Sludge brick production equipment for hydrolysis and carbonization treatment

A technology of carbonization treatment and production equipment, which is applied in the direction of auxiliary forming equipment, stacking of objects, and unstacking of objects, etc. It can solve the problems of labor and time consumption, and the inability to realize the transfer of bricks in batches, so as to achieve the goal of not being easy to collapse and stacking good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

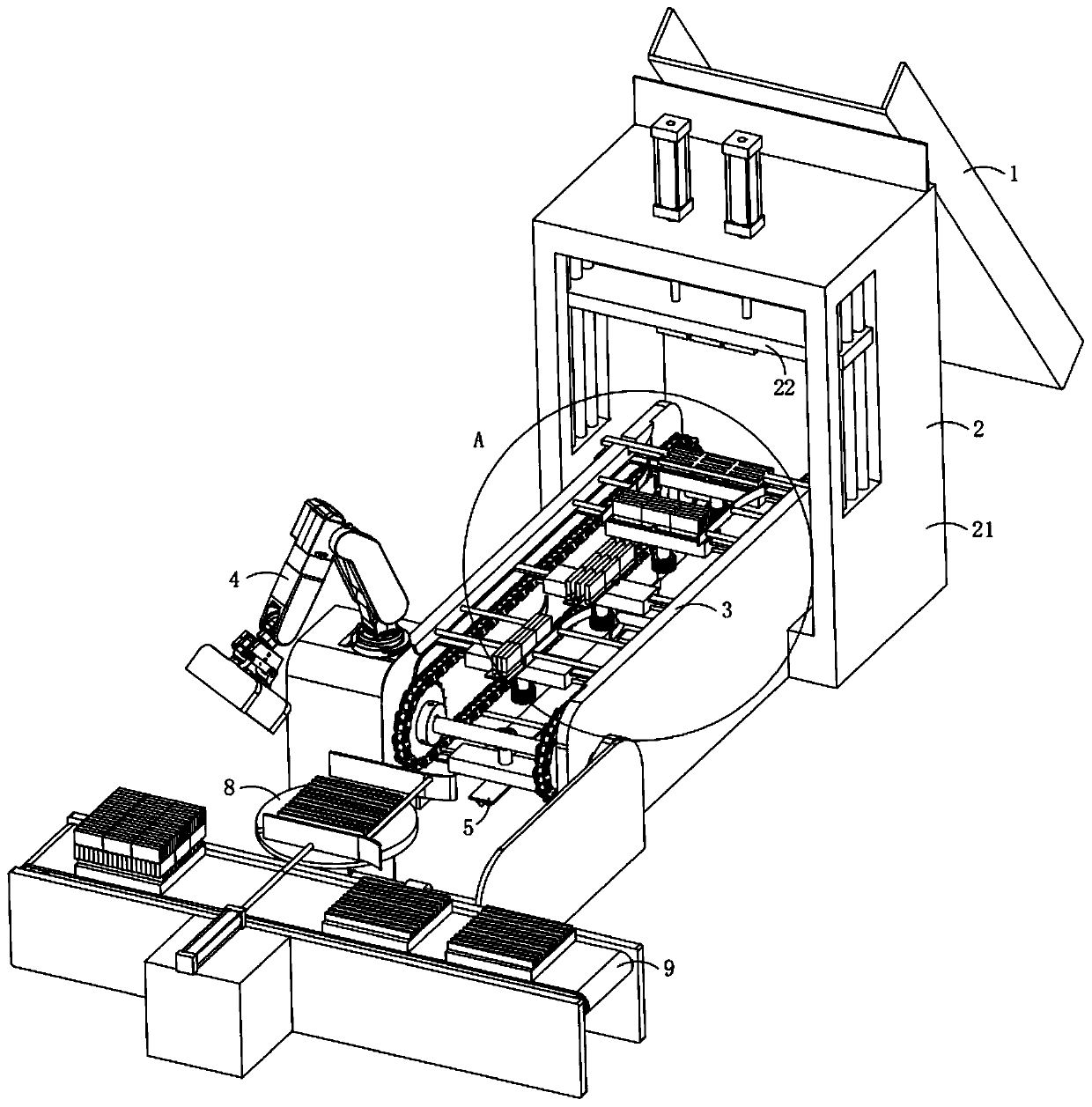

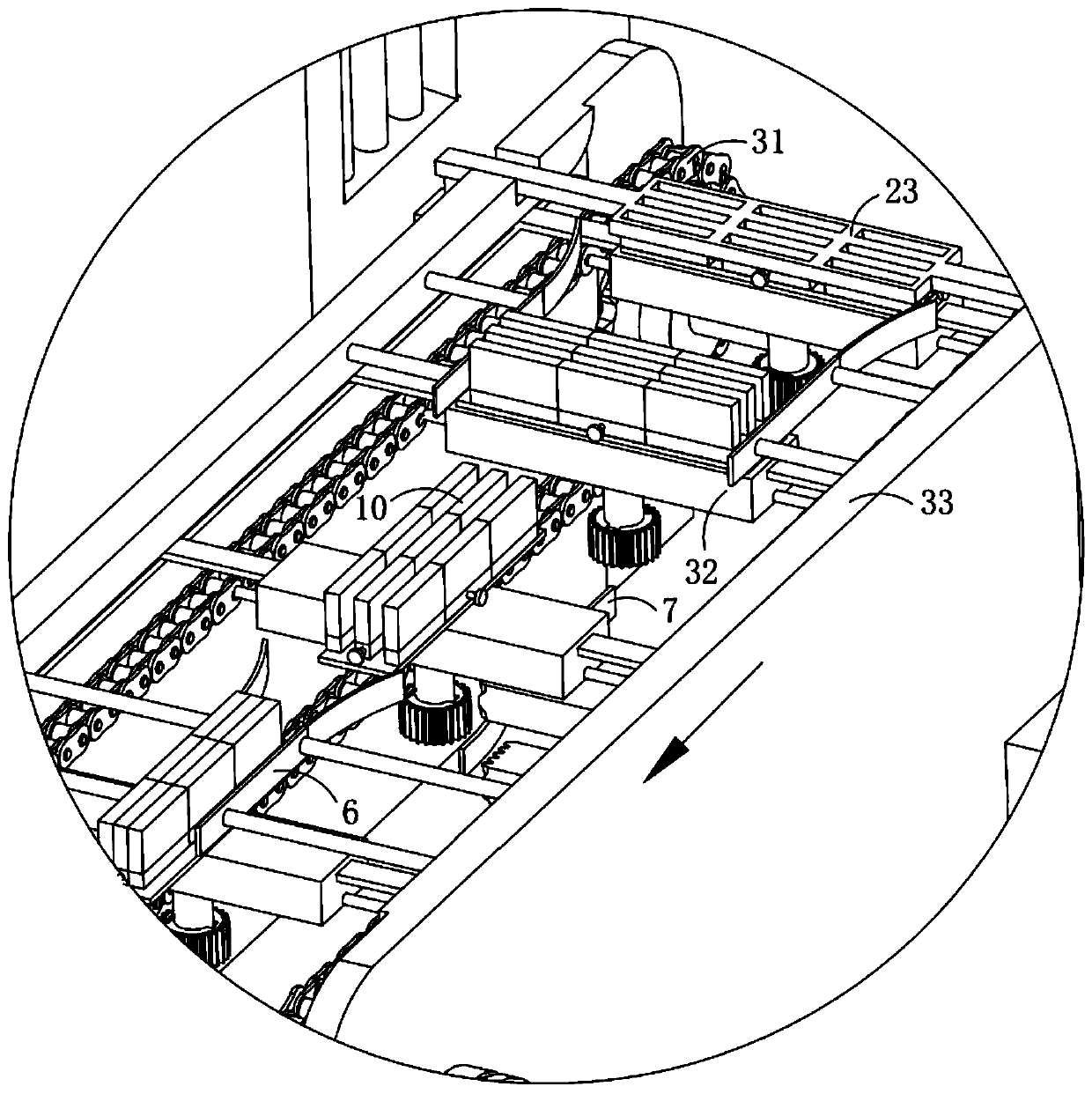

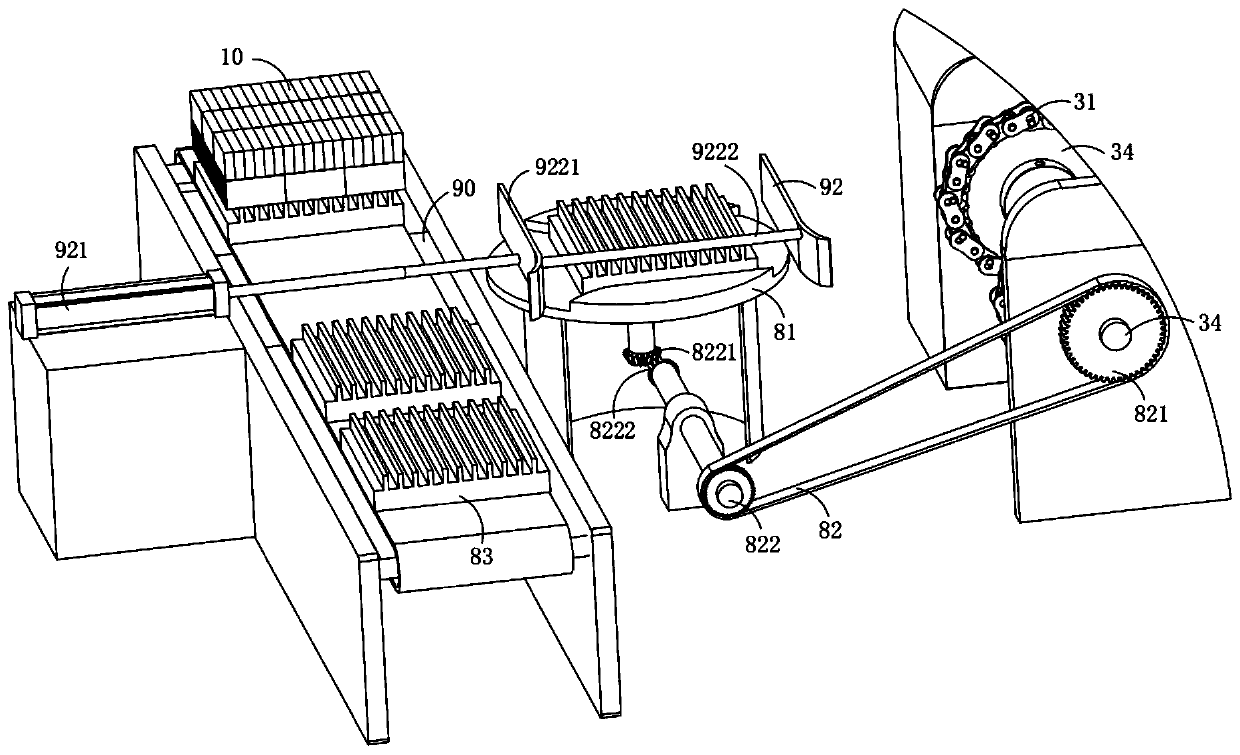

[0040] Such as Figure 1-3 As shown, a sludge brick production equipment for hydrolysis and carbonization treatment includes a feeding mechanism 1, a pressing mechanism 2, a transmission mechanism 3 and a clamping mechanism 4, and the transmission mechanism 3 is provided with several brick connection mechanisms 5, The upper half and the lower half of the transmission mechanism 3 are also fixedly equipped with a retracting mechanism 6 and an unfolding mechanism 7 respectively, and the clamping mechanism 4 is also provided with a rotating stacking mechanism 8 and a push transfer mechanism 9, and the pressed bricks 10 is carried and transported by the brick connecting mechanism 5. During the transmission process, after being folded and arranged by the gathering mechanism 6, it is clamped in batches by the clamping mechanism 4 and stacked on the rotating stacking mechanism 8, and then pushed and output by the push transfer mechanism 9. .

[0041] In this embodiment, a telescopic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com