Method for assembling hull parts

A technology of parts and hulls, which is applied in the field of assembly and distribution of hull parts, can solve problems such as loss, confusion of material collection and distribution, and not involving all parts, so as to improve efficiency and prevent confusion and loss.

Active Publication Date: 2019-07-30

SHANGHAI WAIGAOQIAO SHIP BUILDING CO LTD

View PDF6 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The technical problem to be solved by the present invention is to overcome the ambiguity of the distribution flow of each part in the collection and distribution method of the hull parts in the prior art and the incomplete division of the small groups, which does not involve all the parts and cannot be well applied to In practice, there are defects such as confusion and loss of material collection and distribution, and a method of collection and distribution of hull parts is provided.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

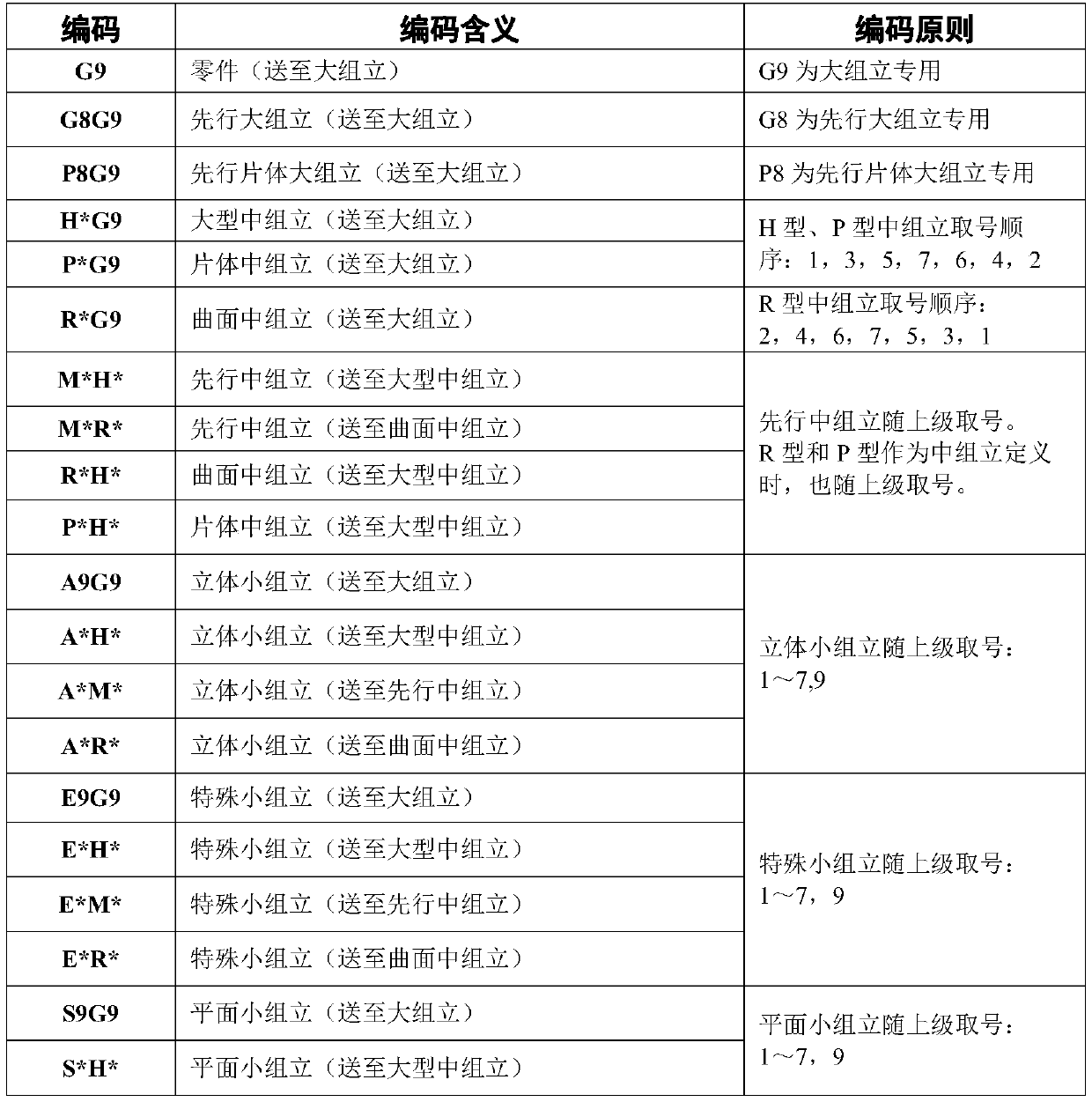

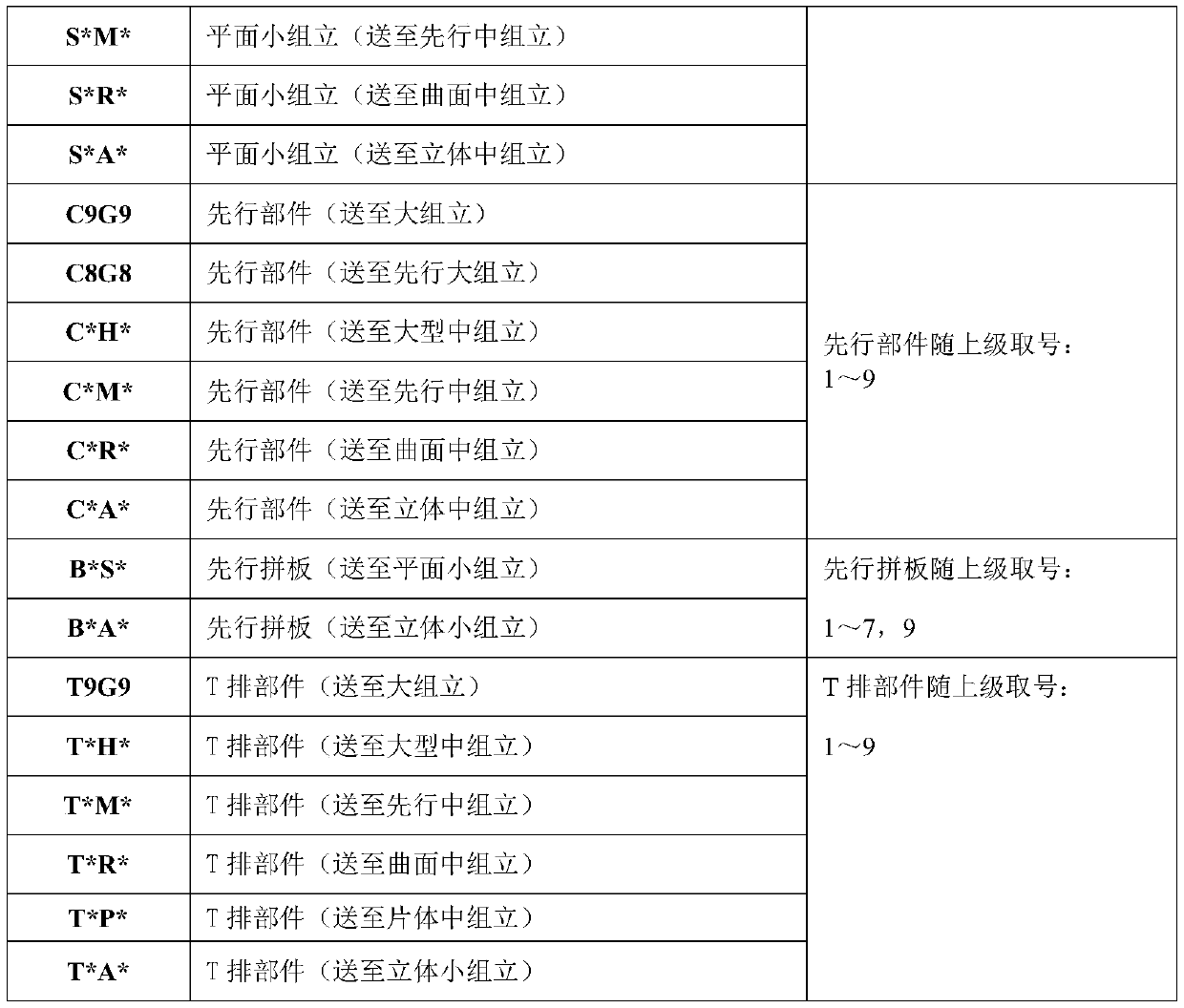

[0022] According to the above-mentioned coding principles, the letters in the codes of each group are defined, and the general code list of each group is summarized, as shown in Table 1 below.

[0023] Table 1 General table of assembly codes

[0024]

[0025]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

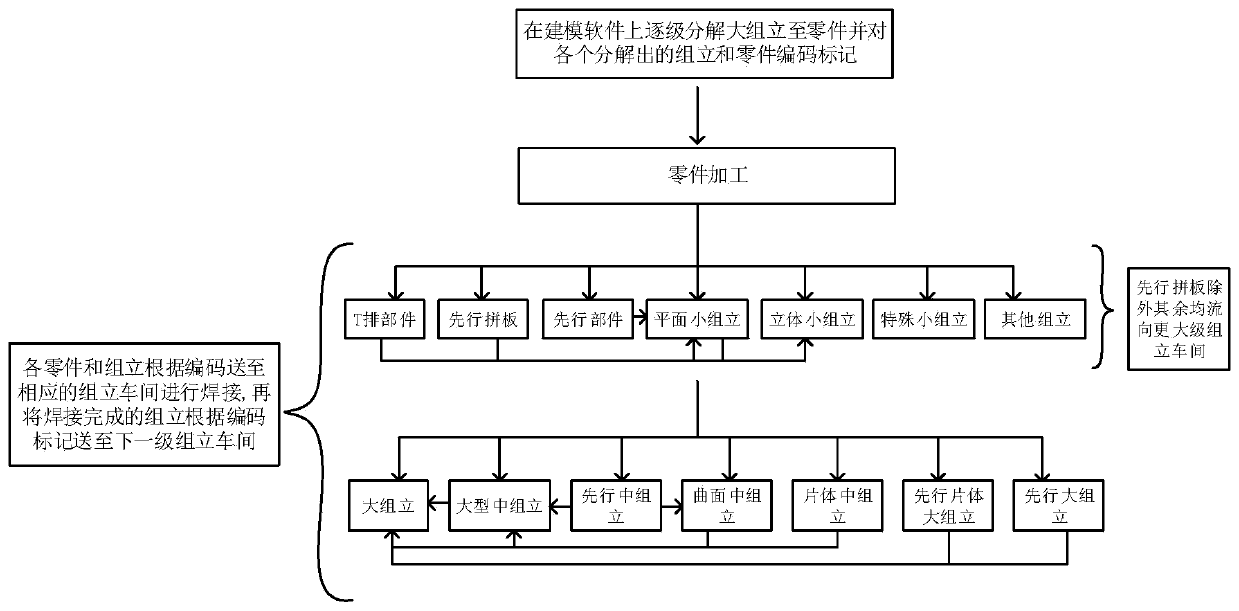

The invention discloses a method for assembling hull parts. The method comprises the following steps that (1) large assemblages set on modeling software are disassembled into parts step by step, and the assemblages and the parts are coded; (2) the parts disassembled are sent to six kinds of small assemblage workshops according to coding; (3) the small assemblages are sent to the corresponding assemblage workshops according to the coding; (4) advanced medium assemblages are sent to large-scale medium assemblage workshops and curved surface medium assemblage workshops according to the coding, and curved surface medium assemblages and sheet medium assemblages are sent to the large-scale medium assemblage workshops; and (5) advanced sheet large assemblages, advanced large assemblages, large-scale medium assemblages, sheet medium assemblages and curved surface medium assemblages are all sent to the large assemblage workshops to complete the assembly of the hull parts. The assembling methodgives a specific distribution flow direction, the small assemblages are divided comprehensively, distribution in lanes can be carried out quickly and orderly, and the problems such as assembly confusion and material loss are not prone to being caused.

Description

technical field [0001] The invention specifically relates to a method for assembly and distribution of hull components. Background technique [0002] With the increasingly large-scale and customized construction of ship products, the most important intermediate product of shipbuilding-the construction of sections is becoming more and more complicated. The logistics mode of material collection and distribution in units of sections often leads to the construction of sections in the shipyard workshop. A large number of structural materials piled up, repeated material turning, material loss and other problems. Corresponding to the lane-by-lane construction, the lane-by-lane distribution of materials required for the segmented construction has become the optimal way to solve the above problems. [0003] At present, most shipyards still use the block as the unit, and carry out extensive distribution of the parts required for block construction. In view of the increasingly obviou...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B63B9/00B63B9/06

CPCB63B73/00B63B71/00

Inventor 吴娜邵丹胡小才蒋林勇

Owner SHANGHAI WAIGAOQIAO SHIP BUILDING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com