Battery module structure

A technology of battery modules and battery packs, which is applied to battery pack components, secondary batteries, structural parts, etc., and can solve problems such as battery box safety hazards, looseness during operation, and open circuits, so as to improve safety and reliability , prevent flatulence, reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

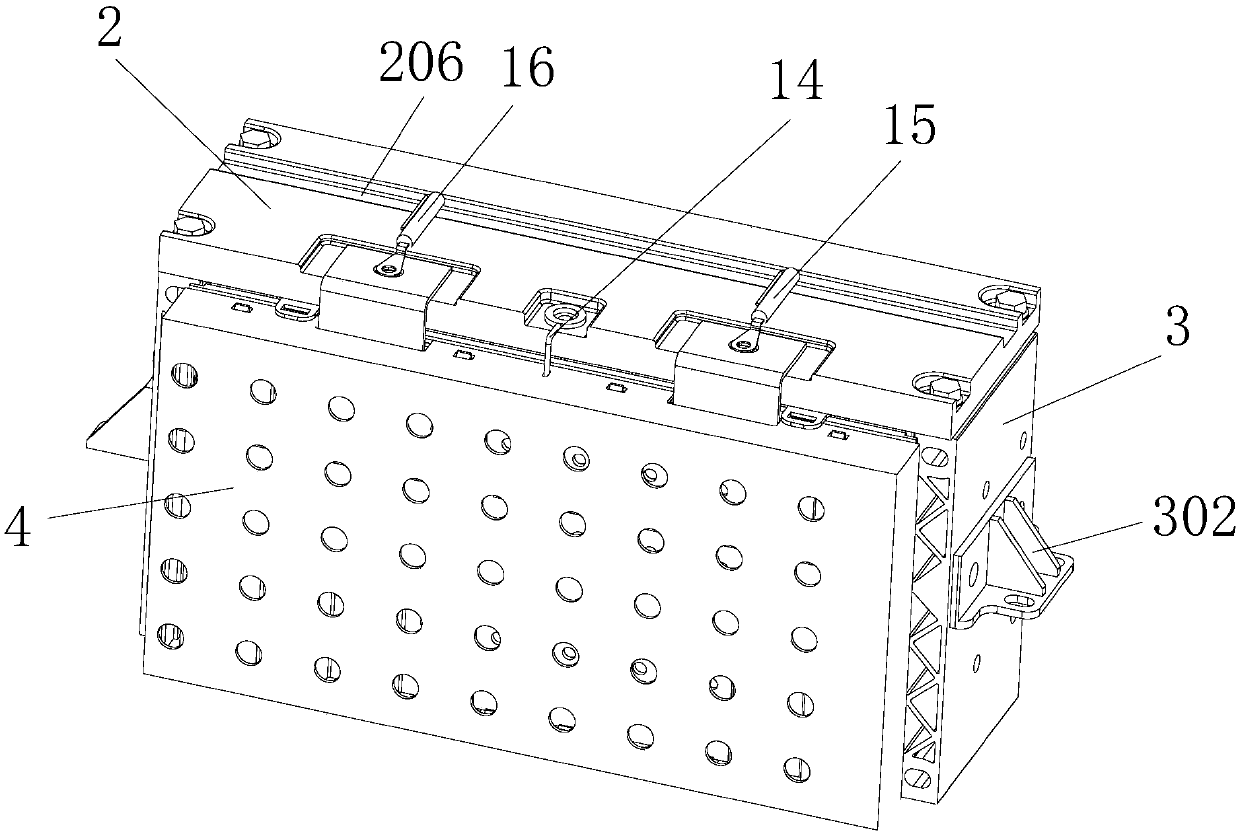

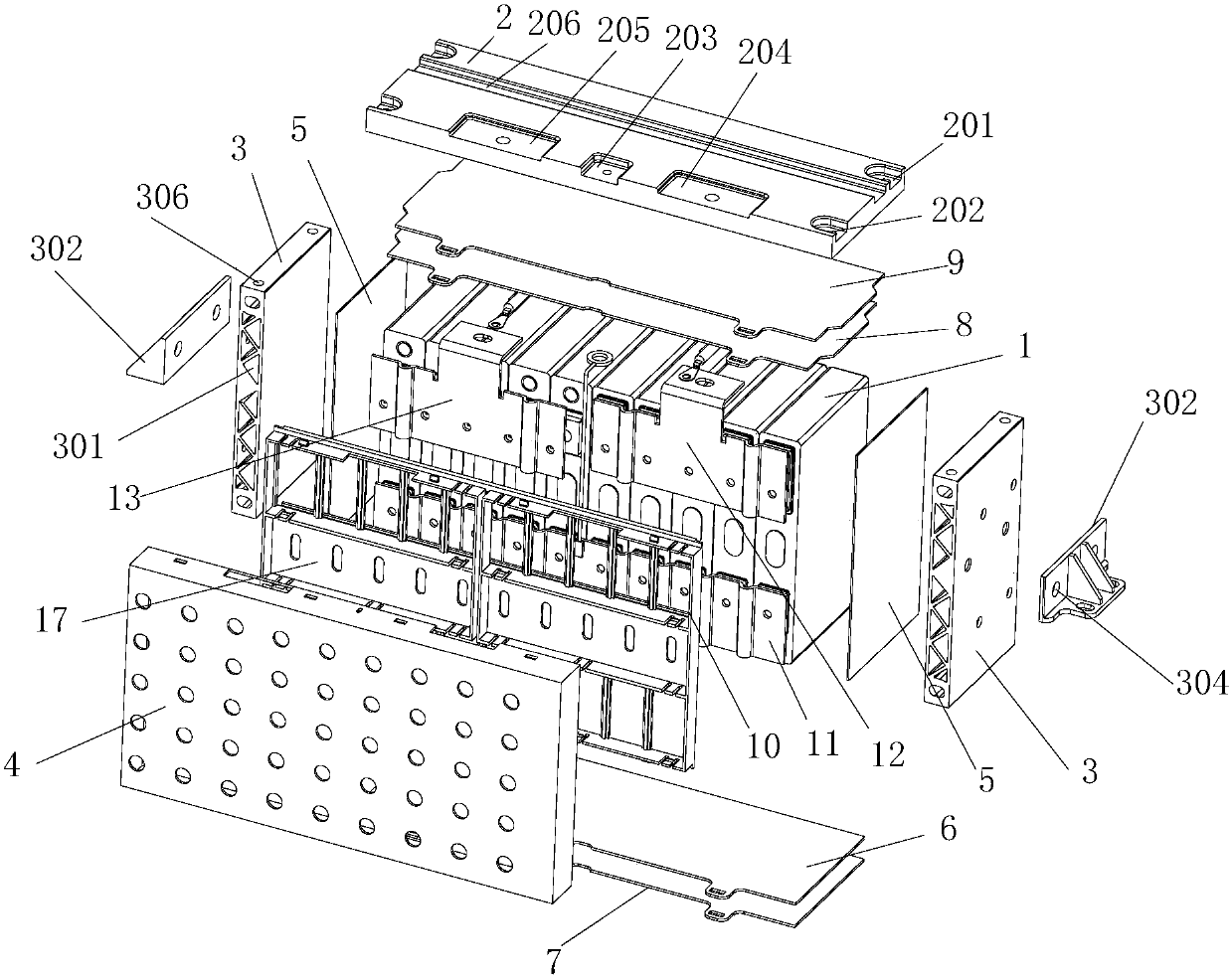

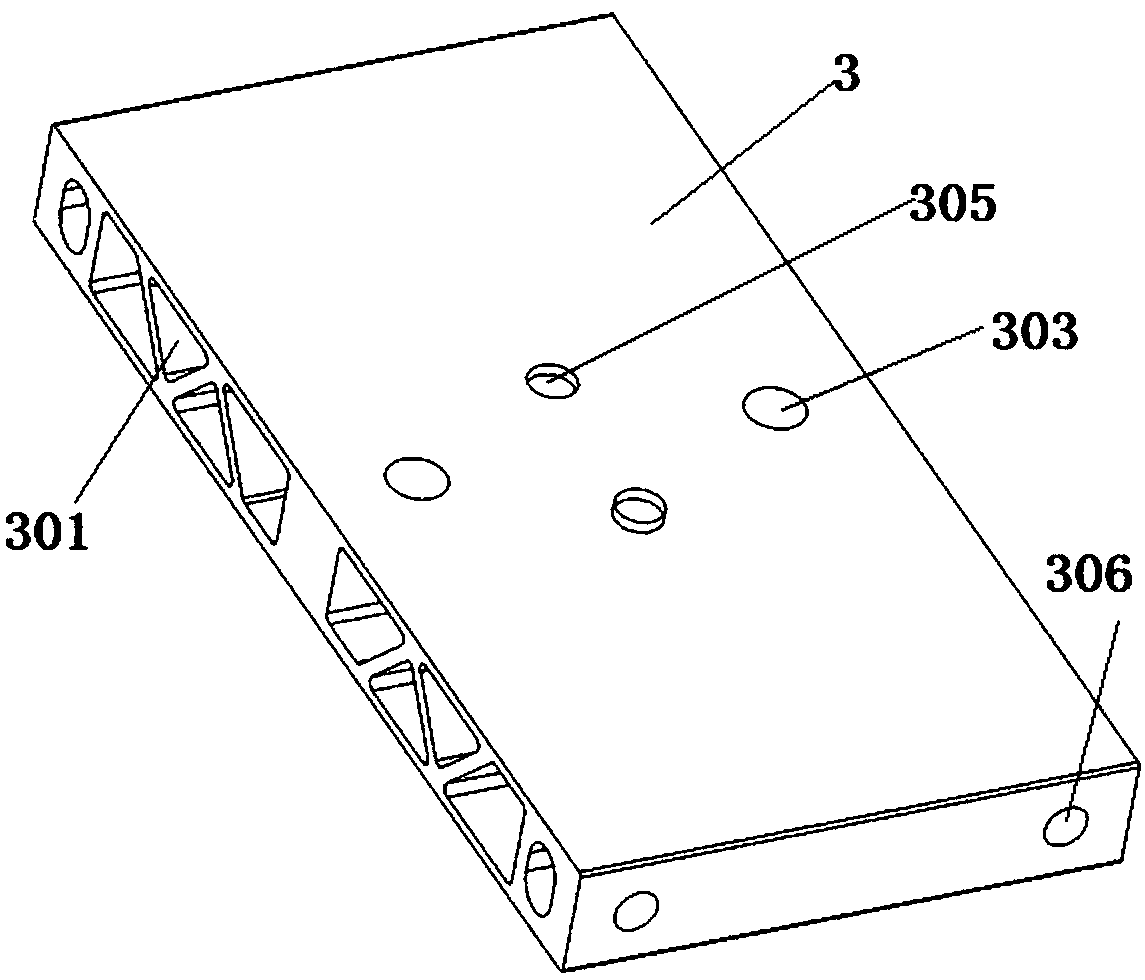

[0026] refer to Figure 1-Figure 7 , the present invention proposes a battery module structure, including a battery pack 1, an upper cover plate 2, two metal end plates 3, an integrated cover plate and a side cover plate 4; wherein:

[0027] The battery pack 1 is formed by a plurality of battery cells arranged in a line. Two metal end plates 3 are arranged oppositely at both ends of the battery pack 1. Mounting holes 306 are provided at the tops of the two metal end plates 3. The metal end plates 3 are connected to the battery pack. 1 is provided with an insulating end plate 5 for insulation, and the insulating end plate 5 and the battery pack 1 are bonded together by structural glue to pre-fix the battery pack 1 . The lower end of the battery pack 1 is sequentially provided with a first insulating side plate 6 and a first metal side plate 7 from inside to outside. The first metal side plate 7 is welded together with the battery pack 1 and two metal end plates 3 by CMT welding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com