Pin roll prestoring device of two-row chain slivering machine

A strip forming machine and pin shaft technology, applied in the direction of metal chains, etc., can solve problems affecting the assembly progress of the chain forming machine, troubles, and jamming at the exit of the hopper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

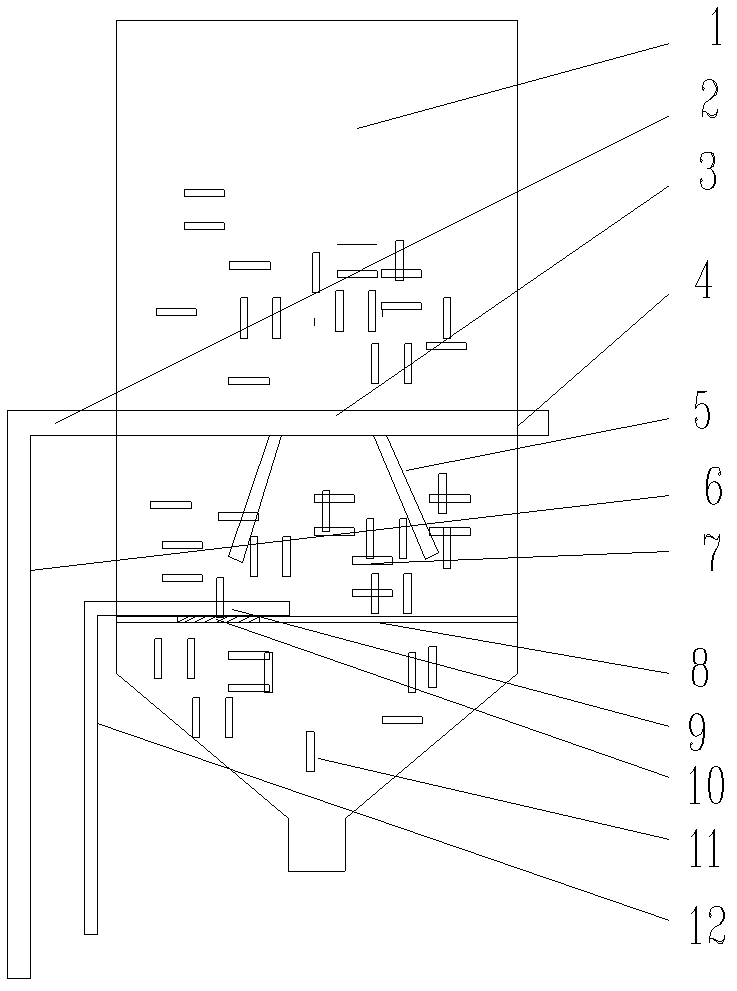

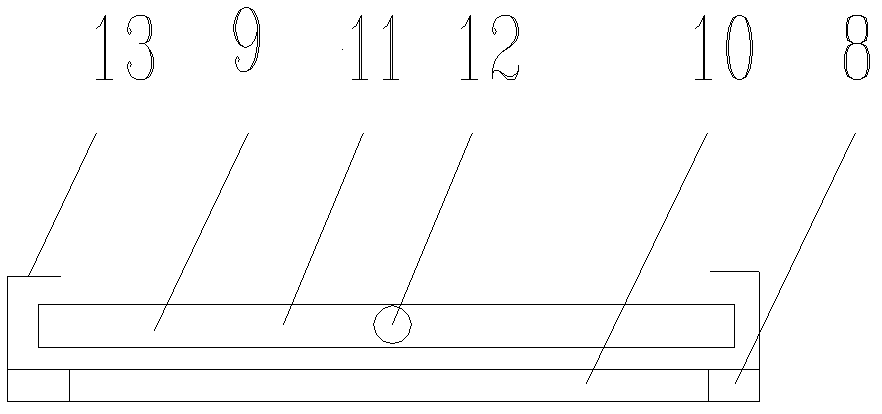

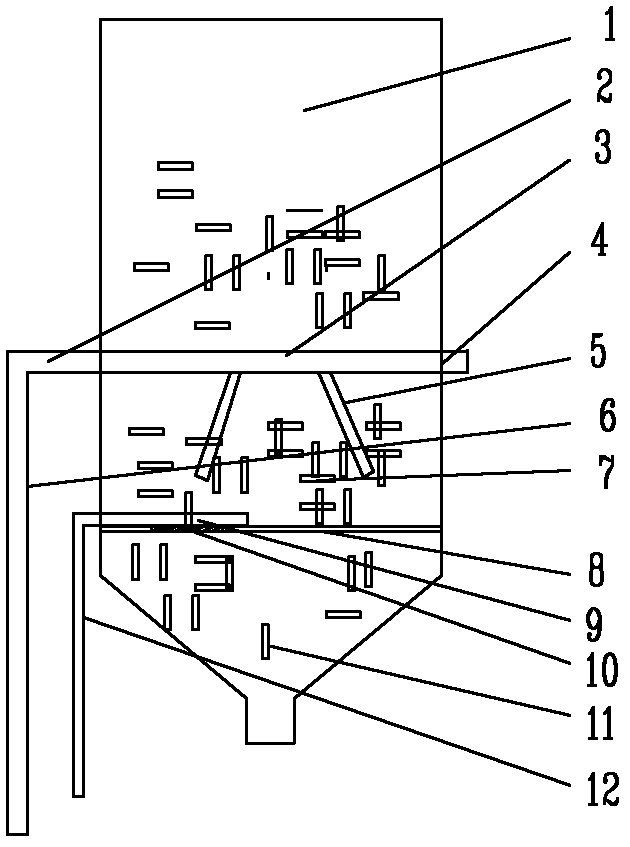

[0010] Such as figure 1 , figure 2 Shown: a pin shaft pre-storage device of a double-row chain forming machine. The utility model relates to a pin shaft pre-storage device of a double-row chain forming machine. The pre-stored cylinder 1 is installed above the lower hopper 11 of the original pin shaft 7, and a blanking hole 10 is opened on the bottom plate 8 below the pre-stored cylinder 1, and upward flanges 13 are provided on both sides of the blanking hole 10. A movable cover plate 9 with a short handle 12 is inserted between the two flanges 13 . The part of the short handle 12 outside the pre-stored cylinder 1 is bent downwards into a vertical direction. Toggle the short handle 12 to pull out the movable cover 9 to open the blanking hole 10, and to toggle the short handle 12 and push the movable cover 9 to close the blanking hole 10. A long-handle shift fork 2 is equipped with in the lower part of the pre-stored tube 1, and the cross bar 3 two ends of the long-handled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com