GaN-enhanced MOSFET formed based on digital wet grating etching technology and preparation method

An enhanced and technical technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as surface morphology degradation, ion damage, and difficulty in controlling the thickness of AlGaN in the gate area, so as to achieve good morphology and avoid Effects of damage, increased electron mobility, and maximum drain current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

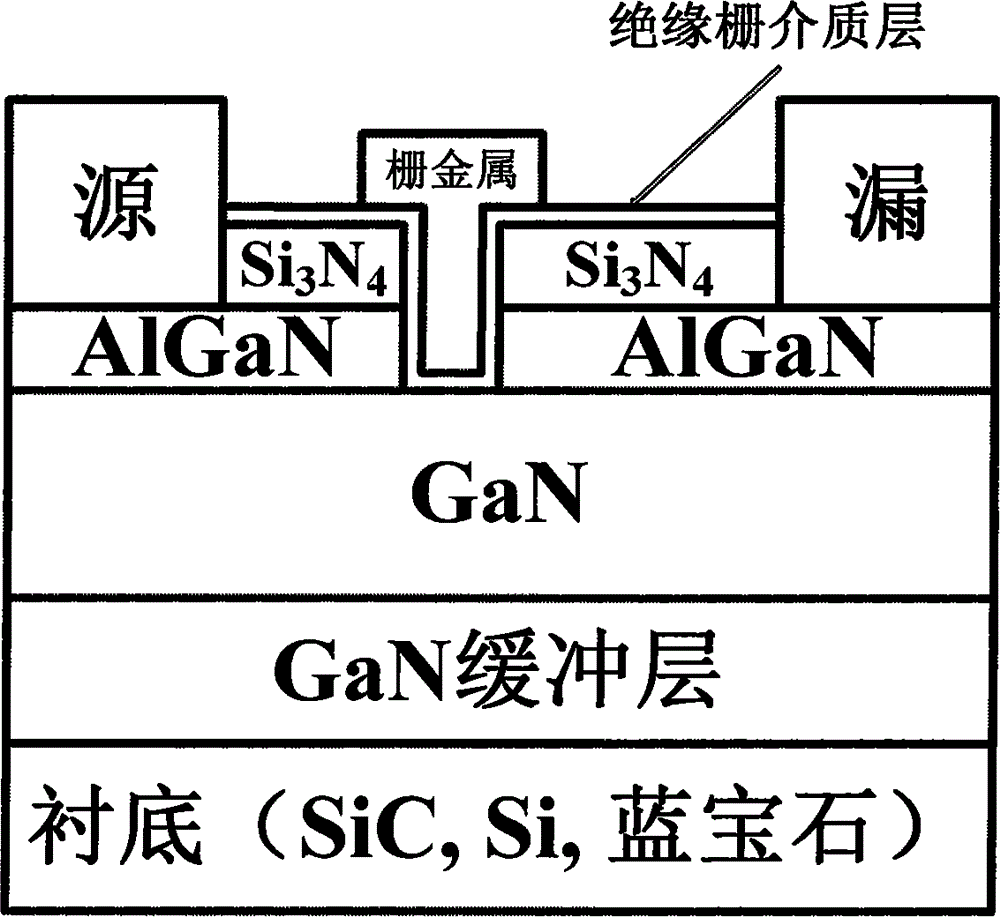

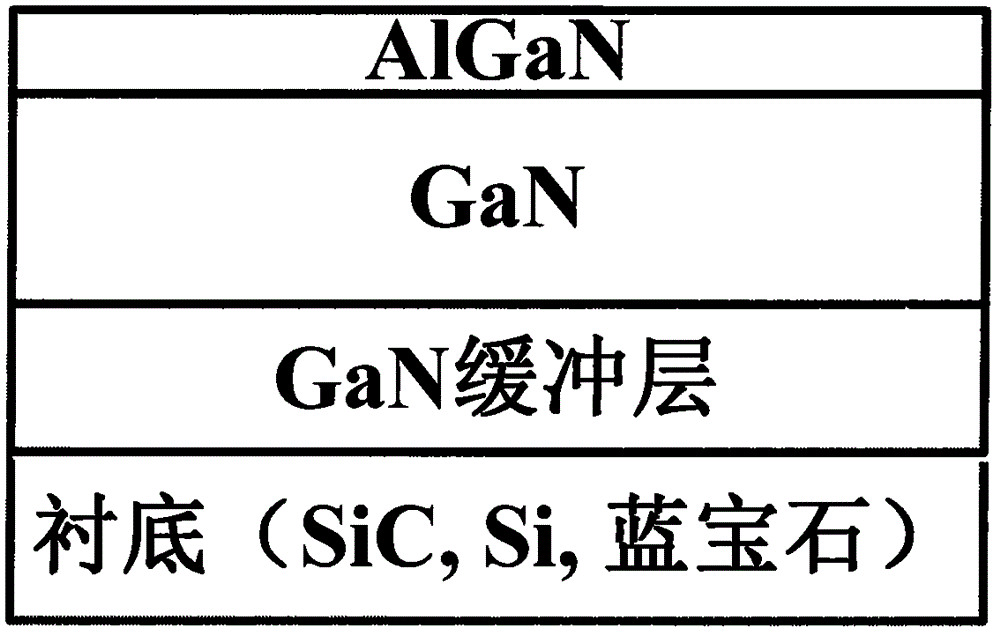

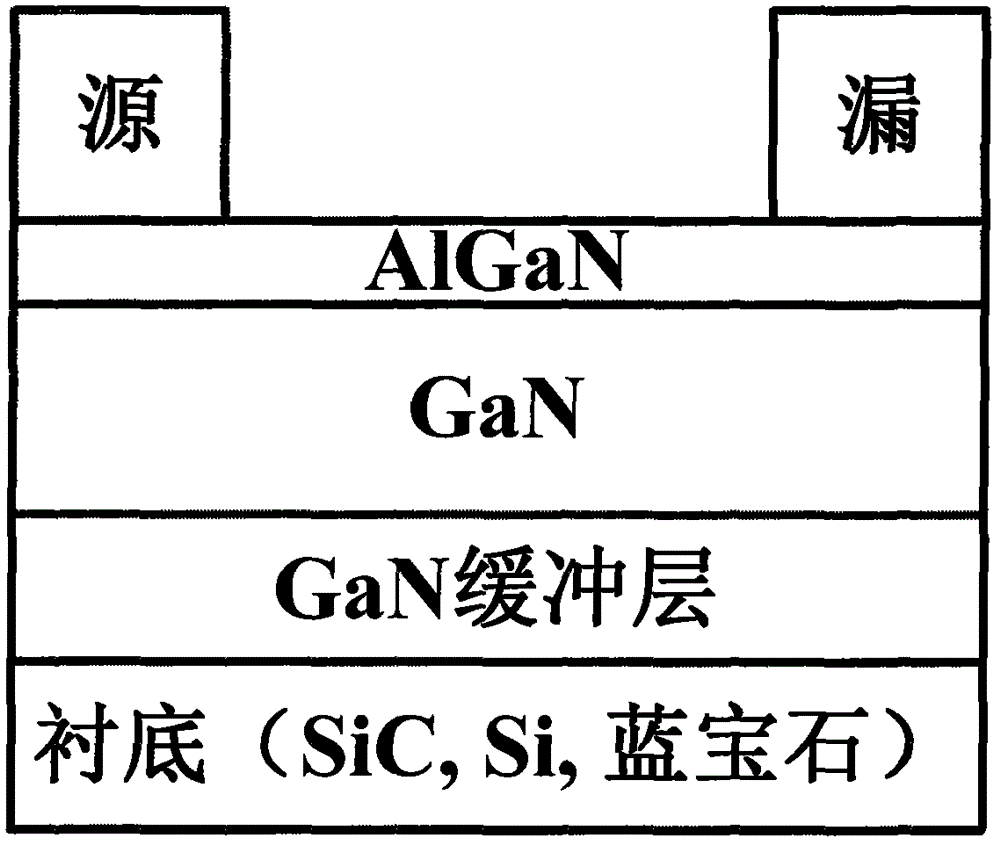

[0026] The schematic diagram of the basic structure of the enhancement mode GaN MOSFET device of the present invention is as figure 1 As shown, it belongs to the metal-oxide-semiconductor field effect transistor. Compared with the enhanced GaN HEMT or MOSFET of the common gate etching technology, the feature of the present invention is that the wet etching technology is used instead of the commonly used plasma dry method. Etching greatly reduces the plasma damage of the gate groove, retains a good surface morphology of the gate groove, and ensures the consistency of the threshold voltage and realizes a high-performance GaN-enhanced MOSFET, wherein the gate metal is the following conductive material A combination of one or more of: platinum, iridium, nickel, gold, molybdenum, palladium, selenium, beryllium, TiN, polysilicon, ITO, the material of the insulating gate dielectric layer is any one of the following materials: Si 3 N 4 、Al 2 o 3 , AlN, HfO 2 , SiO 2 , HfTiO, Sc ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com