Automatic assembling equipment

An automatic assembly and equipment technology, applied in electrical components, electrical switches, circuits, etc., can solve the problem of low assembly efficiency of assembly machines, and achieve the effect of ensuring product assembly quality, reducing waiting time, and realizing automatic assembly operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

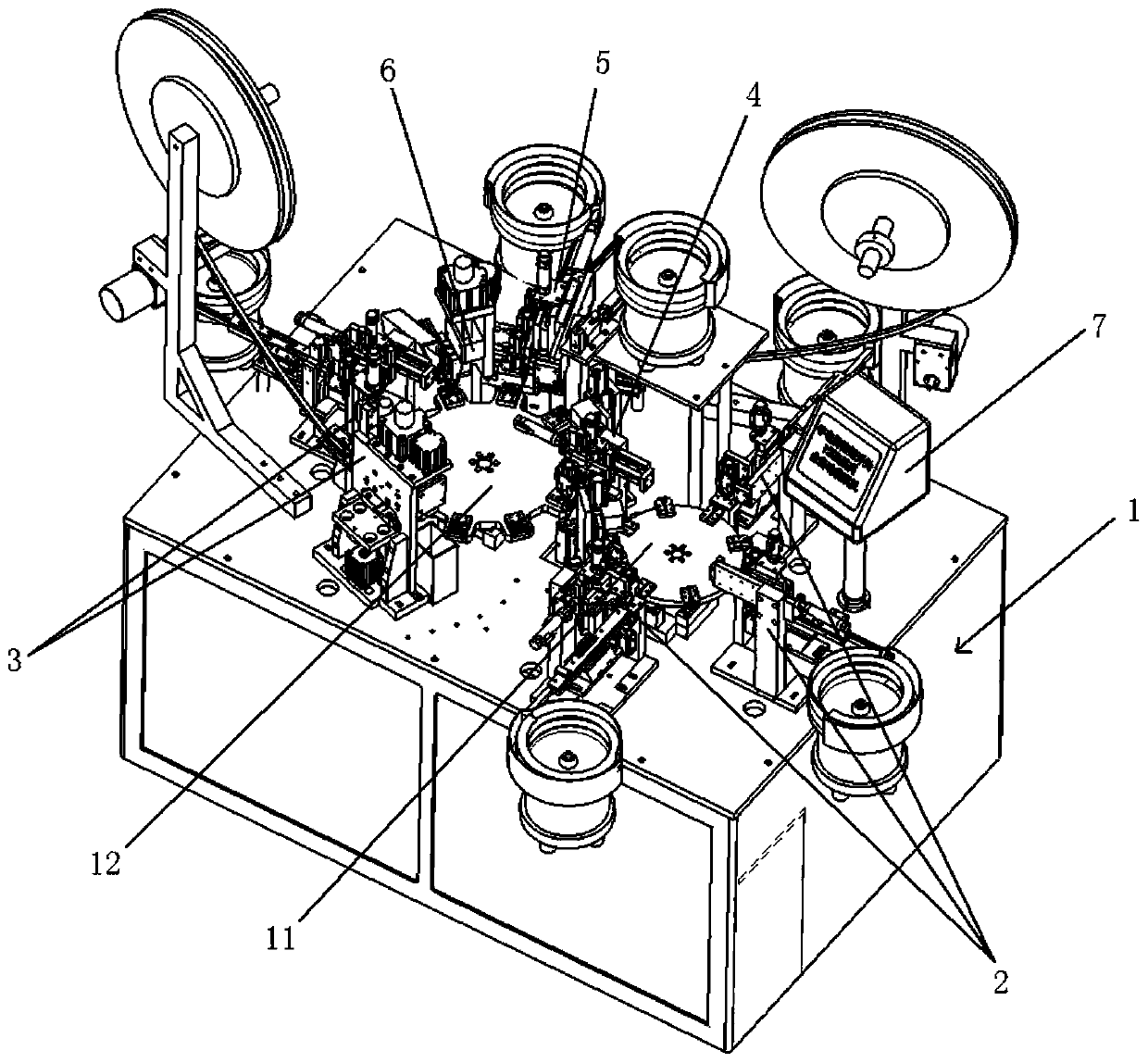

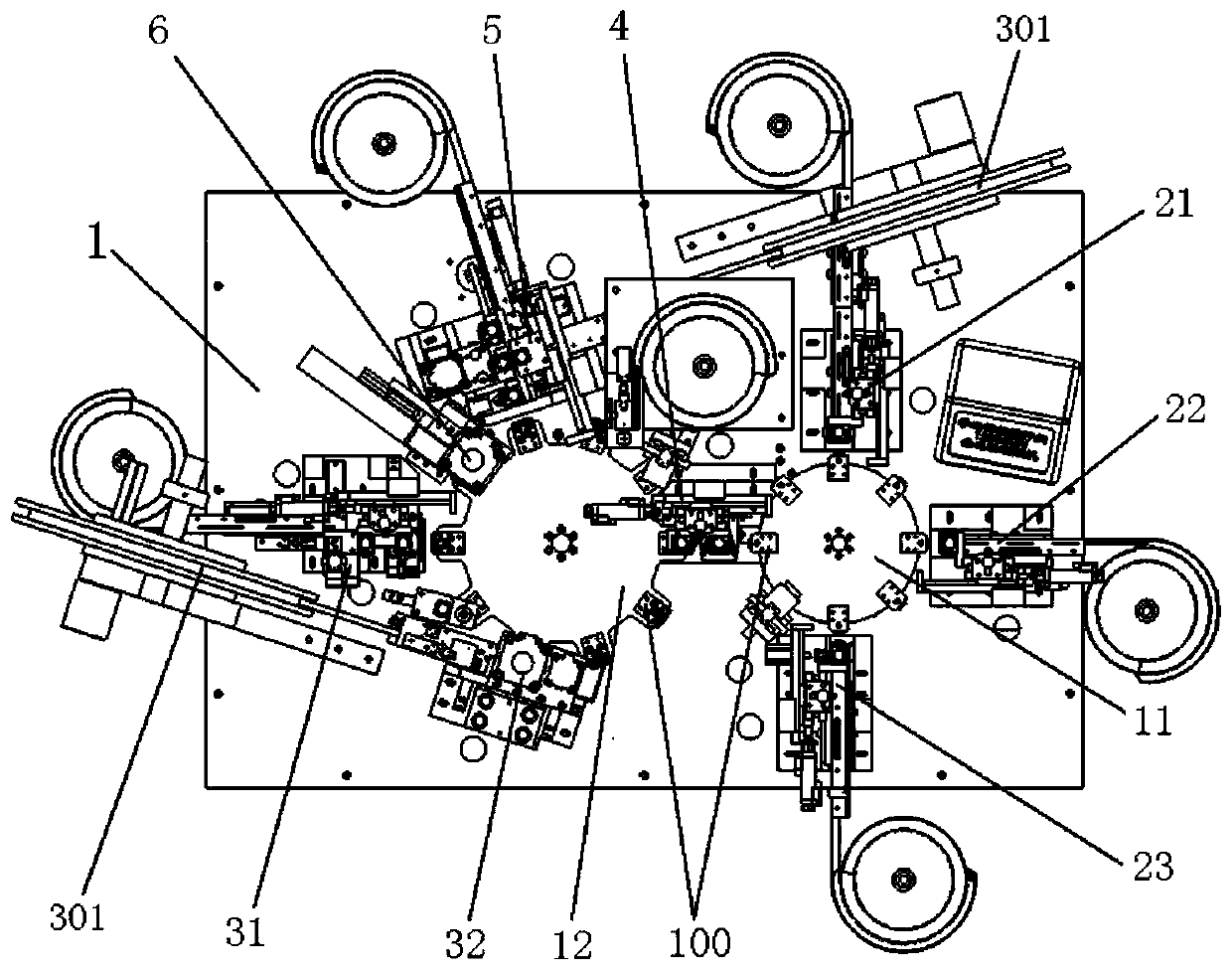

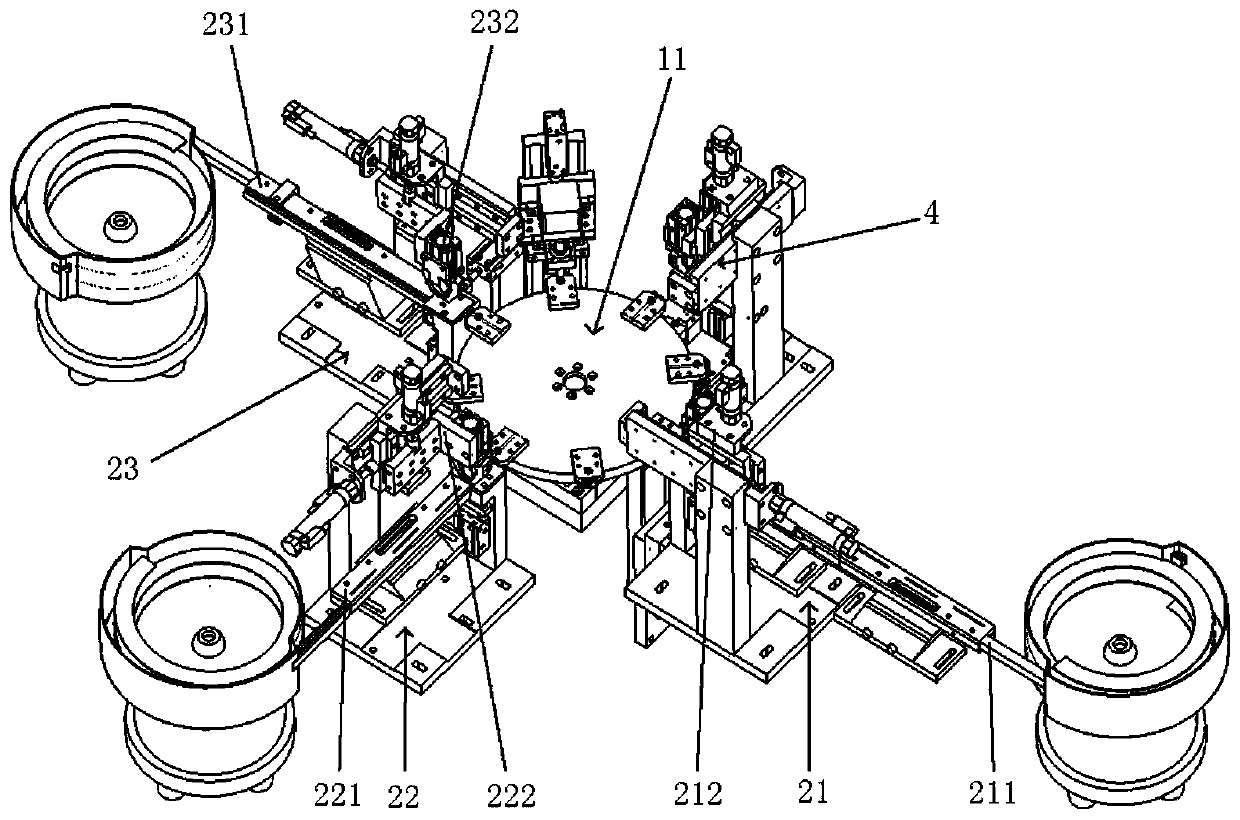

[0078] This embodiment provides as Figure 1-16 A kind of automatic assembly equipment described, comprises:

[0079] The frame 1 is equipped with a rotating first turntable 11 and a second turntable 12. The first turntable 11 and the second turntable 12 are respectively used to transfer the workpieces of the previous assembly process to the next assembly process. ;

[0080] The bottom part assembly assembly 5, the middle part assembly assembly 2 and the upper part assembly assembly 3 are installed on the frame and arranged around one of the first turntable 11 and the second turntable 12, or the bottom part assembly assembly , the assembly ends of the middle part assembly assembly and the upper part assembly assembly are respectively located on one of the corresponding first turntable 11 and the second turntable 12;

[0081]The intermediate assembly device 4 is connected to the first turntable 11 and the second turntable 12 respectively at both ends thereof, and is used for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com