Automatic setting knob and minute hand assembling machine for clock

A clock and needle machine technology, which is applied in the field of automatic watch assembly equipment, can solve the problems of cumbersome operation, loss of enterprises, and inability to continuously and stably operate stably.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

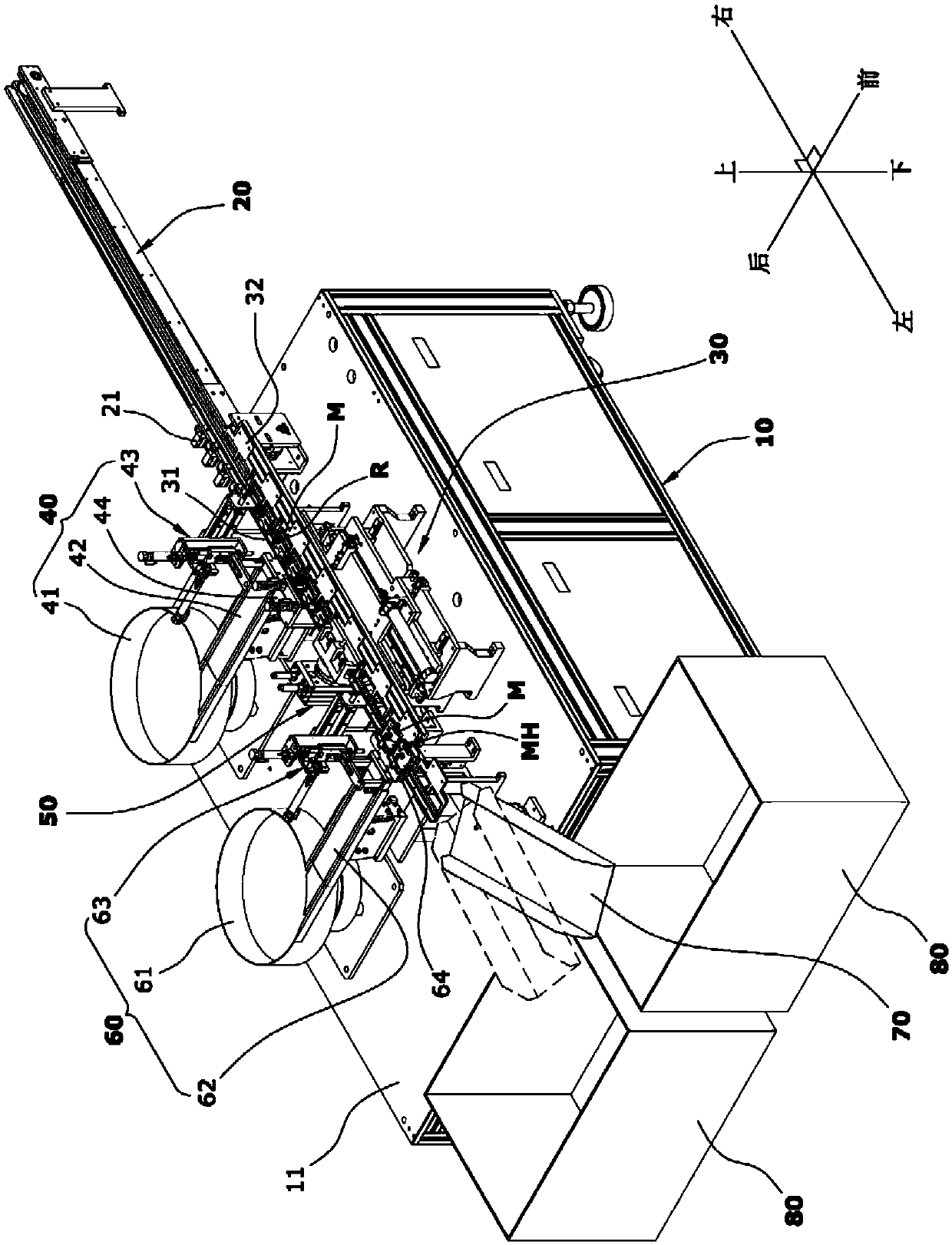

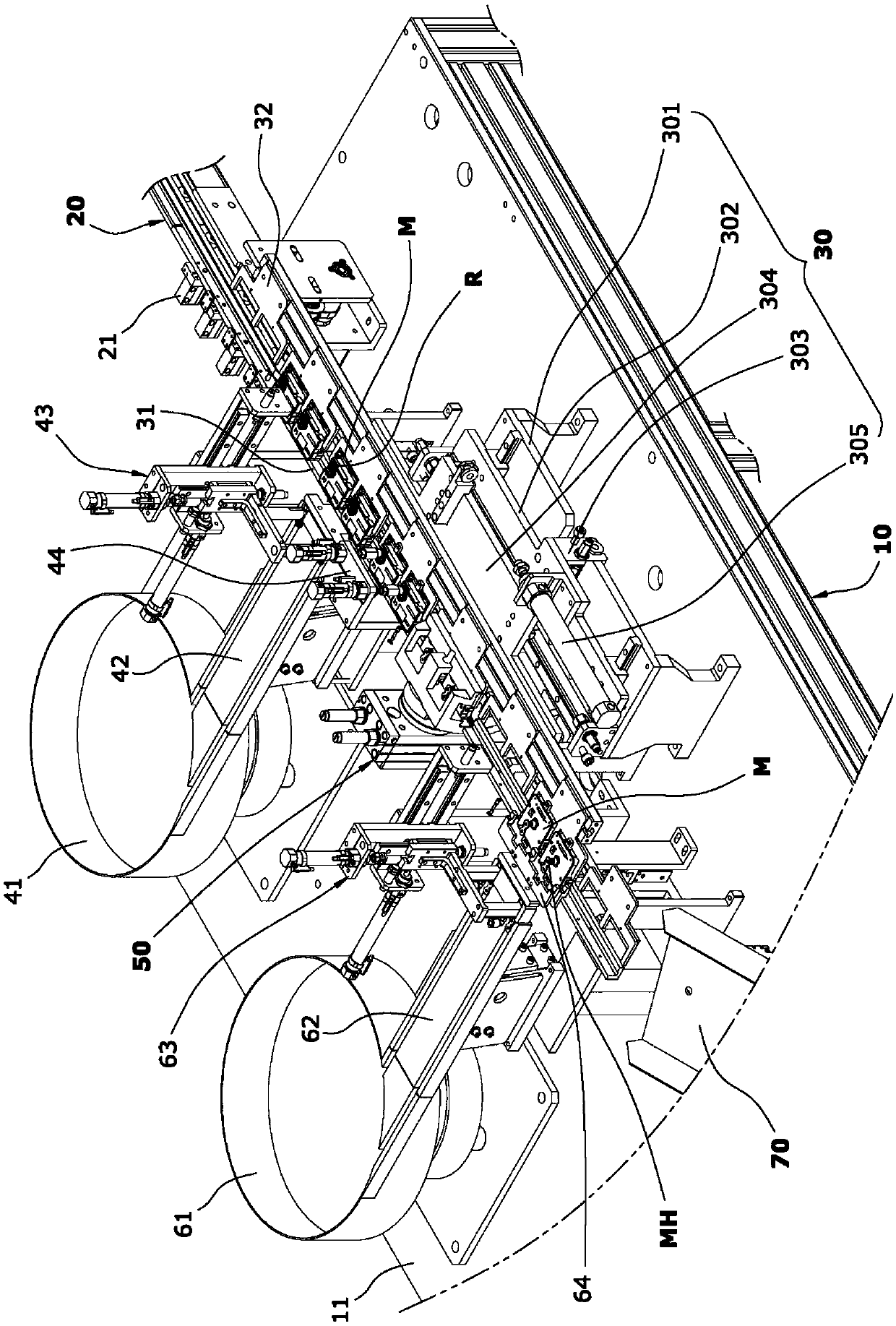

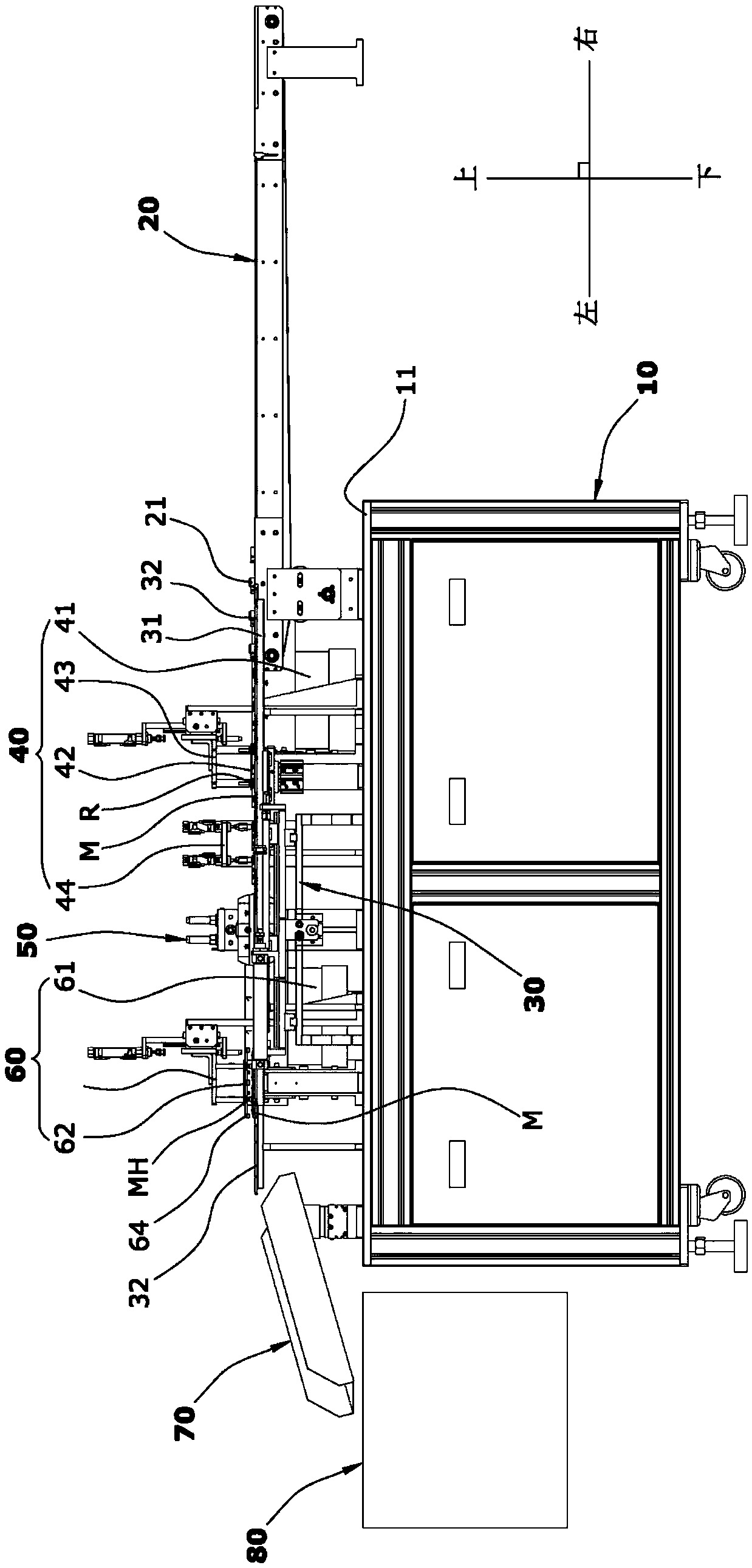

[0022] Such as figure 1 The shown automatic push button and minute hand machine for clocks and watches includes a frame 10 with a table top 11, a movement conveyor belt mechanism 20 for transporting the movement M to be assembled is installed on the right side of the table top 11, and an output conveyor belt mechanism 20 is installed on the left side of the table top 11. The chute 70 of the finished product of the movement is installed on the front portion of the table top 11 and is used to step and shift the movement M to the movement handling device 30 in the chute 70 from the movement conveyor belt mechanism 20; 11 is installed sequentially from right to left with a button pressing machine 40, a movement turning machine 50 and a minute hand pressing machine 60 for assembling the movement M of the movement handling device 30; The front and rear posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com