An automatic riveting machine used for lamp head assembly rivet conveying and correction

A rivet machine and rivet technology, applied in the field of rivet machines, can solve the problems of reduced operating efficiency, rivets are prone to material jams, and increased lamp head defective products, etc., to achieve the effect of improving verticality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

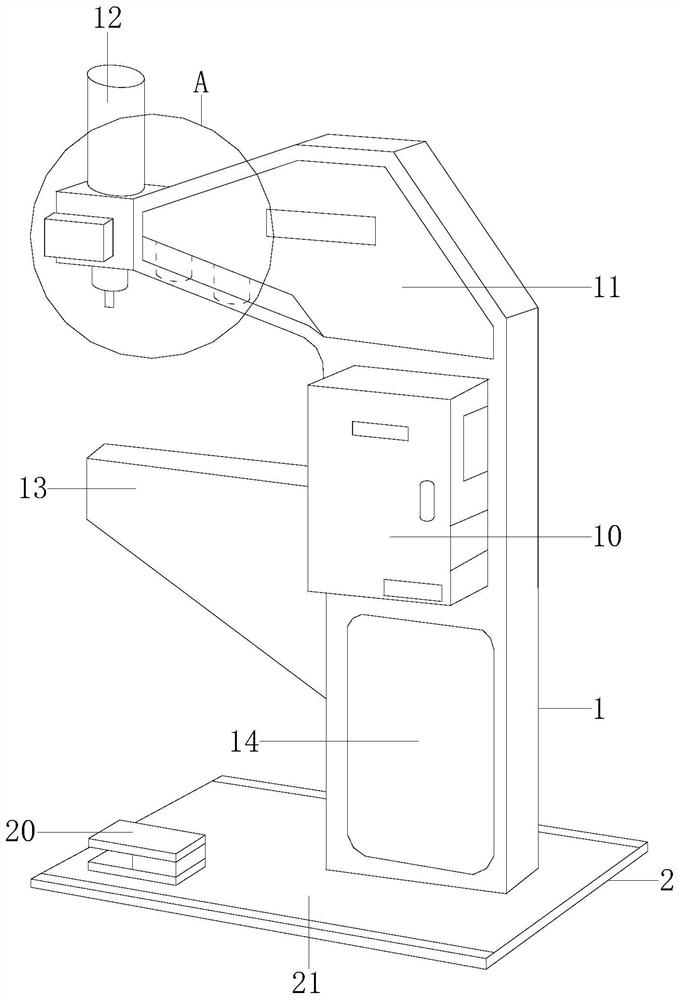

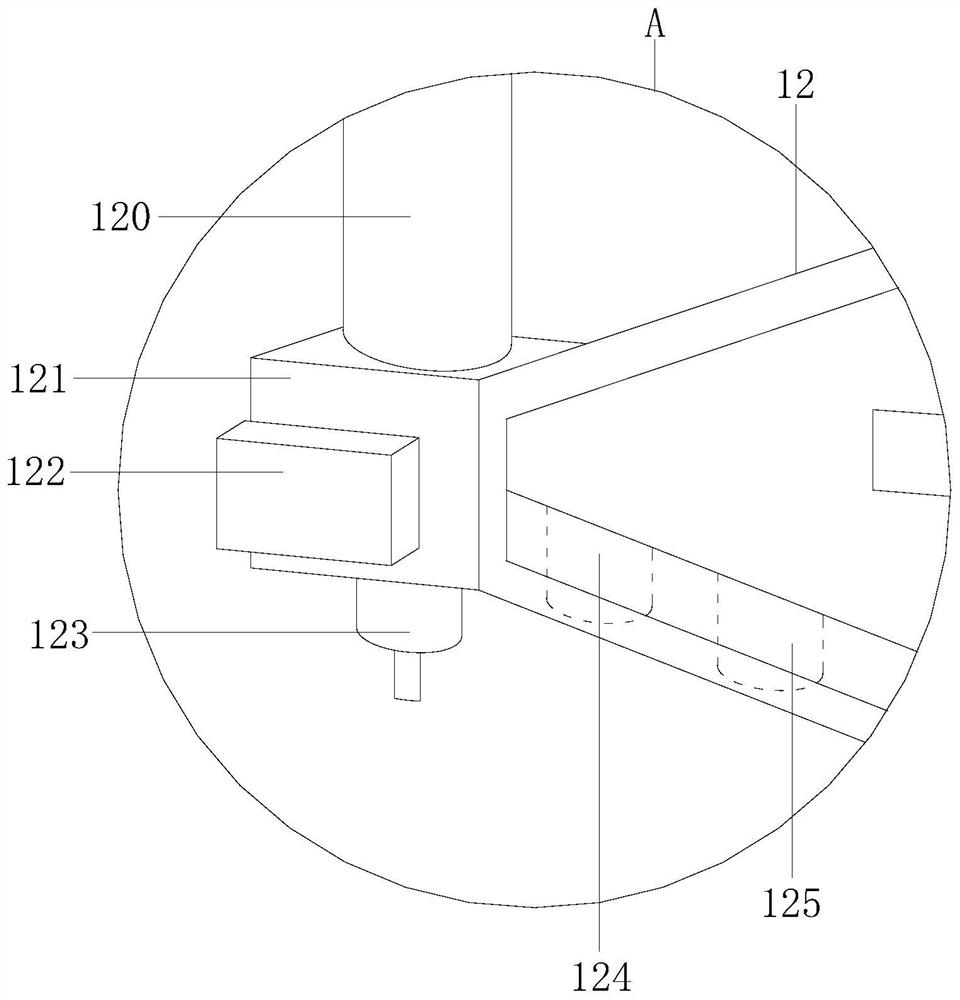

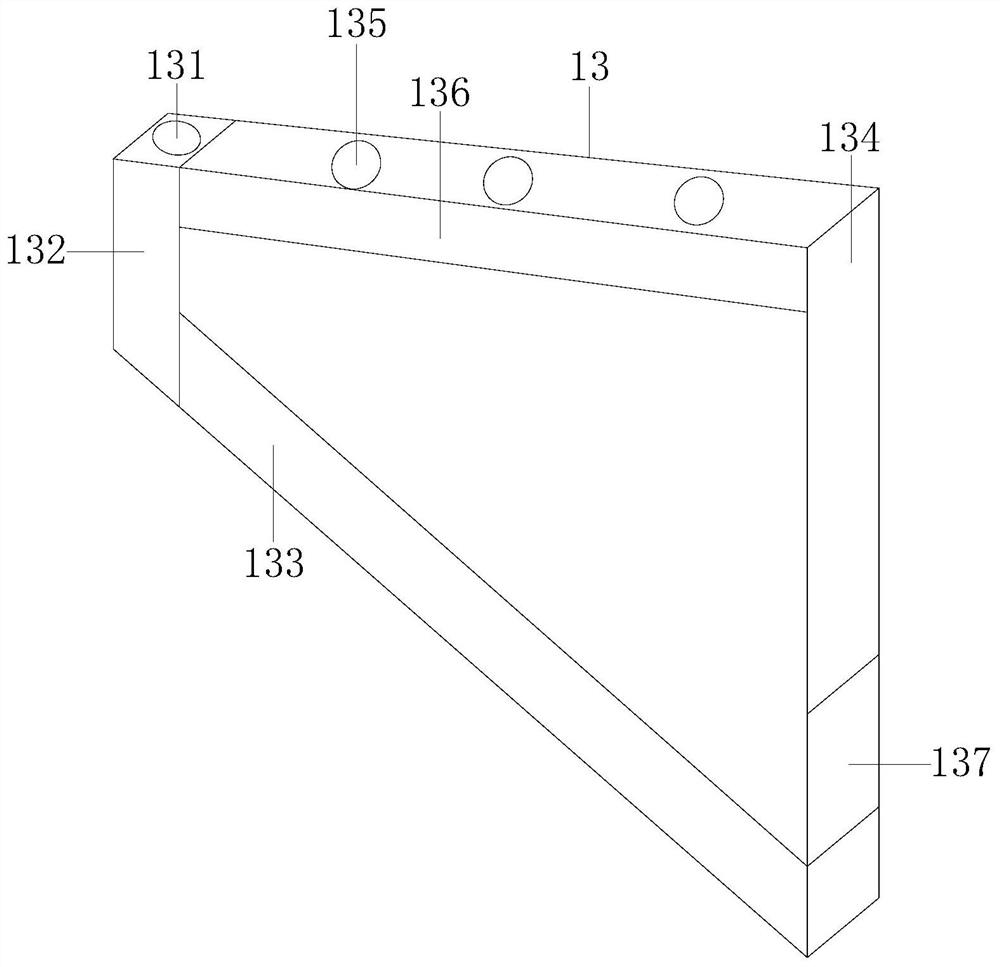

[0031] Example 1 see Figure 1-7, the present invention provides a technical scheme of automatic riveting machine for rivet assembly and correction of lamp caps: its structure includes a nail pressing machine 1 and a base 2, the nail pressing machine 1 is welded to the base 2, and the nail pressing machine 1 is controlled by Box 10, rivet stand 11, rivet press head 12, rivet seat 13, machine door 14, described control box 10 is locked with rivet stand 11, and described rivet press head 12 is installed on the rivet stand 11, and described rivet stand 11 It is assembled and connected with the rivet seat 13. The base 2 is composed of a pedal 20 and a seat plate 21. The pedal 20 and the locking seat plate 21 are connected by bolts. The rivet press head 12 includes a press head motor 120, a mounting frame 121, a press Head control board 122, main pressure head 123, one-position auxiliary pressure head 124, two-position auxiliary pressure head 125, the main pressure head 123, one-po...

Embodiment 2

[0033] Example 2 see Figure 8-11 , the present invention provides a technical scheme of an automatic rivet machine for conveying and correcting lamp cap assembly rivets: its structure is an automatic rivet machine for lamp cap assembly rivet conveying and correcting according to claim 1, characterized in that: the feeding The side rail 1331 includes buckle circle 400, miniature rail frame 401, and welding rail 402. The feeding side rail 1331 and the two-position rail plate 302 not only play a role in stable transportation, but also assist in lifting and adjusting the height of rivet transportation, further improving For the stability of rivet delivery, the buckle circle 400 is buckled with the miniature rail frame 401, the micro rail frame 401 is welded with the welding rail 402, and the two-position rail plate 302 includes a miniature horizontal rail 3021 and a spliced inlay circle 3022. The miniature horizontal rail 3021 is locked with the splicing inlay circle 3022, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com