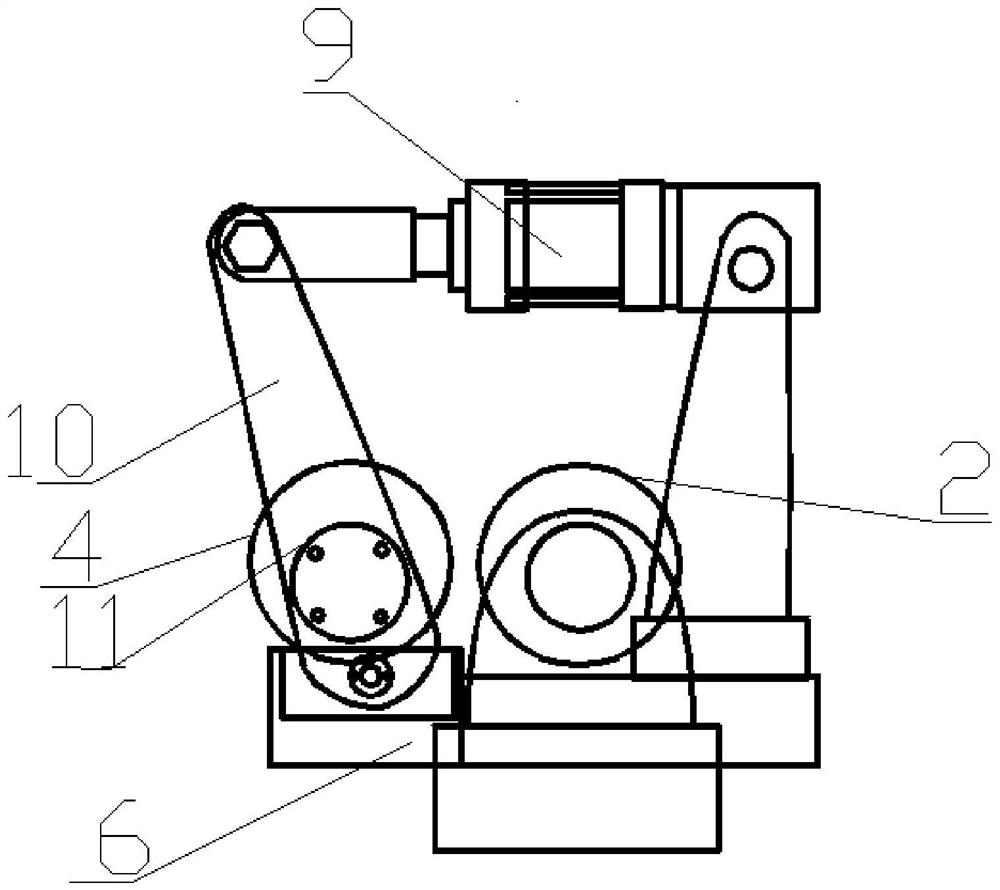

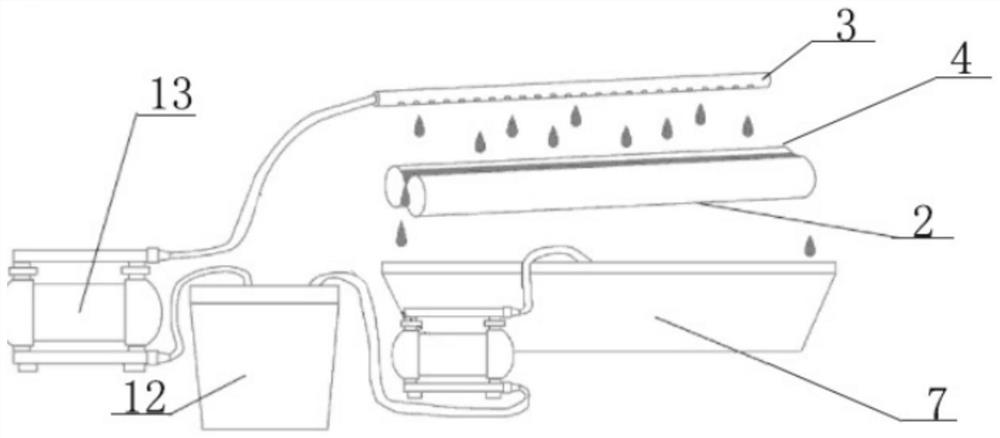

[0025] As shown in the figure, a kind of blanket dyeing device provided by the present invention includes a cloth-in traction device 1, a cloth-out traction device 5, a drying device 14, a frame 6, a pulping device and a pulping device; a cloth-in traction device 1 It includes a cloth-feeding traction roller and a spreading roller driven by a motor. The press device includes a driving roller 2 and a pressure roller 4. The driving roller 2 and the pressure roller 4 are arranged in parallel. The distance between the driving roller 2 and the pressure roller 4 is 0-8cm. The driving roller 2 is arranged on the frame 6, the rotating rod of the driving roller 2 is connected to the motor, the two ends of the pressure roller 4 are connected to the middle and lower end of the handle 10 through the bearing 11, the lower end of the handle 10 is connected to the frame 6 through a stud, and the upper end of the handle 10 is connected to the frame through a screw. The column is connected to t...

Embodiment 2

[0027] A dyeing method utilizing a blanket dyeing device, the specific method is as follows:

[0028] The blanket gray cloth 8 is drawn by the cloth-entry traction device 1 to the top of the driving roller 2, wraps around the driving roller 2, and then comes out from the bottom of the pressure roller 4, and reaches the drying device 14 through the cloth-out traction device 5; the connecting rod of the control cylinder 9 is elongated, The connecting rod control handle 10 drives the pressure roller 4 close to the driving roller 2, so that the groove formed by the pressure roller 4, the gray cloth 8 and the driving roller 2, the distance between the driving roller 2 and the pressure roller 4 is 6 mm, and the driving roller 2 and the pressure roller 4 The pressure between the gray cloth 8 is 0.45MPa; open the suction pump, the flow rate of the suction pump is 9m 3 / h, so that the spray pipe 3 sprays the slurry into the groove through the slurry outlet, fills the groove, turns on t...

Embodiment 3

[0030] A dyeing method utilizing a blanket dyeing device, the specific method is as follows:

[0031] The blanket gray cloth 8 is drawn by the cloth-entry traction device 1 to the top of the driving roller 2, wraps around the driving roller 2, and then comes out from the bottom of the pressure roller 4, and reaches the drying device 14 through the cloth-out traction device 5; the connecting rod of the control cylinder 9 is elongated, The connecting rod control handle 10 drives the pressure roller 4 close to the driving roller 2, so that the groove formed by the pressure roller 4, the gray cloth 8 and the driving roller 2, the distance between the driving roller 2 and the pressure roller 4 is 4mm, and the driving roller 2 and the pressure roller 4 The pressure between the gray cloth 8 is 0.25MPa; open the suction pump, the flow rate of the suction pump is 6m 3 / h, so that the spray pipe 3 sprays the slurry into the groove through the slurry outlet hole, fills the groove, turns ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com