Needle assembly machine

An assembly machine and needle technology, which is applied in the field of medical machinery, can solve the problems of unguaranteed quality, high assembly cost, and waste of manpower and material resources, and achieve the effect of reducing the input of manpower and material resources, reducing assembly costs, and reducing assembly time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

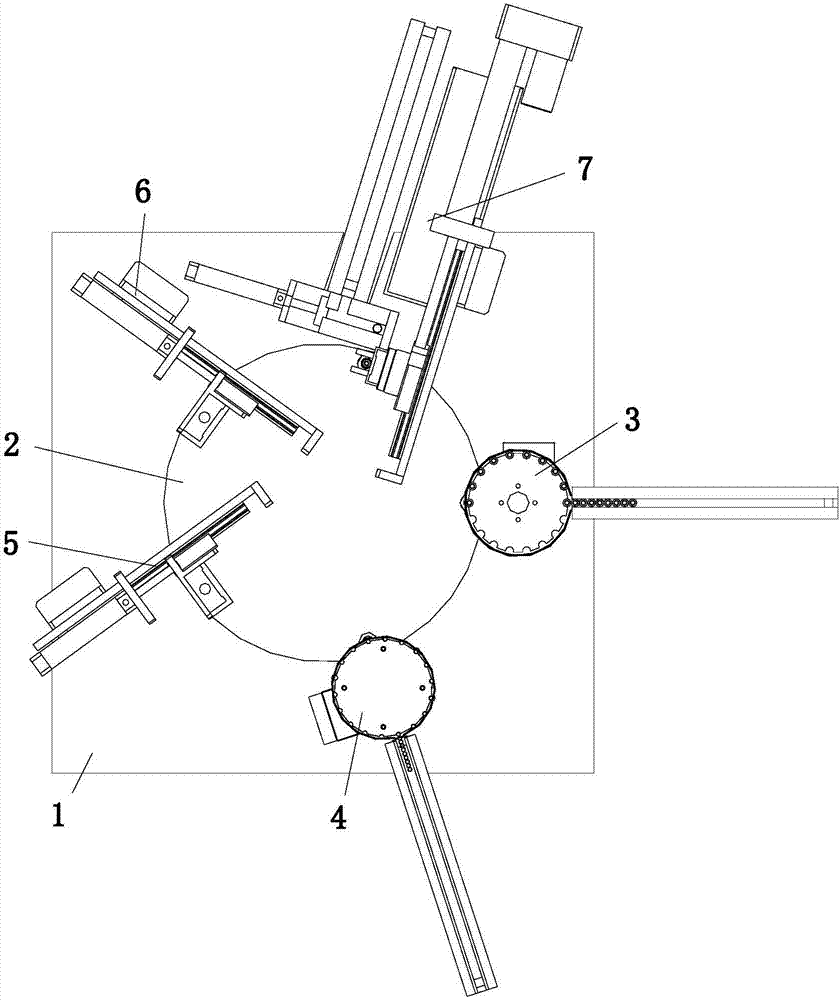

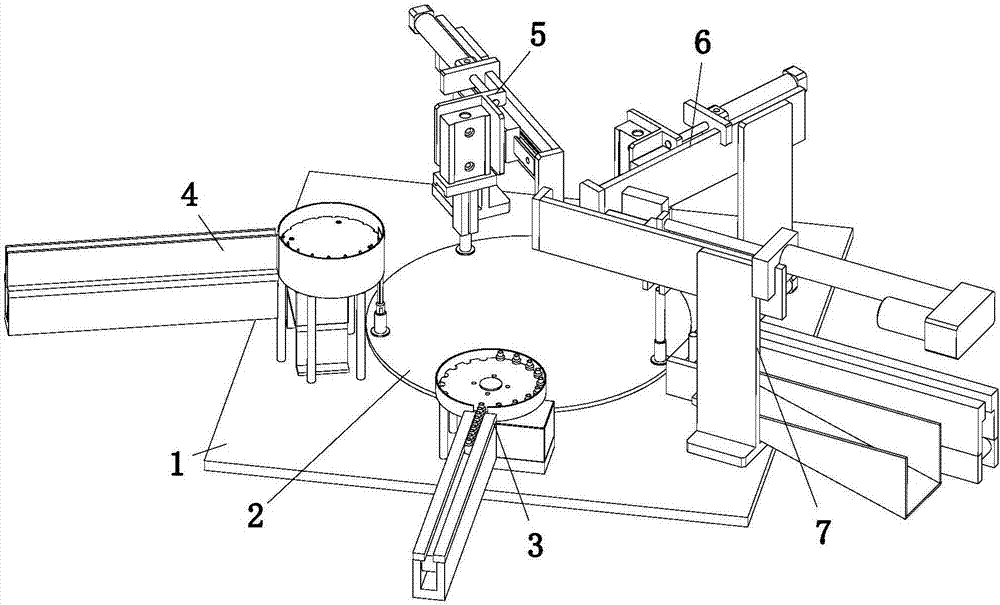

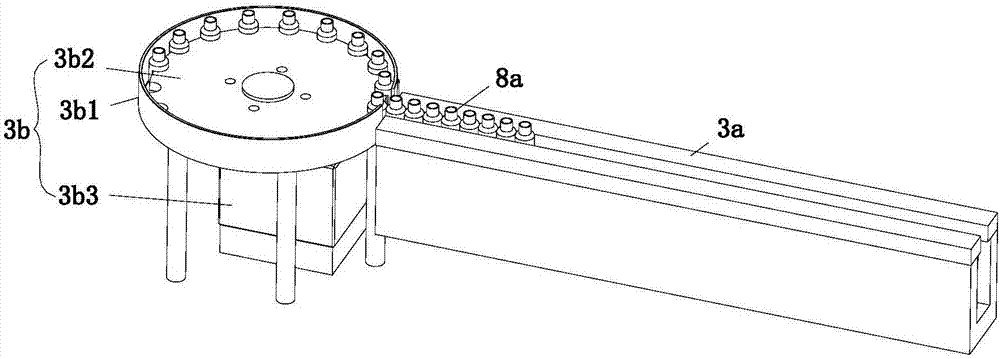

[0026] refer to Figure 1 to Figure 10 The shown needle assembly machine includes a frame, a support plate 1 is provided on the top of the frame, a turntable 2 is provided at the center of the support plate 1, and a first motor for driving the turntable 2 to rotate stepwise is provided inside the frame. The support plate 1 is provided with a pintle feeding device 3 , a needle point feeding device 4 , a needle point calibration device 5 , a press-fitting device 6 and a sheath fitting device 7 arranged along the rotation of the turntable 2 around the turntable 2 . There are several jigs 2a evenly distributed along the circumferential direction, and the jigs 2a are driven by the turntable 2 to pass through the pintle feeding device 3, the needle point feeding device 4, the needle point calibration device 5, the pressin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com