Assembling device for button fixing members

A technology for assembling devices and fixing parts, applied to fasteners, buttons, clothing, etc., to improve quality and prevent buckling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

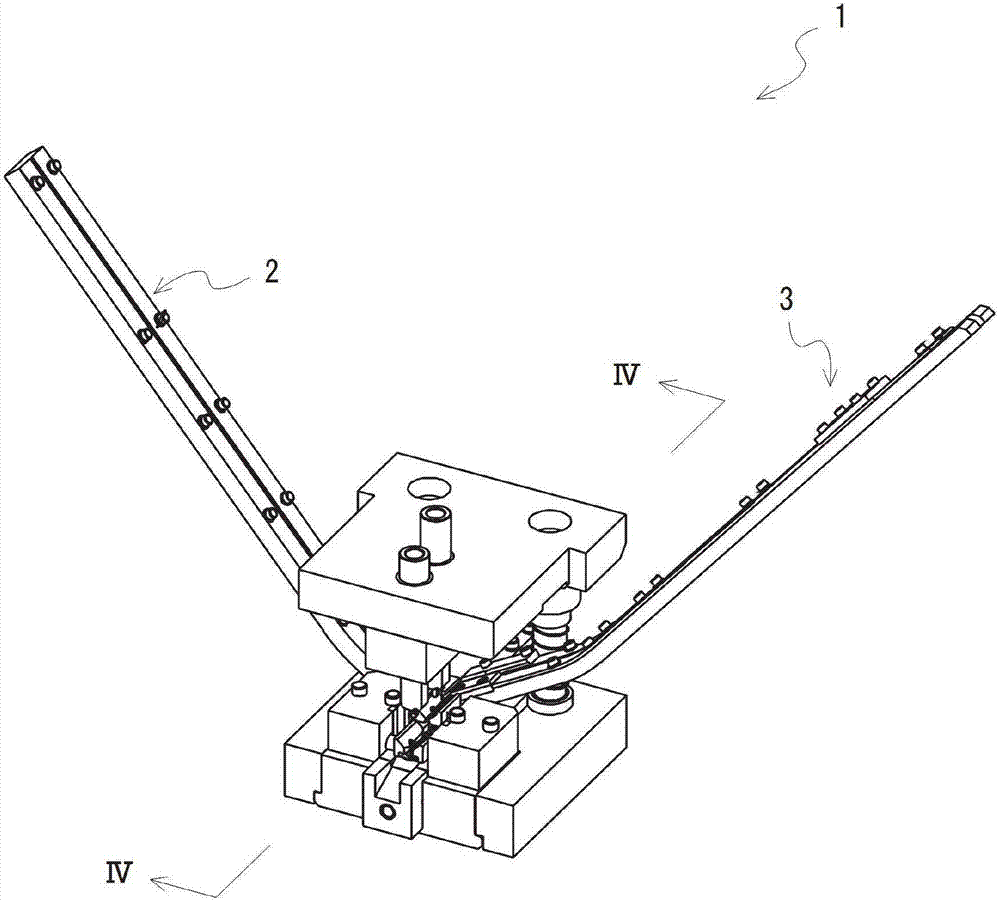

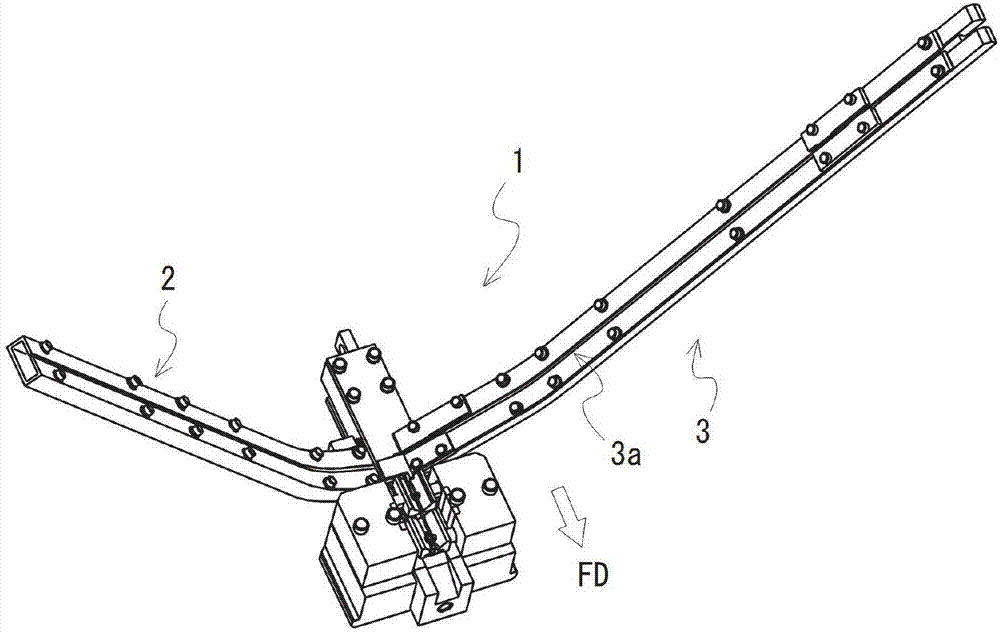

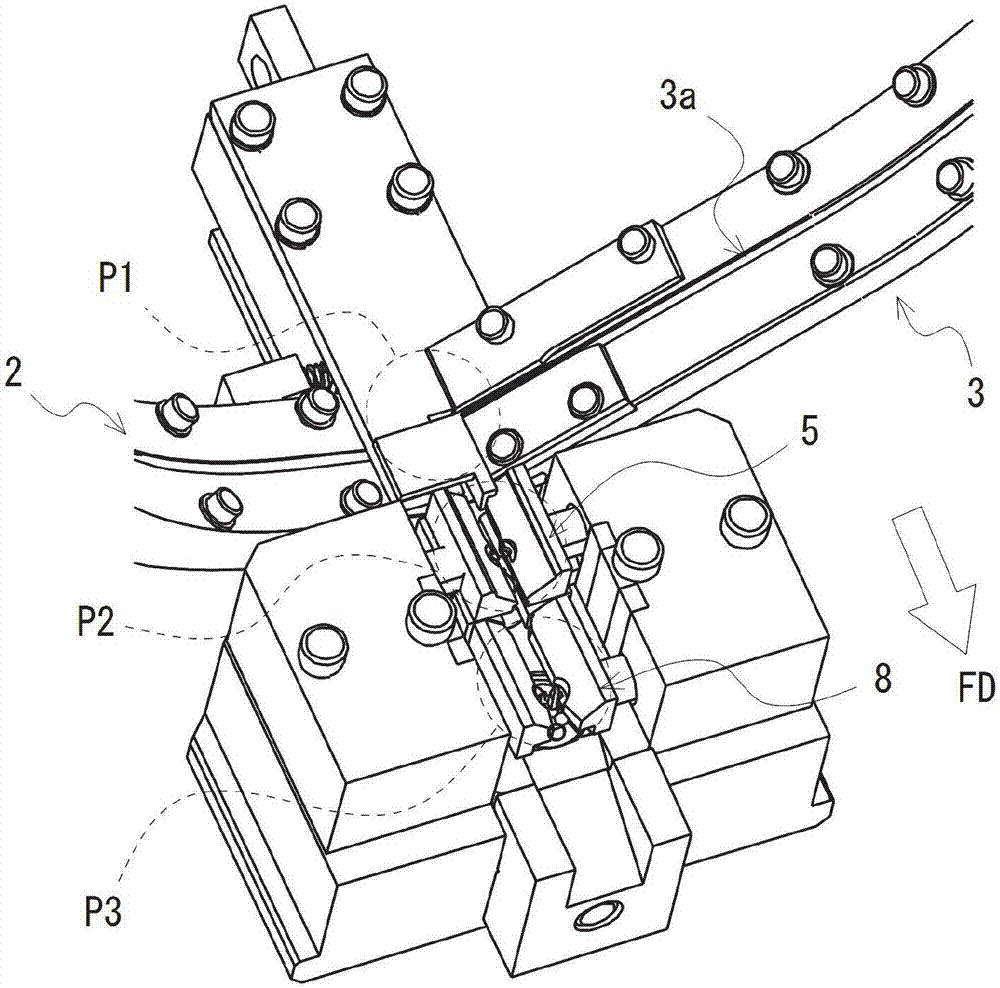

[0079] figure 1 Among them, 1 represents the assembling device of the button fastening part related to one embodiment of the present invention, and the assembling device 1 can be used for such as Figure 18 The assembly of the finished product 101 etc. of the button fastening part shown. According to the assembly apparatus 1, the button fixing member of various shapes other than the illustrated button fixing member 101 can be assembled, Here, the button fixing member 101 is demonstrated as an example.

[0080] The button fixing part 101 is made of such as Figure 19 The claw portion 102 and the housing 103 shown are assembled.

[0081] Here, if Figure 19 As shown in (a), the claw portion 102 includes, for example: a plate-shaped base 102a, which is generally in the shape of a vertically long rectangle in plan view; a pair of pins 102b, which extend from o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com