Energy-saving and noise-reducing vacuum pump

A vacuum pump and noise reduction technology, which is applied in the direction of pumps, pump components, variable displacement pump components, etc., can solve the problems that it is difficult to ensure the concentricity, the operation of the vacuum pump is not stable, and the deflection angle α is easy to occur, so as to reduce vibration and noise , reduce volume, reduce the effect of assembly times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

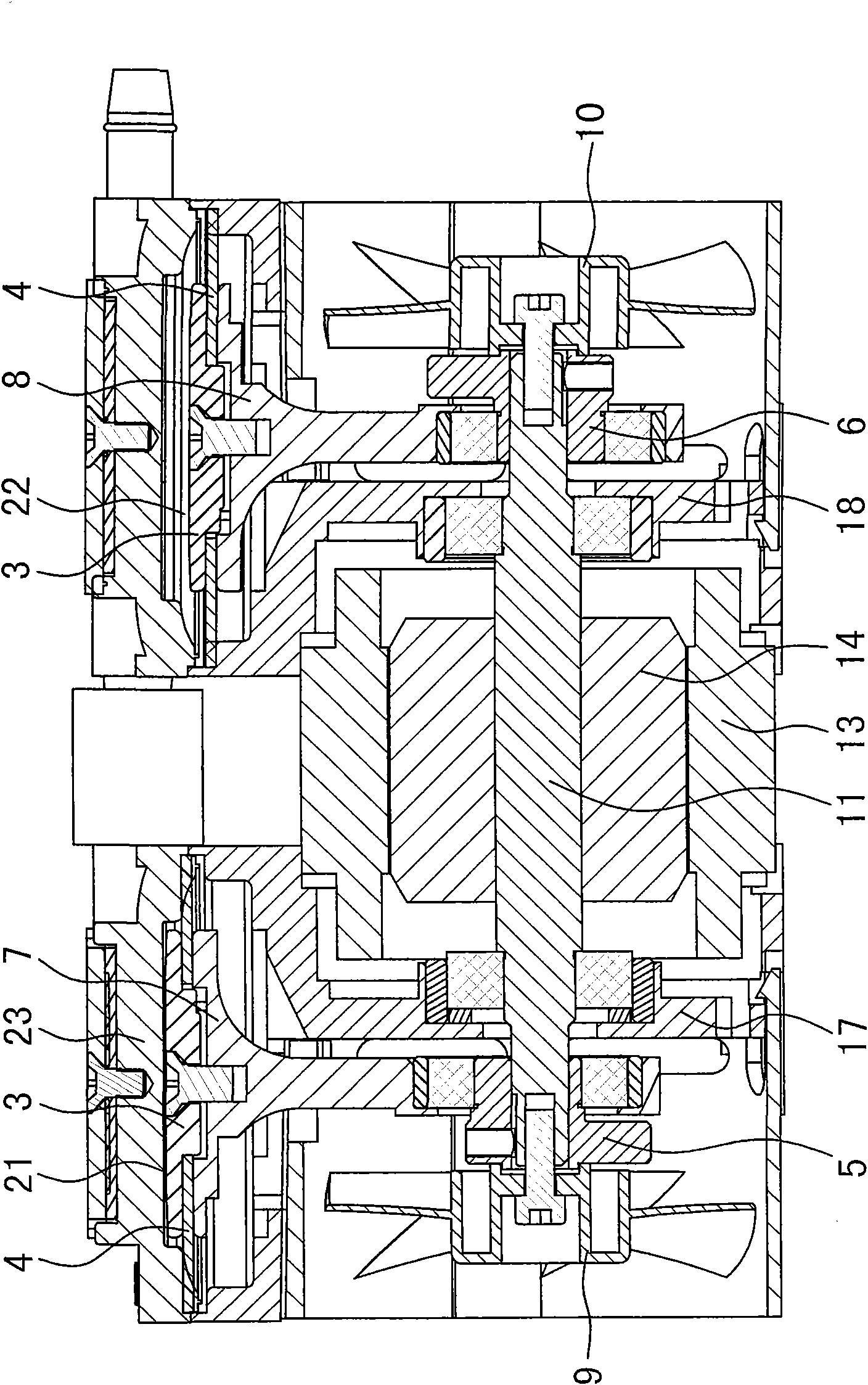

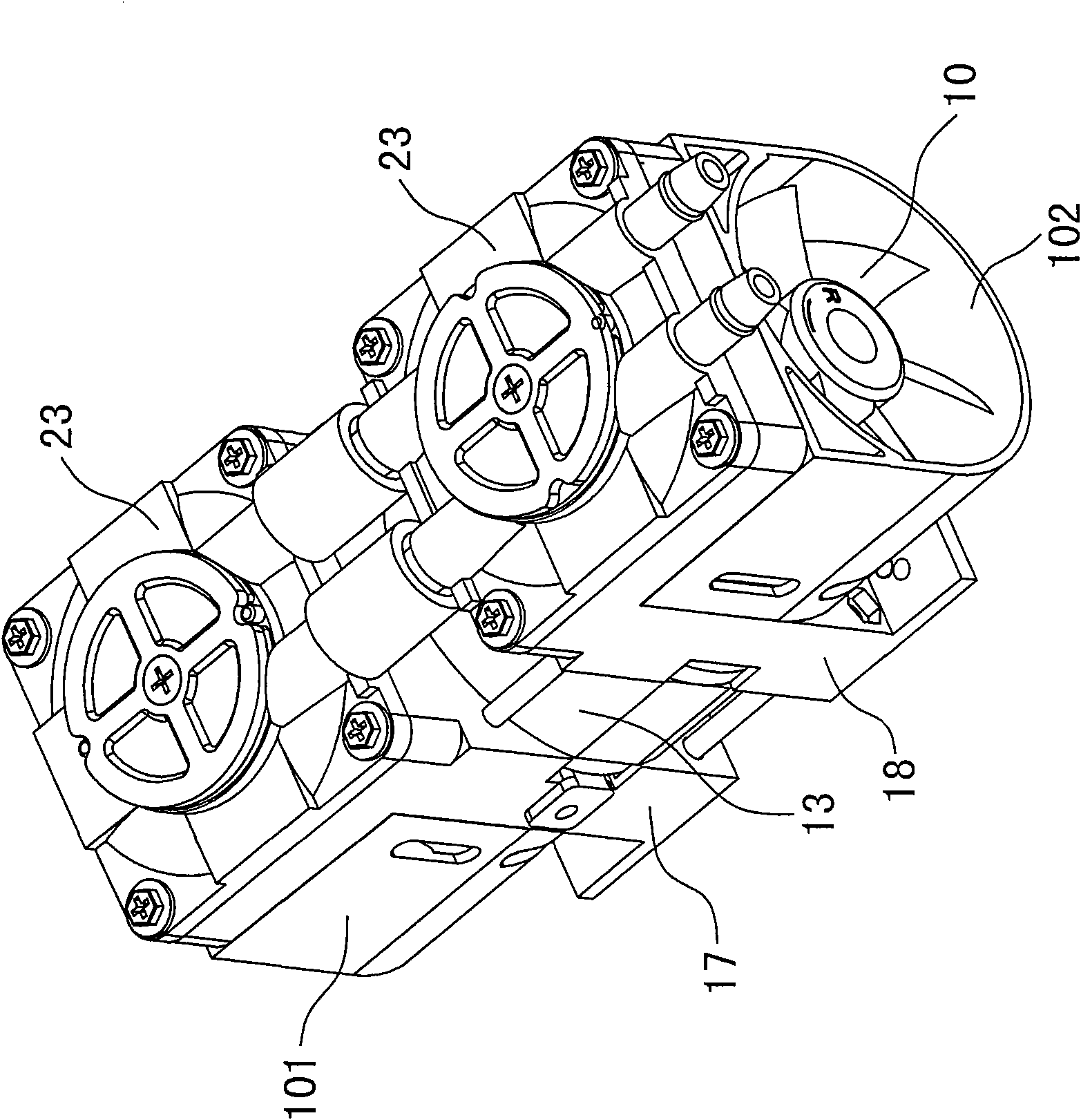

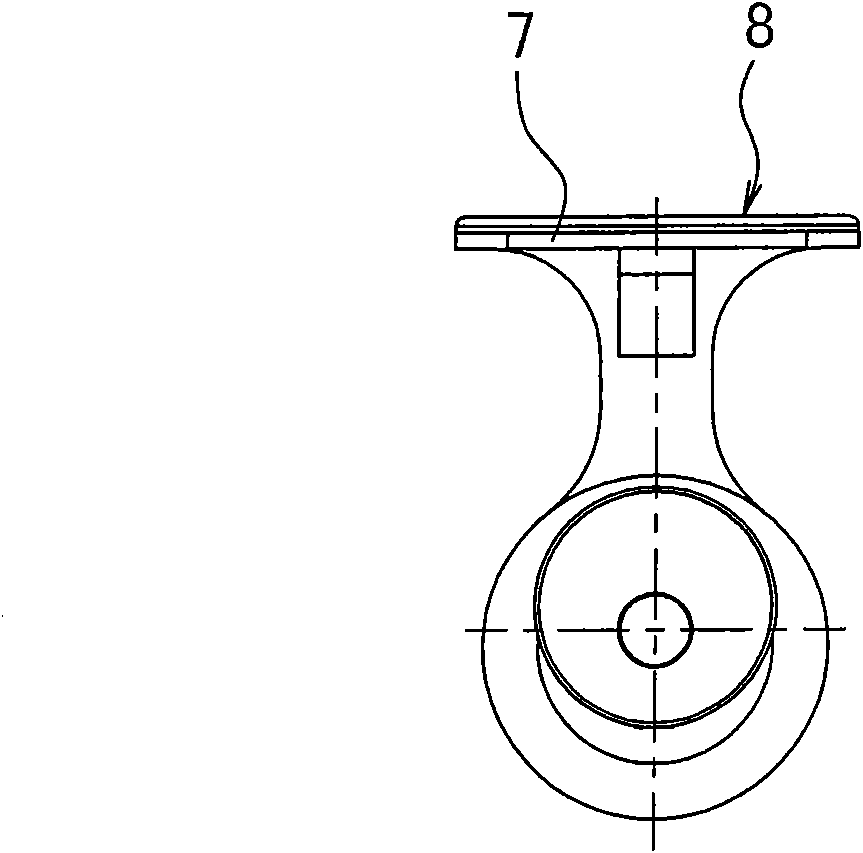

[0011] The invention discloses an energy-saving and noise-reducing vacuum pump, such as figure 1 , figure 2 As shown, it includes a motor (the motor is composed of a stator 13, a rotor 14, a motor shaft 11, and left and right mounting brackets 17, 18), a motor casing, a pump body and a pump cover, and the two ends of the motor shaft 11 are respectively connected to the left and right pull rods 7, 8, the heads of the left and right pull rods 7, 8 are fixedly connected with the film pressing piece 3 and extend into the left and right pump chambers 21, 22, and a diaphragm 4 is installed between the head of the left and right pulling rods and the membrane pressing piece 3, It is characterized in that eccentric wheels 5 and 6 are respectively installed between the two ends of the motor shaft 11 and the left and right pull rods 7 and 8 . The vacuum pumps in the prior art are directly installed with left and right pull rods 7' and 8' at the two ends of the motor shaft. After assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com