Method of fabricating an electroacoustic transducer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

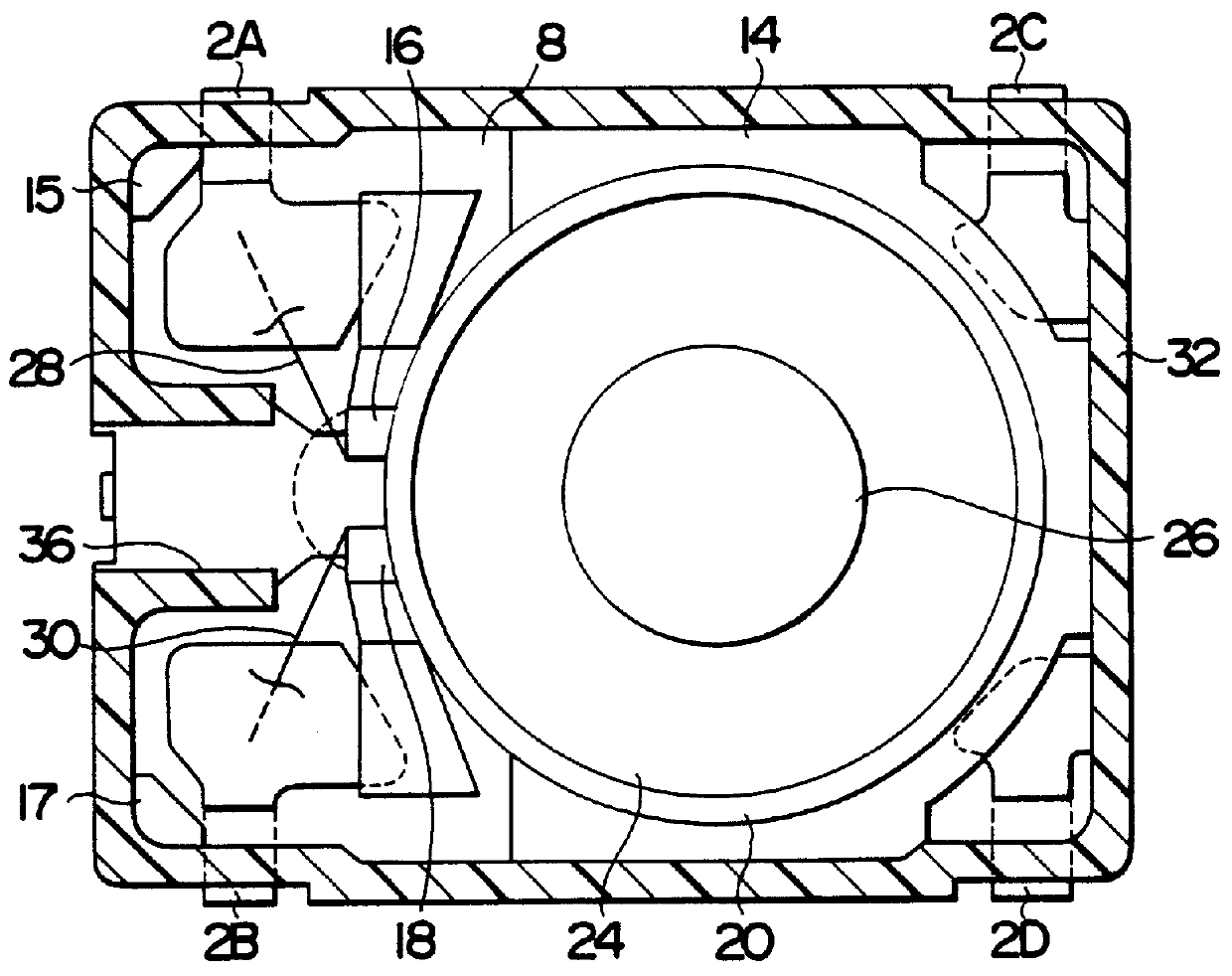

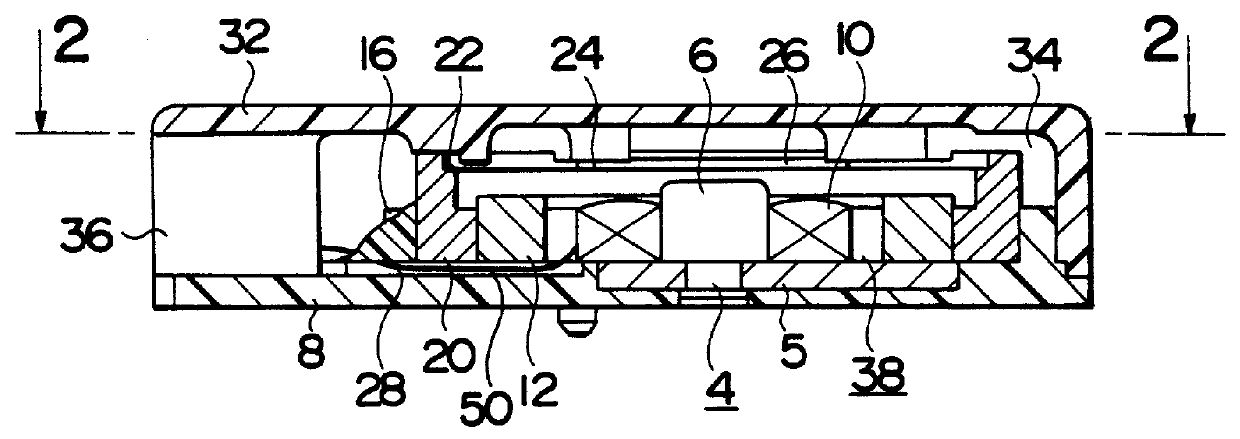

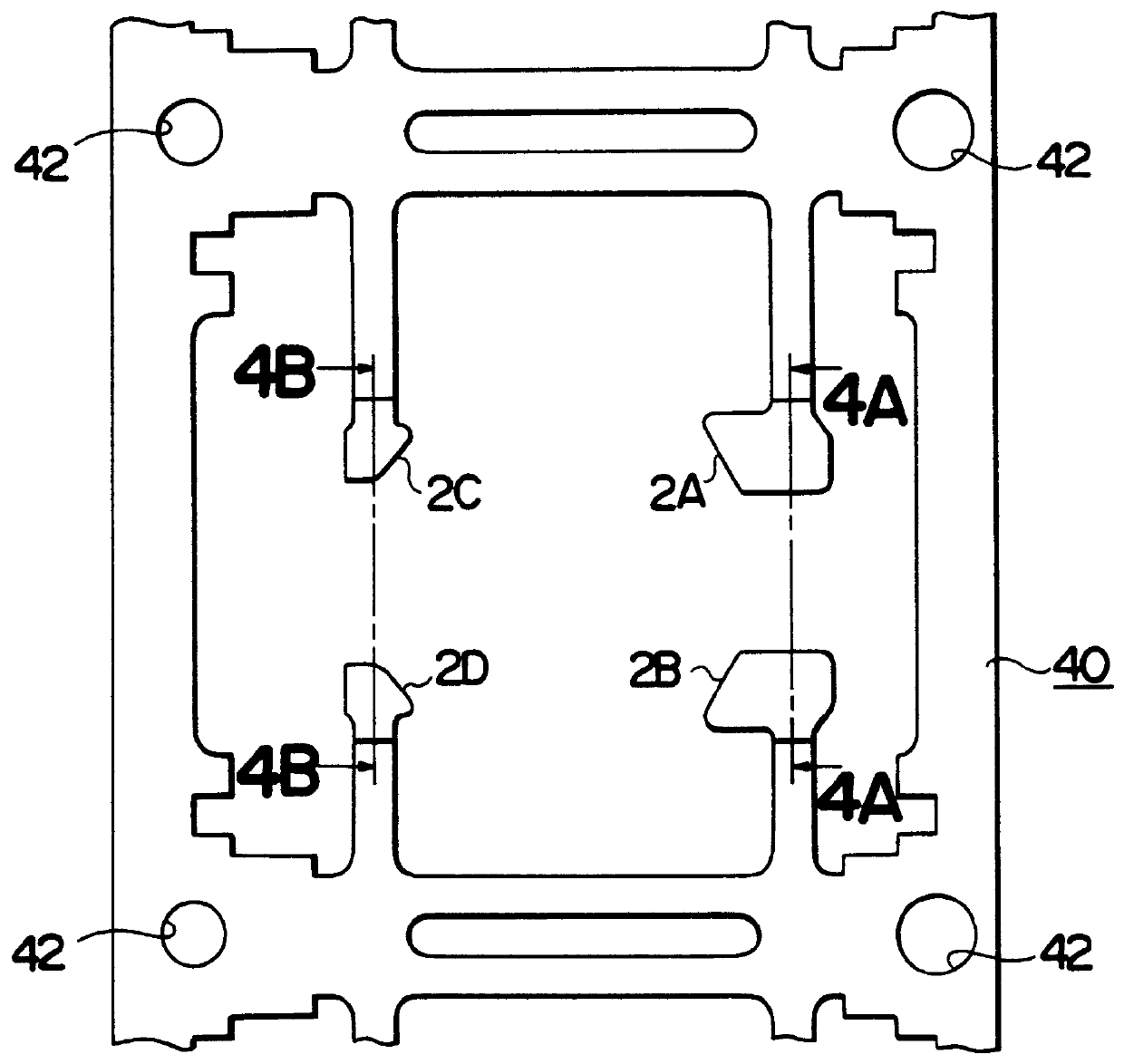

FIGS. 1 and 2 show an electroacoustic transducer fabricated in accordance with the present invention. Lead terminals 2A, 2B, 2C and 2D are integrally formed of a lead frame 40. A pole piece portion 4 consists of a plate-shaped yoke 5 and a core 6 attached to the yoke 5. The lead terminals 2A, 2B, 2C and 2D and the pole piece portion 4 are embedded in a base 8 formed of a synthetic resin in the shape of a rectangular flat plate.

A coil 10 is wound around the core 6, and an annular magnet 12 is disposed so as to surround the coil 10. The magnet 12 and the pole piece portion 4 are magnetically coupled to form a magnetic path. The coil 10 formed of an air-core one is mounted on the core 6 or directly wound around the core 6.

The base 8 is provided on its upper surface with positioning protrusions 14, 15, 16, 17 and 18. A support ring 20 is positioned inside the positioning protrusions 14, 16 and 18 on the base 8. The support ring 20 has a stepped portion 22 on its inner surface at a posit...

case 32

A case 32 is positioned in place on the base 8 by the positioning protrusions 14, 15 and 17, and the case 32 is fixed to the base 8 by a fixing means, such as ultrasonic welding. The case 32 formed of synthetic resin defines a resonance space 34 extending over the surface of the diaphragm 24 and around the support ring 20. The case 32 is provided on one side wall thereof with a sound emitting cylinder 36 by means of which the resonance space 34 communicates with the atmosphere.

In such an electroacoustic transducer, the pole piece portion 4 having the core 6 and combined with the base 8 by insert molding, the coil 10 and the magnet 12 constitute an electromagnetic transducing portion 38. When an ac signal is applied across the lead terminals 2A and 2B, the coil 10 is excited and creates an alternating magnetic field between the core 6 and the diaphragm 24 provided with the magnetic piece 26. Consequently, the diaphragm 24 vibrates to generate sound, the resonant space 34 resonates an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com