Device for automatic exhausting and argon filling of reduction distillation furnace in sponge titanium production

An automatic exhaust and distillation furnace technology, applied in the direction of improving process efficiency, can solve the problem of low pressure, achieve the effect of improving automation, reducing labor intensity, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

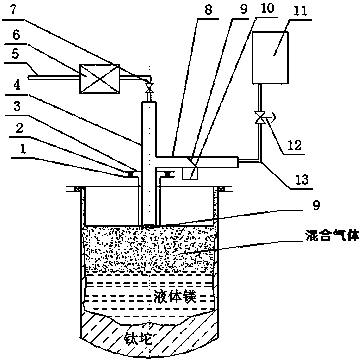

[0017] like figure 1 As shown, the device used for automatic exhausting and argon filling of the reduction distillation furnace in the production of sponge titanium is characterized in that a tee pipe sleeve is provided on the large cover of the reactor, the sleeve flange 1 of the large cover and the flange 3 of the standpipe connection, a sealing gasket 2 is arranged therebetween, a filter screen 14 is arranged at the bottom of the three-way pipe standpipe 4, the three-way pipe standpipe 4 is connected with the argon gas pipeline 5, and the pneumatic high vacuum baffle valve 6 and the stop valve are set on the argon gas pipeline 5 Return valve 7, dust collector 10 is set directly below the filter screen 9 provided in the three-way horizontal pipe 8, the three-way horizontal pipe 8 is connected with the gas recovery tank 11 through the recovery pipeline 13, and the electromagnetic valve 12.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com