Automatic processing system for dyeing loose fibers

A processing system and bulk fiber technology, applied in the field of automated processing systems, can solve the problems of low degree of automation in bulk fiber dyeing, failure to meet fast delivery requirements, and high labor intensity, so as to reduce labor production intensity, shorten production cycle, and reduce The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

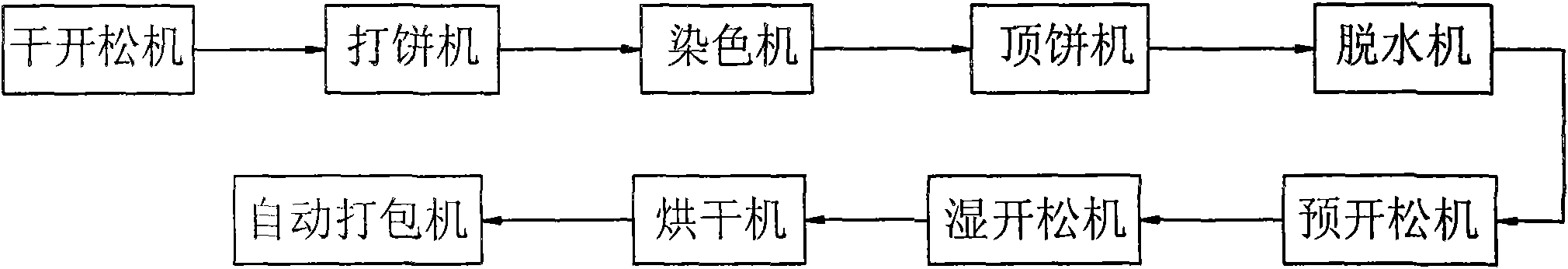

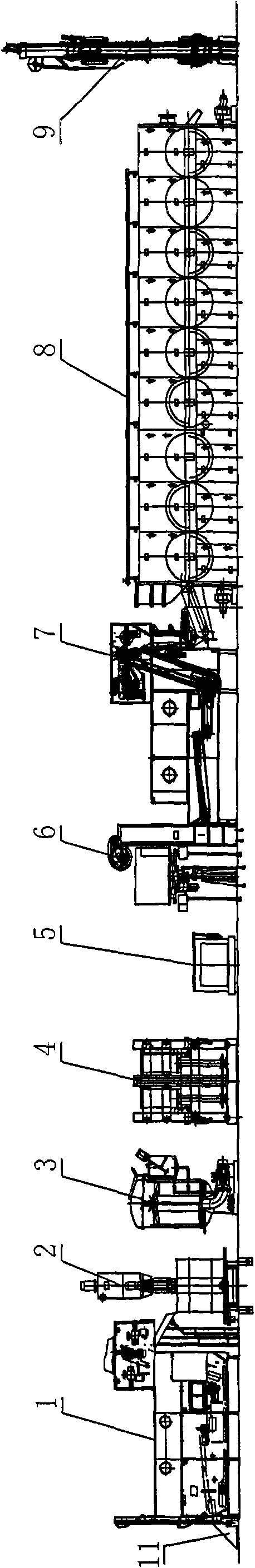

[0030] Such as figure 1 , image 3 As shown, the automatic processing system for loose fiber dyeing of the present invention includes a dry opener 1, a cake maker 2, a dyeing machine 3, a cake top machine 4, a dehydrator 5, a pre-opener 6, a wet opener, and a dry opener connected in sequence. Machine 7, drying machine 8 and automatic packing machine 9, these equipment constitute a production line.

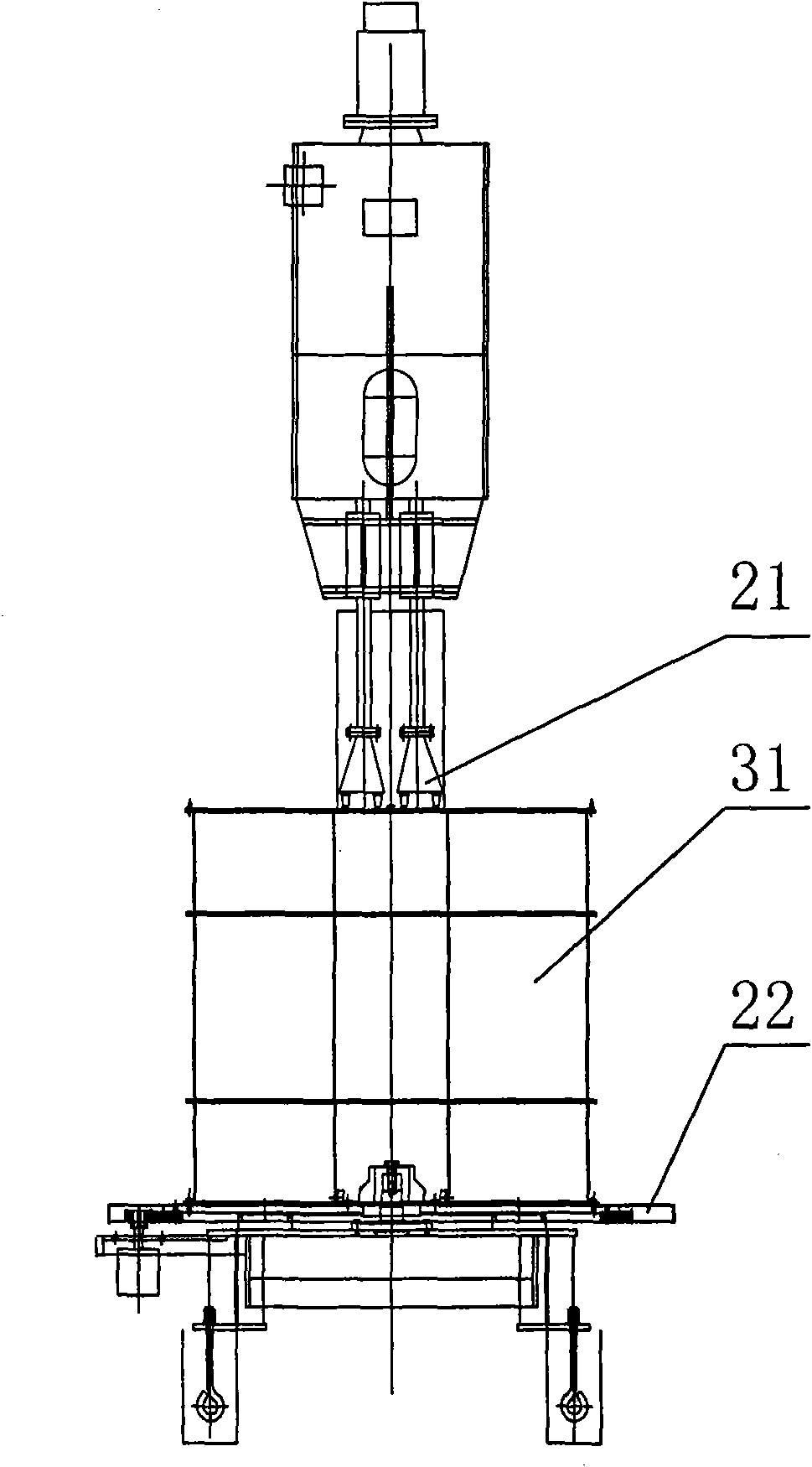

[0031] Such as figure 2 As shown, the cake making machine 2 includes a mechanical foot 21 that can move up and down, and a rotatable turntable 22 is provided below the mechanical foot 21, and a sarong 31 can be placed on the turntable 22.

[0032] The sarong 31 can accommodate loose fibers, and can be put into the dyeing machine 3 as a whole for dyeing. Such as Figure 4 As shown, a tray 32 is arranged inside the sarong 31, and the tray 32 is detachably connected to the bottom of the sarong. Pallet 32 is connected with hoisting chain, so that hoisting. The bottom of the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com