An auxiliary assembly tool for the lower arm of the middle door

A technology to assist assembly and tooling, applied in manufacturing tools, workpiece clamping devices, hand-held tools, etc., can solve the problems of poor assembly quality, affecting assembly progress, and poor assembly accuracy of the lower arm of the middle door.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail;

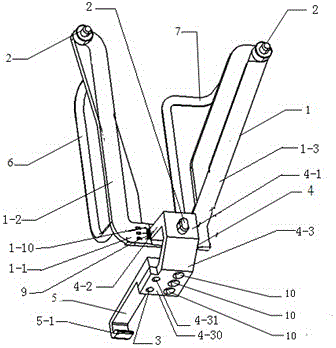

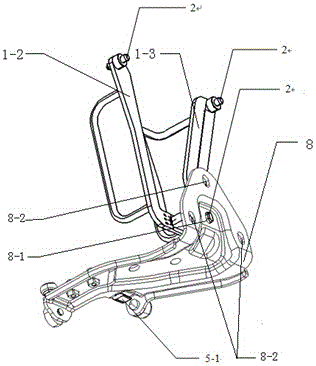

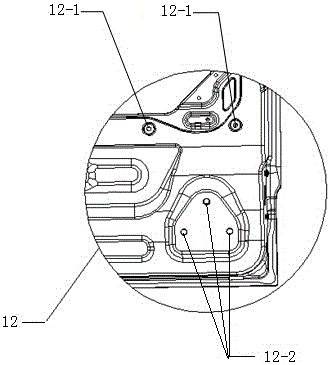

[0021] see figure 1 , figure 2 , image 3 with Figure 4 , the auxiliary assembly tool for the lower arm of the middle door of the present invention includes a connecting plate 1 and a positioning piece 2 . from figure 1 , figure 2 , image 3 with Figure 4 It can be seen that the present invention also includes a movable connecting plate 4 and a lower connecting plate 5. The connecting plate 1 is approximately U-shaped, including a bottom connecting plate 1-1 and extending upward and outward from the left and right ends of the bottom connecting plate 1-1. The left connecting plate 1-2 and the right connecting plate 1-3 of the left connecting plate 4, the overall approximate inverted V shape of the moving connecting plate 4 includes a parallel plate substantially parallel to the left connecting plate 1-2 and the right connecting plate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com