Rod pressing tooling for assembling valves

A pressure rod and valve technology, which is applied in the field of pressure rod tooling for valve assembly, can solve the problems of increasing labor, wasting manpower, and wasting labor strength, etc., and achieve the effect of increasing assembly speed, reducing labor intensity, and improving assembly progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

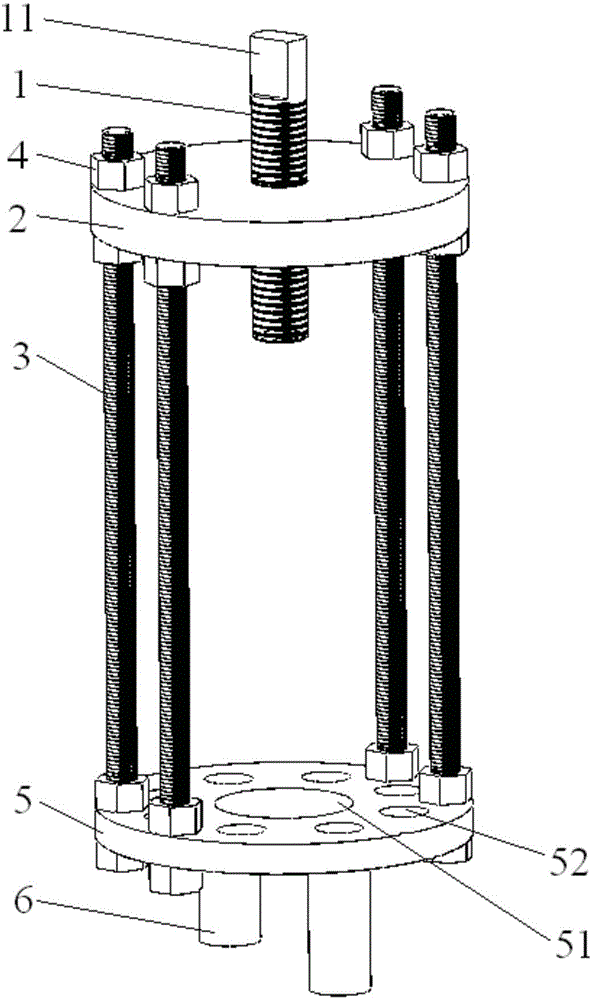

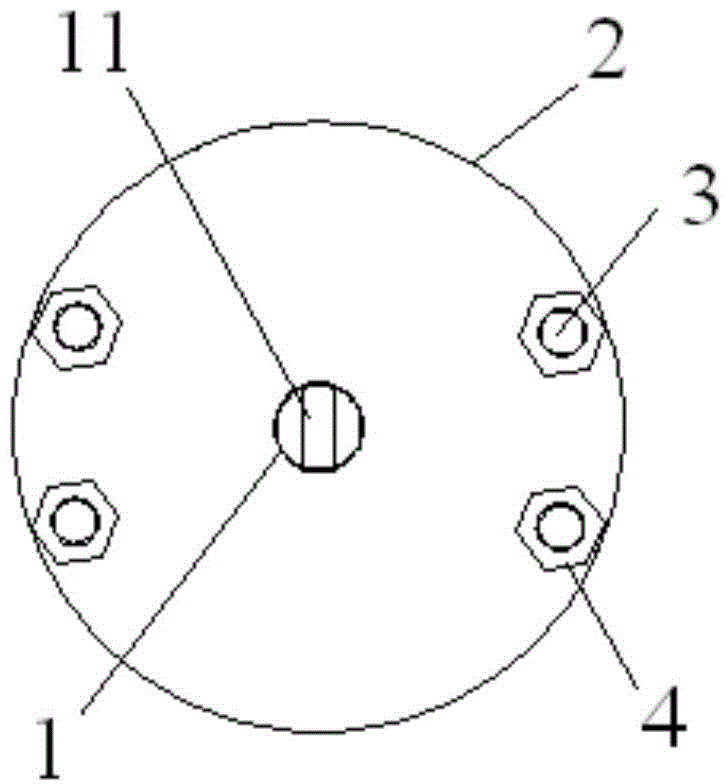

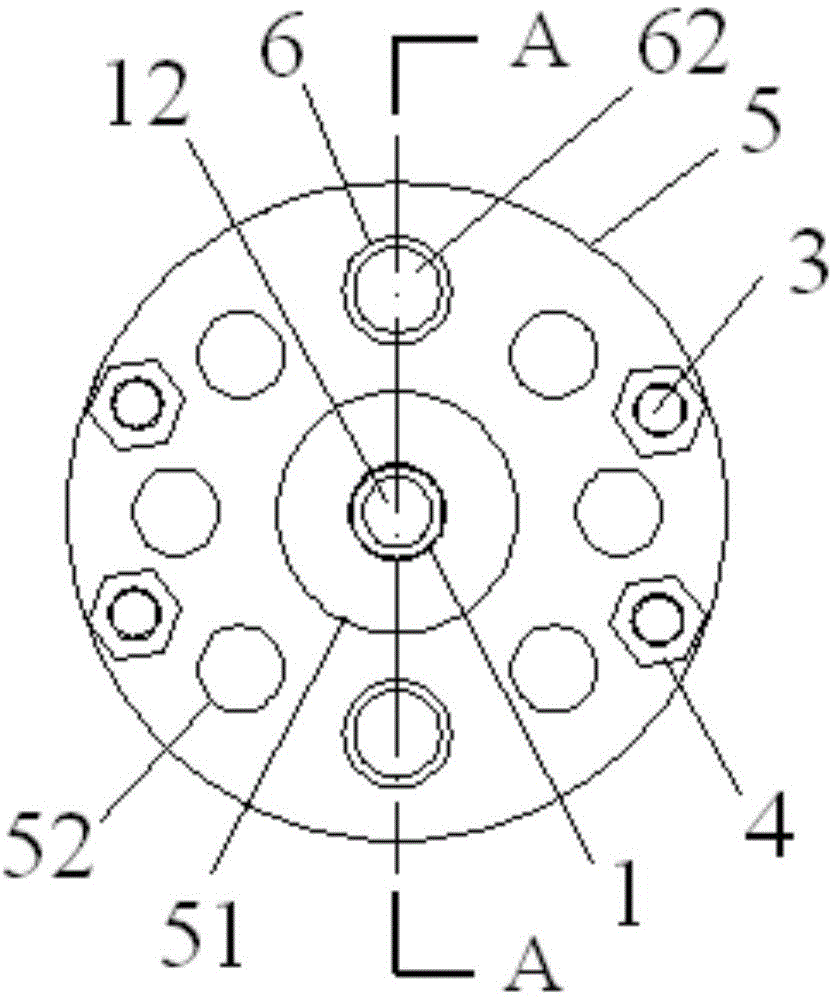

[0024] combine Figure 1 to Figure 8 As shown, a pressure rod tooling for valve assembly includes an operating rod 1, a top plate 2, a fully threaded stud 3, a nut 4, a base 5 and a leg 6; wherein the operating rod 1 is set on the top plate 2 The middle is threadedly connected with the top plate 2; a plurality of fully threaded studs 3 are pierced between the top plate 2 and the base 5; the fully threaded studs 3 are respectively fixedly connected with the top plate 2 and the base 5 through nuts 4; The position corresponding to the operating rod 1 on the base 5 is provided with an operating through hole 51; the bottom of the base 5 is connected with a plurality of legs 6; the upper part of the operating rod 1 is the operating rod boss 11 , threaded from the lower edge of the operating rod boss 11 to the bottom end of the operating rod 1; the operating rod boss 11 is provided with a hand wheel or wrench used in conjunction with the operating rod boss 11; the operating rod 1 Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com