Automatic overturning and conveying device for high-pressure toilet bowl molding blank

A high-pressure molding and conveying device technology, which is applied to ceramic molding machines, auxiliary molding equipment, manufacturing tools, etc., can solve problems such as low production efficiency, green body damage, and high labor intensity, and achieve improved work efficiency, enhanced reliability, The effect of increasing the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

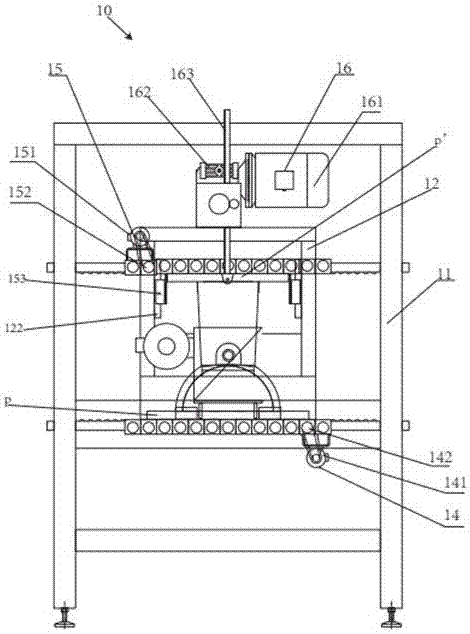

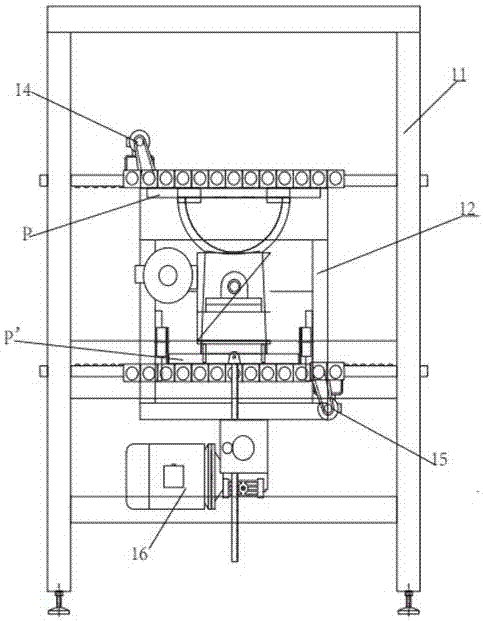

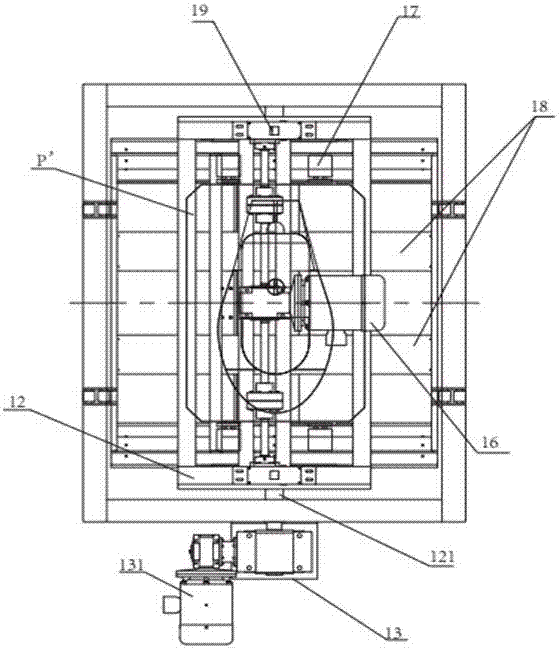

[0035] like Figure 1-Figure 3 As shown, the automatic overturning conveying device 10 of the toilet high-pressure forming green body of the preferred embodiment of the present invention includes a main frame 11, an overturning frame 12, an overturning driving device 13, a first conveying driving device 14, and a second conveying driving device 15. The second conveying drive device is a lifting device 16 , a pallet clamping device 17 , a pressing device 18 and an induction element 19 .

[0036] The preferred implementation structure of each part is described below respectively, not as a limitation to the specific structure of the present invention:

[0037] like figure 1 , image 3 As shown, the main frame 11 has structures such as feet and bolts fixed to the ground, and the main frame 11 is roughly in the shape of a square.

[0038] Flip frame 12, see Figure 1-Figure 3 As shown, it is generally in the shape of a rectangular parallelepiped frame. It is connected to the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com