Patents

Literature

30results about How to "Improve assembly progress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

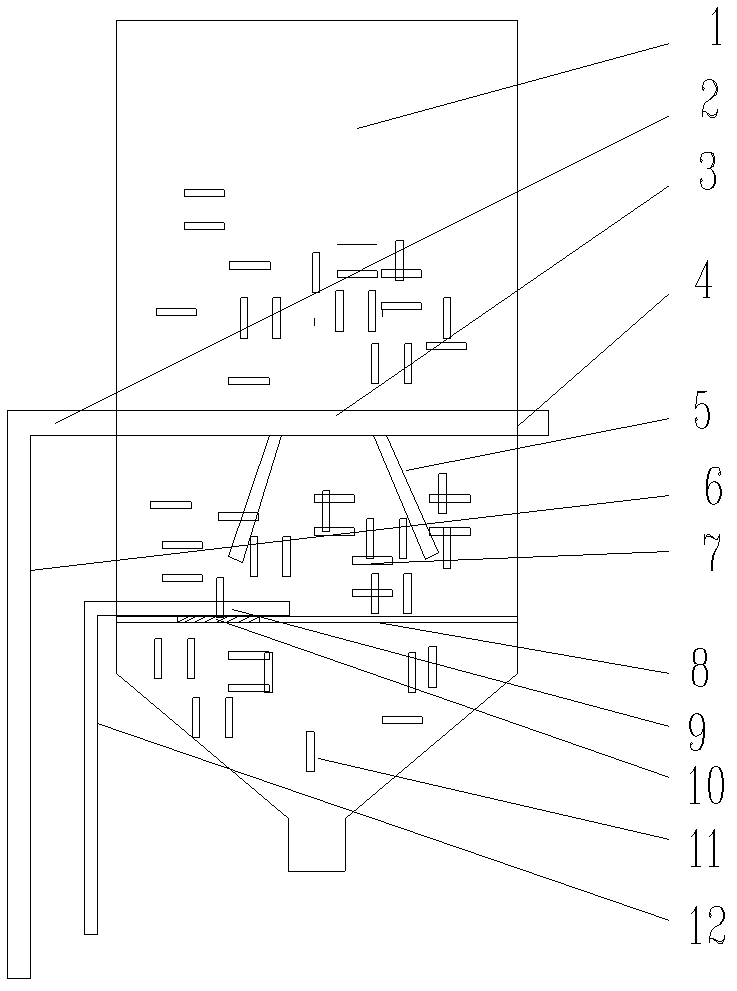

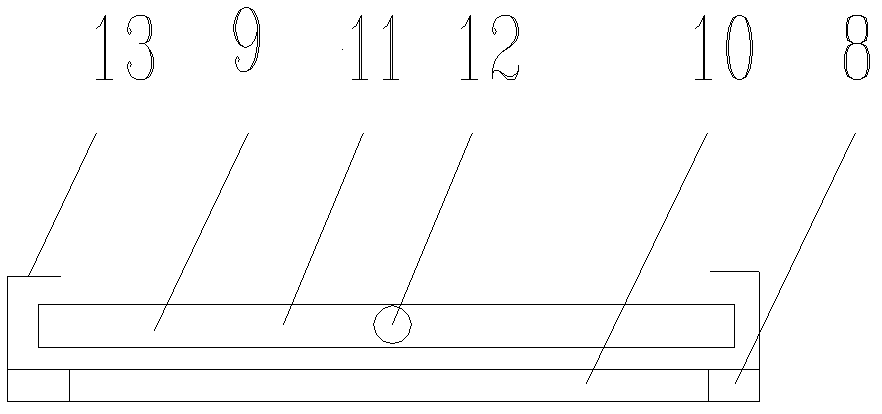

An intermittently pulled-off type cable wiring instrument for an electric power system

InactiveCN106099487AImprove stabilityImprove toughnessLine/current collector detailsCoupling contact membersElectric power systemElectric power equipment

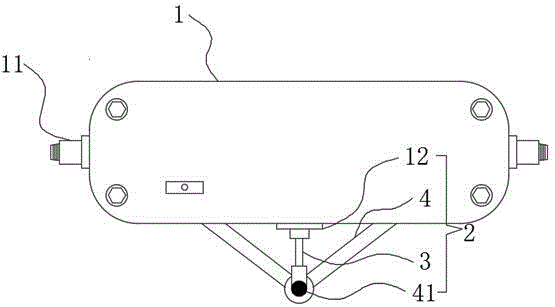

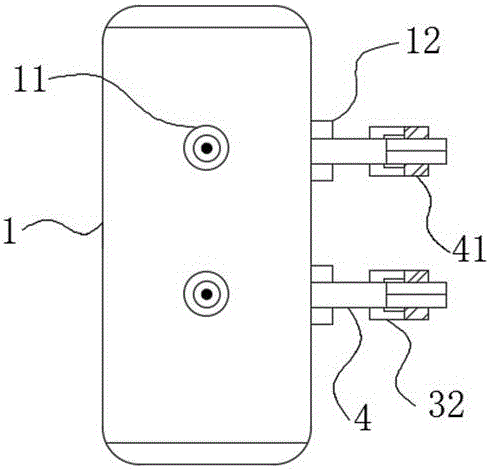

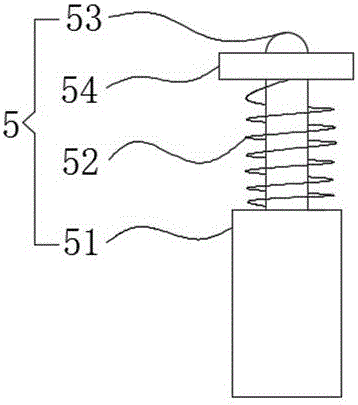

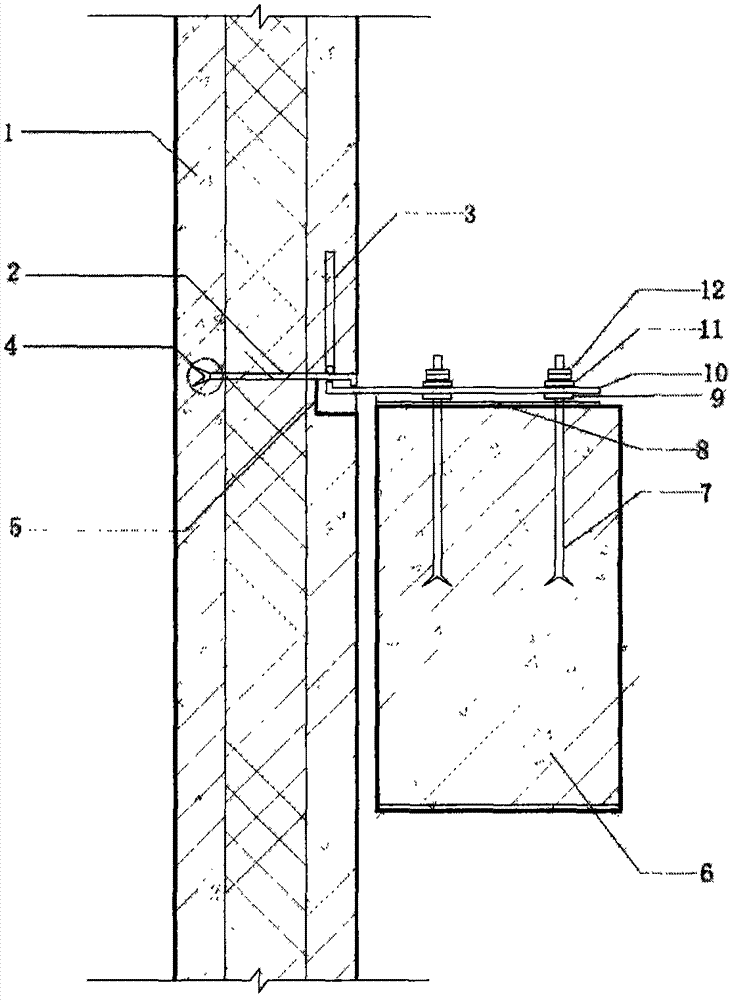

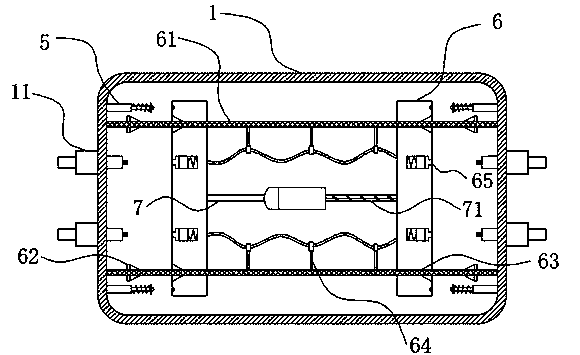

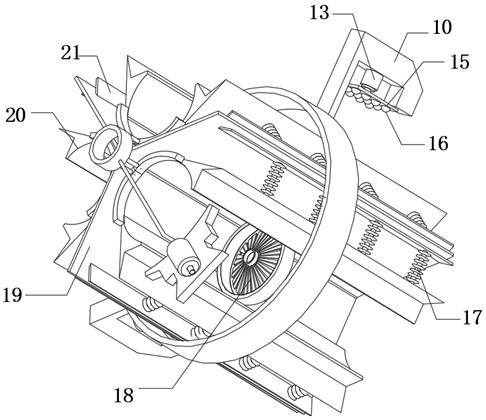

The invention relates to the field of electric power equipment, and specifically relates to an intermittently pulled-off type cable wiring instrument for an electric power system. An intermittently drawn-off type cable wiring instrument for an electric power system includes a wiring instrument body; wiring columns are arranged in the two side walls of the upper end of the wiring instrument body; a support rod penetrates through the upper end and the lower end of each fixing block; buffer devices are connected to the portions, on the two sides of the support rods, of the internal portion of the wiring instrument body; each cushioning device comprises a base, a reset spring, a buffer rod and a buffer plate; conductive blocks slide in wiring grooves through cooperation between slide blocks and slide rails; and the bottom ends of jacks are provided with electromagnets which are connected to permanent magnets through magnetism. The intermittently pulled-off type cable wiring instrument of the invention can realize intermittent power-on and power-off of the wiring instrument, so that the assembling progress and the assembling quality of the electric power system are raised to a great extent; favorable conditions are provided for maintenance, repairing and replacing of the electric power system; and the intermittently drawn-off type cable wiring instrument has a broad market application prospect.

Owner:STATE GRID HENAN ELECTRIC POWER COMPANY ZHENGZHOU POWER SUPPLY +2

Cable wiring instrument

ActiveCN108418026AImprove stabilityImprove toughnessLine/current collector detailsCoupling contact membersElectric power systemElectric power equipment

The invention relates to the electric power equipment field, and specifically relates to a cable wiring instrument. The cable wiring instrument includes a wiring instrument body, wherein binding postsare arranged on two side walls of the upper end of the wiring instrument body; the upper end and the lower end of a fixed block are each equipped with a support pole in a penetrated manner; the sidewall of the inner cavity of the wiring instrument body is connected with buffer devices at two sides of the support poles; the each buffer device includes a pedestal, a return spring, a buffer beam and a buffer plate; a conduction block slides in a wiring groove through coordination between a slide block and a slide way; an electromagnet is arranged at the bottom end of a jack; and the electromagnet and a permanent magnet are mutually connected through magnetic coordination. The cable wiring instrument can realize intermittent power on and power off of the wiring instrument, can improve the assembling progress and the assembly quality of an electric power system to a great extent, can provide favorable conditions for maintenance, repair and exchange of the electric power system, and has awide market application prospect.

Owner:YINQIAO CONSTR GRP CO LTD

Cold-formed thin-walled steel web combined PC box girder

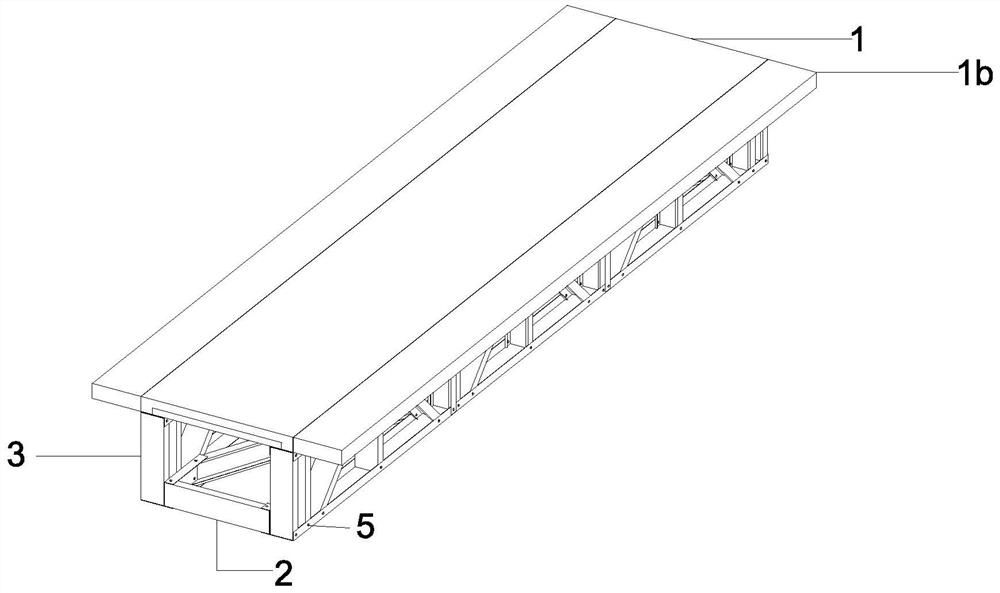

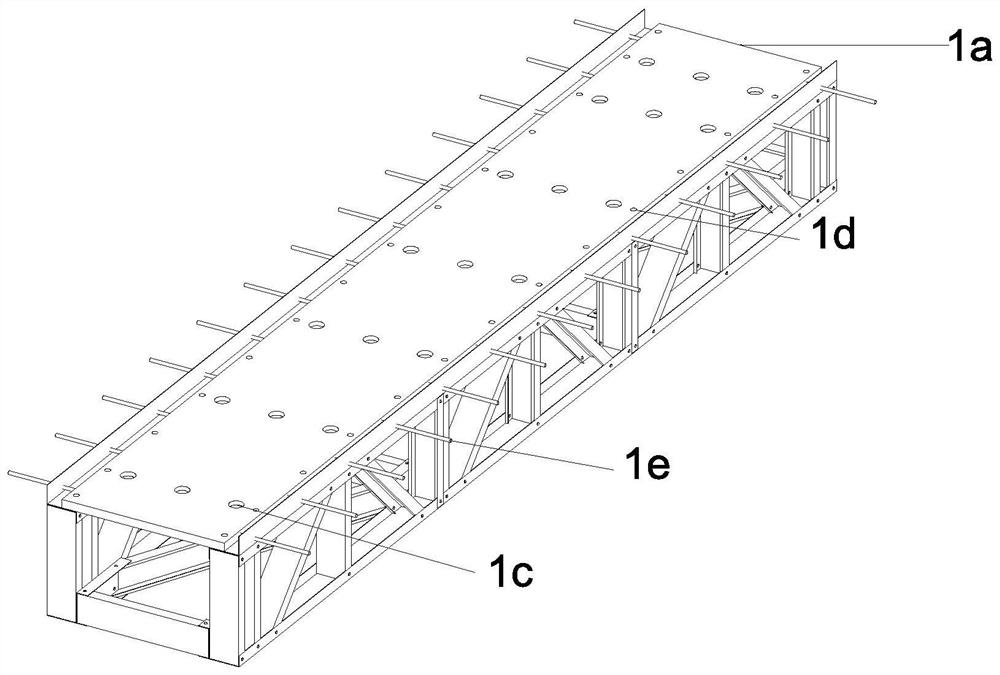

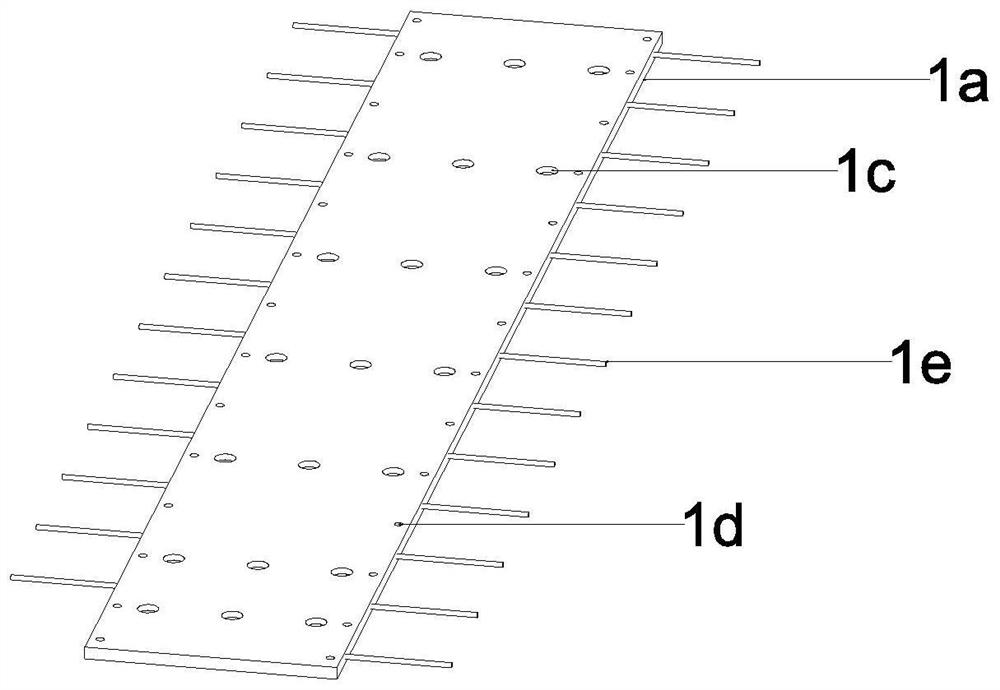

ActiveCN112982142ALose weightImprove mechanical propertiesBridge structural detailsBridge materialsPrestressed concrete beamCrack resistance

The invention discloses a cold-formed thin-walled steel web combined PC box girder, comprising an upper flange, a lower flange and two truss type cold-formed steel combined webs. According to the invention, the web and the lower flange are both formed by combining the cold-formed thin-walled steel, the dead weight of the girder body is reduced, and span breakthrough is achieved; the web and the lower flange are in a truss form, so the overall stability of the structure can be improved, and the problem of poor local stability of the cold-formed thin-walled steel is solved; the webs are made of the cold-formed thin-walled steel, so the problem that webs of common prestressed concrete beam bridges are prone to cracking is fundamentally solved; and factory production of the cold-formed thin-walled steel and a prefabricated laminated slab can effectively accelerate the construction progress and improve the quality of components. The box girder of the invention has the advantages of being high in assembly speed, high in standardization degree, low in manufacturing cost, light in self-weight and excellent in bending resistance and crack resistance, can effectively solve the problems that a traditional concrete box girder component is complex in construction, high in manufacturing cost, large in self-weight, prone to web cracking and the like, and is suitable for bridge structure girders or main and secondary beams and other components of a building structure.

Owner:BEIJING UNIV OF TECH

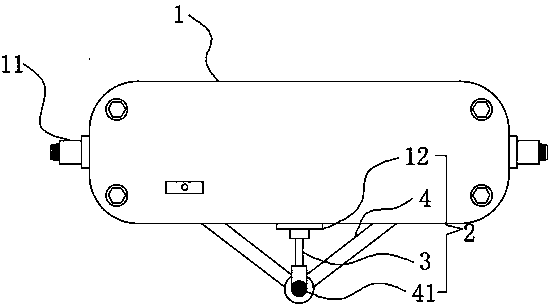

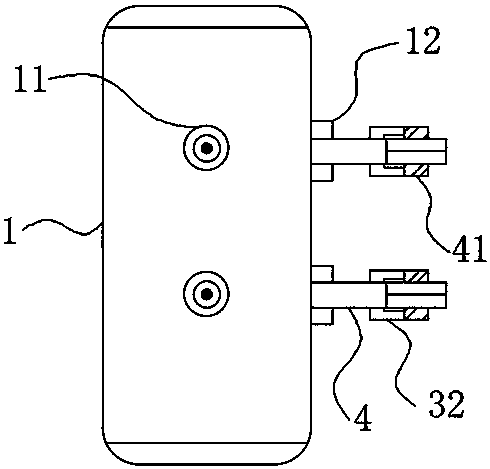

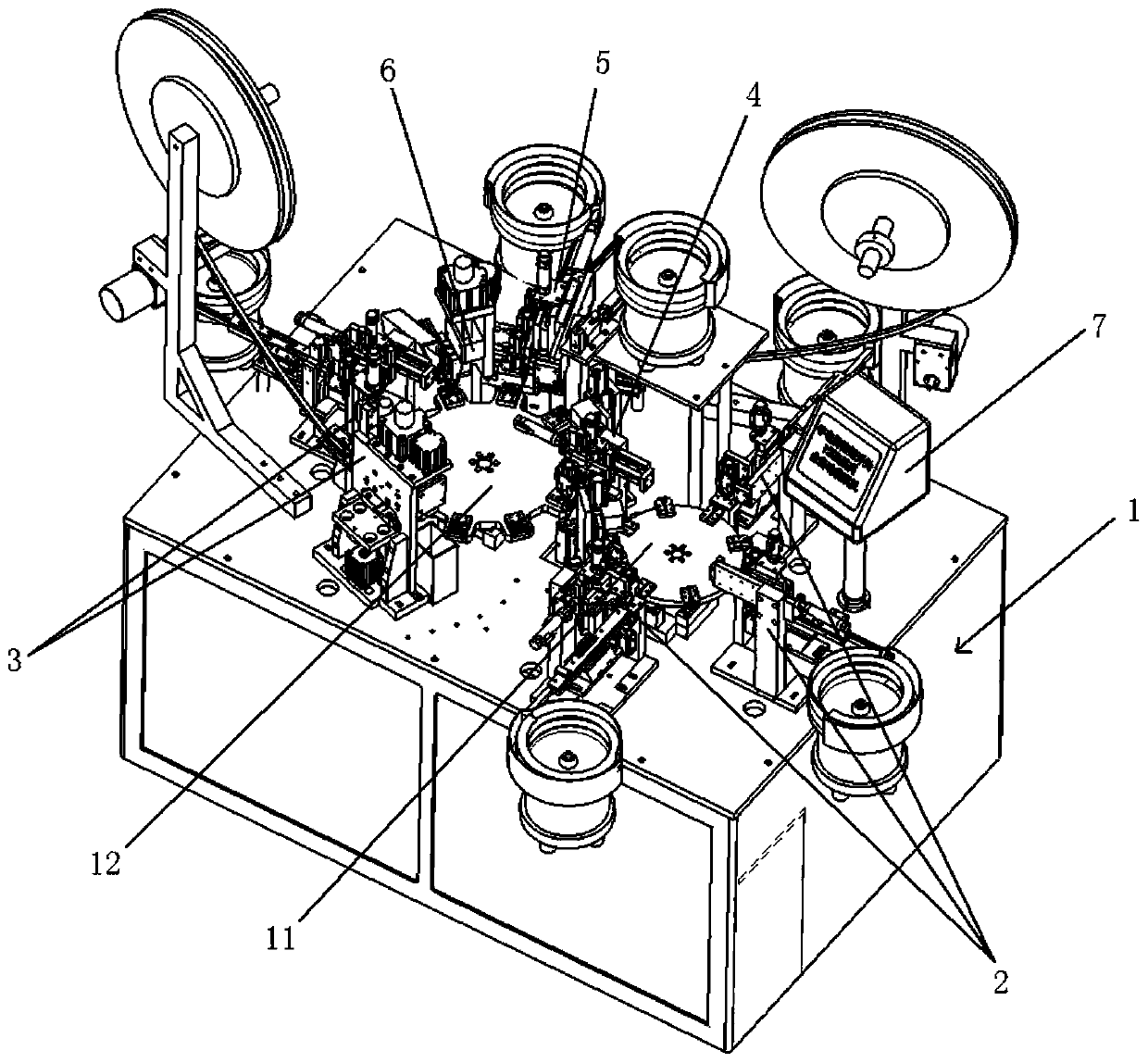

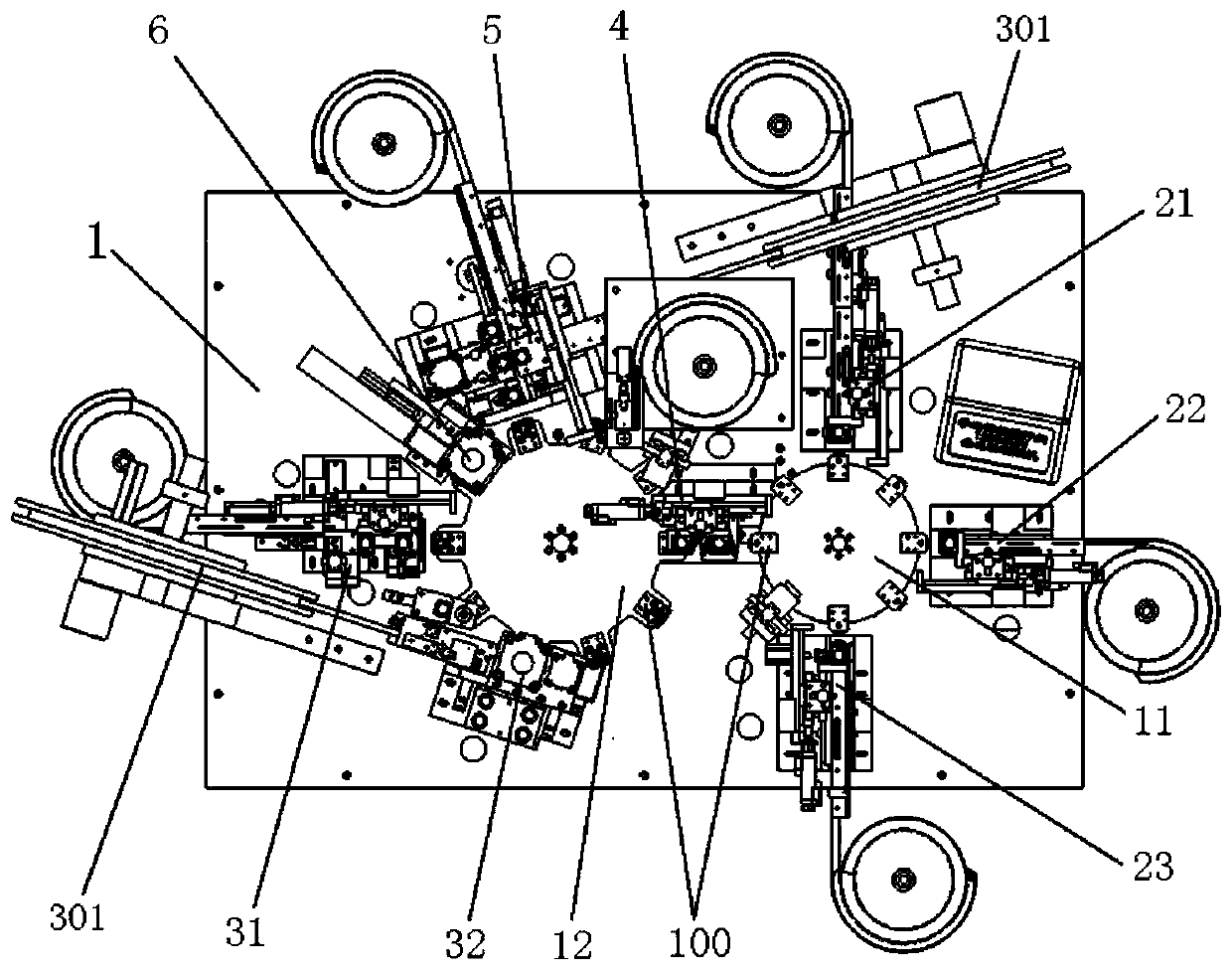

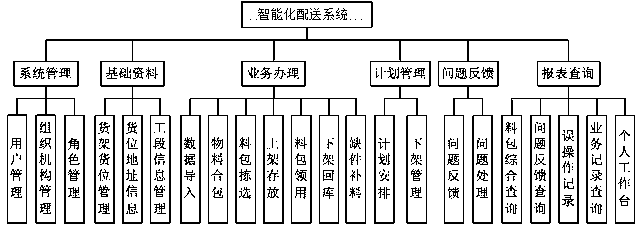

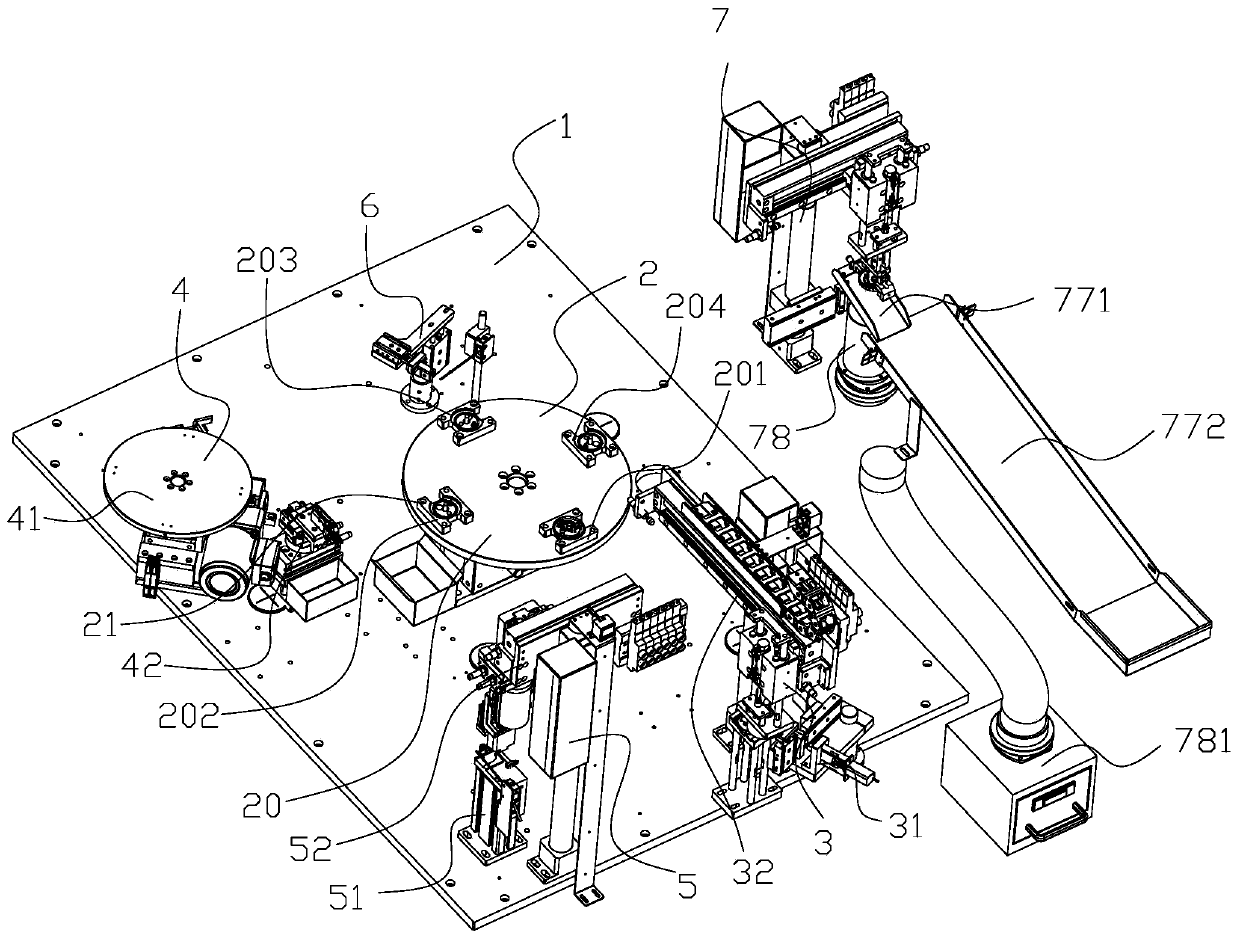

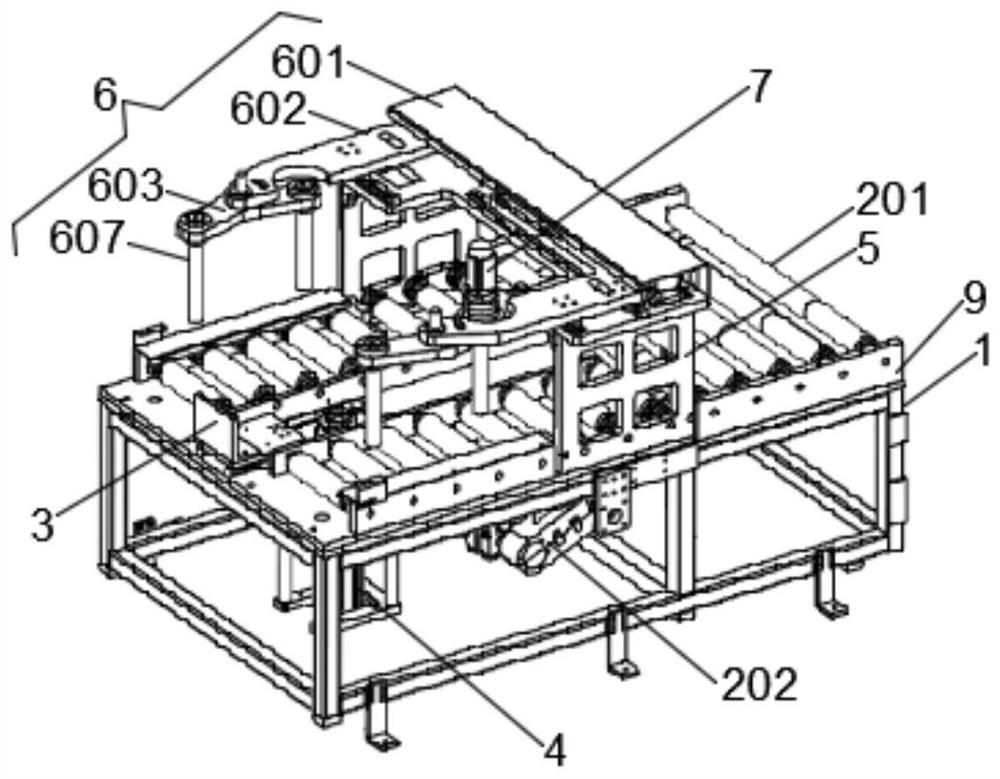

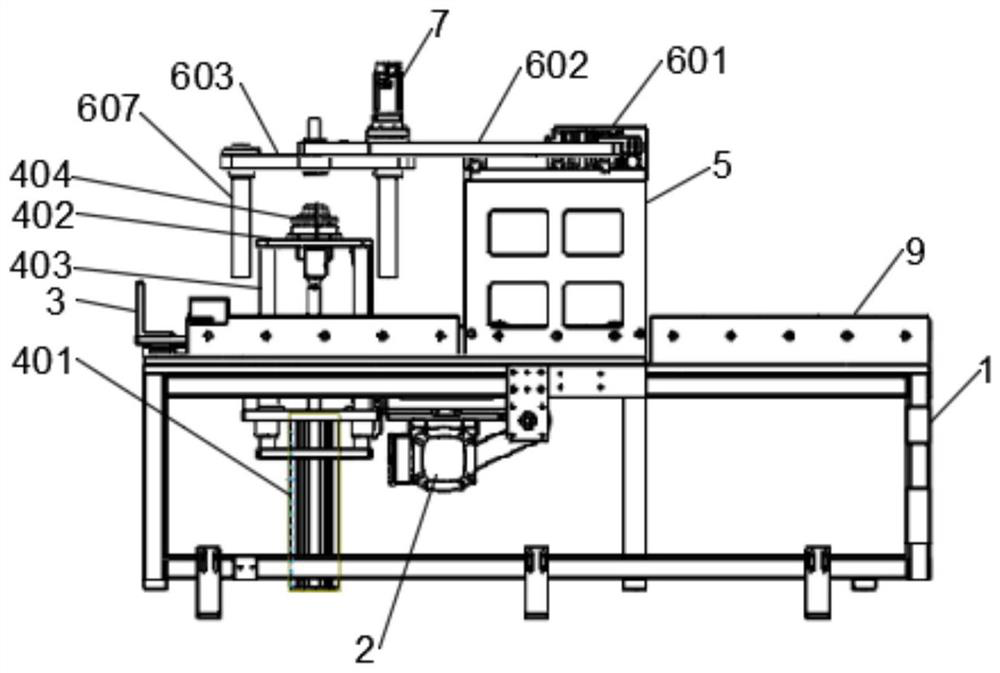

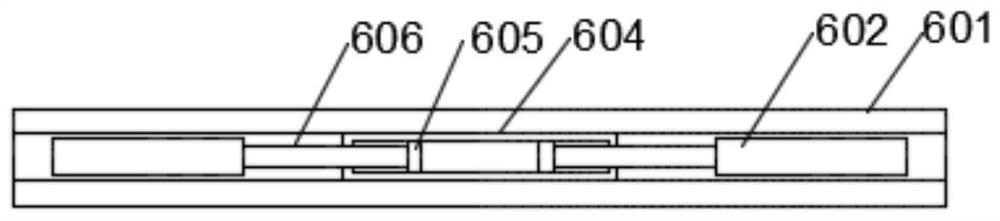

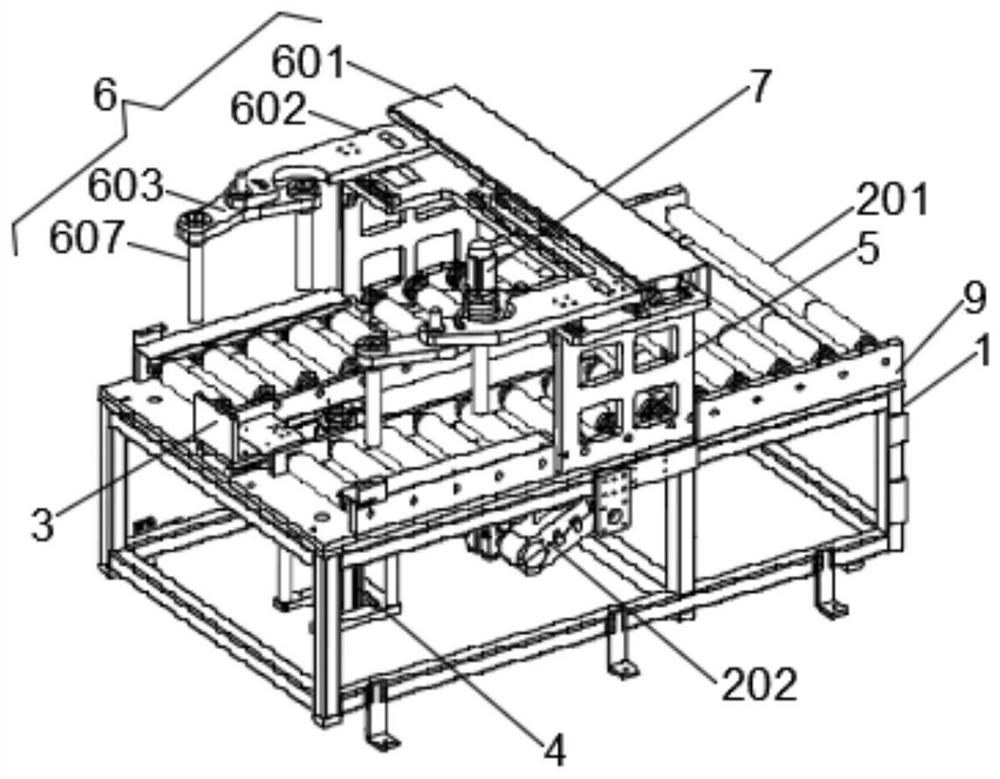

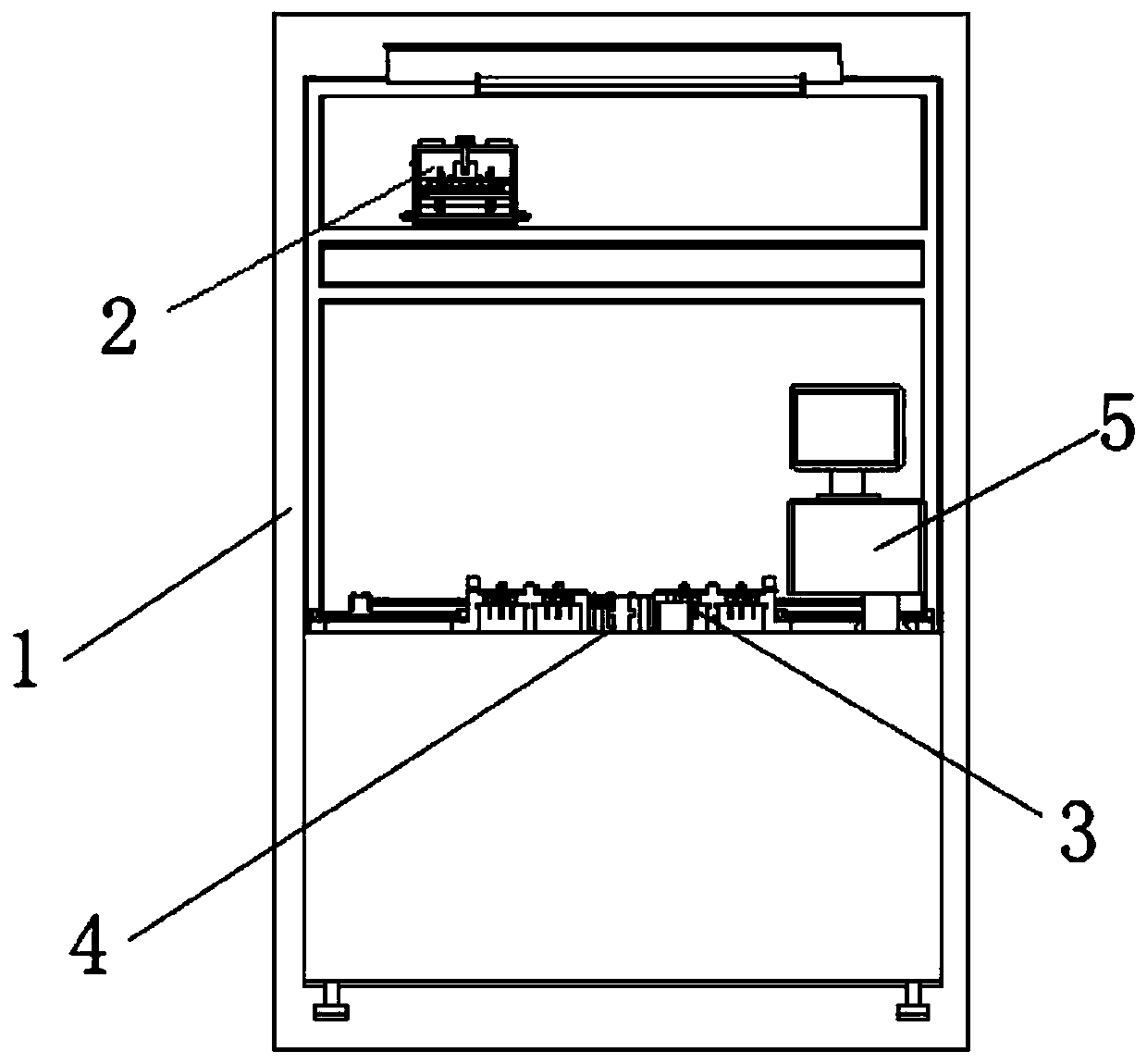

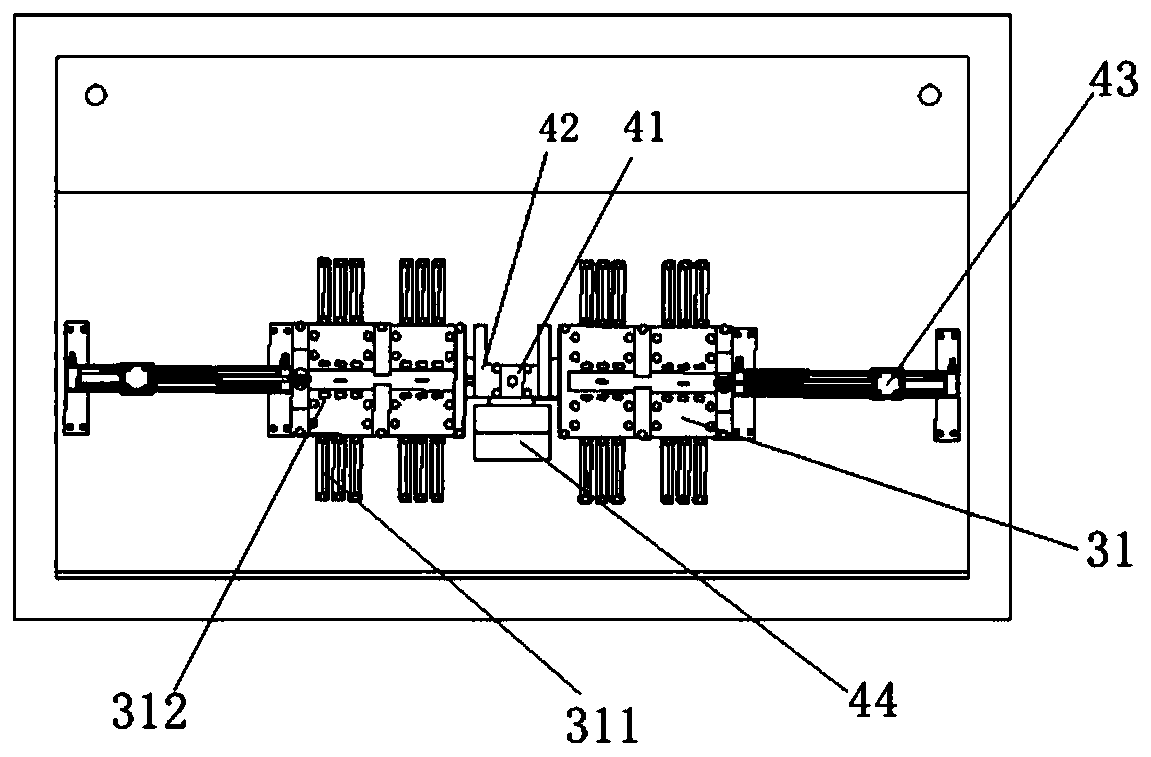

Automatic assembling equipment

PendingCN110033968AImprove assembly timeReduce waiting timeElectric switchesIndustrial engineeringWaiting time

The invention discloses automatic assembling equipment, which is used for assembling a button switch. The automatic assembling equipment comprises a rack, and a first rotary table, a second rotary table, a bottom part assembling component, a middle part assembling component, an upper part assembling component and a middle assembling device arranged on the rack; the middle assembling device is usedfor assembling a finished bottom part of the bottom part assembling component and a finished middle part of the middle part assembling component into a semi-finished part; and according to the condition that the assembling tail end of the middle assembling device is positioned on the first rotary table or the second rotary table, the first rotary table or the second rotary table continues to rotate for enabling the semi-finished part and the finished bottom part of the bottom part assembling component to finish finished product assembling. By adopting the technical scheme, the waiting time ofeach assembling process can be greatly shortened, so that the total assembling time is shortened, the overall assembling progress is accelerated, the assembling time of the button switch is shorter,the assembling efficiency is improved, the automatic assembling operation is realized, the product assembling quality is guaranteed, and the labor cost is reduced.

Owner:YUEQING BOFENG ELECTRONICS CO LTD

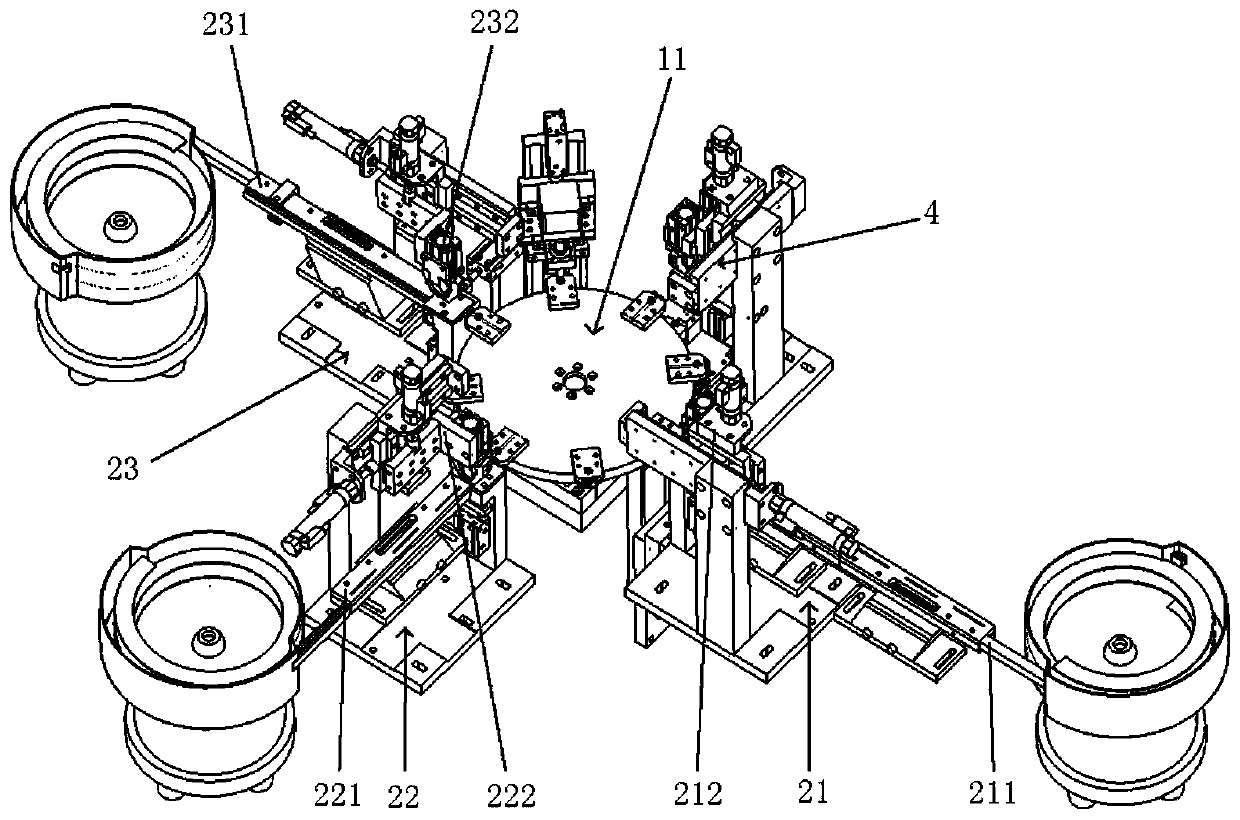

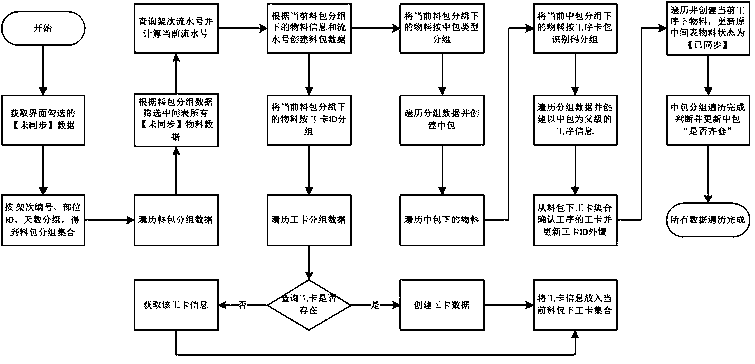

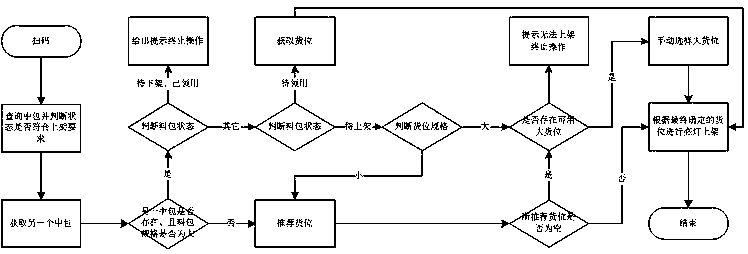

Intelligent distribution system and method for aviation equipment

InactiveCN109858853AReduce mistakesReduce inquiry inconvenienceLogisticsManufacturing computing systemsAviationManagement process

The invention relates to an equipment intelligent distribution system and method, and the system is characterized in that the system comprises a basic data management module, a business handling module, and a plan management module. The method comprises the following steps: optimizing a management process, combining all small material packages distributed from a first-level storehouse into large material packages for each shelf, storing the large material packages in the storehouse in a centralized manner, and then distributing the material packages required by assembly to an intelligent container one day before according to the arrangement of a planner; and on the next day, an assembly worker uses the corresponding material bag on the intelligent container through a work card, so that thephenomena of wrong material taking, material loss, inconvenient material query, wrong material distribution and the like are effectively reduced, and the assembly progress of the product is greatly improved.

Owner:国营芜湖机械厂 +1

Pin roll prestoring device of two-row chain slivering machine

The invention provides a pin roll prestoring device of a two-row chain slivering machine. In the invention, a prestoring barrel is arranged above an original pin roll feeding hopper, a discharging hole is arranged on a bottom plate below the prestoring barrel, upward flanges are arranged at two side edges of the discharging hole, a movable cover plate with a short handle is inserted between the two flanges, a part of the short handle outside the prestoring barrel is downwards bent to form the vertical direction, the short handle can be poked to pull out the movable cover plate so as to open the discharging hole, the short handle can be poked to push the movable cover plate in so as to close the discharging hole, a long-handle fork is arranged at the middle lower part of the prestoring barrel, two ends of a cross bar of the long-handle fork are prestored on the wall of the prestoring barrel, 2-6 downwards inclined forks are arranged on the cross bar in the prestoring barrel, and a long handle at the outer part of the prestoring barrel is arranged downwards and vertically. The forks can swing left and right by swinging the long handle left and right, and due to the left-and-right swing of the forks, pin rolls in the prestoring barrel can be fed. The pin roll prestoring device can be used for prestoring a plurality of pin rolls; a pin roll outlet cannot be blocked; and the assembly progress of the chain slivering machine can be greatly increased.

Owner:溧阳市超强链条制造有限公司

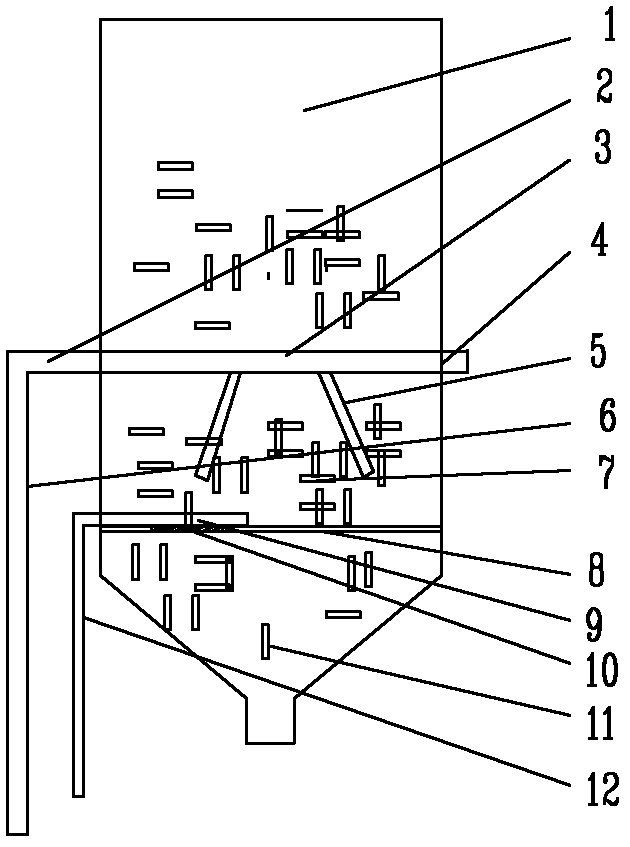

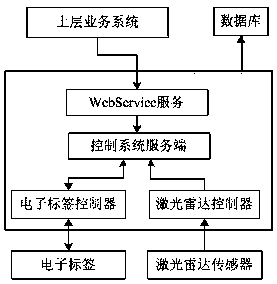

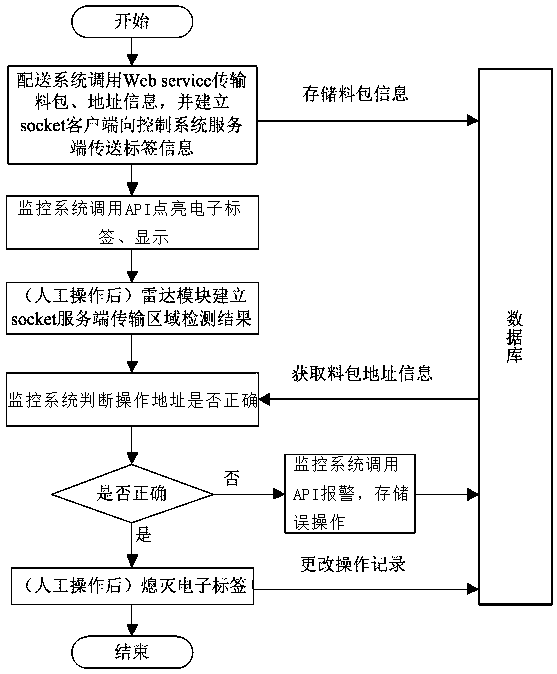

System and method for monitoring smart shelf of temporary repository

The invention relates to a system for monitoring a smart shelf of a temporary repository. The system comprises a Web Service module, a control system service end, an electronic tag controller and a laser radar controller; the Web Service module is used for receiving and storing the information of material bags, goods location addresses and the like transmitted by a top-layer business system; and the control system service end is used for receiving the information of the top-layer Web Service module and the lower-layer electronic tag controller and the laser radar controller, and performing logical processing. A prompt is performed about material putaway and getting operation through an electronic tag to realize rapid positioning of goods locations; and a mistake-proof alarm and a misoperation record of material putaway and getting are realized through a laser radar, and thus, a 24-hour monitoring mistake-proof and anti-theft alarm is realized, the frequent phenomena that materials of the temporary repository are taken by mistake, the materials are lost, the materials are inconvenient to query, material distribution is wrong, and the like are effectively reduced, and the product assembly schedule is greatly promoted.

Owner:CHENGDU SIWI HIGH TECH IND GARDEN

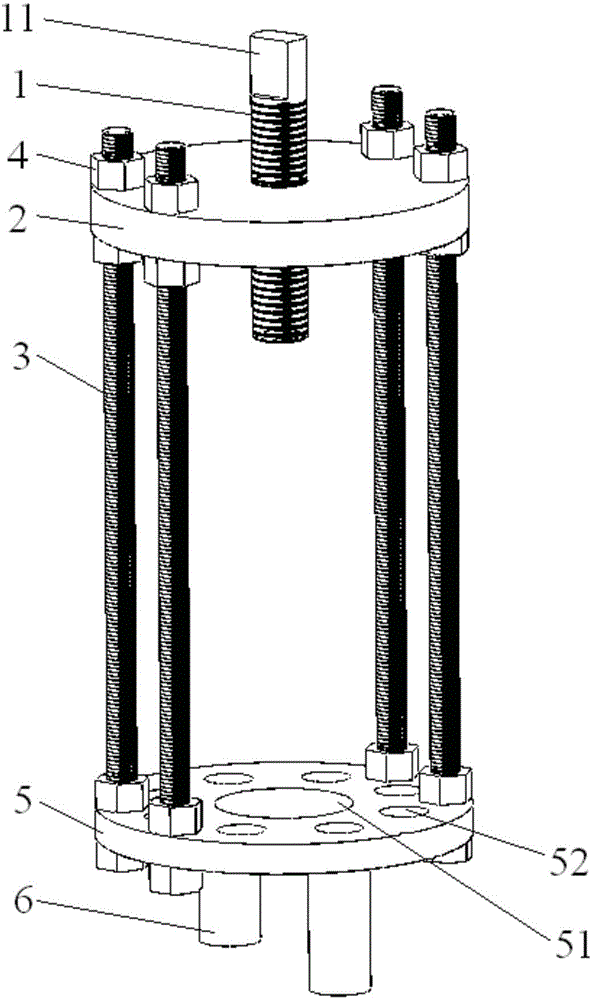

Rod pressing tooling for assembling valves

InactiveCN104308800ASimple structureEasy to operateMetal-working hand toolsEngineeringUltimate tensile strength

The invention discloses a rod pressing tooling for assembling valves, relates to the field of valves, and solves the problems that a large amount of strength of workers is required, the assembly speed is limited, the final production efficiency of products is influenced, certain risk exists when a flashboard and a valve seat are assembled manually, and as thread lines of threads of a valve rod are sharp, the centers of gravity of a human body and a valve body are instable and fingers of the workers are scratched or the workers are personally injured or subjected to other injury when the valve rod and the flashboard are pressed. The rod pressing tooling for assembling the valve comprises an operating rod, a top plate, full-thread studs, nuts, a base and legs. The rod pressing tooling for assembling the valves is simple in structure, and convenient to operate; in the using process, the rod pressing assembly speed of the valves is improved, and the assembly speed of the whole product is improved; meanwhile, by adopting the rod pressing tooling for assembling the valves, the labor intensity of the workers is reduced and the operating safety is greatly guaranteed.

Owner:SUZHOU DOUSON DRILLING & PRODION EQUIP

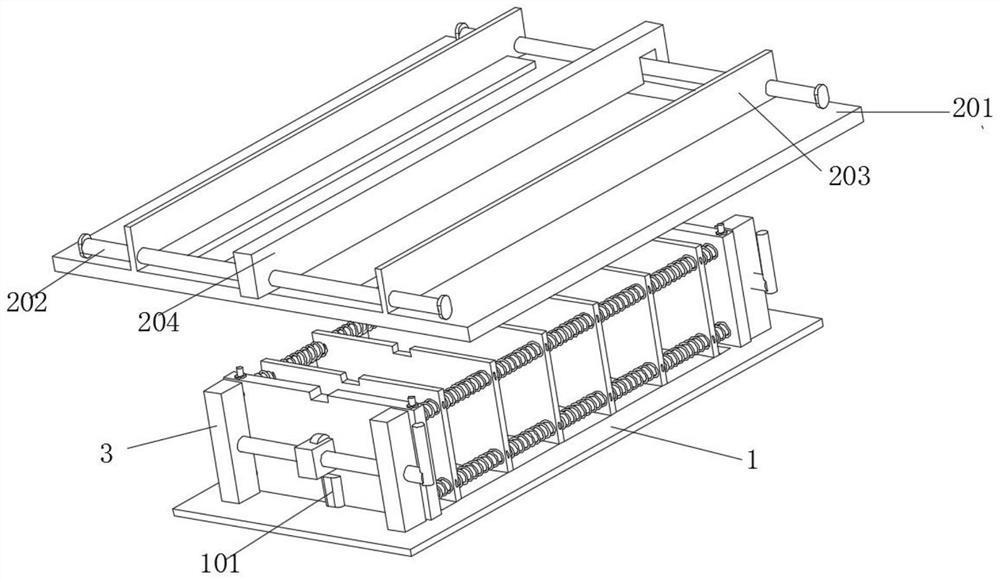

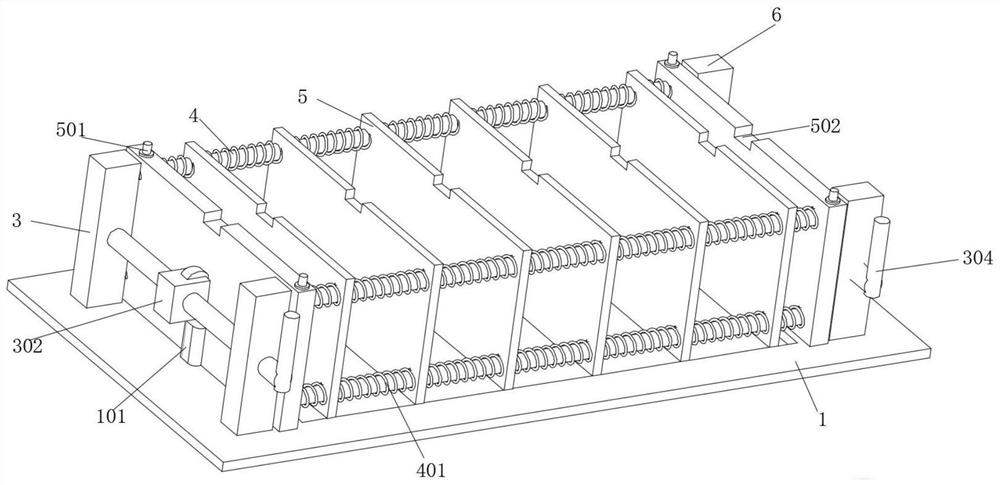

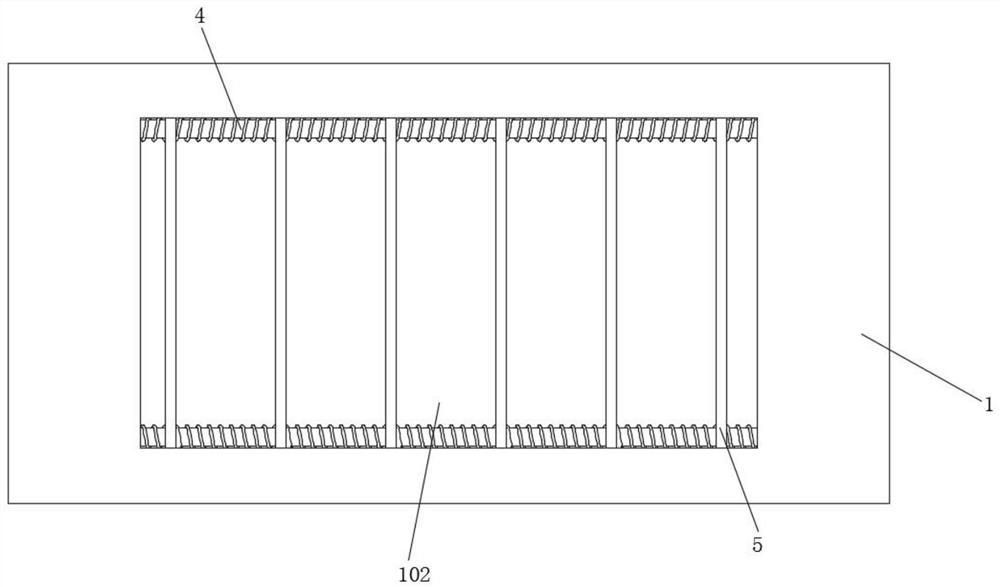

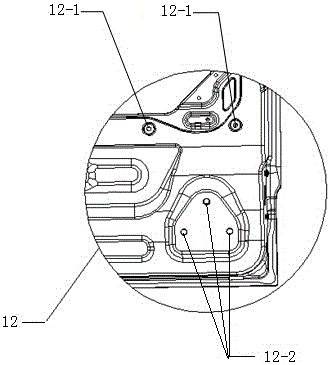

Pre-slotting groove shaping device for storage battery processing

InactiveCN112201861ATidy up and downImprove assembly progressFinal product manufactureLead-acid accumulators constructionStructural engineeringMechanical engineering

The invention discloses a pre-slotting shaping device for storage battery processing, and relates to the technical field of storage battery production. The device comprises a bottom plate, a first concave hole is formed in the lower surface of the bottom plate, and two first fixing blocks and two sliding blocks are connected to the upper surface of the bottom plate; a plurality of extrusion platesare movably inserted into the guide rods in a penetrating mode, a spring is arranged between the two extrusion plates, grooves are formed in the upper end faces of the extrusion plates, and a pressing plate assembly is connected to the grooves in a matched mode, and rotating shafts are rotationally connected between the two first fixing blocks and between the two sliding blocks correspondingly, rotating blocks are fixedly connected to the rotating shafts and rotationally connected with sliding wheels, and one ends of the rotating shafts are connected with shifting rods. According to the invention, a pressing plate in a pressing plate assembly is matched with the groove in the extrusion plate, and the movable plates at the two sides of the pressing plate assembly are matched with a transverse plate, so that the positions of each plate group and tabs on the plate groups are tidy, the processing and assembling progress of the storage battery is accelerated, the fault time is reduced, andthe production efficiency is improved.

Owner:TIANNENG BATTERY WUHU

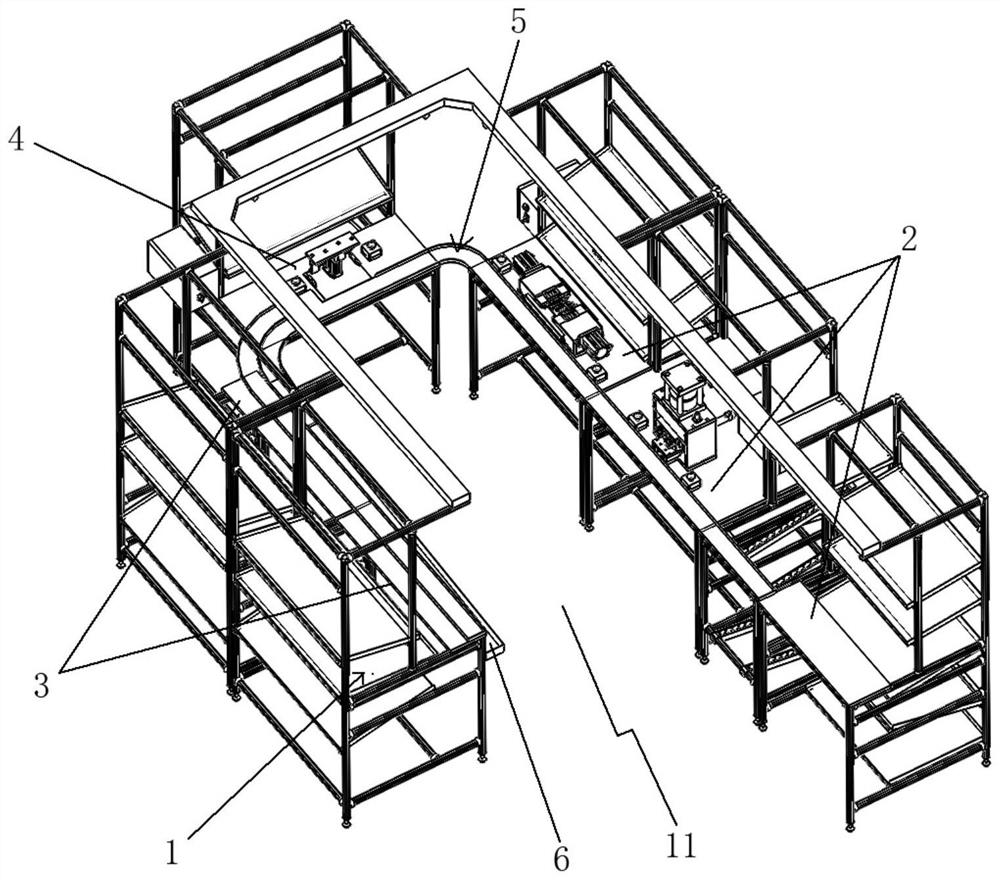

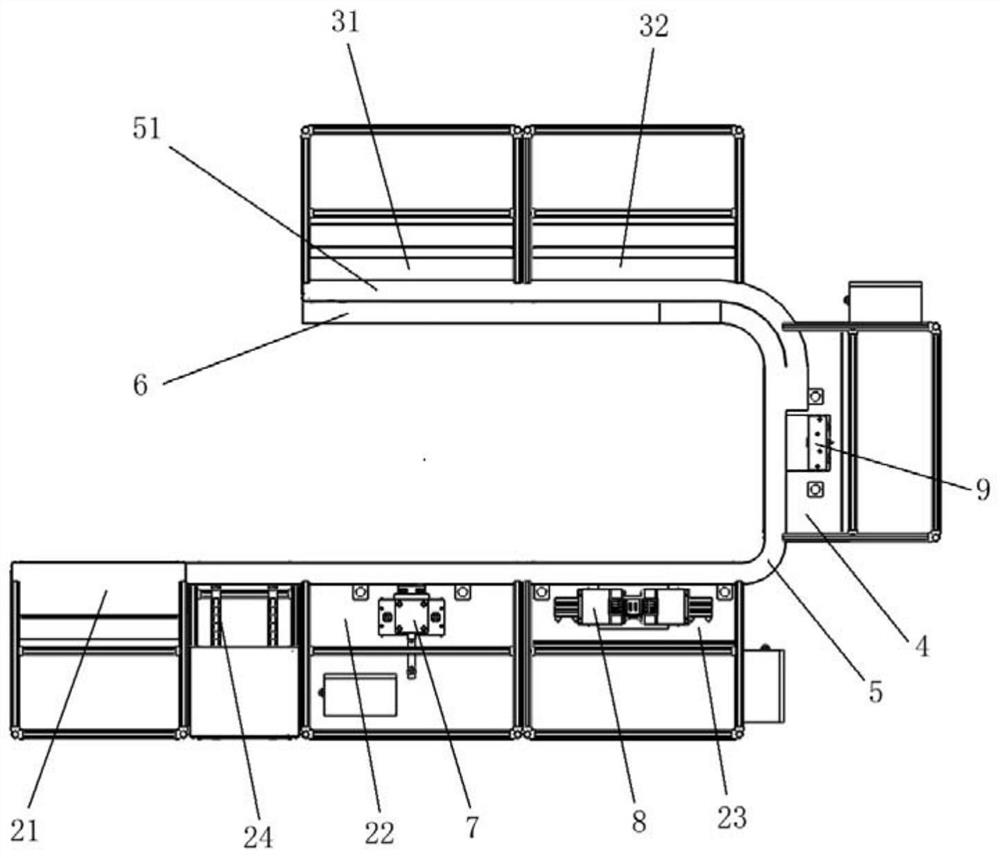

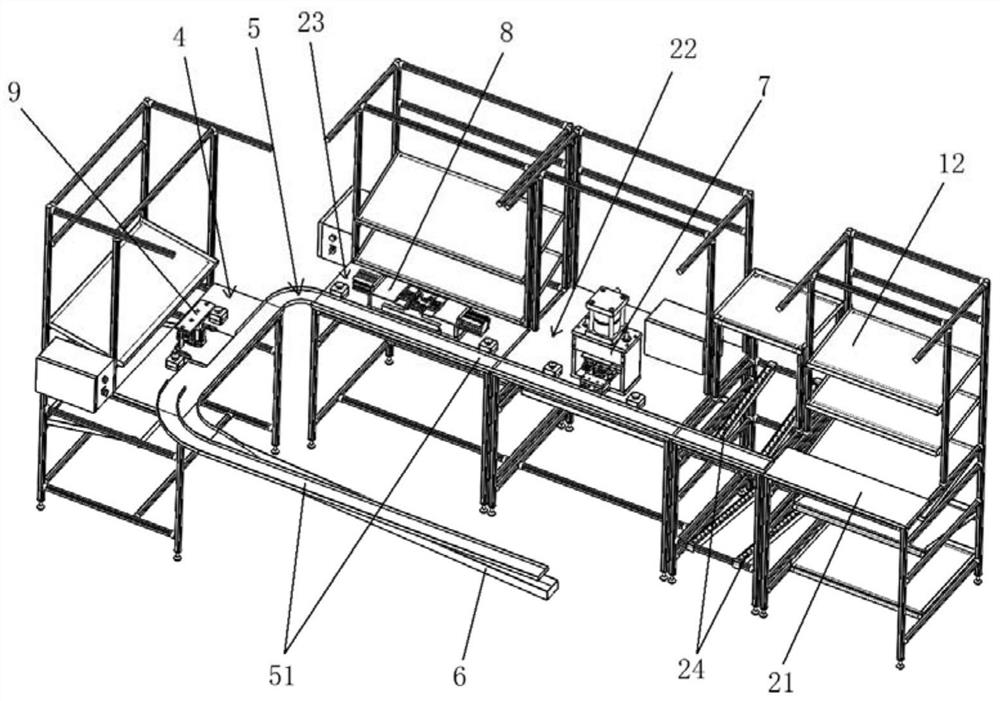

Contactor production line

The invention discloses a contactor production line. The production line comprises a feeding assembly table, and a base part assembly line, a middle assembly line and a base part assembly line which are arranged around a U-shaped section of the feeding assembly table. U-shaped runner structures are arranged among the base part assembly line, the middle assembly line and the base part assembly line in an extending mode, the middle assembly line is used for assembling base semi-finished products of the base part assembly line and base semi-finished products of the base part assembly line into finished products of the contactors, the U-shaped production line design reduces operation sites, the procedure layout is reasonable. The base part assembly line and the base part assembly line independently complete assembly of respective parts, finally, final assembly is completed through the middle assembly line, the waiting time of assembly procedures can be shortened, the overall assembly progress is improved, all the procedures are smoothly connected, the assembly efficiency is high, in addition, the number of workers is remarkably reduced. The labor cost and the management difficulty are reduced, and the competition of contactor products is improved.

Owner:ZHEJIANG PEOPLE ELE APPLIANCE

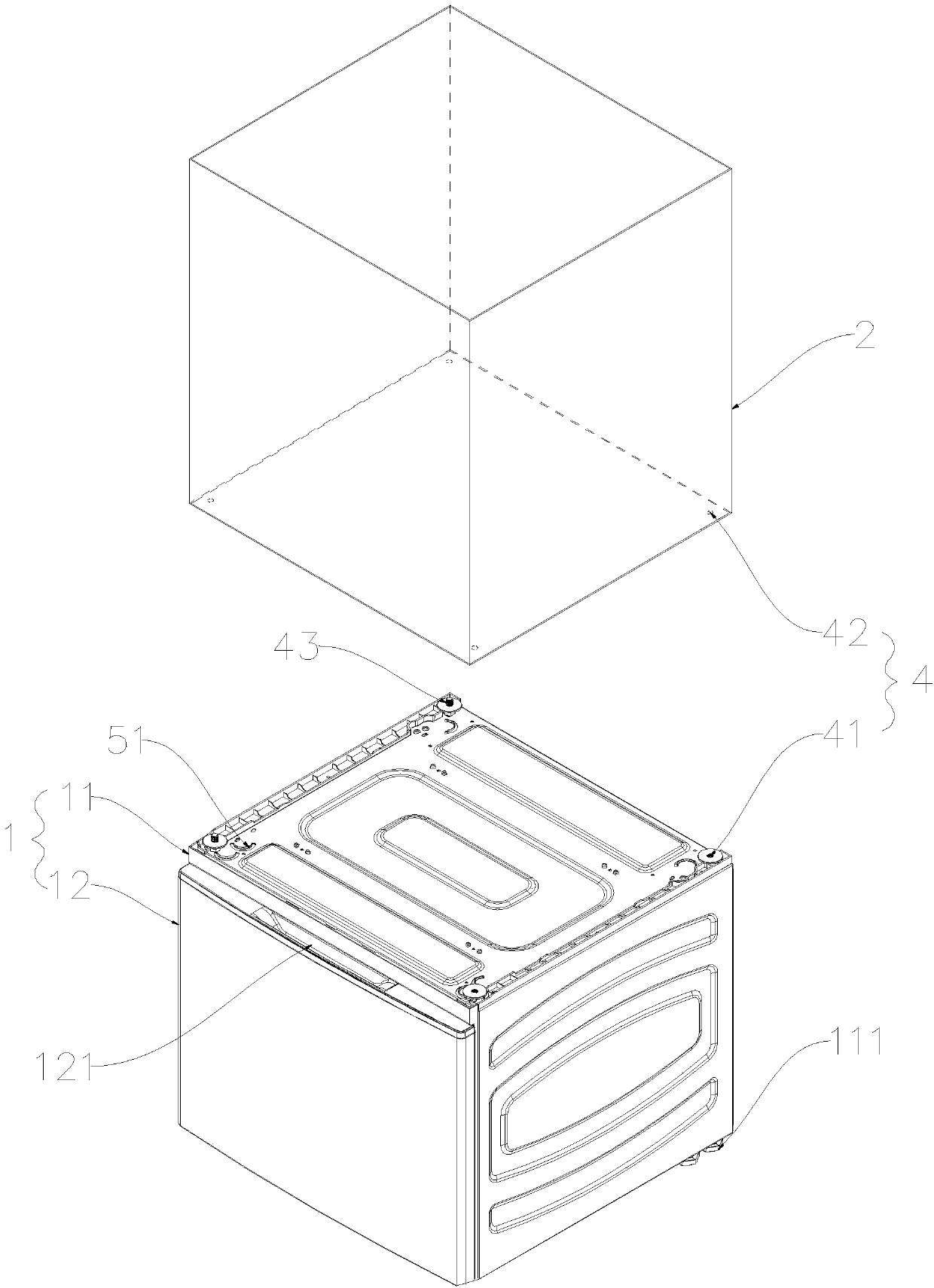

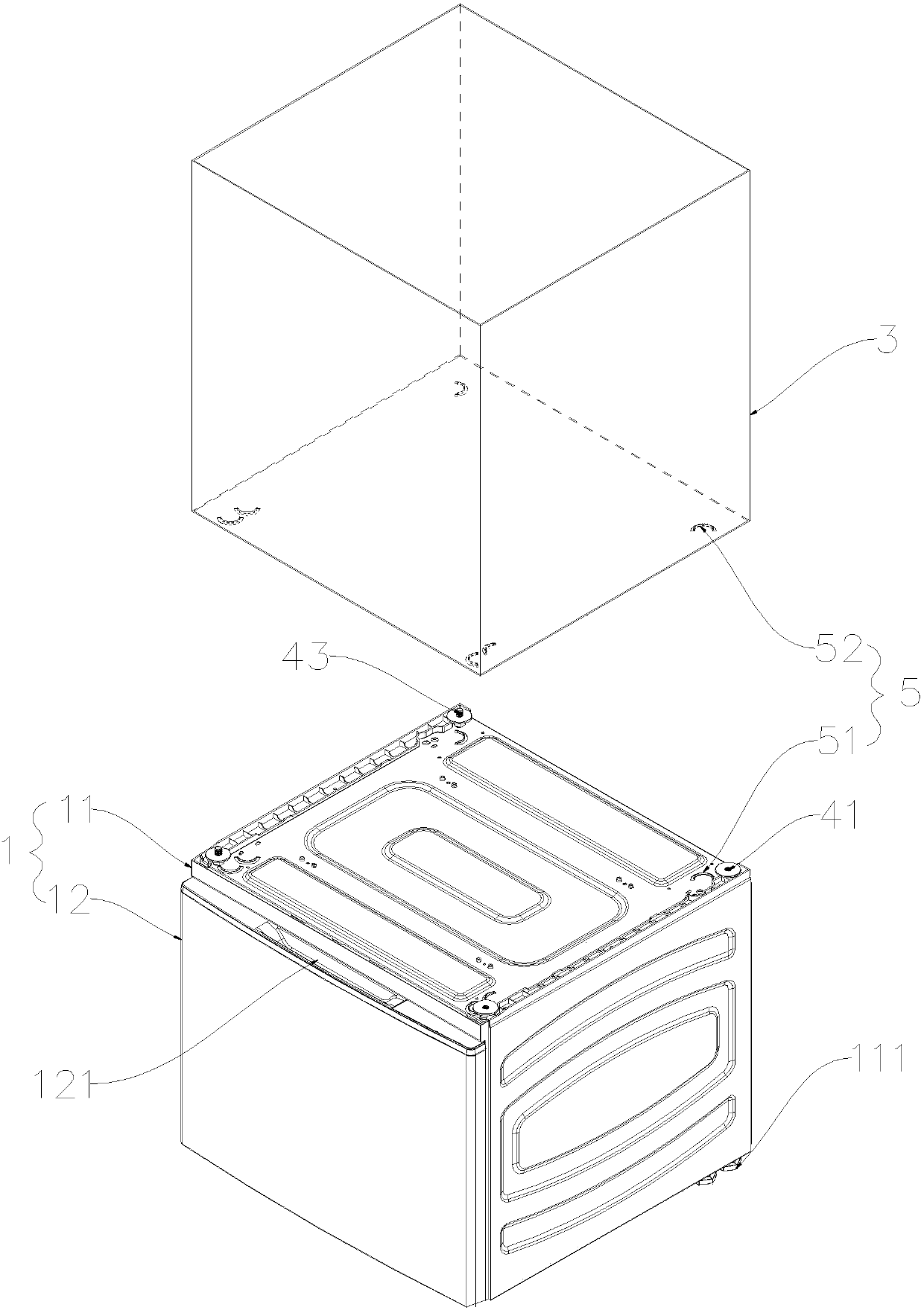

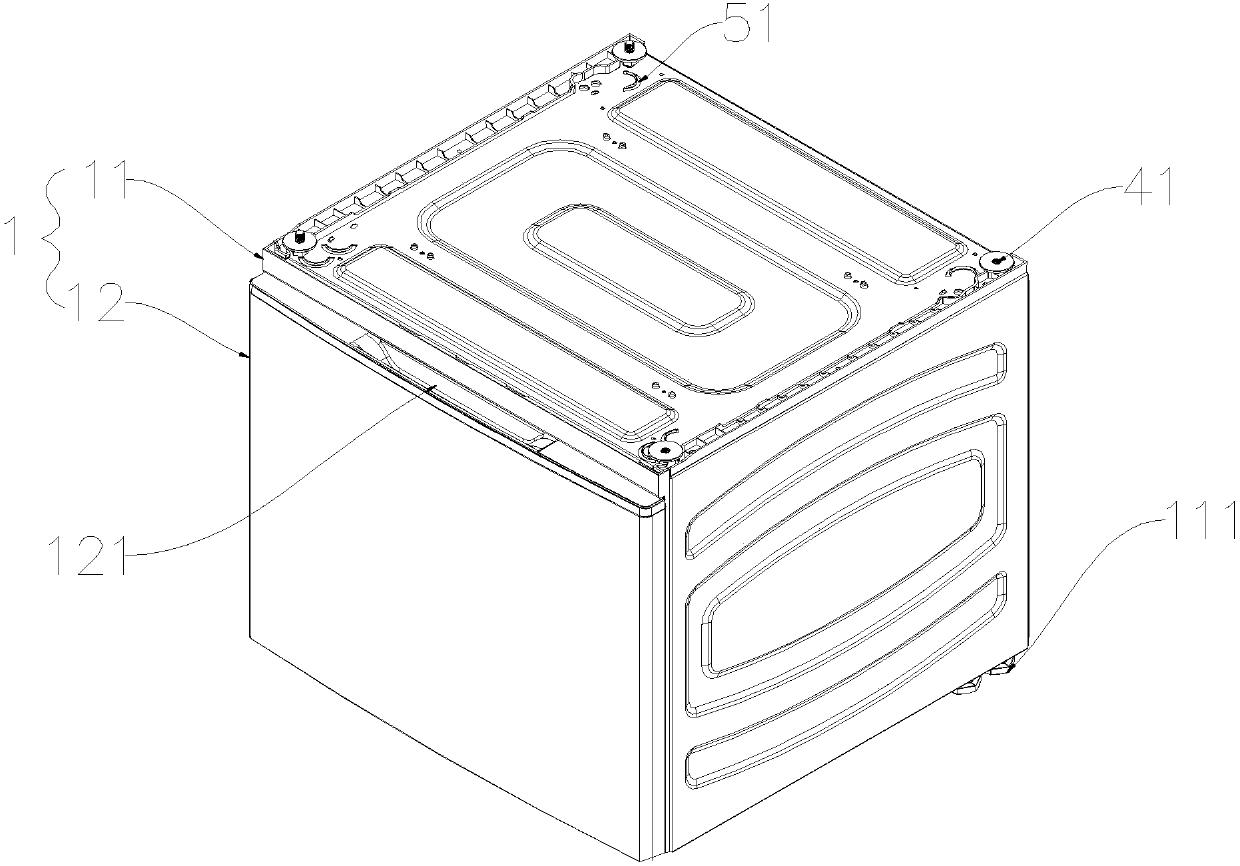

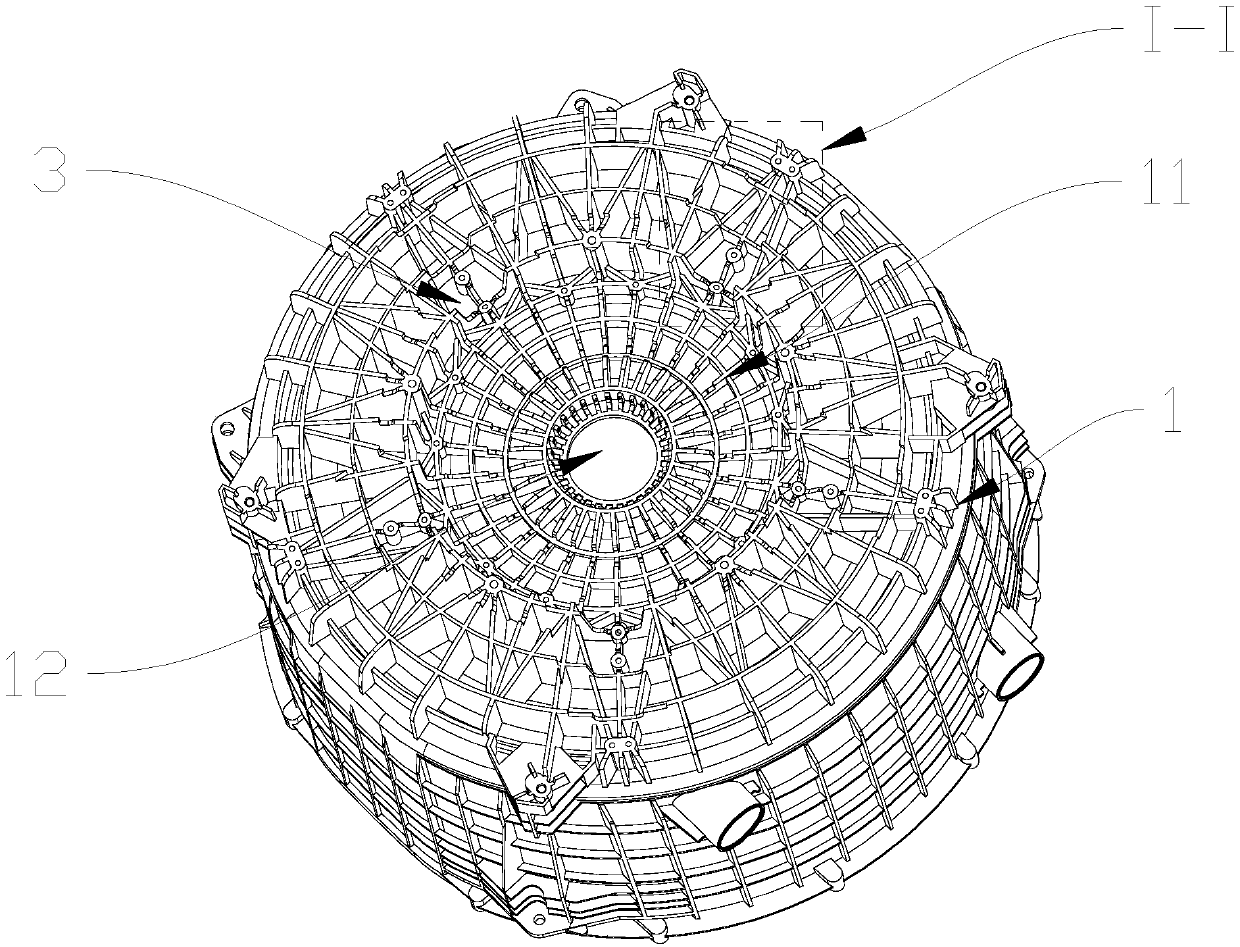

Clothes treating equipment

PendingCN110387667AAvoid secondary pollutionImprove health and safetyOther washing machinesTextiles and paperPulp and paper industryContamination

The invention relates to the technical field of clothes treatment, particularly provides clothes treating equipment, and aims at solving the problem that existing clothes treating equipment is prone to cross contamination. The clothes treating equipment comprises a shoe washing device, a clothes treating device and a mounting and positioning assembly arranged between the shoe washing device and the clothes treating device, wherein the mounting and positioning assembly can mount and position the clothes treating device to the top of the shoe washing device. Preferably, the shoe washing device is a shoe washing machine and the clothes treating device is a washing machine or a clothes dryer. The washing machine or the clothes dryer is mounted and positioned on the shoe washing machine by themounting and positioning assembly, so that the clothes treating equipment has both a shoe washing function and a clothes treating function, the shoe washing machine and the washing machine have independent spaces, contamination to the washing machine by residual bacteria in the shoe washing machine is prevented, and use experience of users is improved.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

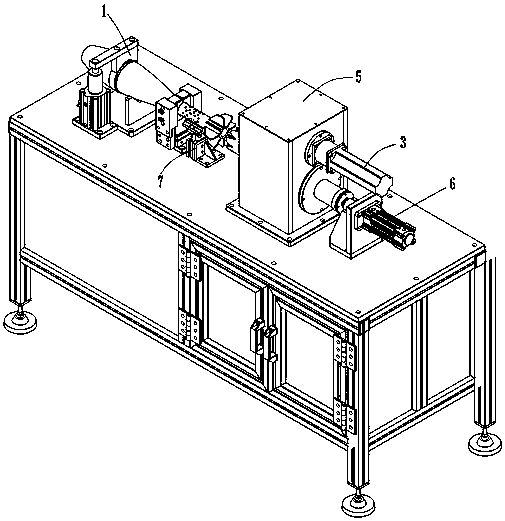

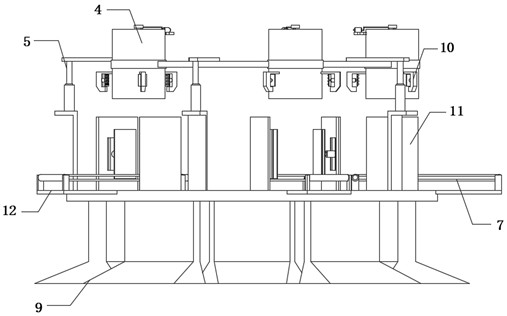

Empennage assembling equipment

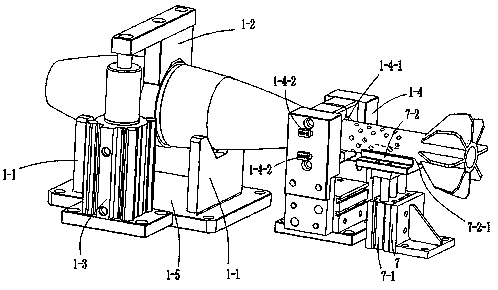

PendingCN110802383AIncrease productivityReduce labor intensityMetal working apparatusClassical mechanicsEngineering

The invention discloses empennage assembling equipment. The empennage assembling equipment comprises a projectile positioning tool, an empennage supporting seat, a floating wrench rod, a driving mechanism, a transmission sleeve, a box body and a feeding assembly. Both the driving mechanism and the transmission sleeve are arranged in the box body. The projectile positioning tool is used for positioning and clamping a projectile. The empennage supporting seat is arranged between the transmission sleeve and the projectile positioning tool. The top of the empennage supporting seat is used for placing an empennage. The driving mechanism drives the transmission sleeve to rotate in the circumferential direction. The floating wrench rod is axially slidably arranged in the transmission sleeve and is circumferentially fixed opposite to the transmission sleeve. An empennage wrench is arranged at the front end of the floating wrench rod. The floating wrench rod moves axially under the driving of the feeding assembly, so that the empennage wrench is matched with the empennage. According to the empennage assembling equipment, the projectile is positioned by the projectile positioning tool, the feeding assembly pushes the floating wrench rod to move, the empennage wrench is matched with the empennage, the driving mechanism drives the empennage to rotate, the empennage is screwed with the projectile, automatic projectile empennage assembling work is achieved, and the production efficiency is improved.

Owner:HUNAN JUNCHENG TECH

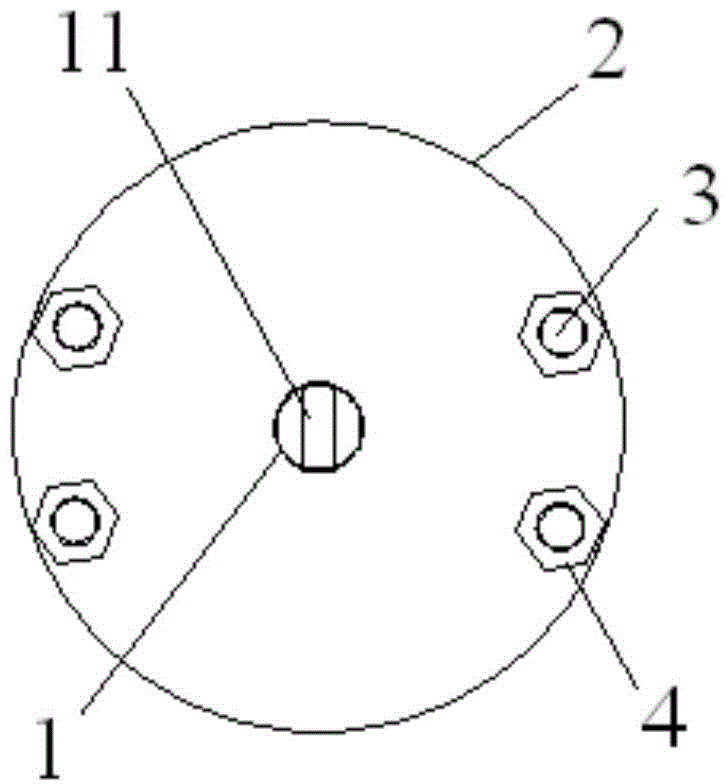

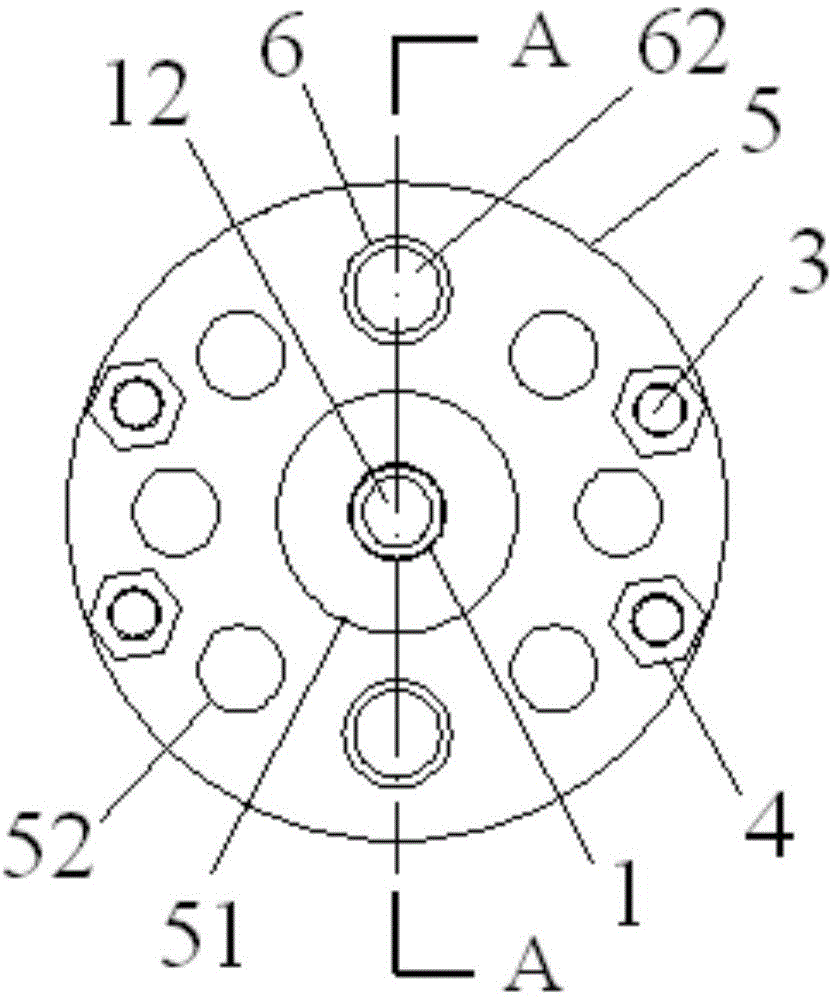

Quick tightening tooling for studs

ActiveCN103612233BQuick tightenReduce workloadPower driven toolsMetal-working hand toolsEngineeringImpact wrench

The invention discloses a quick stud screwing tool comprising a base body and an ejector head. The base body is composed of an operation part and a screwing part. The operation part is provided with an operation hole used for cooperating with an air wrench or an electric wrench. The screwing part is provided with a threaded hole. The ejector head is composed of a threaded section and a conical section. The top of the conical section is a spherical surface. The ejector head is installed in the screwing part of the base body. The threaded section of the ejector head is matched with the inner end of the threaded hole of the screwing part of the base body. The conical section of the ejector head faces towards the outer side of the threaded hole of the screwing part of the base body. The outer end of the threaded hole of the screwing part of the base body is matched with a thread of a screwed stud. By means of the quick stud screwing tool, workloads of workers are lightened, little labor is occupied, labor cost is reduced, operation safety is improved, and use efficiency and the assembly progress of a whole product are improved. In addition, the quick stud screwing tool is easy to machine and operate, uses fewer materials and saves cost.

Owner:SUZHOU DAWSON DRILLING EQUIP CO LTD

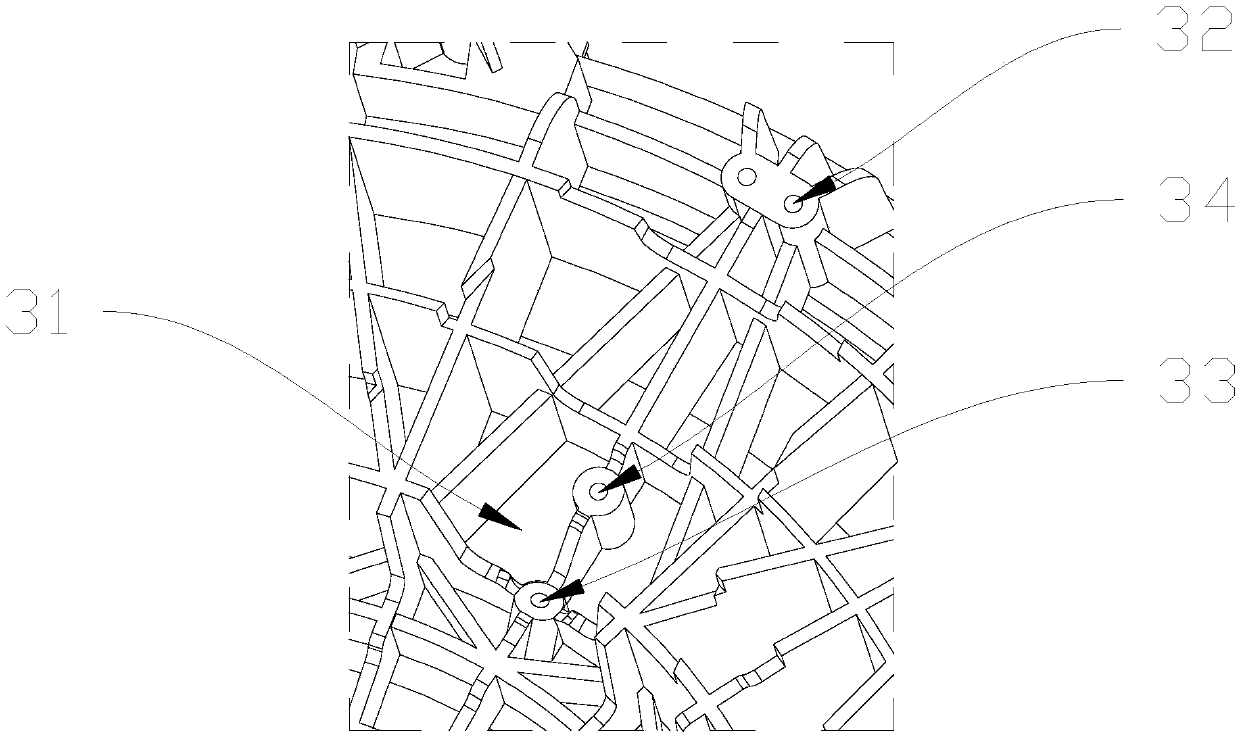

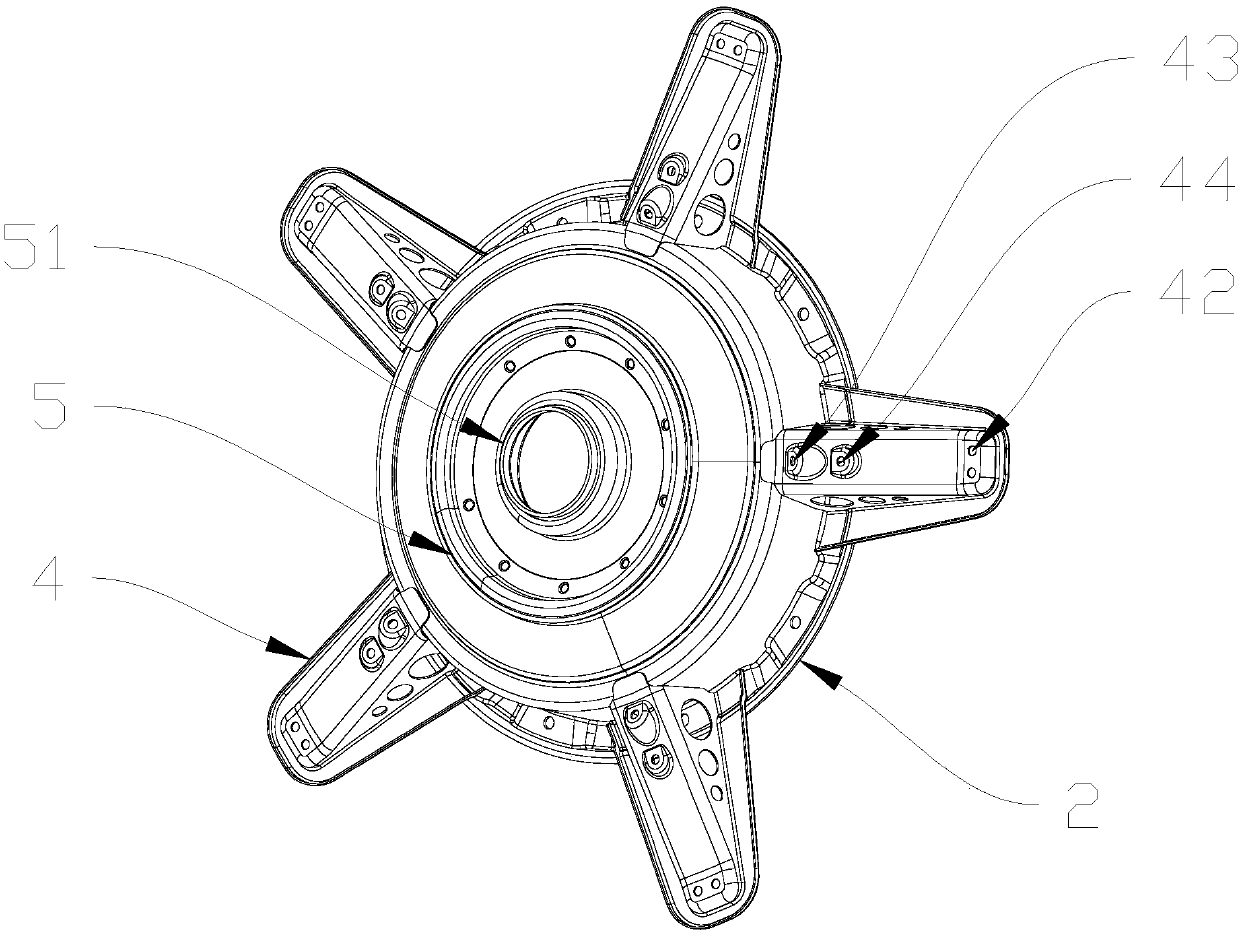

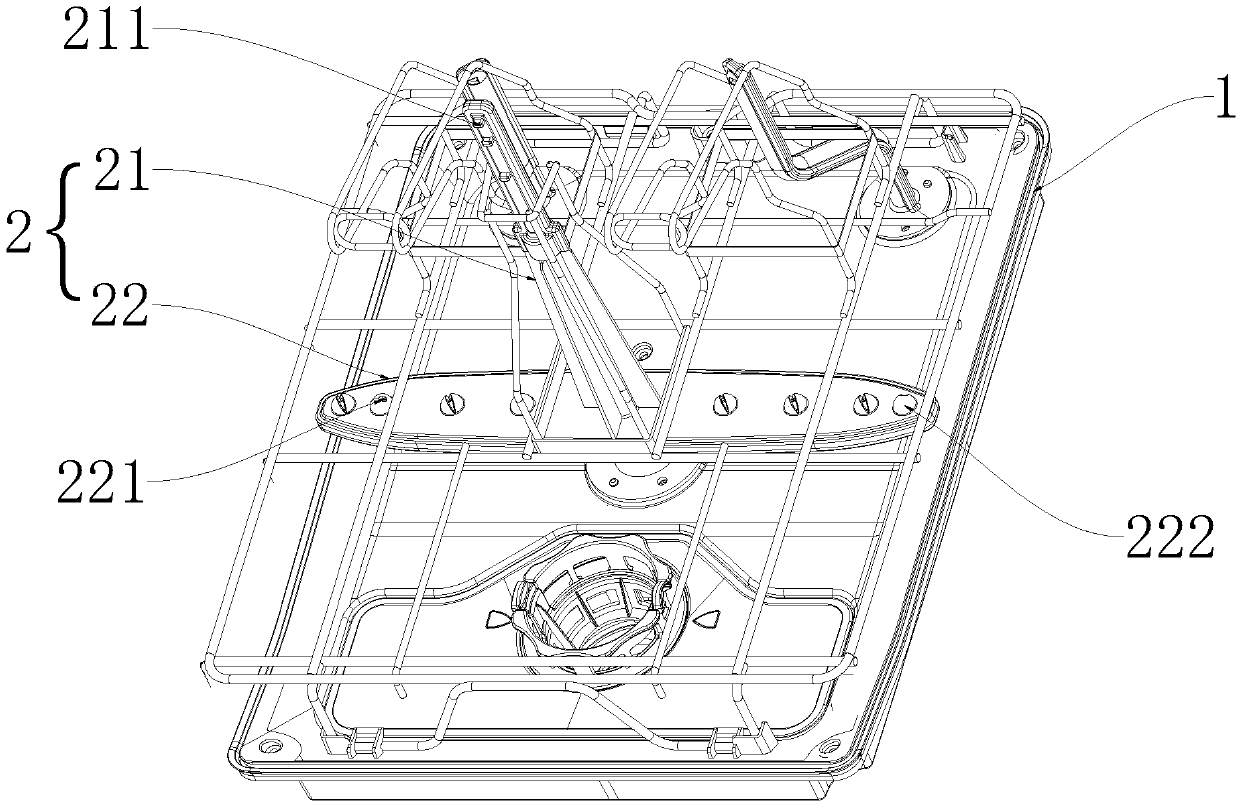

Clothes treatment equipment

PendingCN110318217AFirmly connectedImprove firm performanceOther washing machinesTextiles and paperEngineeringDrive motor

The invention relates to the technical field of clothes treatment equipment, and particularly provides clothes treatment equipment. The clothes treatment equipment aims at solving the problem that there are big errors of pre-locating cooperation between an existing clothes treatment drum and a shell of an existing direct drive motor. For the purpose, the clothes treatment equipment comprises an outer drum, an inner drum rotatably arranged in the outer drum, a direct drive motor and a clamping assembly used for tightly connecting the outer drum with the shell, and the direct drive motor comprises a shell and a driving assembly arranged in the shell and used for driving the inner drum to rotate; a reinforcement member is arranged on the shell and used for improving the strength of the shell.According to the clothes treatment equipment, the outer drum is tightly connected with the shell of the direct drive motor through the clamping assembly, the outer drum and the shell of the direct drive motor are pre-located, and the assembly progress rate of a drum washing machine is increased. By arranging the reinforcement member on the shell, the strength of the shell is improved, and the direct drive motor can bear the outer drum of the drum washing machine and loaded clothes in the work state.

Owner:QINGDAO HAIER DRUM WASHING MACHINE

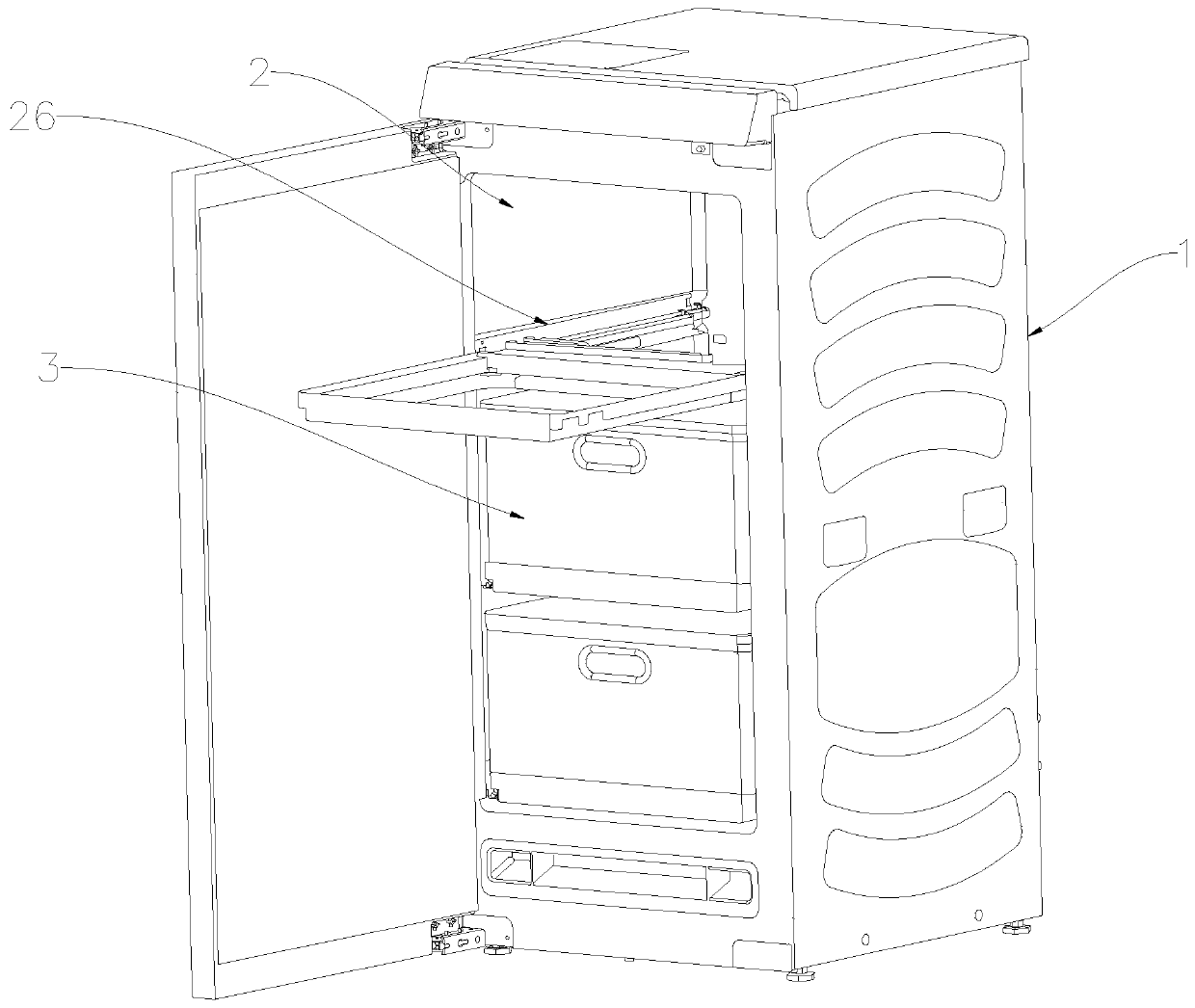

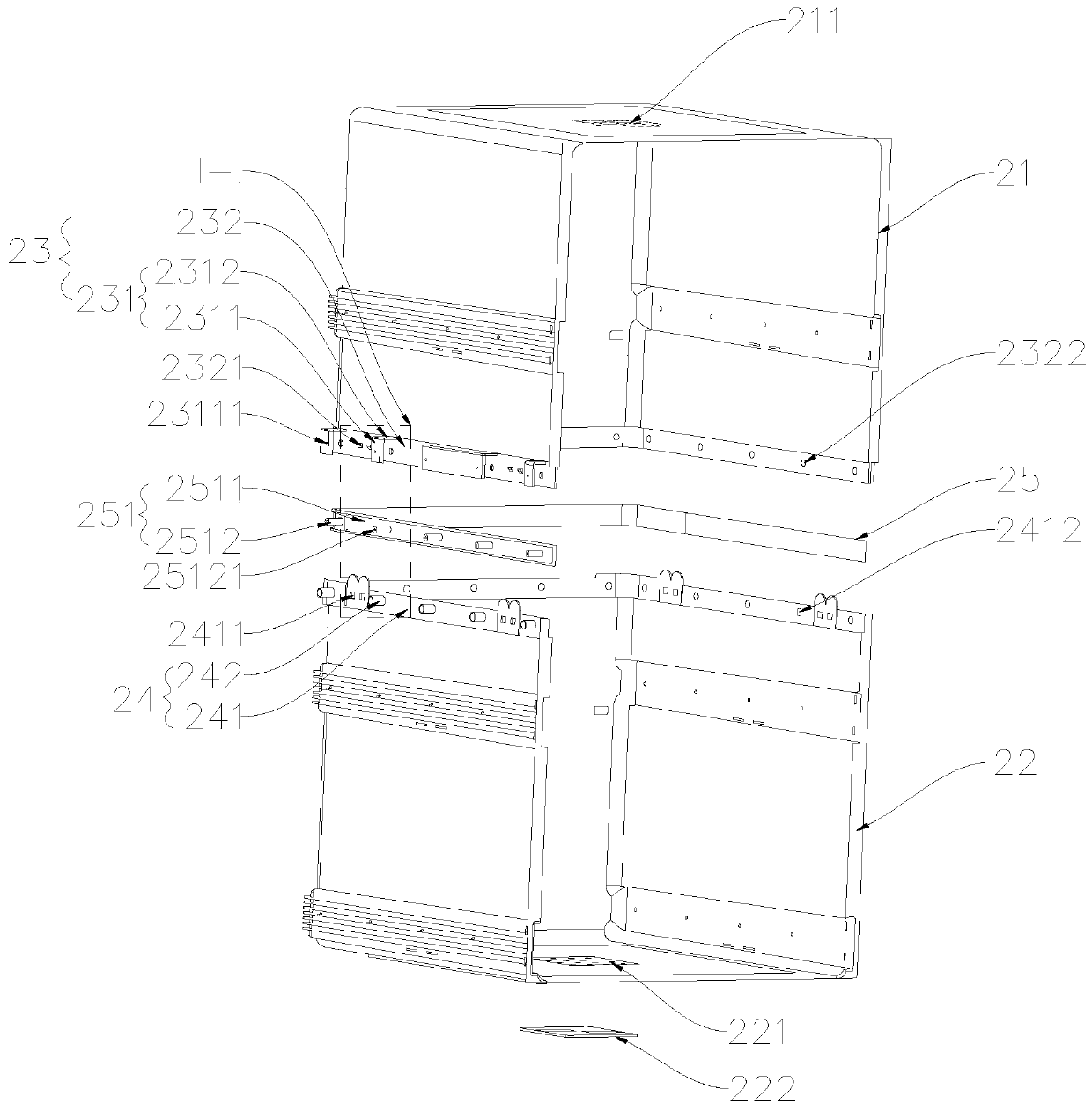

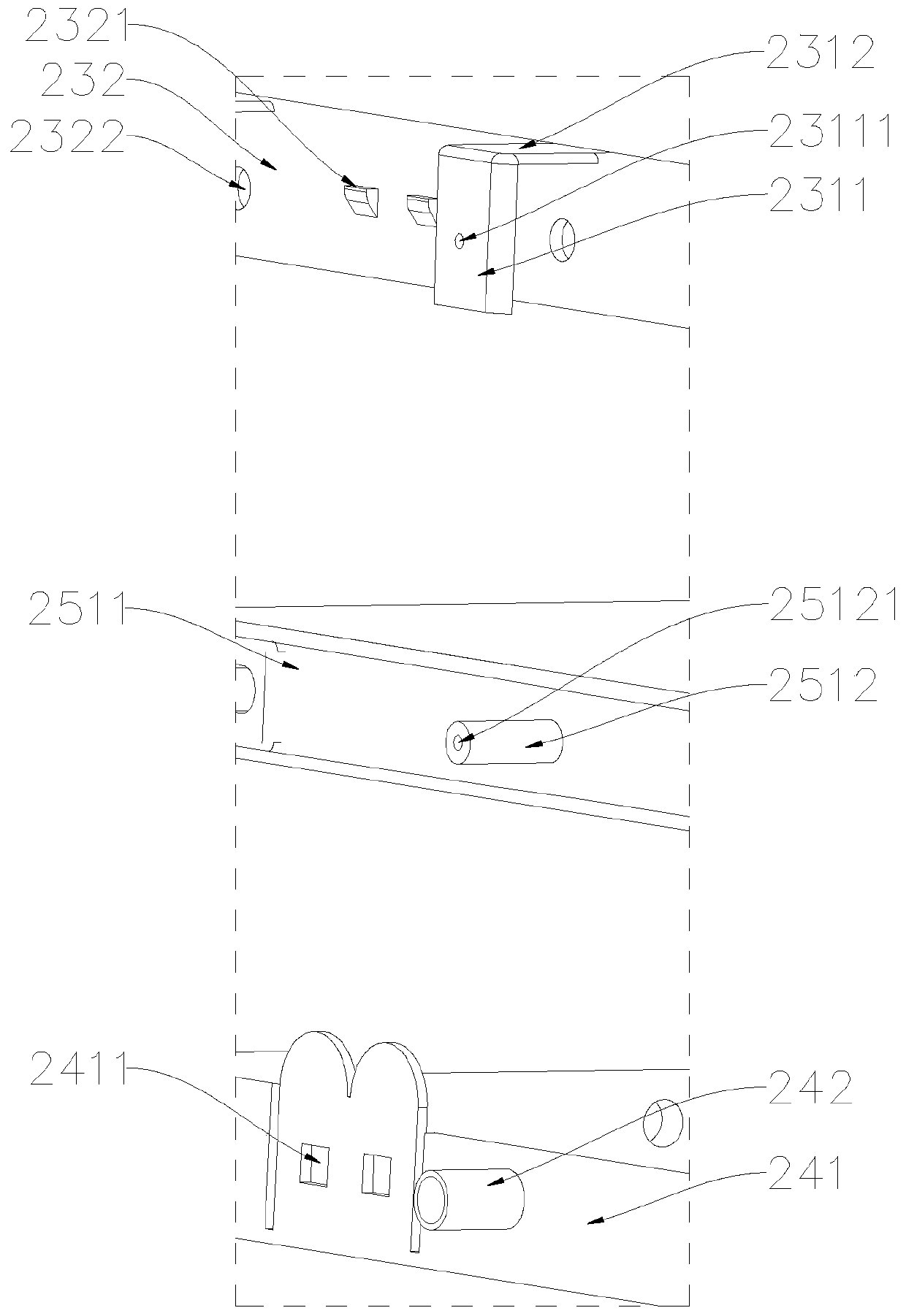

Clothes storage equipment

ActiveCN111345597ASimplify the assembly and disassembly processPrevent shrinkageWardrobesSheet joiningMechanical engineeringIndustrial engineering

The invention relates to the technical field of clothes storage, particularly provides clothes storage equipment, and aims at solving the problem that an inner container of existing clothes storage equipment is inconvenient to install. For this purpose, the clothes storage equipment comprises a shell and an inner container arranged in the shell, the inner container comprises a first containing component, a second containing component and an installation positioning assembly arranged between the first containing component and the second containing component, and the installation positioning assembly can install and position the first containing component to the top of the second containing component. The first containing component is mounted and positioned to the top of the second containing component through the mounting and positioning assembly, the liner mounting and dismounting process is simplified, convenience is provided for mounting personnel to mount and dismount the inner container, the assembling efficiency of the mounting personnel is improved, the assembling progress of the clothes storage equipment is accelerated, mounting operation of the clothes storage equipment isfacilitated, machining and manufacturing of a mold are facilitated, and shrinkage of the inner container due to the too large height is avoided.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

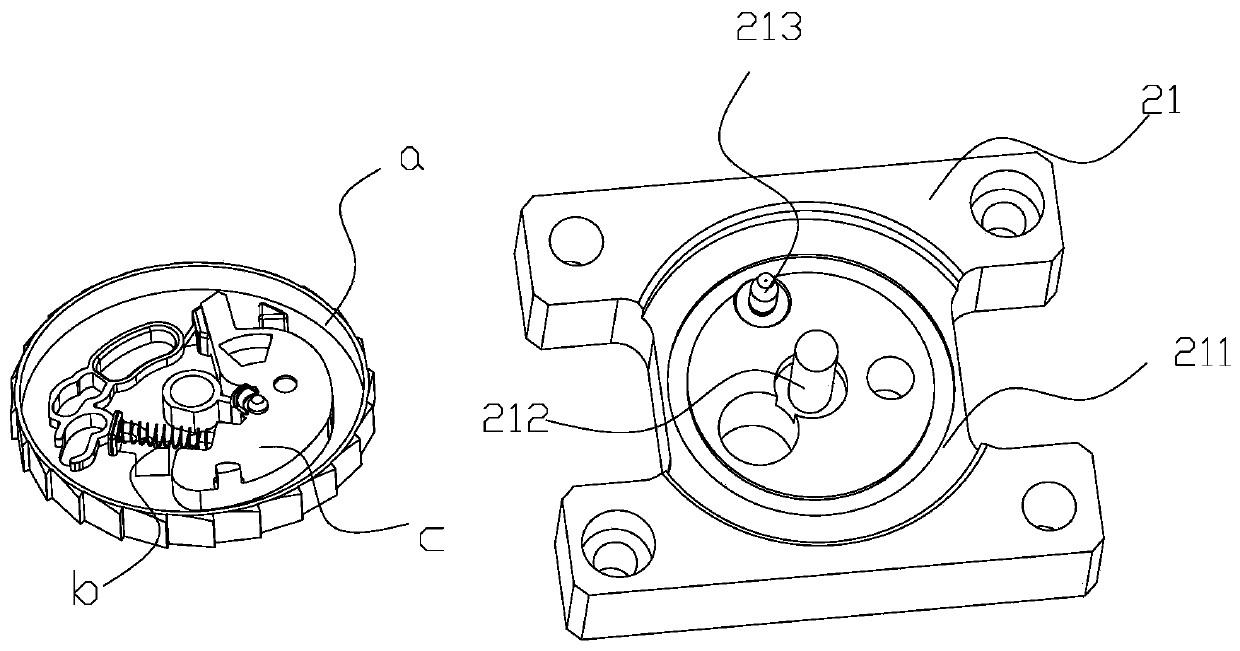

Feeding device for ratchet wheel of locking device of automobile safety belt retractor

ActiveCN111230482AEasy to correctImprove stabilityAssembly machinesMetal working apparatusRatchetEngineering

The invention relates to the technical field of safety belt retractors, and discloses a feeding device for a ratchet wheel of a locking device of an automobile safety belt retractor. The feeding device comprises a ratchet wheel conveying vibration disc, a ratchet wheel supporting frame, a ratchet wheel correcting assembly and a ratchet wheel transferring assembly; the ratchet wheel supporting frame is connected with the discharging end of the ratchet wheel conveying vibration disc, the ratchet wheel correcting assembly is located on one side of the ratchet wheel supporting frame and used for correcting the conveyed ratchet wheel, and the ratchet wheel transferring assembly is used for transferring the corrected ratchet wheel. The feeding device has the advantages that the firmness of sucking the ratchet wheel is improved, and the stability of the ratchet wheel in the transferring process is improved.

Owner:JIANGSU XINHUOTEHE FAYE

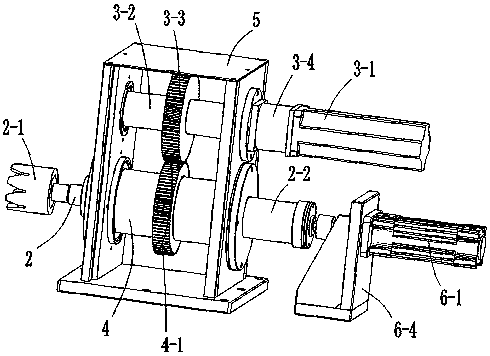

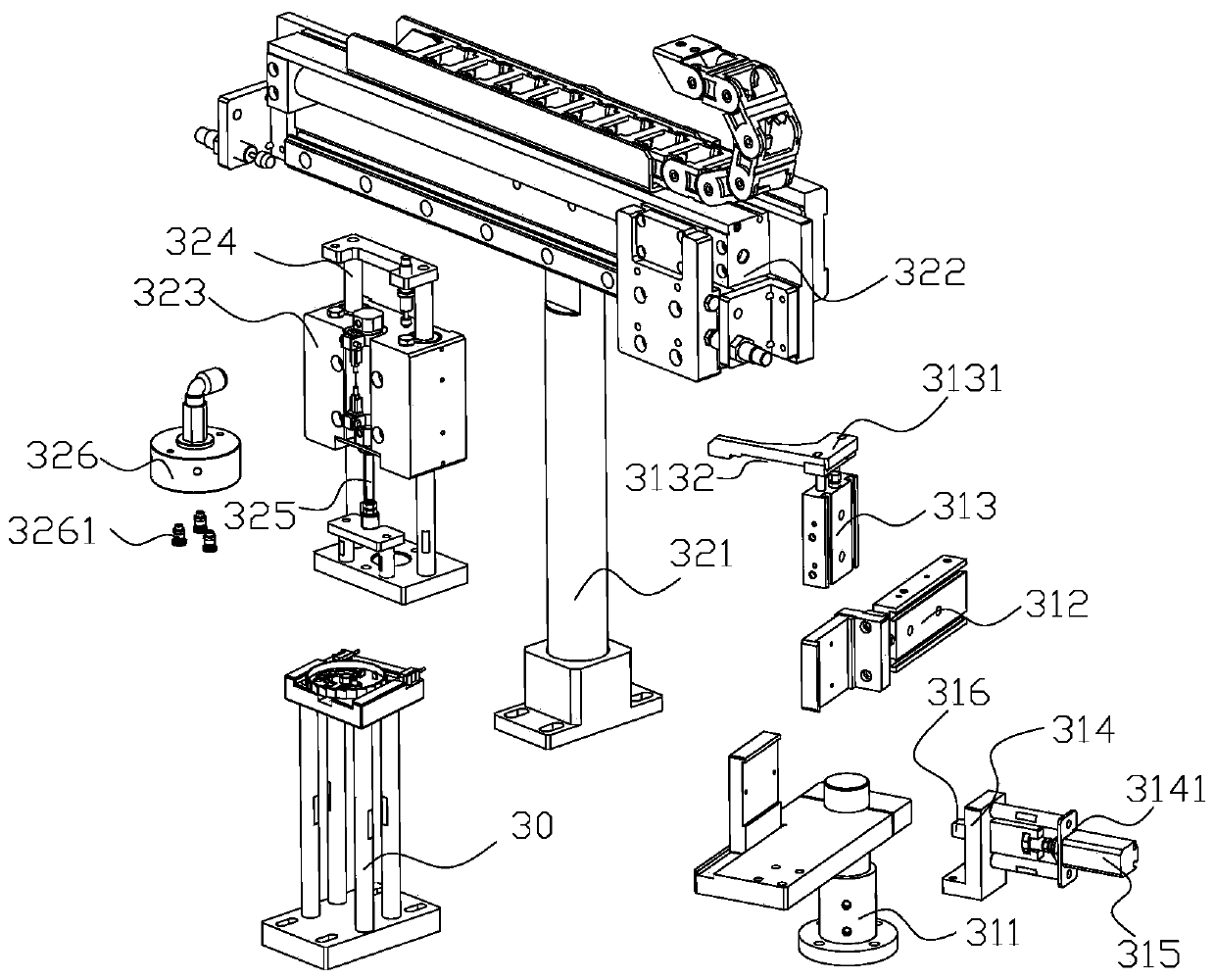

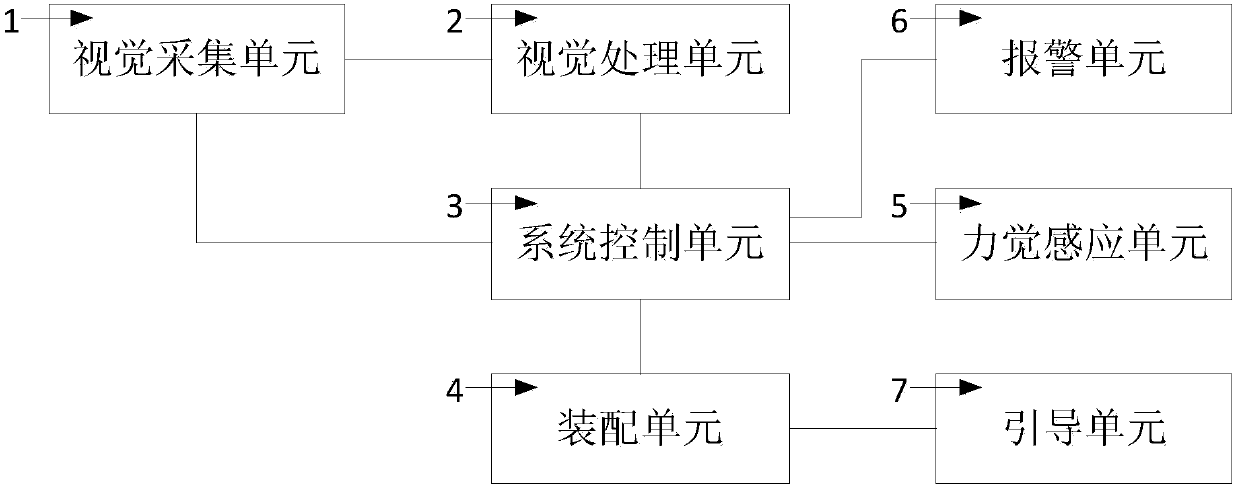

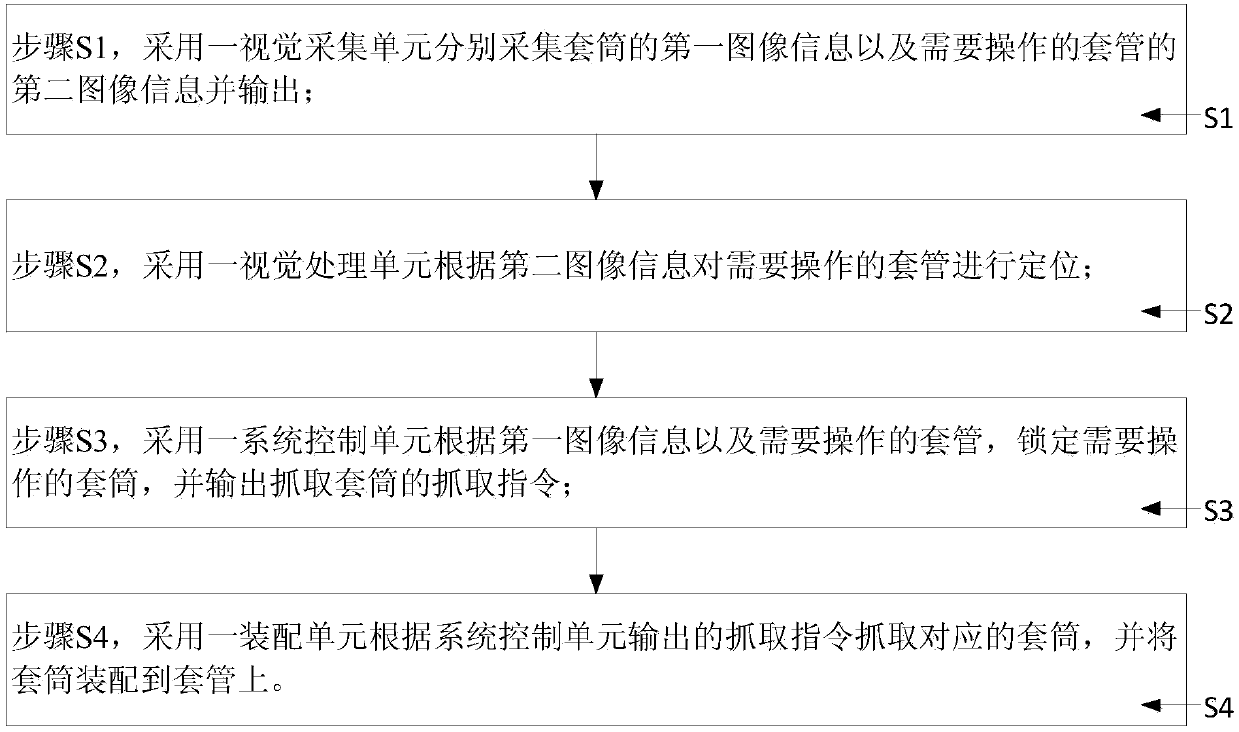

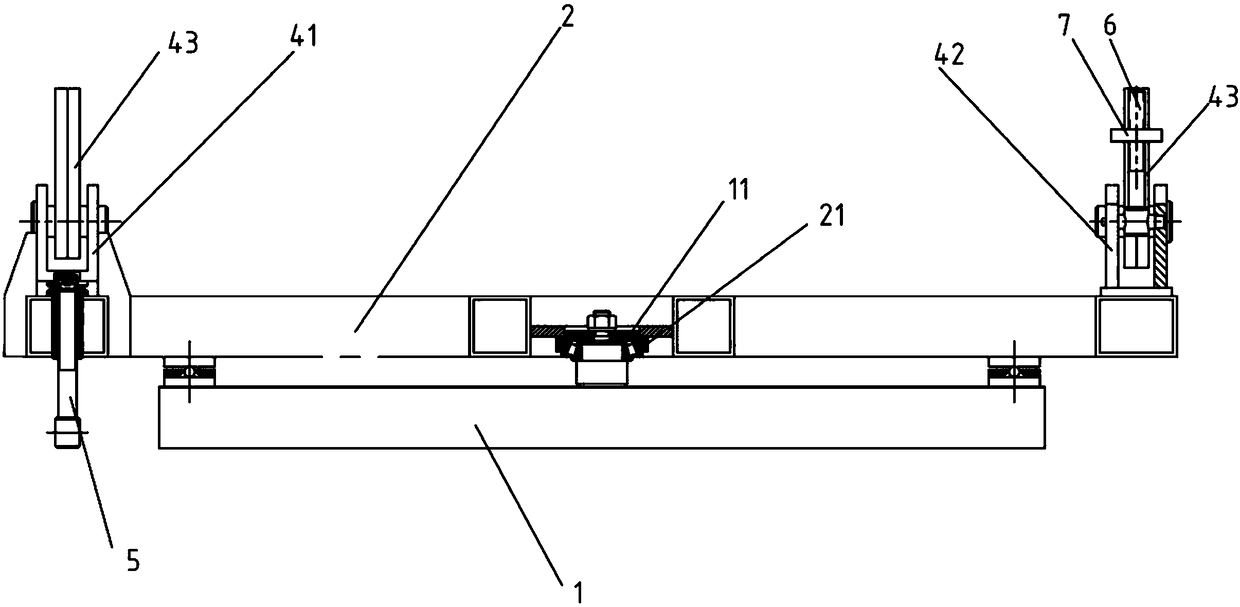

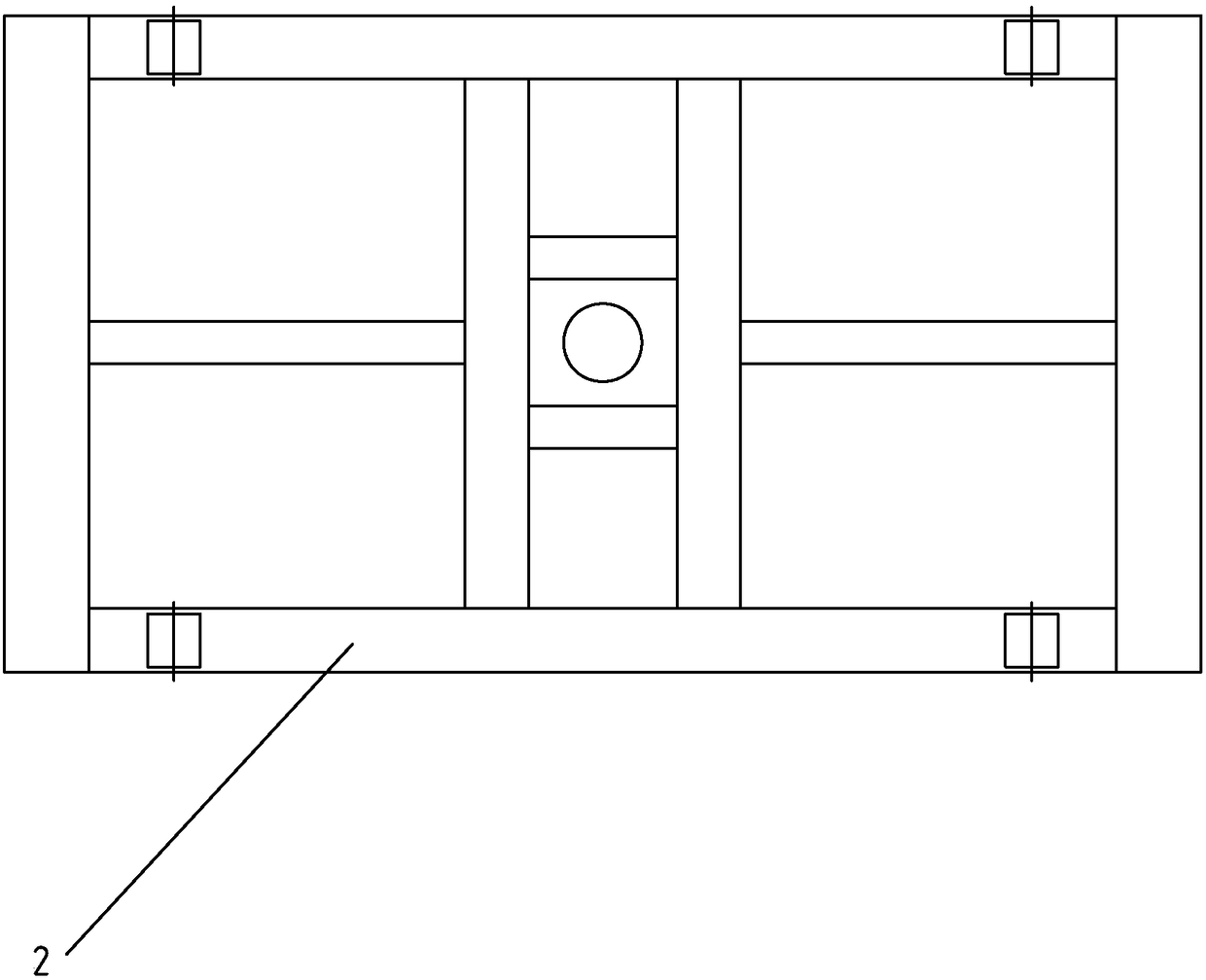

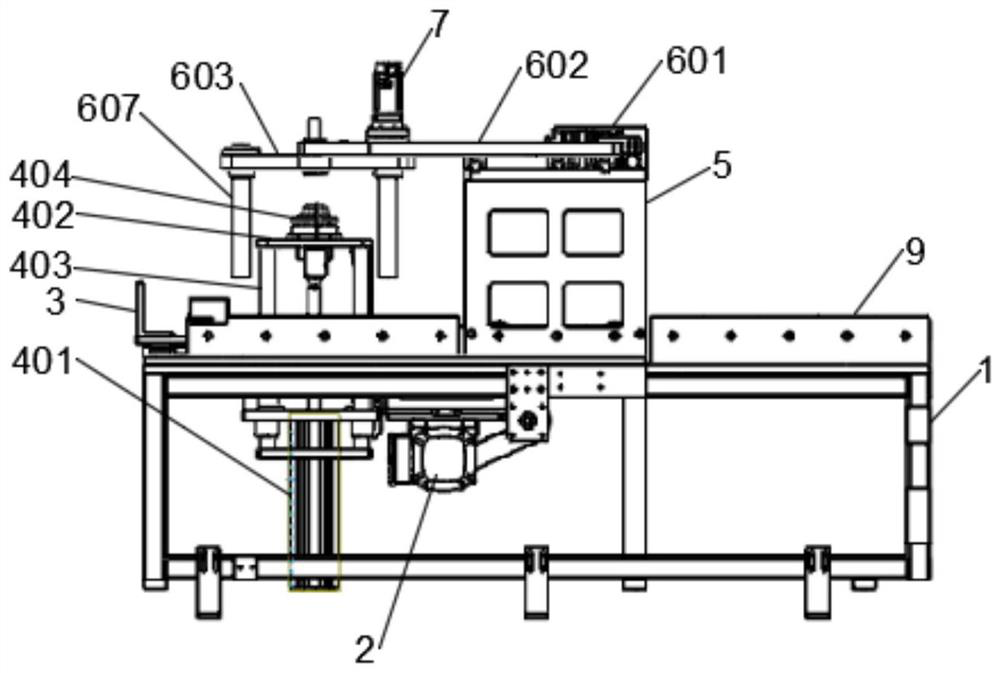

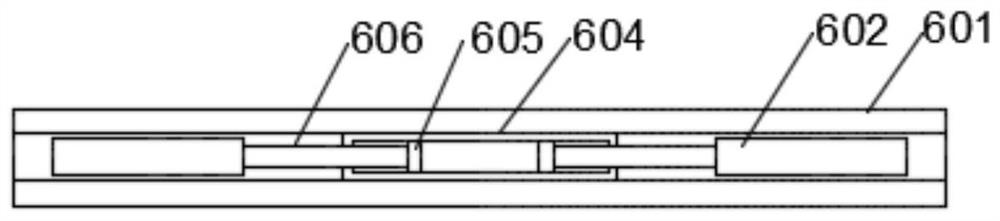

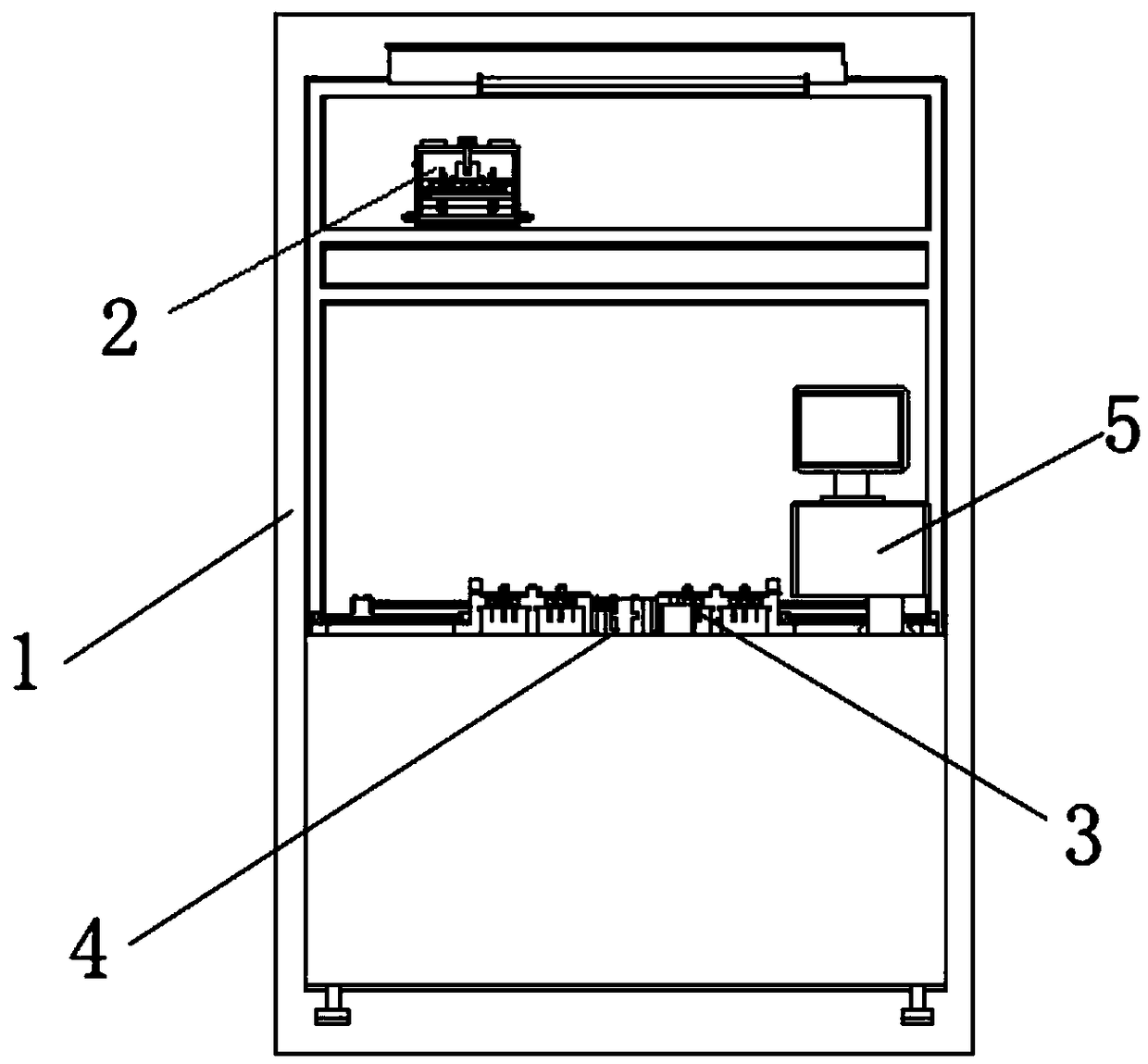

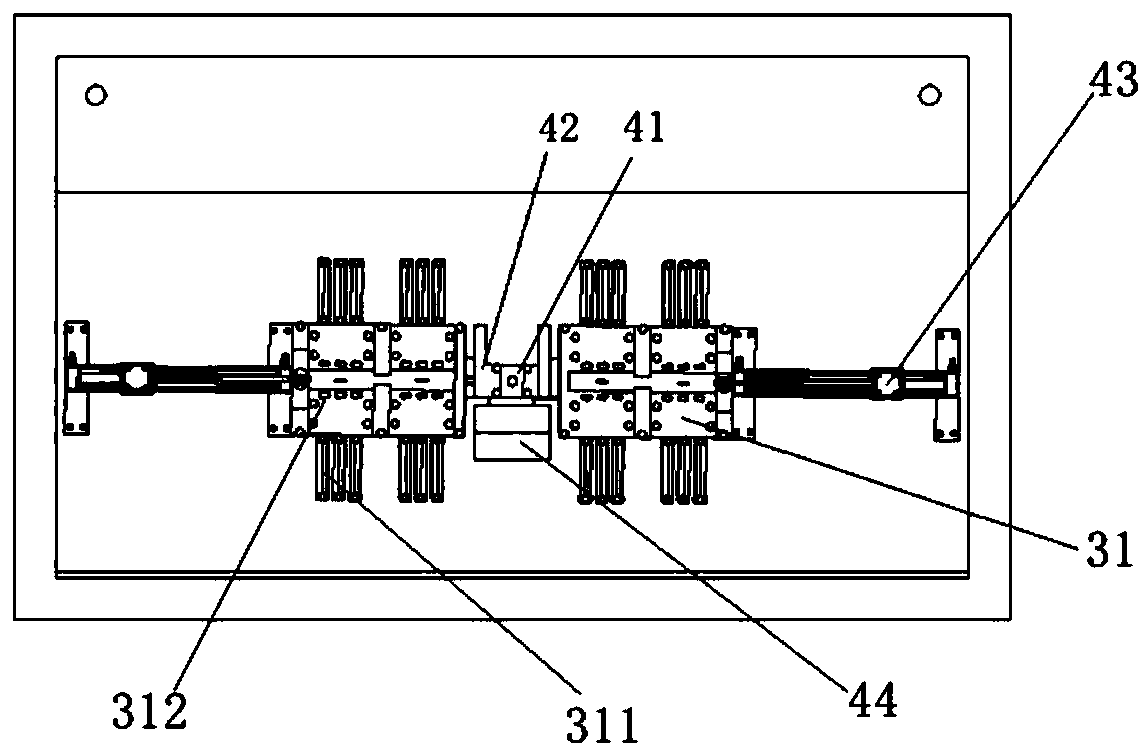

An automatic assembly system and method

ActiveCN106141645BReduce labor costsImprove assembly progressMetal working apparatusVision processing unitComputer science

The invention discloses an automatic assembling system and method and belongs to the technical field of sleeve assembling. The system comprises a visual collecting unit, a visual processing unit, a system control unit and an assembling unit. The method includes the following steps that firstly, the visual collecting unit is used for collecting and outputting first image information of a sleeve and second image information of a casing pipe to be operated; secondly, the visual processing unit is used for positioning the casing pipe to be operated according to the second image information; thirdly, the system control unit is used for locking the sleeve to be operated according to the first image information and the casing pipe to be operated, and outputting a grabbing instruction for sleeve grabbing; and fourthly, the assembling unit is used for grabbing the corresponding sleeve according to the grabbing instruction output by the system control unit and assembling the sleeve on the casing pipe. According to the technical scheme, the automatic assembling system and method have the beneficial effects of reducing labor cost in the assembling process, accelerating assembling progress and guaranteeing the automatic assembling accuracy rate.

Owner:SHANGHAI FANUC ROBOTICS

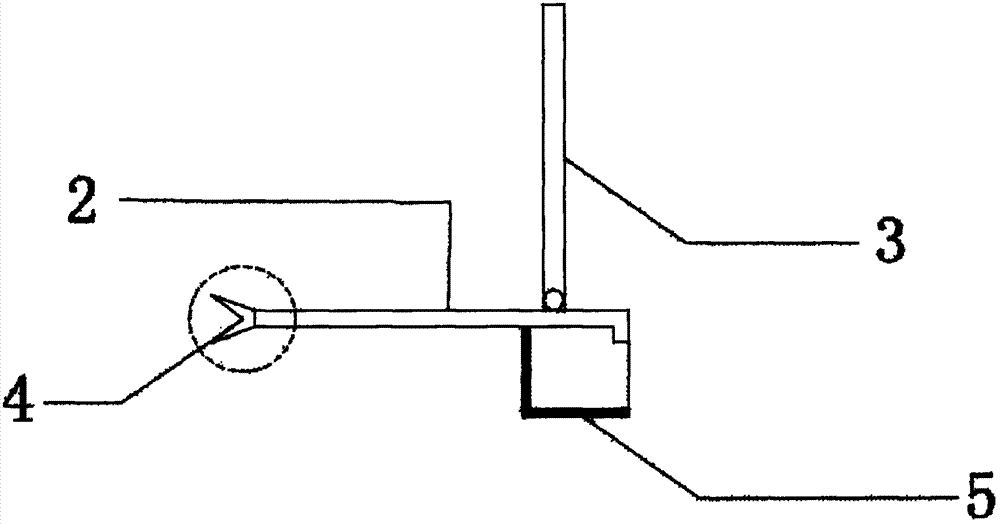

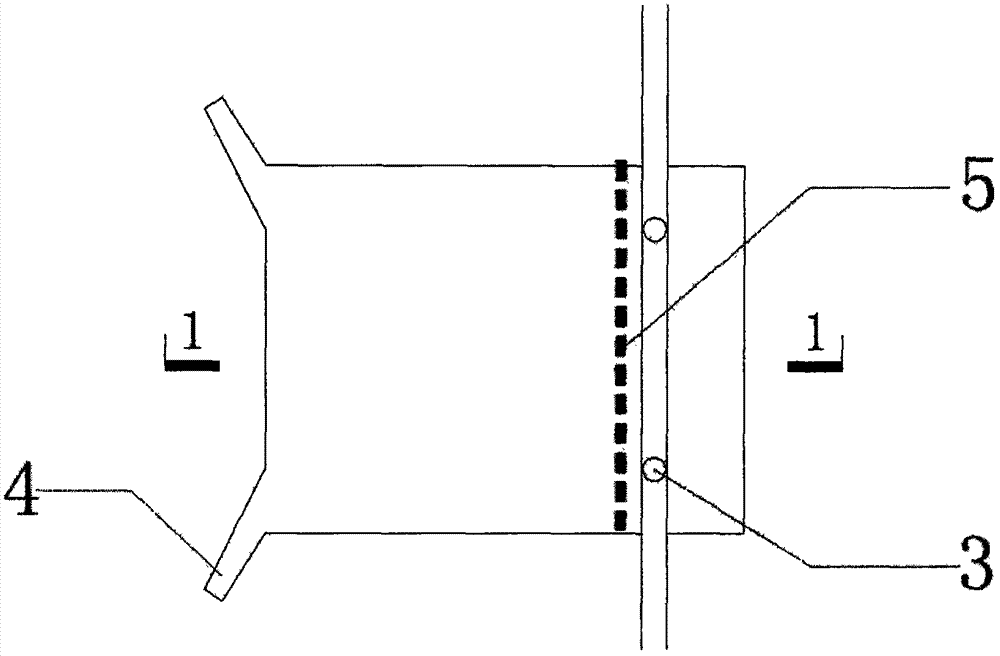

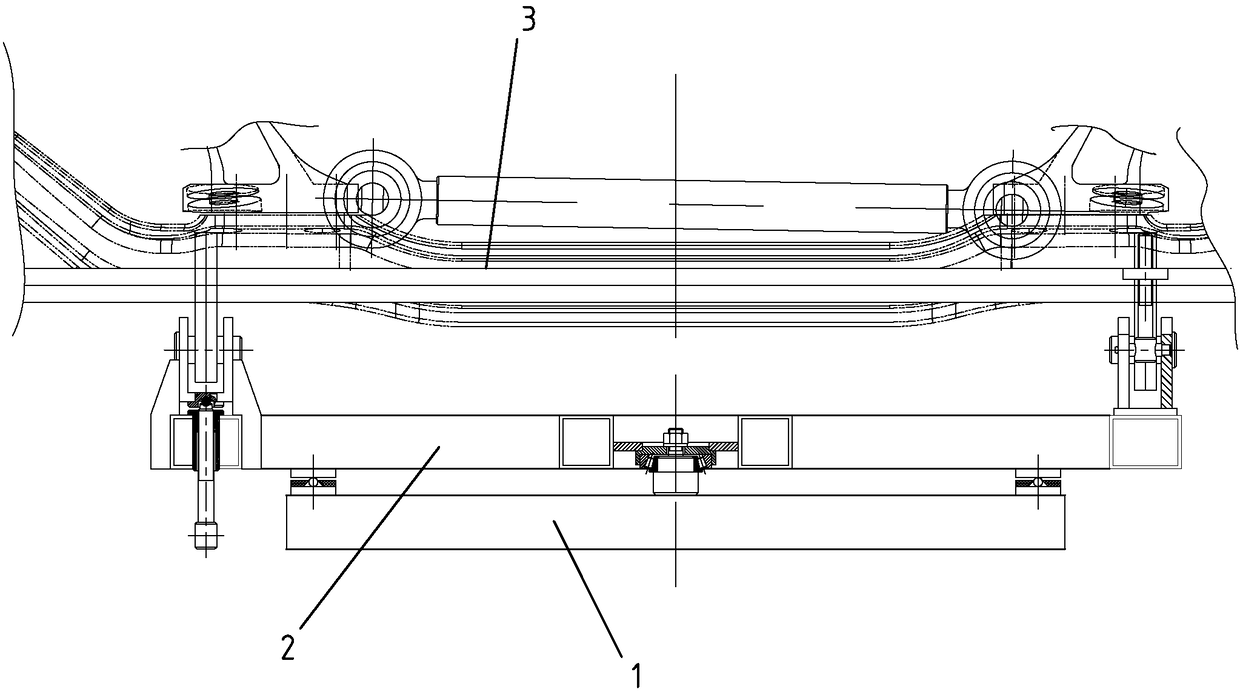

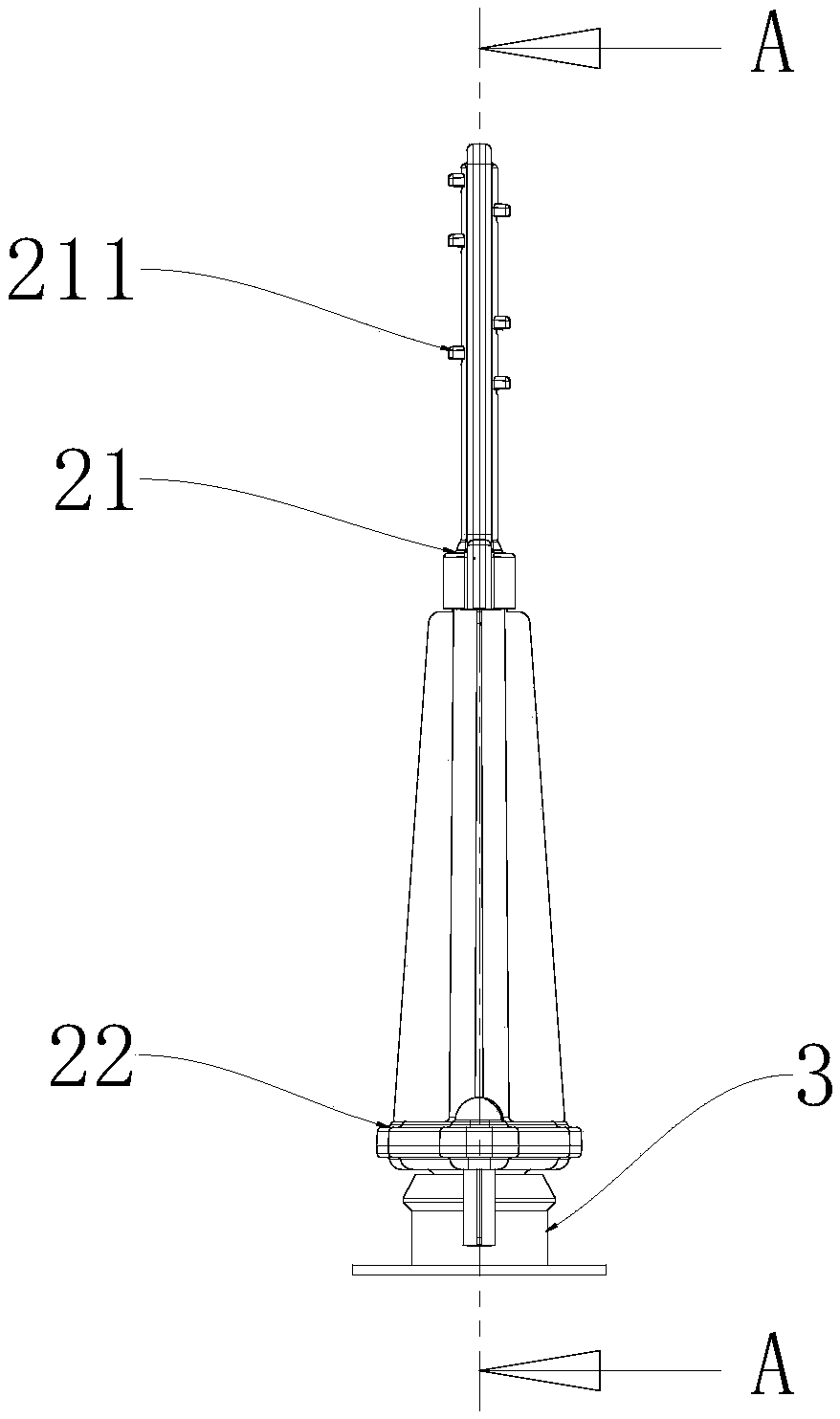

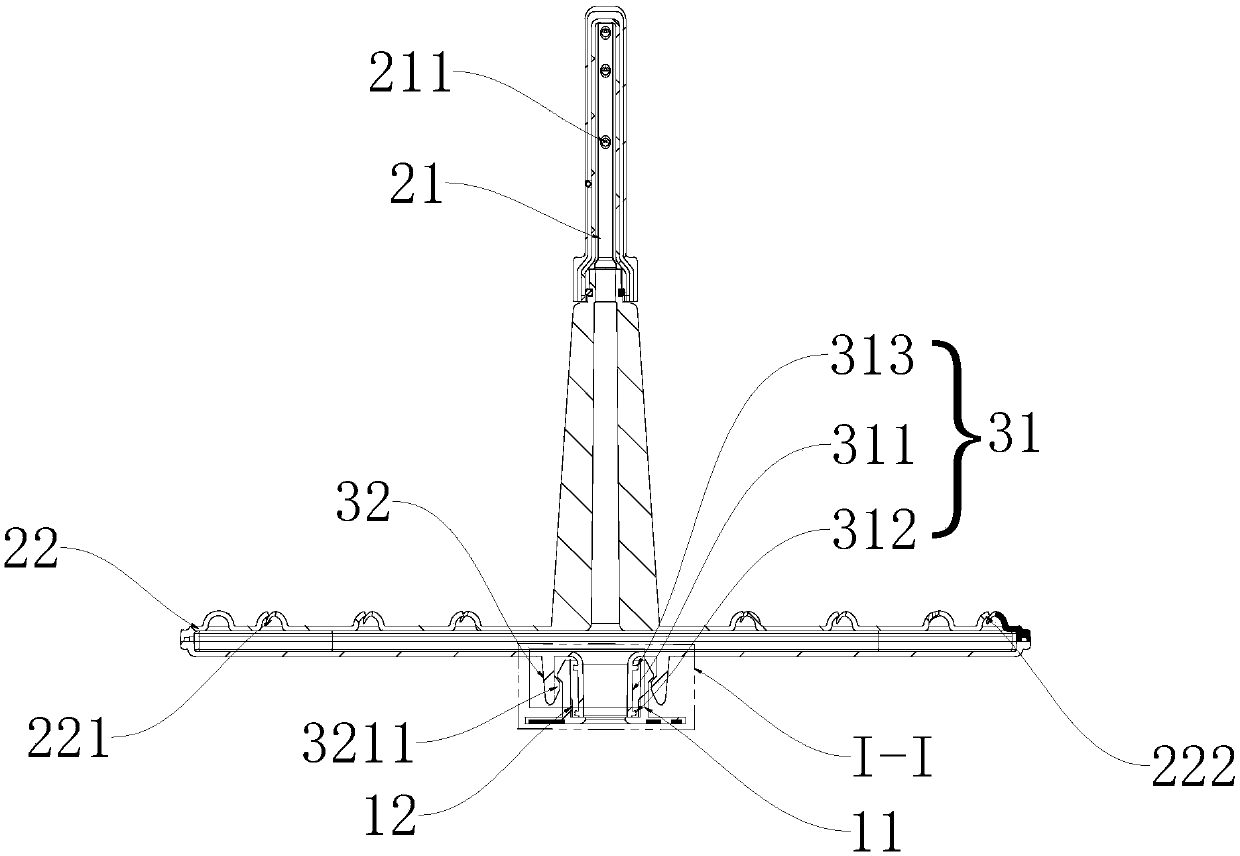

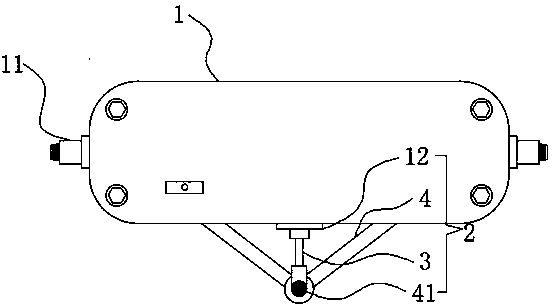

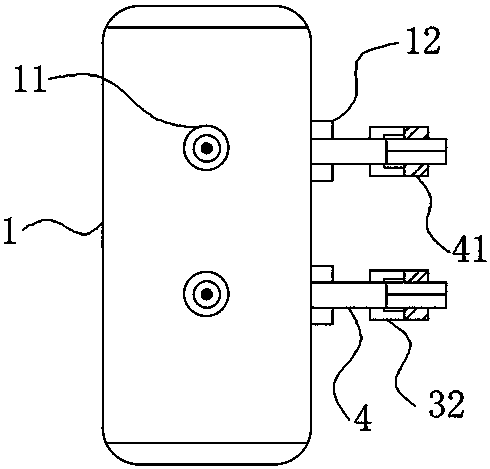

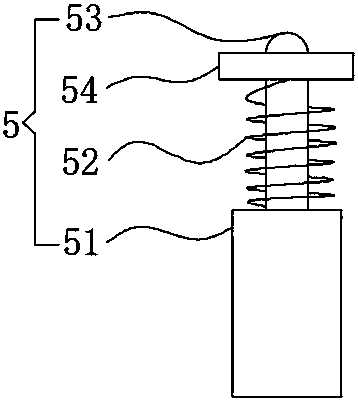

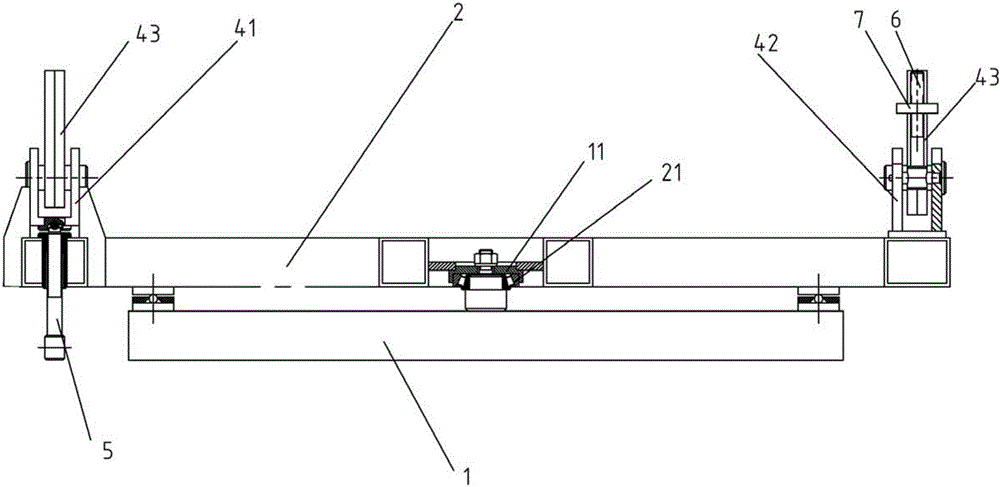

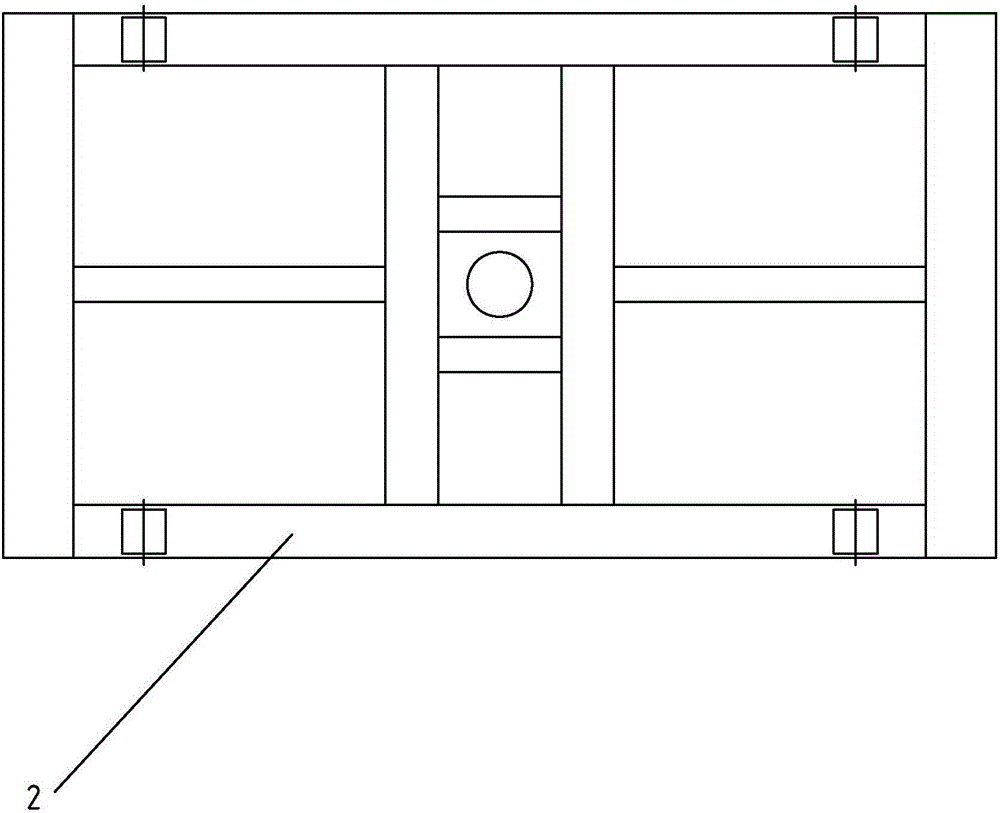

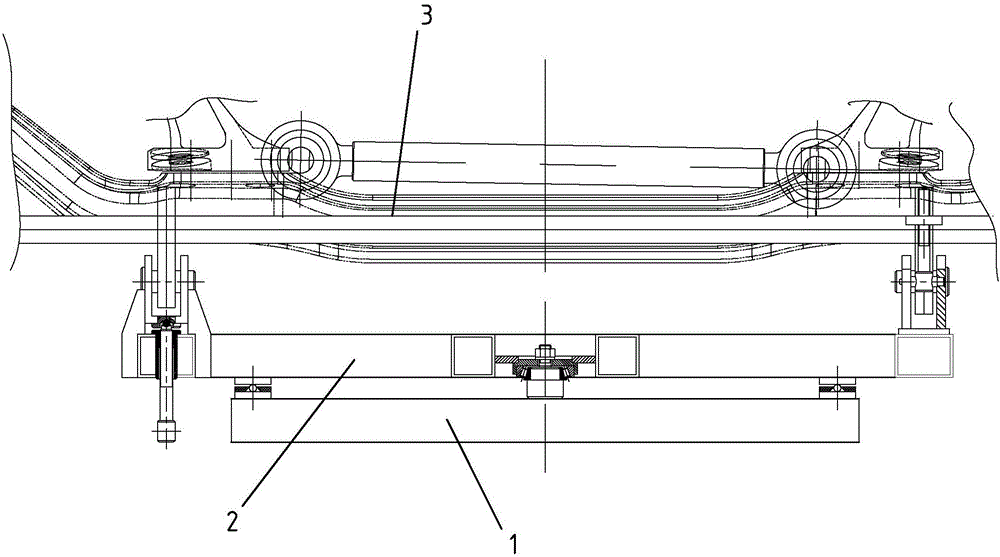

Front and rear suspension assembly fine-tuning device for passenger car chassis

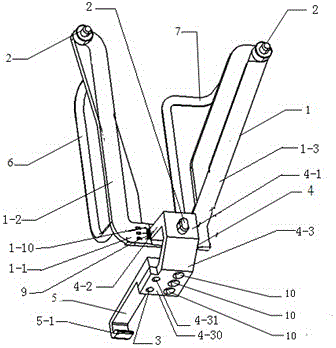

ActiveCN105752205BReduce the difficulty of operationImprove assembly progressVehiclesDegrees of freedomEngineering

The invention discloses a fine adjusting device for assembling front and rear suspensions of a chassis of a passenger car. The fine adjusting device comprises a base, an adjusting seat and a supporting component, wherein the suspensions are supported on the support component; the middle part of the adjusting seat is hinged to the base, and a mechanism for driving rotation around a Z shaft and enabling the suspensions to rotate around the Z shaft is arranged between the adjusting seat and the base; the supporting component comprises a first supporting assembly, a second supporting assembly and a supporting assembly for rotation around a Y shaft; the suspensions are supported on the first supporting assembly and the second supporting assembly and can also be supported on the supporting assembly for rotation around the Y shaft; the supporting assembly for rotation around the Y shaft is mounted on the adjusting seat; when the supporting assembly for rotation around the Y shaft is moved, the suspensions can rotate around the Y shaft. According to the fine adjusting device disclosed by the invention, fine adjustment can be performed on the degree of freedom of the front and rear suspensions of the chassis of the passenger car, so that the operating difficulty of workers is reduced, improvement of the assembling progress of products is facilitated, and the production efficiency is improved.

Owner:CHANGZHOU INST OF MECHATRONIC TECH

A tire automatic centering equipment suitable for automobile tire automatic tightening system

ActiveCN112607407BImprove assembly progressControl devices for conveyorsRoller-waysTire rotationControl theory

The invention discloses an automatic tire centering equipment suitable for an automatic tire tightening system of an automobile. An external controller controls the work of a clamping cylinder to make a symmetrical moving plate move in opposite directions, and the clamping jaws at the free end of the moving plate face oppositely accordingly. Move, the gripper is in contact with the tire to clamp the tire, and the tire rotation component works, so that the gripper rotates at the free end of the moving plate to rotate the tire until the detection of the photoelectric sensing area detects the position of the tire positioning hole, and the tire rotation component Stop working, at this time the tire is in the posture to be grasped, and the robot will take the tire away. This equipment adjusts the tire to a fixed posture and positions it before the tire is grasped, and removes the link of image position recognition on the robot. Tires are grabbed, which simplifies the action of robots automatically grabbing tires in the tire automatic assembly system, effectively speeding up the assembly process.

Owner:DESIGN INST NO 9 MINISTRY OF MECHINE BUILDING

Tire automatic centering equipment suitable for automobile tire automatic tightening system

ActiveCN112607407AImprove assembly progressControl devices for conveyorsRoller-waysAutomotive engineeringTire rotation

The invention discloses tire automatic centering equipment suitable for an automobile tire automatic tightening system. An external controller controls a clamping air cylinder to work, symmetrical moving plates move oppositely, clamping jaws located at the free ends of the moving plates move oppositely along with the moving plates, the clamping jaws make contact with a tire to clamp the tire, a tire rotating assembly works, the clamping jaws rotate at the free ends of the moving plates to rotate the tire until the position of a tire positioning hole is detected by detection photoelectricity of a photoelectric induction area, the tire rotating assembly stops working, the tire is in a to-be-grabbed posture at the moment, and the tire is taken away by a robot; and according to the equipment, before the tire is grabbed, the tire is adjusted into a fixed posture and positioned, the link of image position recognition on the robot is removed, the robot directly grabs the tire, the action that the robot automatically grabs the tire in a tire automatic assembling system is simplified, and the assembling progress is effectively accelerated.

Owner:DESIGN INST NO 9 MINISTRY OF MECHINE BUILDING

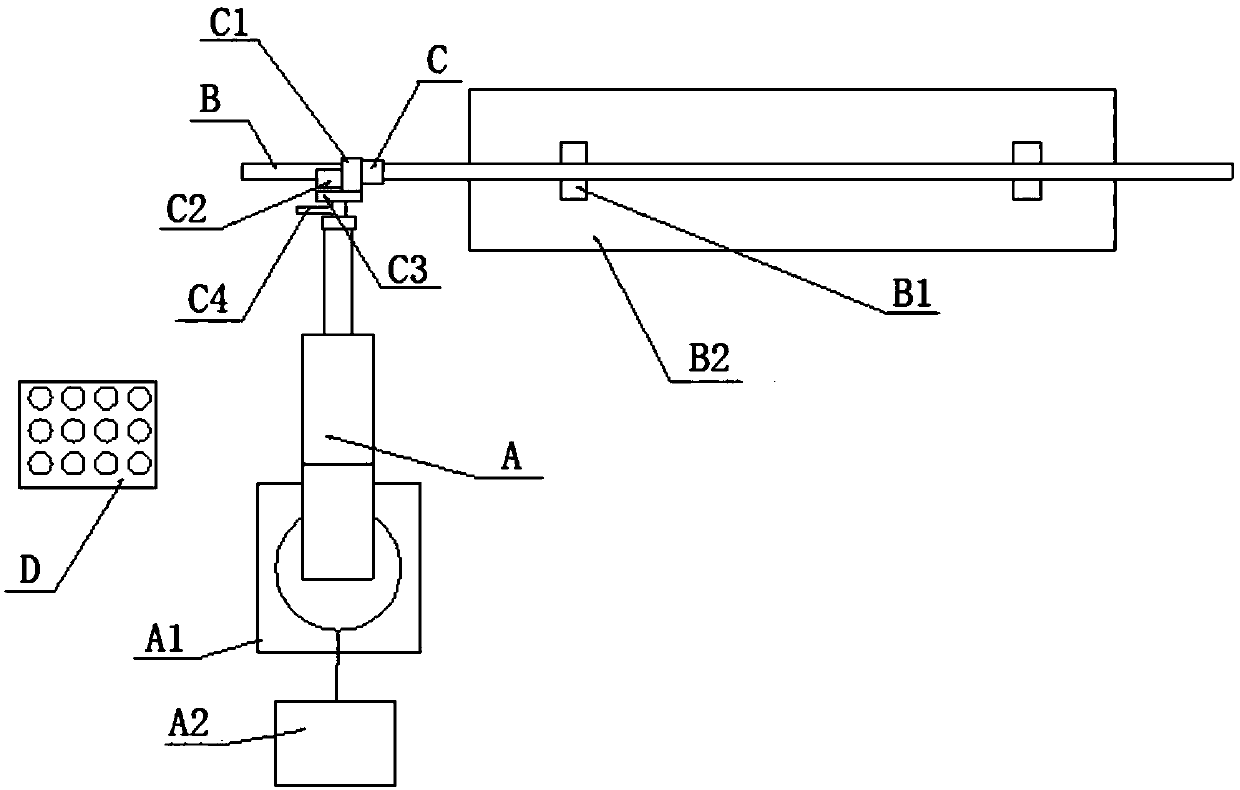

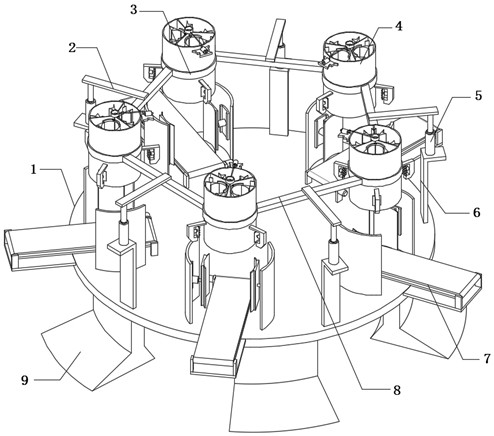

Automatic assembling machine for lock cylinder

ActiveCN108994605AImprove assembly efficiencyImprove assembly accuracyAssembly machinesMetal working apparatusEngineeringControl circuit

The invention discloses an automatic assembling machine for a lock cylinder. The automatic assembling machine comprises a rack, a spring sorting device, a blade sorting device, a final assembly deviceand a master control circuit; the spring sorting device comprises a main box body arranged above the rack and a spring stirring barrel arranged inside the main box body; the blade sorting device comprises four blade sorting air-cylinders arranged on the left side of the rack and four blade sorting air-cylinders arranged on the right side of the rack; each blade sorting air-cylinder comprises a plurality of independent air cylinder push rods; the final assembly device comprises a lock cylinder fixture arranged in the center of the rack, a concave clamping block surrounding the lock cylinder fixture as well as left and right assembling air-cylinders arranged on two sides of the concave clamping block; and the final assembly device can be controlled by the master control circuit to assemblesprings provided by the spring sorting device and blades provided by the blade sorting device for mounting inside the lock cylinder.

Owner:江苏圣龙智能科技有限公司

A lock cylinder automatic assembly machine

ActiveCN108994605BImprove assembly efficiencyImprove assembly accuracyAssembly machinesMetal working apparatusEngineeringControl circuit

The invention discloses an automatic assembling machine for a lock cylinder. The automatic assembling machine comprises a rack, a spring sorting device, a blade sorting device, a final assembly deviceand a master control circuit; the spring sorting device comprises a main box body arranged above the rack and a spring stirring barrel arranged inside the main box body; the blade sorting device comprises four blade sorting air-cylinders arranged on the left side of the rack and four blade sorting air-cylinders arranged on the right side of the rack; each blade sorting air-cylinder comprises a plurality of independent air cylinder push rods; the final assembly device comprises a lock cylinder fixture arranged in the center of the rack, a concave clamping block surrounding the lock cylinder fixture as well as left and right assembling air-cylinders arranged on two sides of the concave clamping block; and the final assembly device can be controlled by the master control circuit to assemblesprings provided by the spring sorting device and blades provided by the blade sorting device for mounting inside the lock cylinder.

Owner:江苏圣龙智能科技有限公司

Automatic knife feeding device for razor head assembly

ActiveCN114102092BImprove work efficiencyImprove securityMetal working apparatusEngineeringAir compressor

The invention belongs to the technical field of razor assembly, in particular to an automatic feeding device for the blade net used for assembling the razor head. The following proposal is proposed, including an operation table and an assembly cylinder, the inner wall of which is fixedly connected with a middle The partition, and the outer wall of the middle partition is fixedly connected with the inner interference plate at equal distances, and the outer wall of each inner interference plate is fixedly connected with the adjustment spring rod at the same distance, and the outer walls of the multiple adjustment spring rods on the same inner interference plate are fixedly connected The same drop limiter. In the present invention, an air compressor, an annular connecting plate and an air plate are provided, and after placing the knife screen body in the assembly cylinder, the air compressor is started, and the air compressor guides the compressed gas into each air plate through the annular connecting plate, and blows it to the air through the air hole. The knife net body can accelerate the speed of the knife net body being unloaded from the assembly barrel. At the same time, the momentum of the compressed gas prevents the knife net body from being stuck in the assembly barrel and can be successfully assembled.

Owner:JIANGSU MKODO ELECTRONICS TECH CO LTD

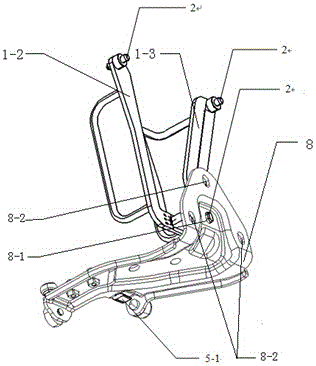

An auxiliary assembly tool for the lower arm of the middle door

ActiveCN104907974BLimited spatial locationControl consistencyWork holdersMetal-working hand toolsEngineeringMechanical engineering

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

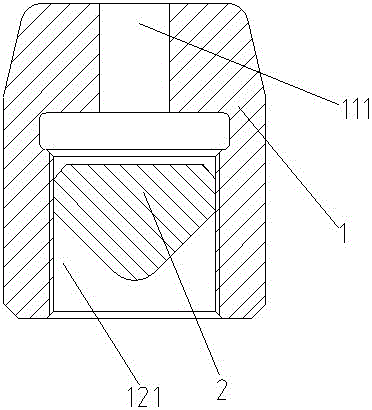

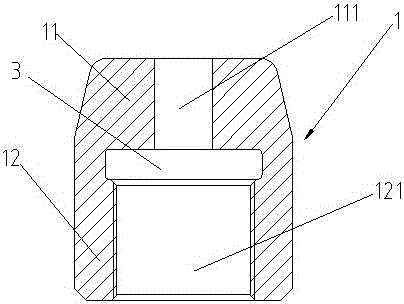

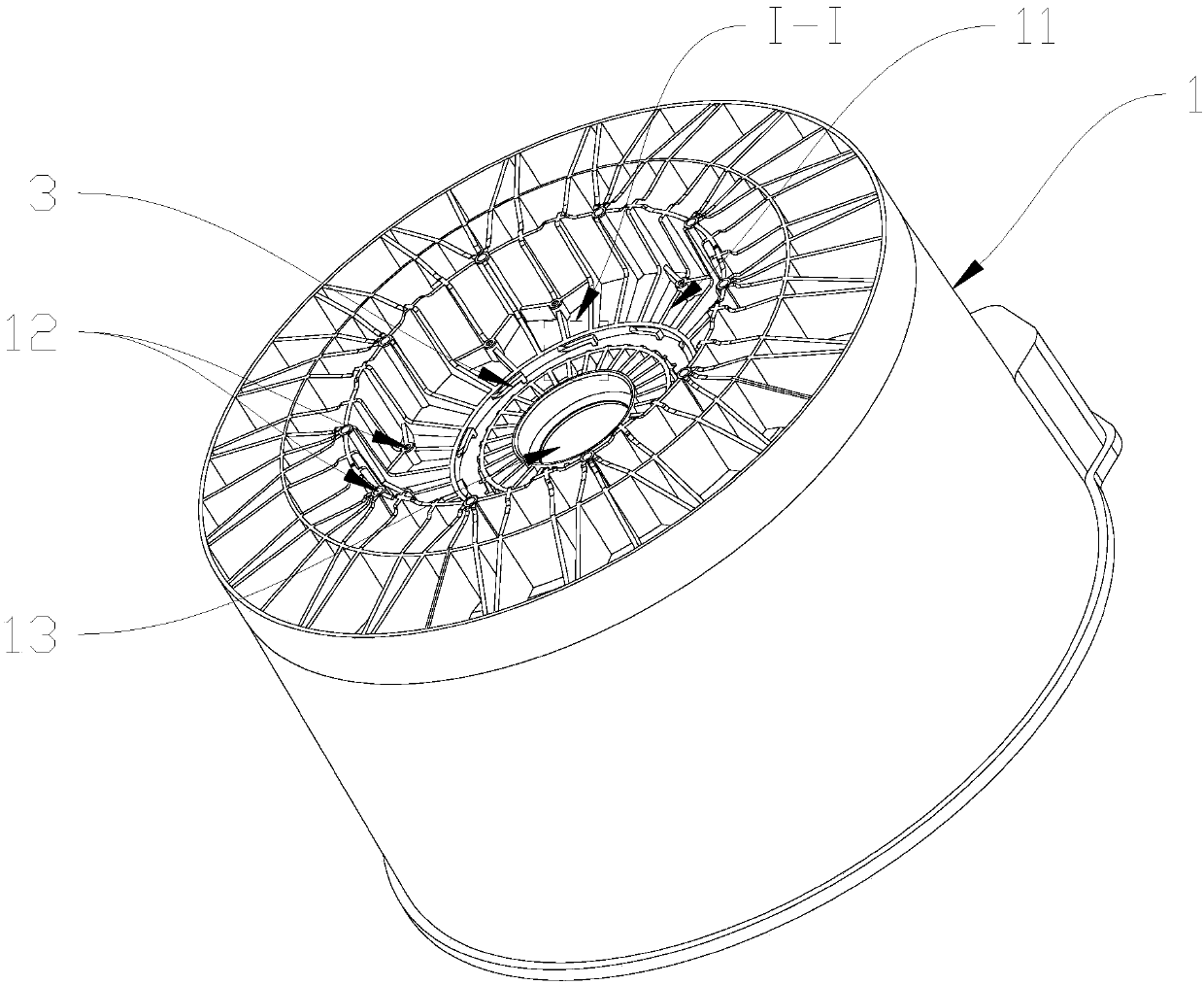

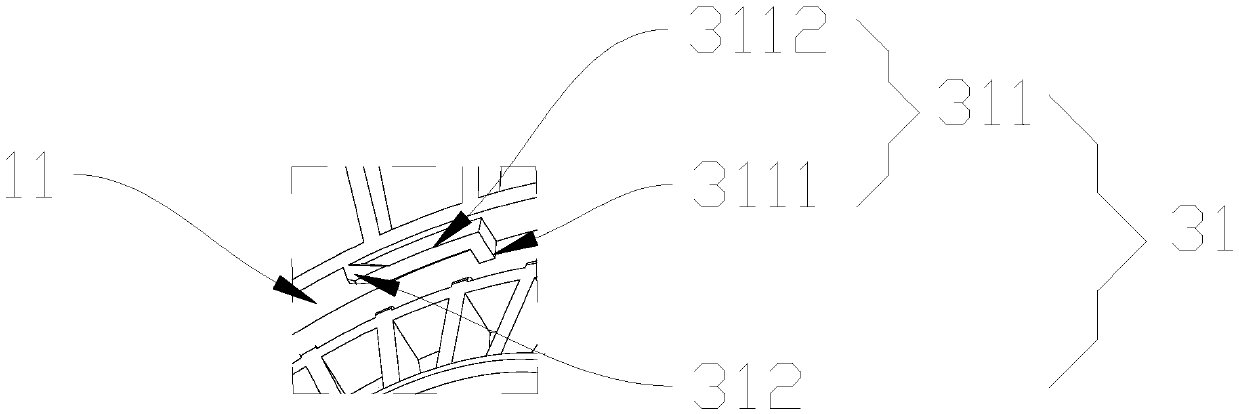

Clothes treatment equipment

PendingCN110318218AImprove assembly progressEasy to installOther washing machinesTextiles and paperDrive motorProgress rate

The invention relates to the technical field of clothes treatment equipment, and particularly provides clothes treatment equipment. For the purpose, the clothes treatment equipment aims at solving theproblem that there are big errors of pre-locating cooperation between an existing clothes treatment drum and an existing direct drive motor. The clothes treatment equipment comprises a clothes treatment drum, a direct drive motor and a locating assembly used for tightly connecting the clothes treatment drum with the direct drive motor. According to the clothes treatment equipment, the washing drum is tightly connected with the direct drive motor through the locating assembly, pre-locating of the washing drum and the direct drive motor is achieved, and it is effectively avoided that the directdrive motor shifts relative to the washing drum; the precision of pre-locating cooperation between the washing drum and the direct drive motor is improved, and the assembly progress rate of a drum washing machine is increased, which is beneficial for the installation operation of the drum washing machine.

Owner:QINGDAO HAIER DRUM WASHING MACHINE

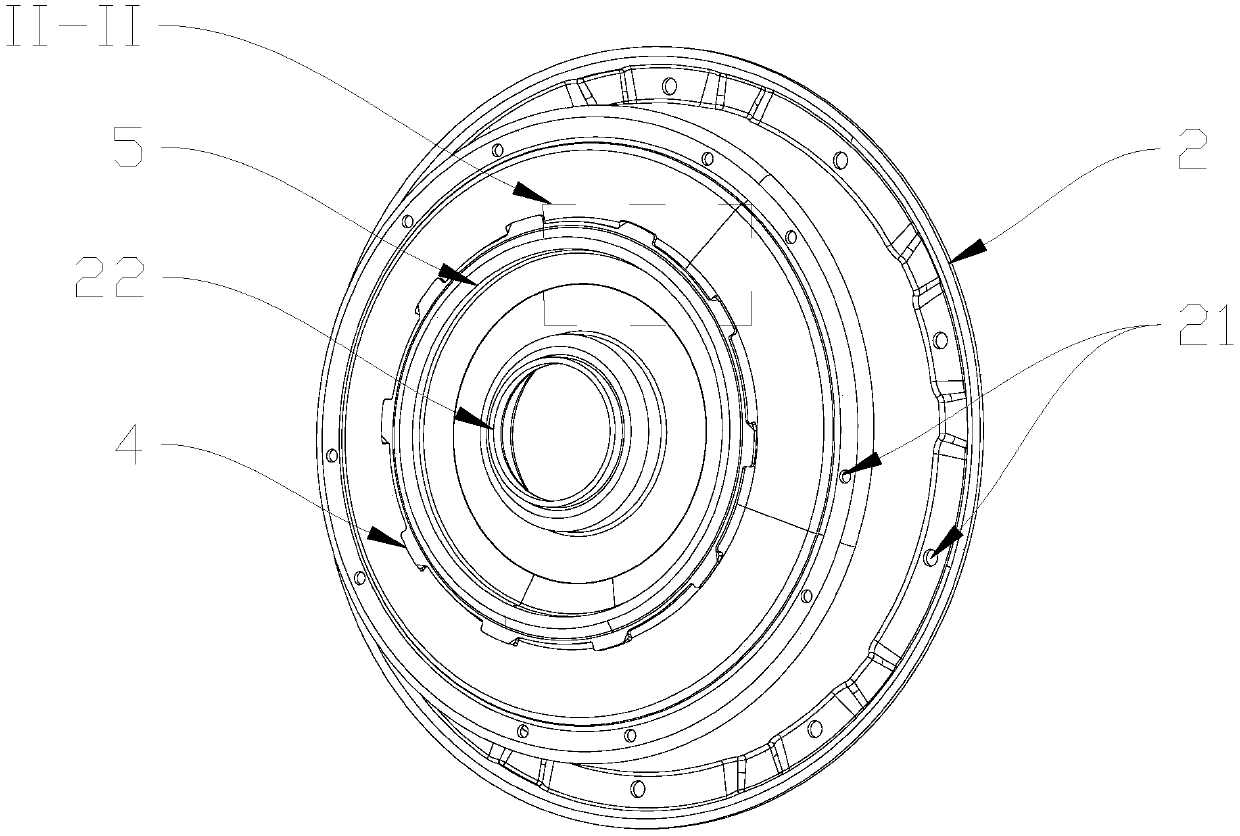

Shoe washing machine

PendingCN110384457AImprove assembly progressEasy to installFootwear cleanersEngineeringMechanical engineering

The invention relates to the technical field of shoe washing machines, in particular to a shoe washing machine and aims to solve the problems that a spraying mechanism of an existing shoe washing machine is inconvenient to mount, maintain and dismount. For the purpose, the shoe washing machine comprises a shell and the spraying mechanism arranged in the shell, wherein the spraying mechanism is detachably connected with the shell. The spraying mechanism is detachably connected with the shell, so that the dismounting process of the spraying mechanism is simplified, the convenience is provided for maintenance personnel to mount and dismount the spraying mechanism, the maintenance personnel can replace and maintain the spraying mechanism according to the wearing condition of the spraying mechanism, the assembling progress of the shoe washing machine is improved, the mounting operation of the shoe washing machine is facilitated, the service life of the shoe washing machine is prolonged, andthe usage experience of a user is greatly improved.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

Intermittent pull-off type cable connection instrument for power system

InactiveCN106099487BImprove stabilityImprove toughnessLine/current collector detailsCoupling contact membersElectric power systemElectric power equipment

The invention relates to the field of electric power equipment, and specifically relates to an intermittently pulled-off type cable wiring instrument for an electric power system. An intermittently drawn-off type cable wiring instrument for an electric power system includes a wiring instrument body; wiring columns are arranged in the two side walls of the upper end of the wiring instrument body; a support rod penetrates through the upper end and the lower end of each fixing block; buffer devices are connected to the portions, on the two sides of the support rods, of the internal portion of the wiring instrument body; each cushioning device comprises a base, a reset spring, a buffer rod and a buffer plate; conductive blocks slide in wiring grooves through cooperation between slide blocks and slide rails; and the bottom ends of jacks are provided with electromagnets which are connected to permanent magnets through magnetism. The intermittently pulled-off type cable wiring instrument of the invention can realize intermittent power-on and power-off of the wiring instrument, so that the assembling progress and the assembling quality of the electric power system are raised to a great extent; favorable conditions are provided for maintenance, repairing and replacing of the electric power system; and the intermittently drawn-off type cable wiring instrument has a broad market application prospect.

Owner:STATE GRID HENAN ELECTRIC POWER COMPANY ZHENGZHOU POWER SUPPLY +2

Fine adjusting device for assembling front and rear suspensions of chassis of passenger car

ActiveCN105752205AReduce the difficulty of operationImprove assembly progressVehiclesDegrees of freedomEngineering

The invention discloses a fine adjusting device for assembling front and rear suspensions of a chassis of a passenger car. The fine adjusting device comprises a base, an adjusting seat and a supporting component, wherein the suspensions are supported on the support component; the middle part of the adjusting seat is hinged to the base, and a mechanism for driving rotation around a Z shaft and enabling the suspensions to rotate around the Z shaft is arranged between the adjusting seat and the base; the supporting component comprises a first supporting assembly, a second supporting assembly and a supporting assembly for rotation around a Y shaft; the suspensions are supported on the first supporting assembly and the second supporting assembly and can also be supported on the supporting assembly for rotation around the Y shaft; the supporting assembly for rotation around the Y shaft is mounted on the adjusting seat; when the supporting assembly for rotation around the Y shaft is moved, the suspensions can rotate around the Y shaft. According to the fine adjusting device disclosed by the invention, fine adjustment can be performed on the degree of freedom of the front and rear suspensions of the chassis of the passenger car, so that the operating difficulty of workers is reduced, improvement of the assembling progress of products is facilitated, and the production efficiency is improved.

Owner:CHANGZHOU INST OF MECHATRONIC TECH

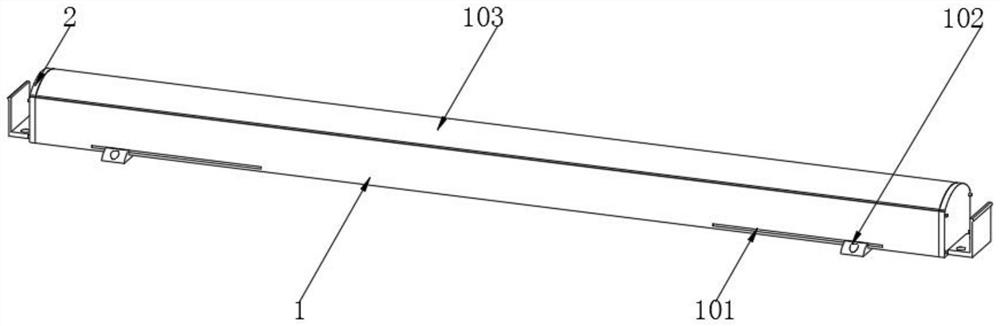

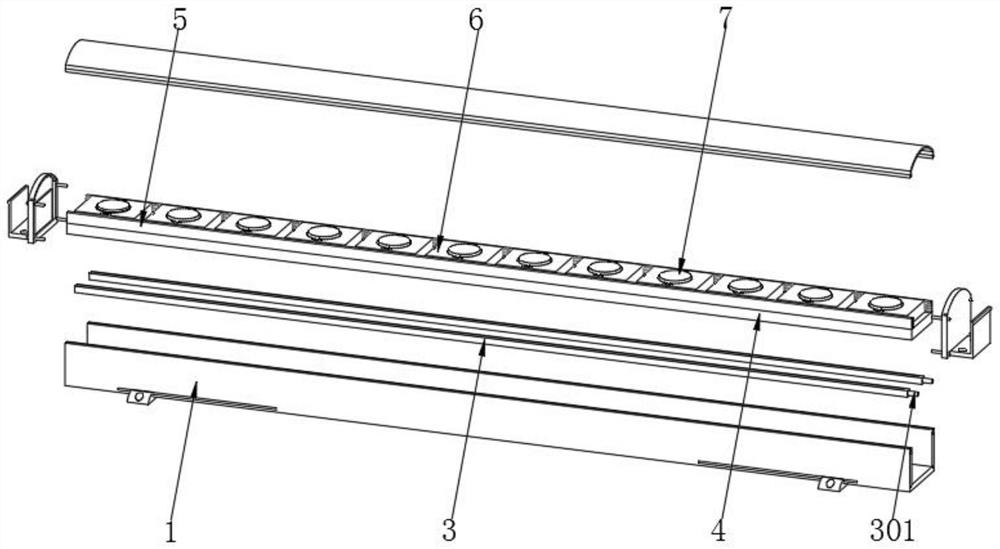

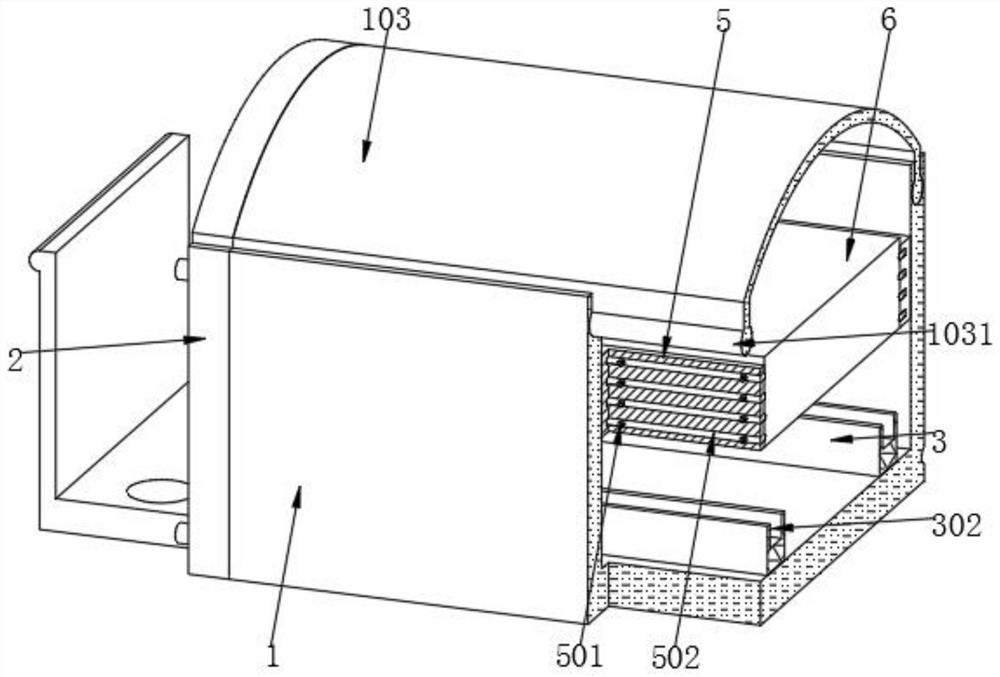

Flexible line lamp combination structure with integrated module and line lamp assembly method thereof

ActiveCN113847560AEasy to assembleEasy to disassemble and repairElongate light sourcesElectric circuit arrangementsEngineeringMaterials science

The invention discloses a flexible line lamp combination structure with an integrated module and a line lamp assembly method thereof, and relates to the technical field of lamps. According to the flexible line lamp combination structure with the integrated module and the line lamp assembling method thereof, through the arrangement of light source assemblies and positioning assemblies, when the lamp body is assembled, the light source assemblies can be assembled through the cooperation of the positioning outer cover, the fixing piece and the protective shell; and meanwhile, the assembled light source assemblies are sequentially fixed into the base through the fixing frames on the two sides, so that the assembled light source assemblies can be sequentially assembled when the lamp body is produced and assembled, and more convenience is achieved while the assembling progress is accelerated; and when the phenomena of damage, short circuit and the like occur in the used lamp body, the damaged light source assemblies can be taken out independently by disassembling the transparent light cover, so that the step of disassembling the whole light source is avoided, and the lamp body is more convenient to assemble, disassemble and maintain.

Owner:杭州亿美光电科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com