A pressing device for magnet and spring sheet in stator

A press-fitting device and spring leaf technology, applied in the manufacture of stator/rotor bodies, etc., can solve the problems of inability to ensure product assembly consistency, affecting assembly speed and quality, and inability to achieve automation, reducing manpower, improving assembly efficiency, Ensure consistent quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

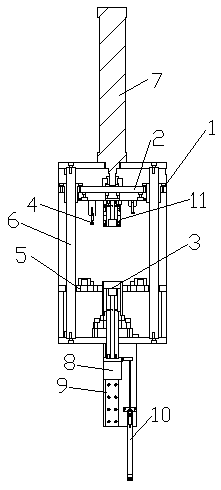

[0013] Such as figure 1 As shown, a device for pressing magnets and spring sheets in a stator is characterized in that it includes a first power unit, a second power unit, a support frame 1, and an upper mold 2, and first guides are installed on the left and right sides of the inside of the support frame. The column 6, the upper mold and the first guide column can be moved up and down through sliding cooperation. The first power unit is connected with the upper mold to provide power for the upper mold to move up and down; the first power unit includes a press-fit cylinder 7, and the press-fit cylinder is installed on the support frame Above, the piston rod end is fixedly connected with the upper mold. The central position of the bottom of the upper mold is equipped with a press-in mold core 3, and the both sides of the end of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com