Automatic blanking wooden ball processing apparatus and method

A processing device and automatic blanking technology, which is applied to metal processing equipment, manufacturing tools, spherical grinders, etc., can solve the problems of low automation, high production cost, and low production efficiency, so as to improve the automation of production and reduce production costs , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

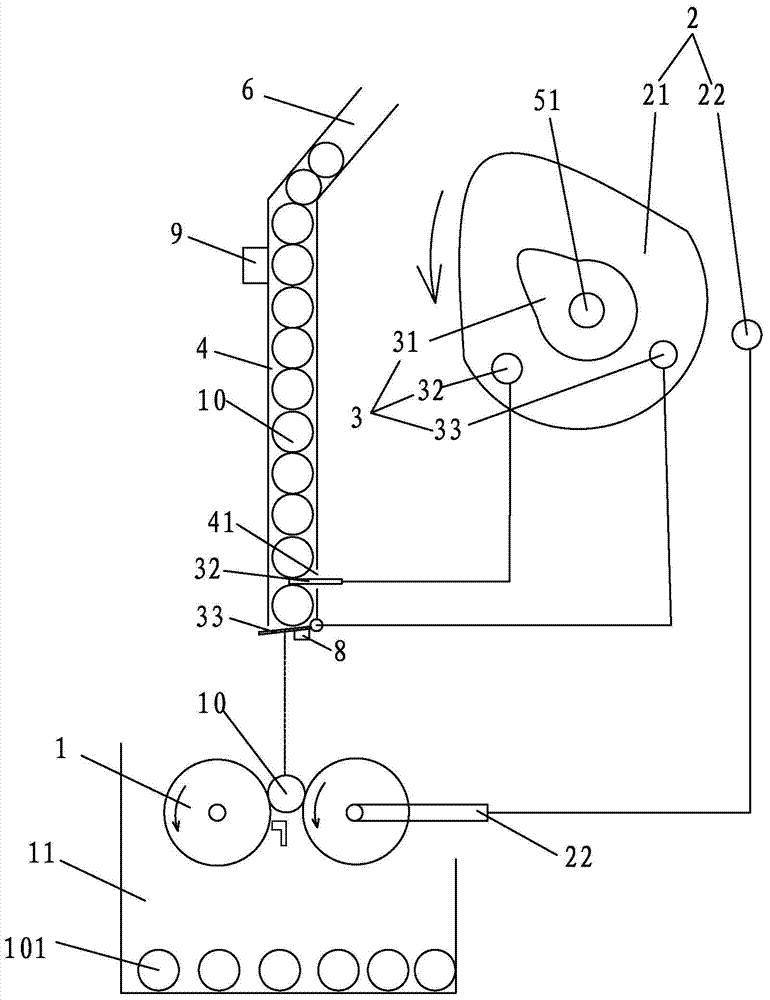

[0027] see Figure 3 to Figure 10 As shown, an automatic blanking wood pellet processing device and method, including a rolling mechanism 1, a large cam mechanism 2, a small cam mechanism 3, a wooden stick placement bin 4, a motor 5, and a wooden stick loading slot 6. A frame 7 , a detector 8 , a PLC controller (not shown) and an oscillator 9 .

[0028] The large cam mechanism 2 and the small cam mechanism 3 are all arranged above the rolling mechanism 1, and the large cam mechanism 2 and the small cam mechanism 3 are all driven by the shaft 51 of the motor 5; The placement bin 4 is arranged at the front ends of the large cam mechanism 2 and the small cam mechanism 3;

[0029] The inner wall of the wooden rod placement warehouse 4 is provided with a small hole 41; the small cam mechanism 3 includes a small cam 31, a pressing assembly 32 and an opening and closing assembly 33; the opening and closing assembly 33 is arranged on the wooden The bottom of the stick placement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com