Prefabricated assembled structure automatic splicing control device system and method

A technology of prefabricated assembly and control equipment, which is applied to underwater structures, infrastructure engineering, lifting devices, etc., and can solve the problems of complex installation and control process of prefabricated structural components, the influence of excessive gaps, component assembly errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

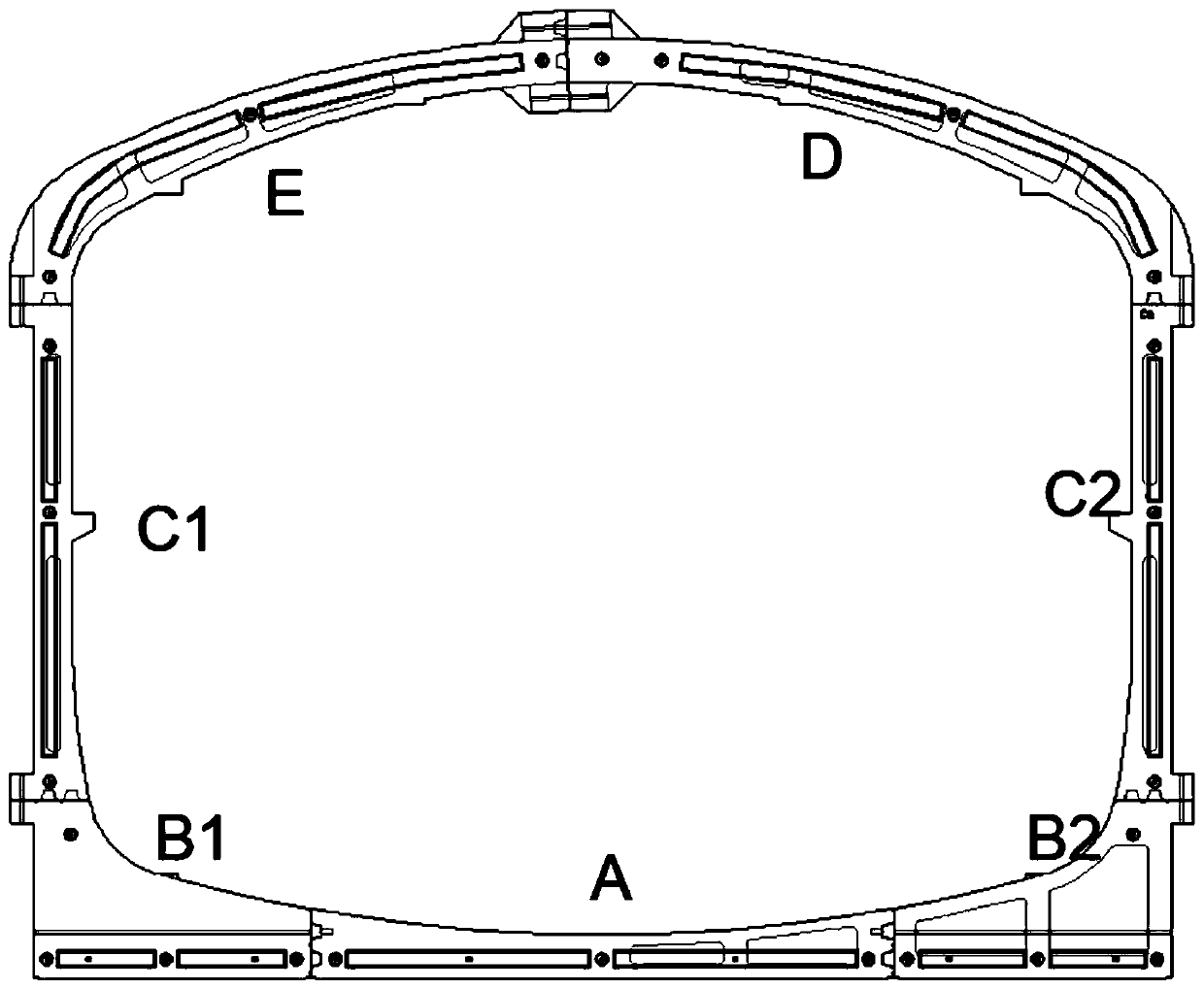

[0092] see figure 1 , shows a prefabricated assembly structure applying the present invention, which is composed of seven assembled components, including the bottom middle horizontal block A, the left horizontal block B1, the right horizontal block B2, and the left middle vertical block C1 , middle vertical block C2 on the right, top horizontal block D, and top horizontal block E. Generally speaking, when assembling a prefabricated structure, start assembling from the bottom middle horizontal block A as the first block, and the left horizontal block B1 Assemble with the right horizontal block B2 as the second and third blocks, the left middle vertical block C1 and the right middle vertical block C2 as the fourth and fifth blocks, and the top horizontal block D and the top horizontal block E Assembling the sixth and seventh pieces, and those skilled in the art know that the present invention can be applied to prefabricated structures such as railway and urban rail transit stati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com