Plastic pelletizing production line

A production line and plastic technology, applied in the field of plastic granulation processing equipment, can solve the problems of affecting the floor sanitation of the workshop, staff falling down, wasting products, etc., and achieve the effect of improving the degree of automatic production, convenient and quick installation, and reducing human resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The technical solution of the invention will be described in detail below in conjunction with the accompanying drawings.

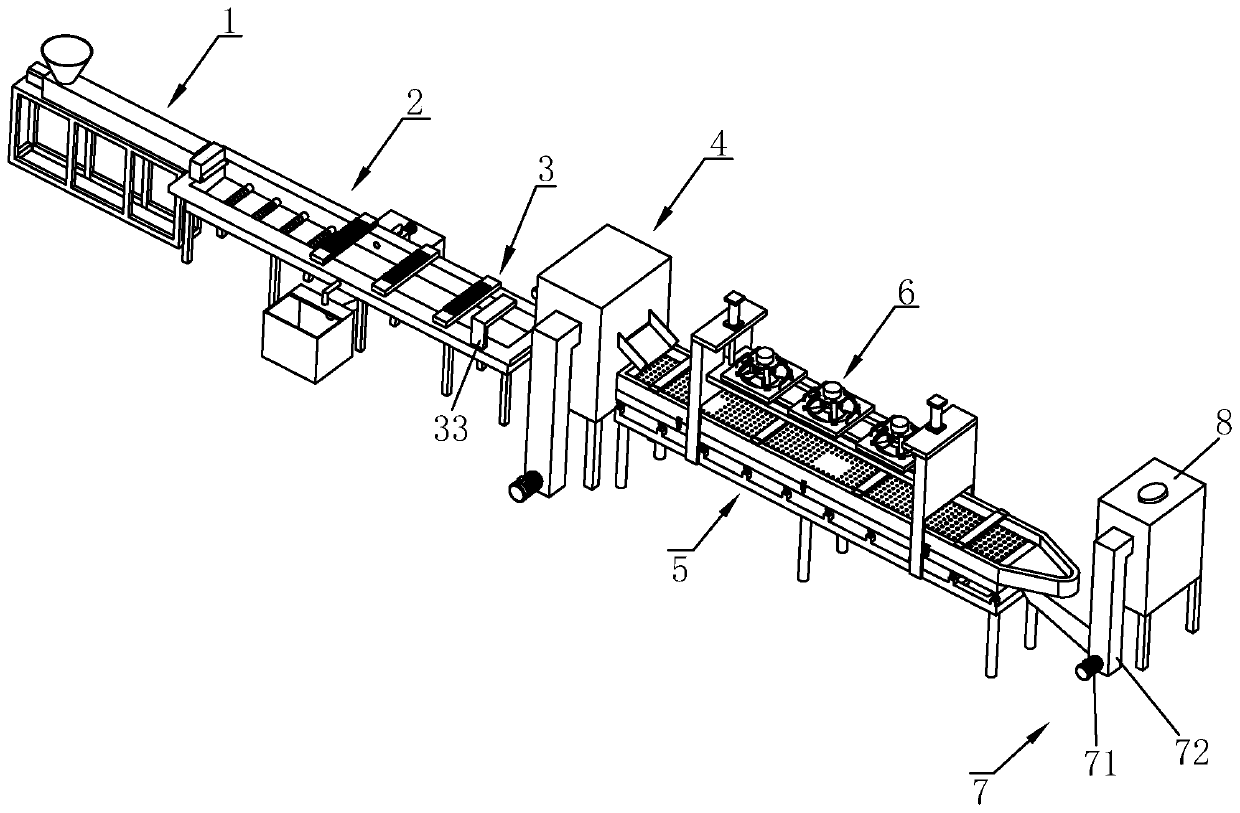

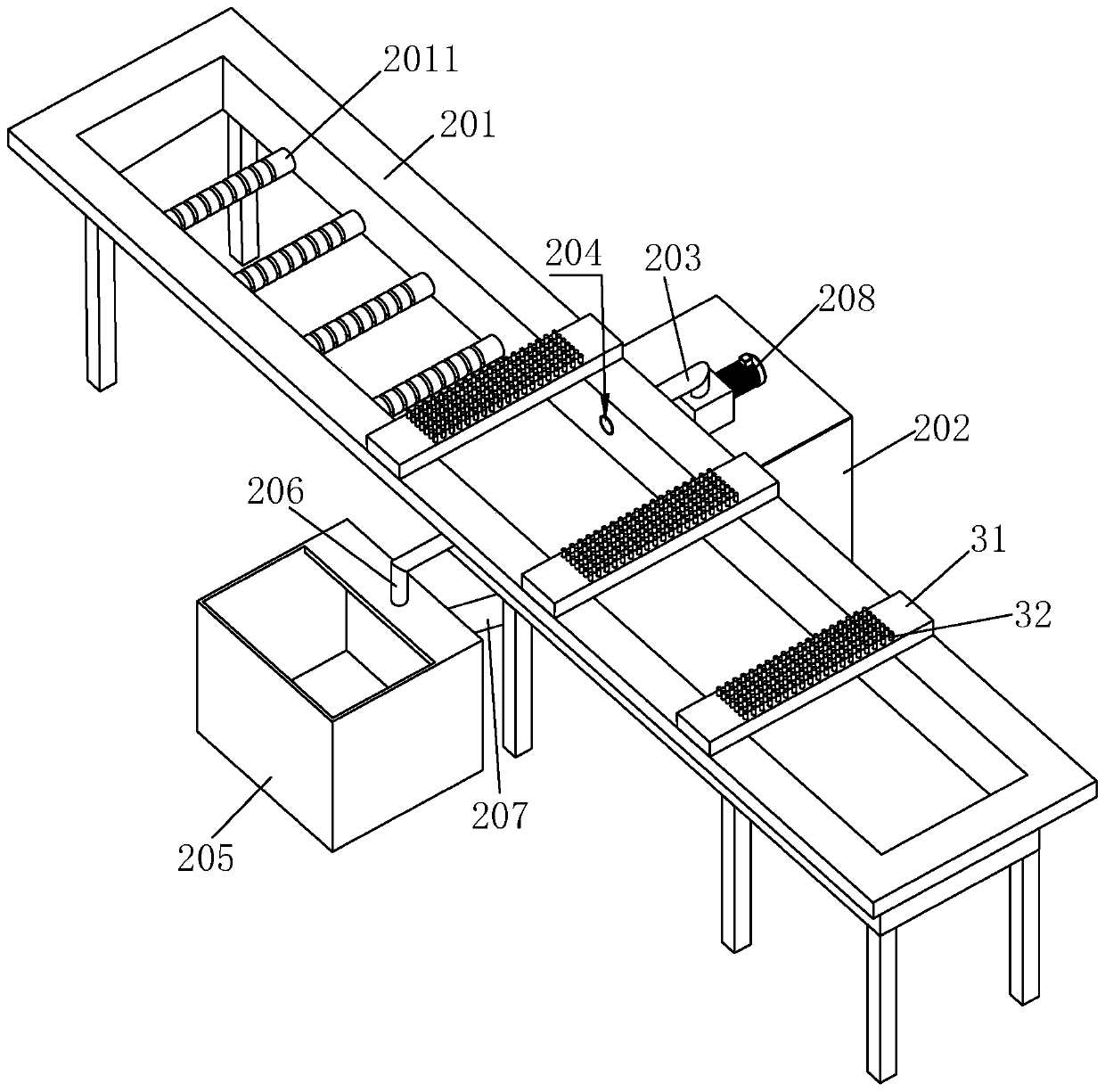

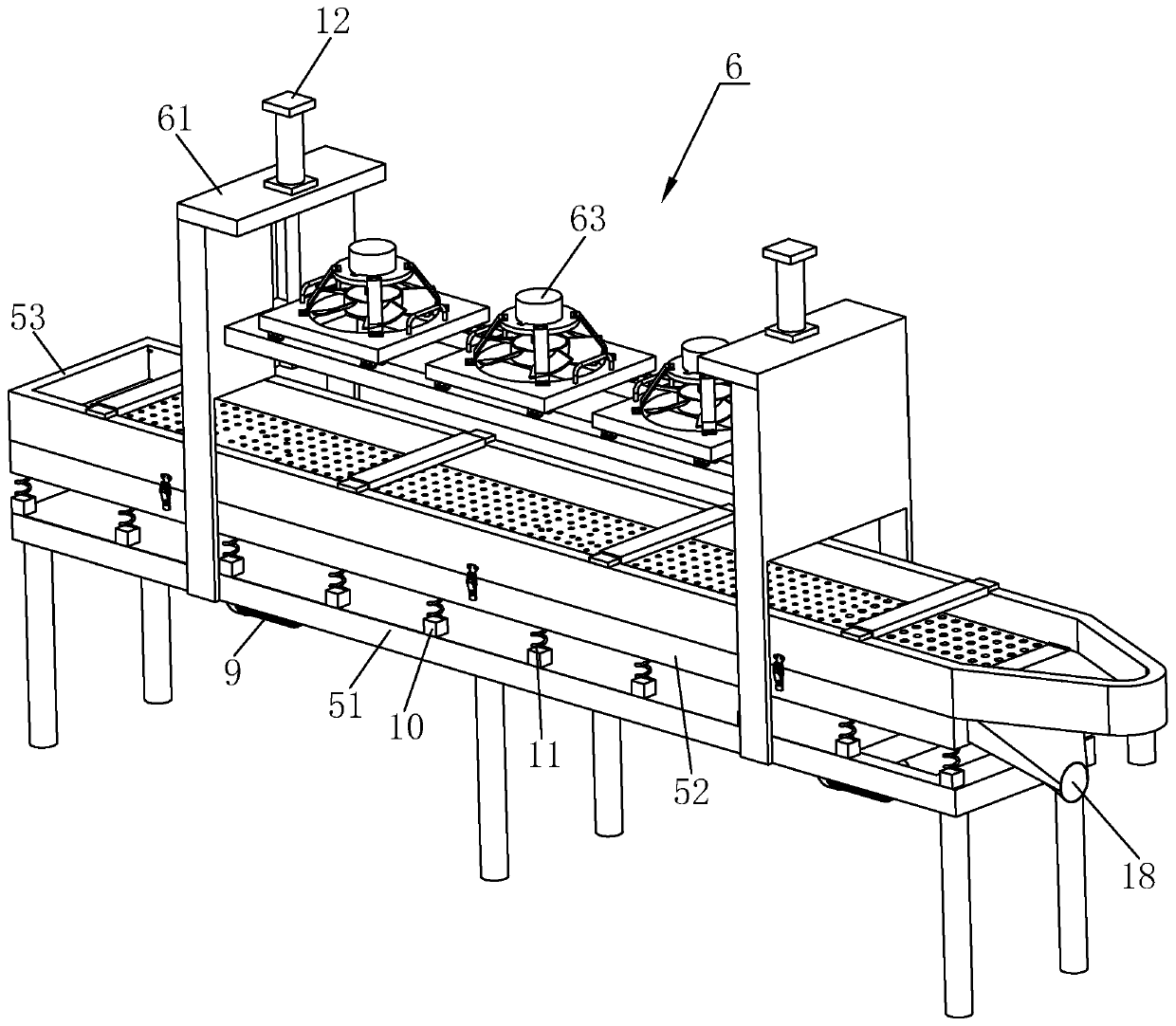

[0042] A plastic granulation production line, with reference to figure 1 , including a plastic extruder 1, a water cooling mechanism 2, a water removal mechanism 3, a granulator 4, a screening mechanism 5, an air drying mechanism 6, a material suction mechanism 7 and a material storage tank 8 connected in sequence along the material conveying direction, for After the material is heated and melted, the strip material is output; the water cooling mechanism 2 is used to cool the extruded strip material; the water removal mechanism 3 is used to remove the moisture on the surface of the strip material passing through the water cooling mechanism 2; the granulator 4, It is used to cut the strip material into plastic granules; the screening mechanism 5 is used to accept the cut plastic granules and screen out plastic granules with different diameters; the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com