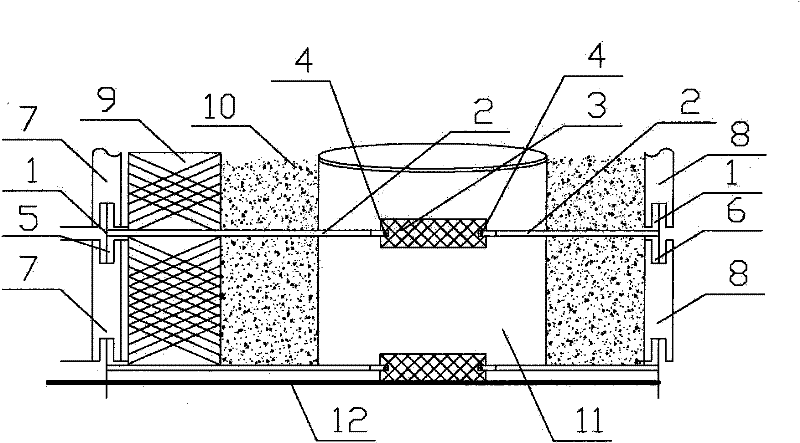

Mold pipe building construction technology

A building construction and mold tube technology, which is applied in construction, sustainable construction, building construction, etc., can solve the problems of indoor environmental pollution, inability to continuous production, and high labor intensity of workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

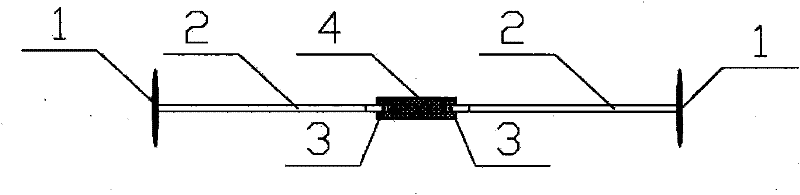

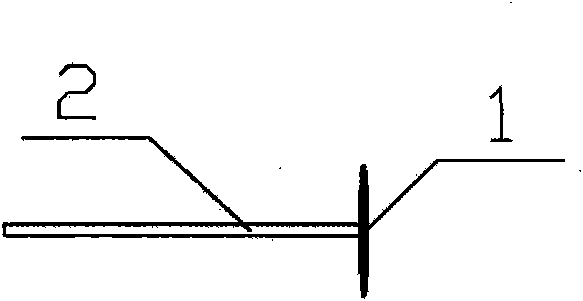

Method used

Image

Examples

Embodiment Construction

[0097] The premise is that materials such as mold pipes and steel bars used for the frame plus structure are prepared according to the size according to the design data, and the concrete is mixed and cast on site.

[0098] First inside and then outside order: install the load-bearing floor formwork and load-bearing staircase formwork (the eighth and ninth molds will be removed after use, and the thirteenth mold will not be dismantled).

[0099] 1. Starting from any corner of the inner surface of the outer wall, there are two herringbone ladders. There are two people on the ladder and one person on the ground. A load-bearing pipe column (removed after eight molds are used) is placed on the bottom seat, the workers below insert the screwdriver into the screw hole of the lower head to adjust the height, and the workers above screw the upper screw rod of the column into the middle hole of the formwork. After screwing through, Then screw the 1 / 2 position of the lower inner wire of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com