Coaxial radio frequency connector

A radio frequency connector, coaxial technology, applied in the direction of antenna connector, connection, two-part connection device, etc., can solve the problems of difficult automatic assembly, poor electrical characteristics, complex automatic assembly machine, etc., to increase the cost of low-cost sealant materials , copper or zinc alloy reduction, the effect of reducing resource consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

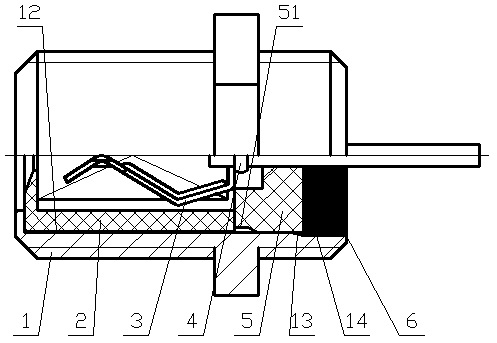

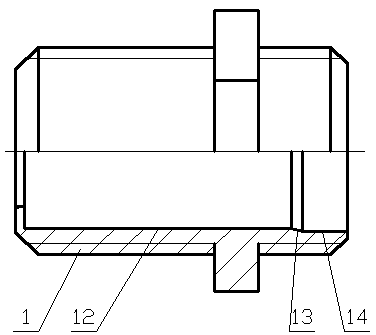

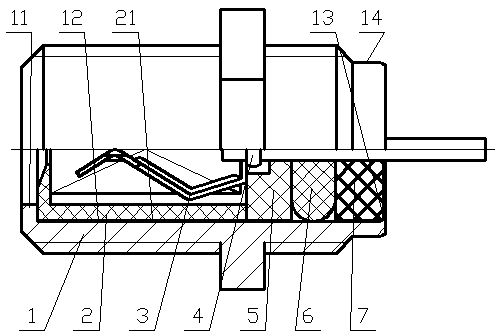

[0019] As shown in the figure, a coaxial radio frequency connector includes a housing 1, a central conductor is arranged inside the housing 1, and a front insulating part 2 and a rear insulating part 5 are respectively arranged on both sides of the central conductor. The insulators 5 are nested at both ends of the center conductor one by one, the front insulator 2 and the rear insulator 5 are embedded in the housing 1; the outer end of the rear insulator 5 is sealed by a sealant 6; the center conductor is formed by a contact spring 3 and PIN pin 4 are connected by riveting or welding. The rear side of the central conductor is fitted with a rear insulator 5, and the front side is fitted with a front insulator 2. The front insulator 2 and the rear insulator 5 are fitted with a central conductor and then embedded into the shell. 1, the rear insulator 5 and the inner hole of the housing 1 are installed through interference fit; there is a certain distance between the outer end surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com