A strut spring assembly equipment

A technology for assembling equipment and mounting plates, applied in metal processing equipment, assembly machines, manufacturing tools, etc., can solve the problems of easy deformation of springs and difficult assembly, and achieve the effect of improving response speed, shortening assembly time, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

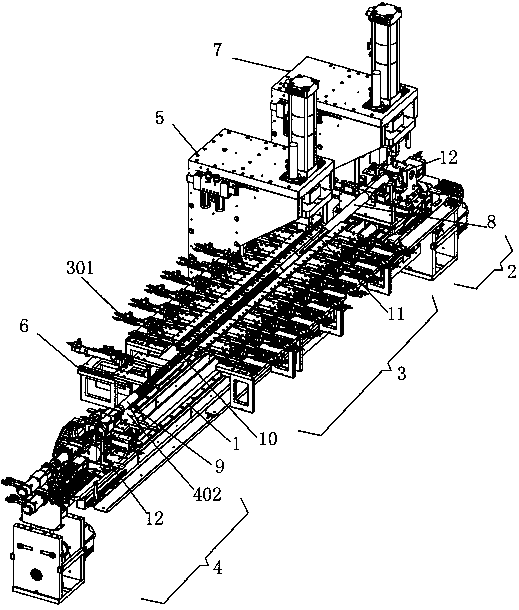

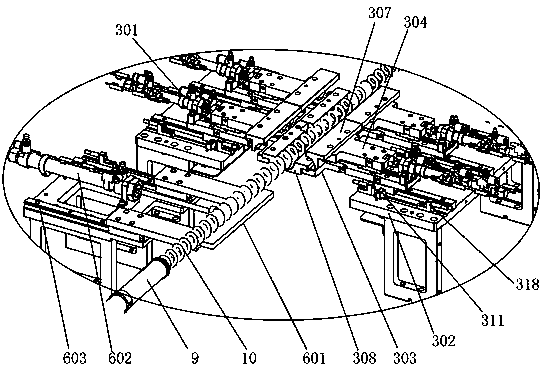

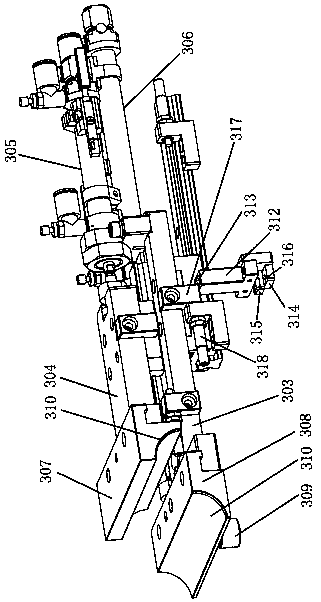

[0036] Figure 1 to Figure 10It shows the strut spring assembly equipment provided by the present invention, including the slide rail line 1, the outer casing positioning part 2 arranged in sequence along the slide rail line 1 from front to back, the spring holding part 3 and the spring compression part 4, the spring compression part 4 and the outer sleeve positioning part 2 are all slidably arranged on the slide rail line 1; the outer sleeve positioning part 2 includes a positioning slide plate 201, an outer sleeve clamping seat 202 arranged on the positioning slide plate 201; the spring holding part 3 is arranged along the slide rail line 1 Multiple groups arranged in sequence, each group includes two holding mechanisms 301, and the two holding mechanisms 301 of each group are mirrored above the slide rail line 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com