Patents

Literature

310results about How to "Reduce time wasted" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pharmaceutical product manufacturing execution system and method

InactiveCN104808639AImprove development efficiencyImprove maintainabilityTotal factory controlProgramme total factory controlDatabase serverManufacturing execution system

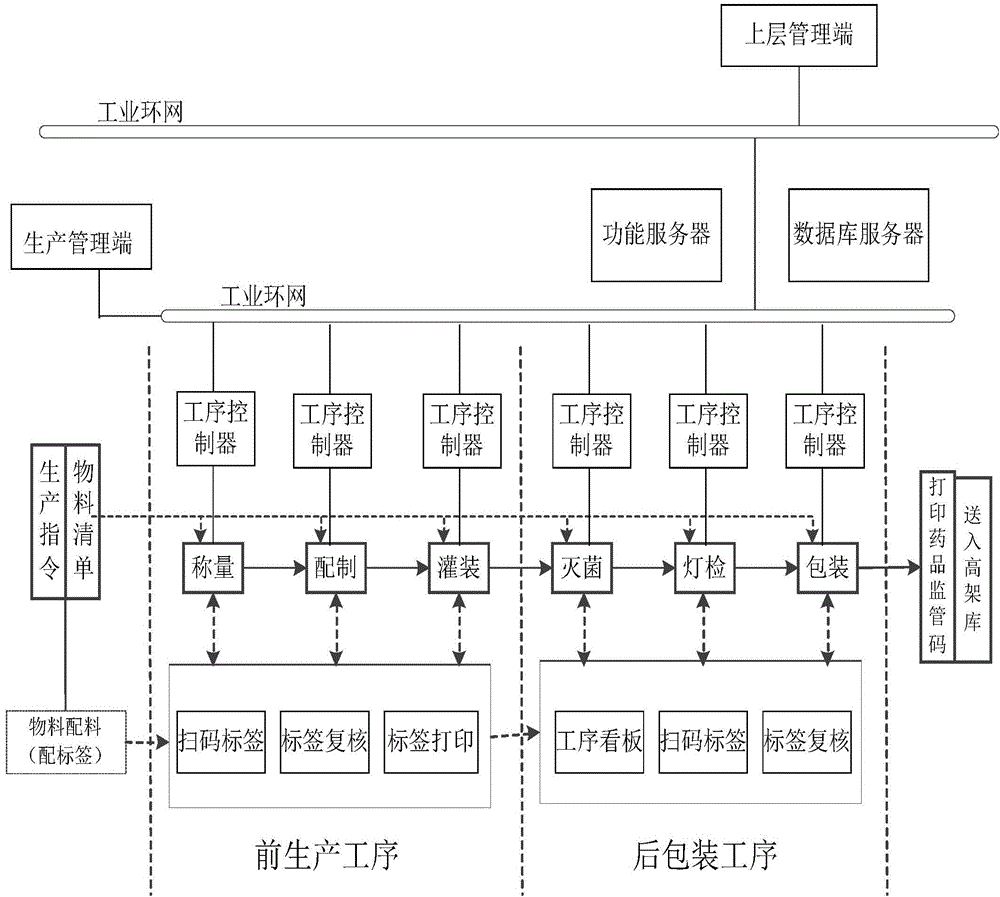

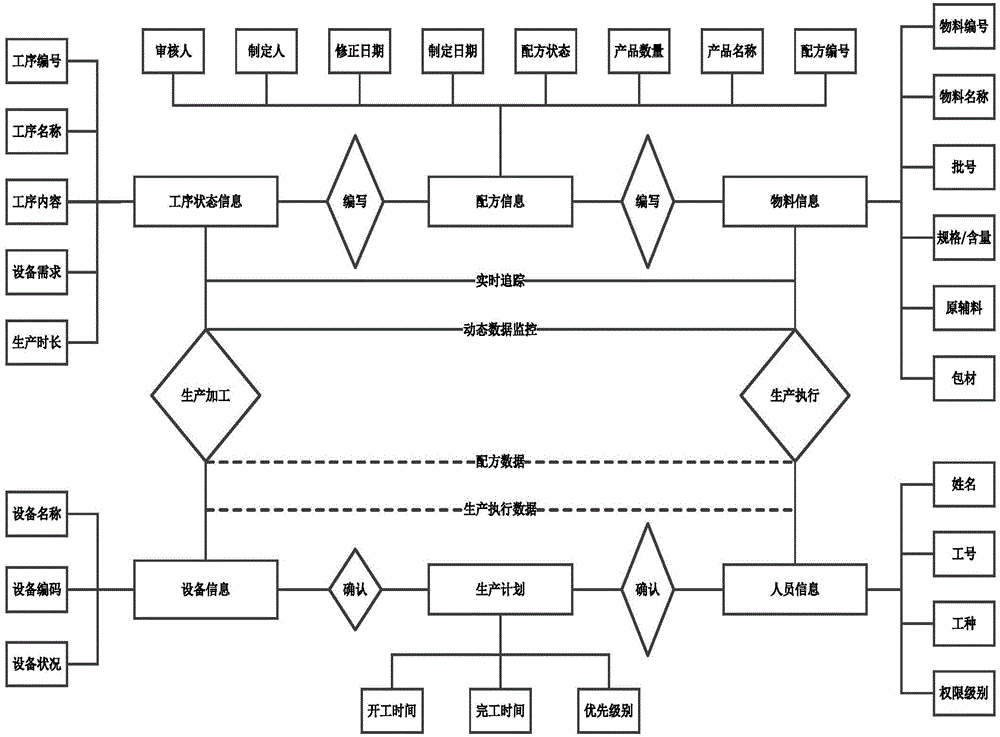

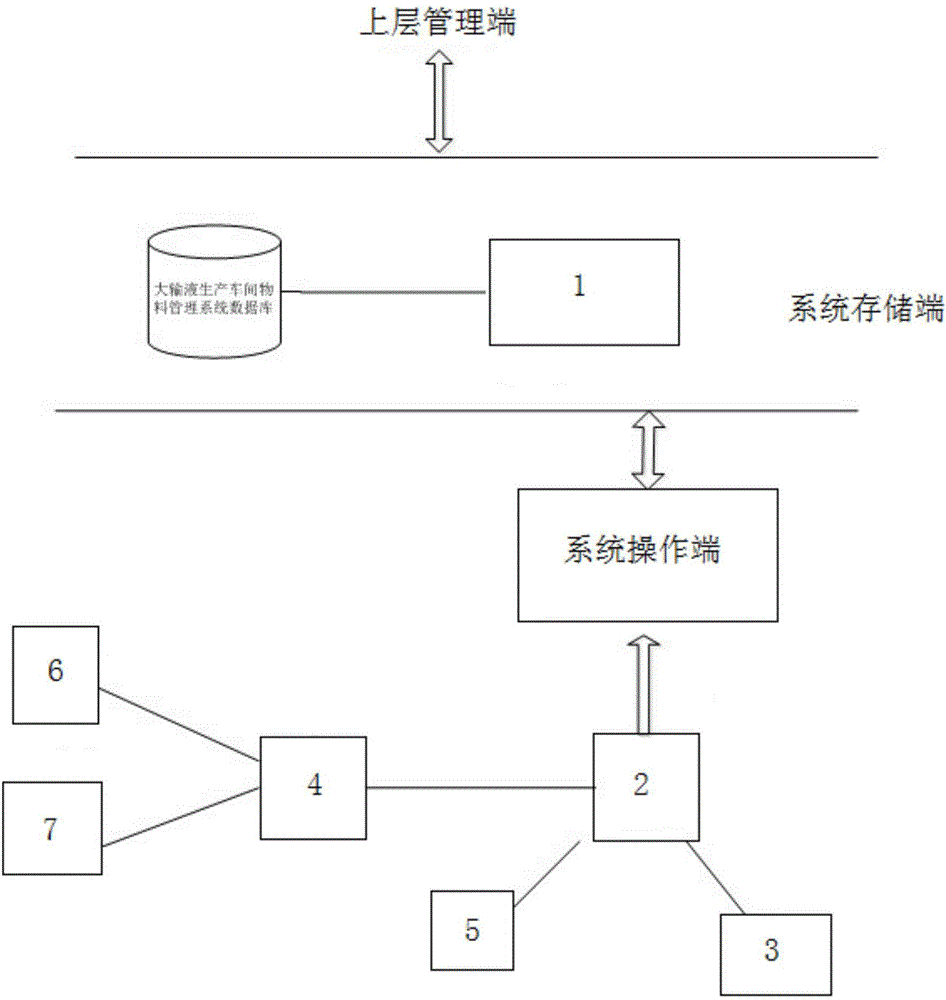

The invention discloses a pharmaceutical product manufacturing execution system and method. The method includes connecting a manufacturing execution system function server and a manufacturing execution system database server to an upper-level management terminal through an industrial loop network; allowing the manufacturing execution system function server to perform data exchange with a production management terminal through the industrial loop network; allowing the production management terminal to connect to a bottom procedure controller through the industrial loop network; allowing the production management terminal to receive a production planning instruction from the upper-level management terminal, divide the production planning instruction into a production instruction and a material list and transmit the production instruction to the bottom procedure controller, and allowing the bottom procedure controller to control corresponded production procedures and acquire staff producing operation information and corresponded equipment information. The method has the advantages that the corresponded material is encoded correspondingly and respectively, the workshop producing material data management and tracking are implemented, the statistical graph and report support is provided, and the material management is simplified.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

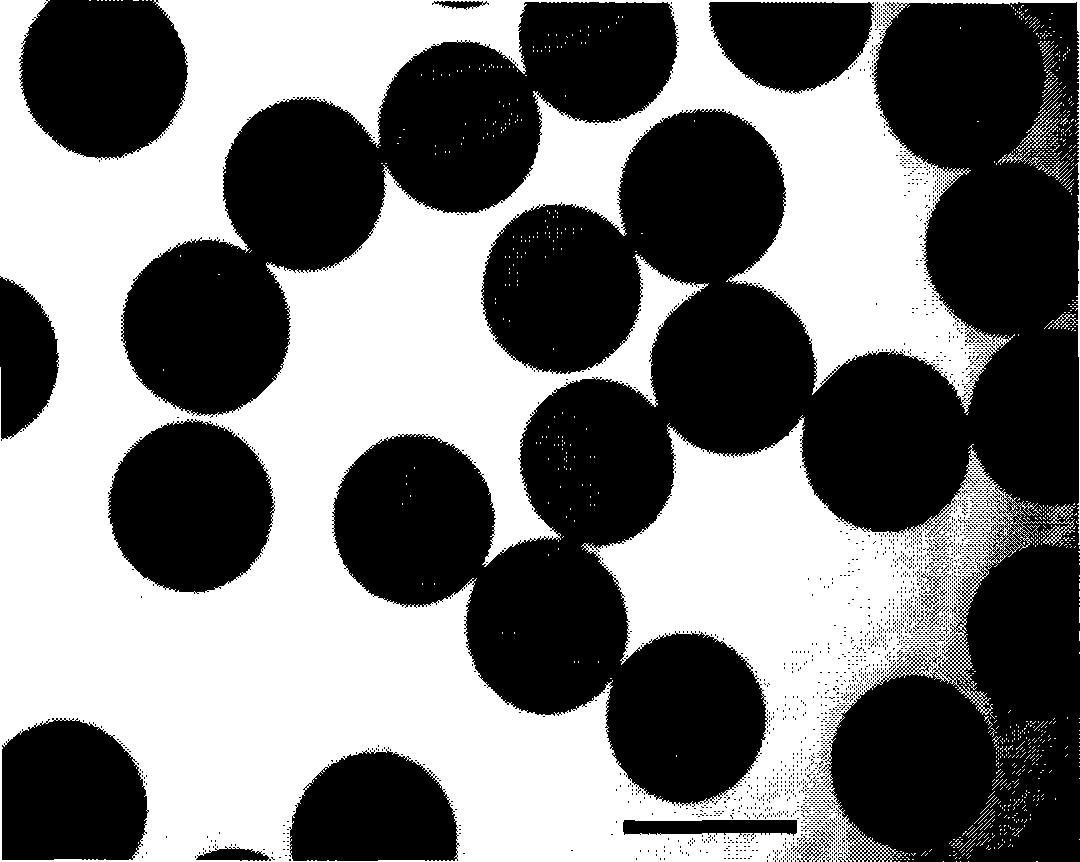

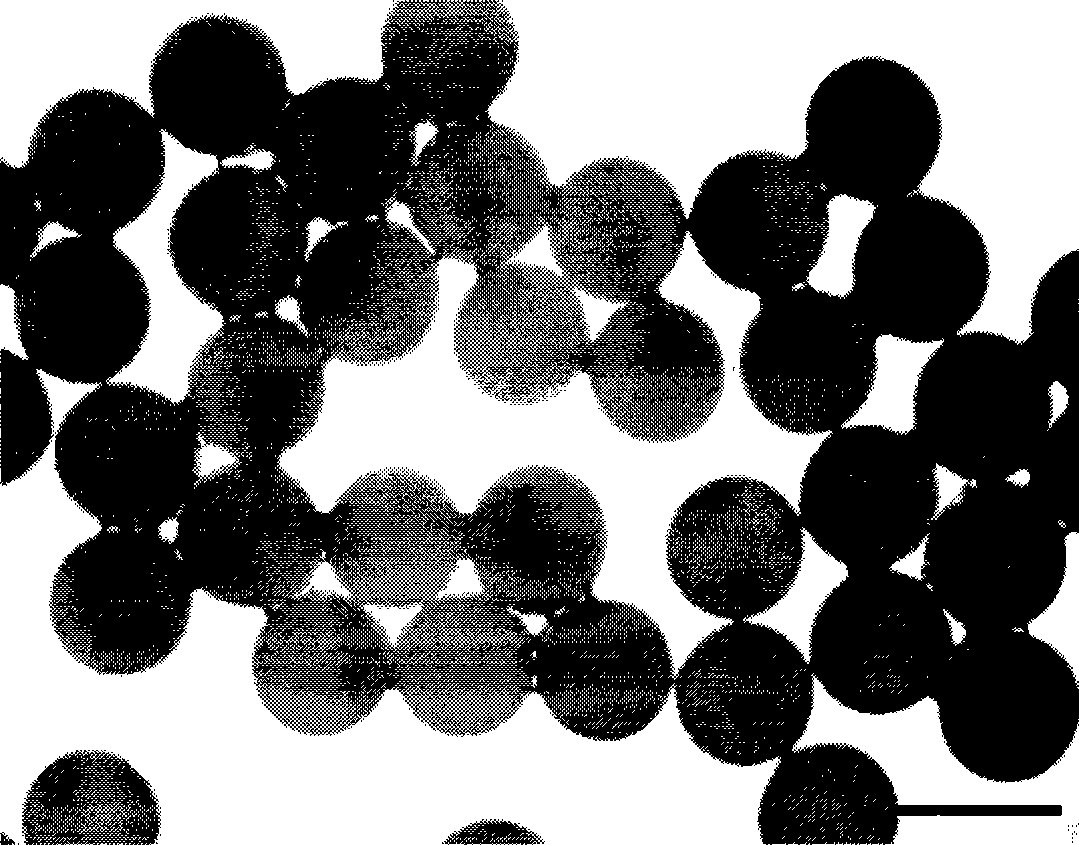

Method for preparing monodisperse polylactic acid microsphere

The invention relates to a preparation method of monodisperse polylactic acid (PLA) microballoon spheres, which includes: (1) the PLA is dissolved in methylene dichloride so as to be taken as a dispersed phase and polyvinyl alcohol is dissolved in water so as to be used as a continuous phase; (2) two solutions are respectively put into injectors and the injectors are arranged on two boost pumps and connected with a microchannel reactor, and then the flow velocities of the dispersed phase and the continuous phase are adjusted to ensure that liquid drops with uniform size are continuously generated at the joint of the two phases; (3) the generated liquid drops are collected in the aqueous solution of the polyvinyl alcohol and a variable frequency oscillator is adopted to assist the volatilization of a solvent so as to ensure that the liquid drops are solidified to spheres; and (4) the spheres are washed by ionized water for a plurality of times and arranged in an oven for drying to obtain the monodisperse PLA microballoon spheres. The monodisperse PLA microballoon spheres prepared by the invention have a smooth surface and a particle size ranging from 200 Mum to 1000 Mum; a reaction device has simple and easy preparation process and controllable dimension of microchannels. The size of the prepared microballoon spheres can be conveniently adjusted and controlled and the variable frequency oscillator is adopted for quickening the solidification process of the PLA microballoon spheres, with low cost and less time consumption.

Owner:DONGHUA UNIV

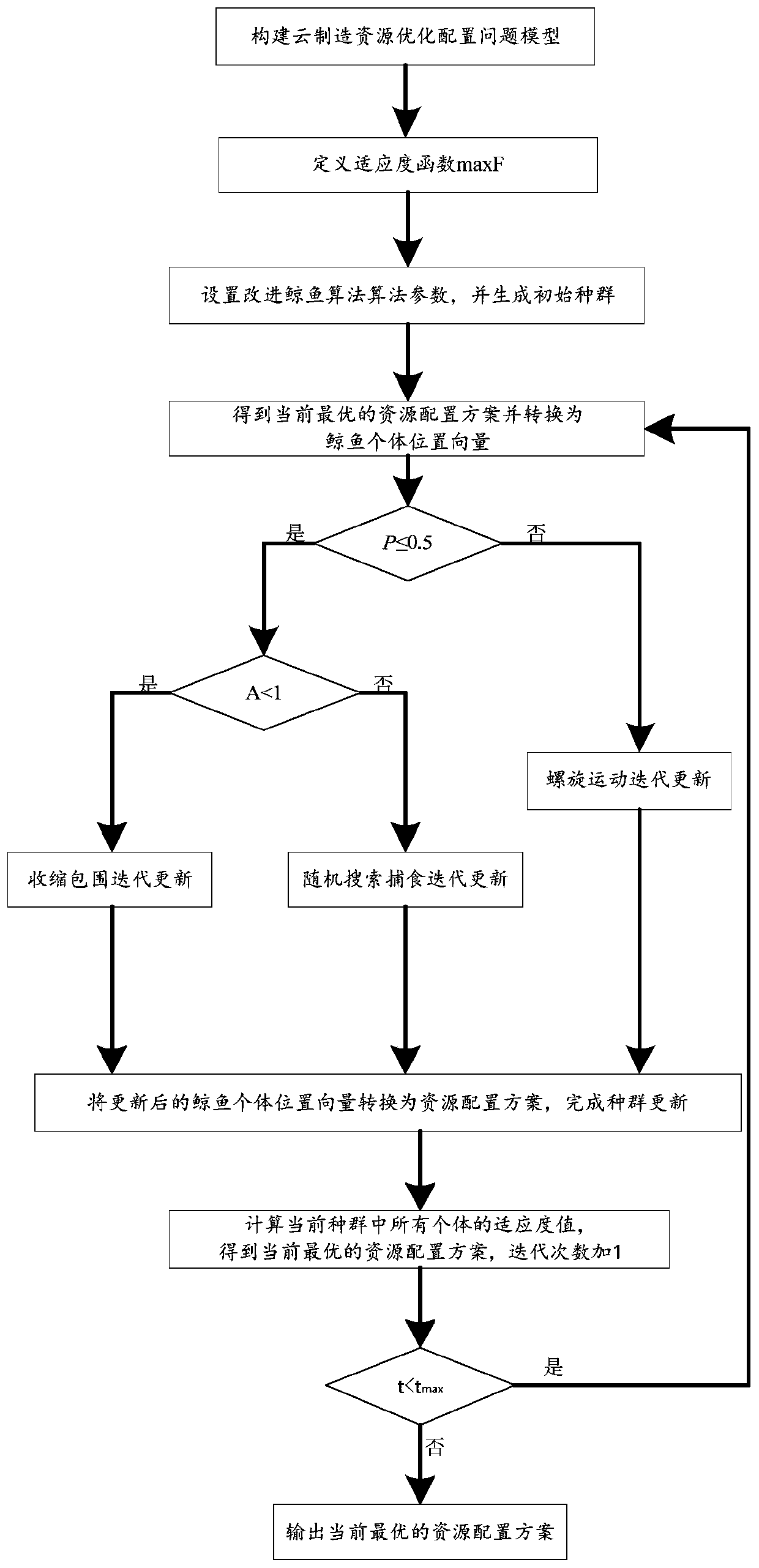

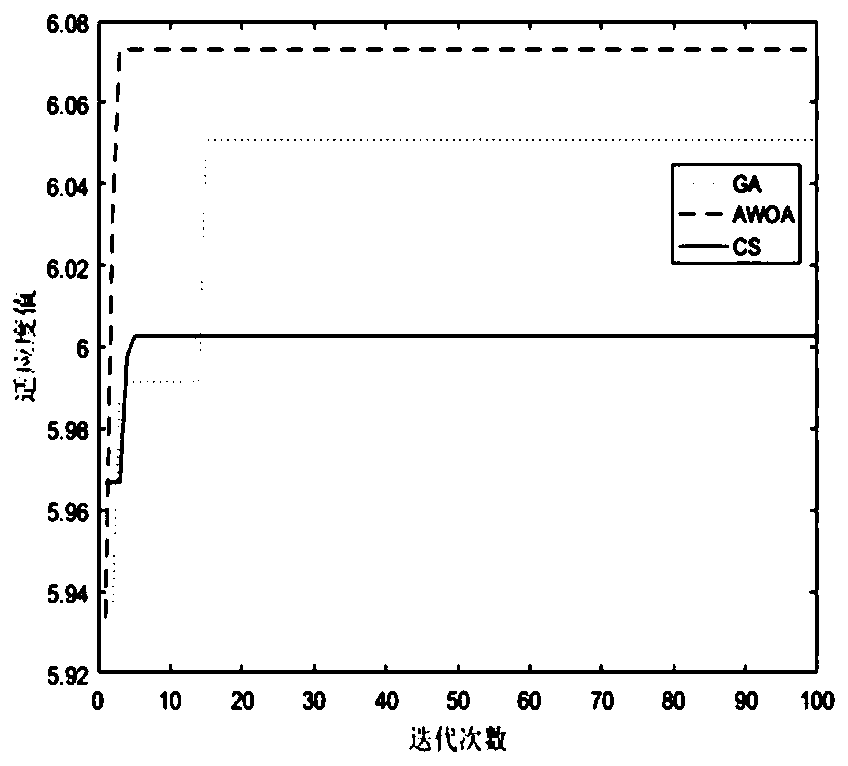

A cloud manufacturing resource configuration method based on an improved whale algorithm

PendingCN109902873AImprove local search capabilitiesImprove convergence accuracyForecastingBiological modelsPredationAlgorithm convergence

The invention discloses a method for cloud manufacturing resource optimization configuration based on an improved whale algorithm, and the method comprises the steps: building a problem model, and defining a fitness function; setting improved whale algorithm parameters, and generating an initial population; Calculating fitness values of all individuals in the population, obtaining a current optimal resource allocation scheme and converting the current optimal resource allocation scheme into whale individual position vectors; Introducing a parameter p, and judging whether p is less than or equal to 0.5; If not, performing spiral motion iteration updating to complete population updating; If yes, whether the value A (1) of the coefficient vector of the improved whale algorithm is met or not is judged; If yes, performing shrinkage encircling iteration updating; If not, performing random search predation iteration updating; Obtaining a current optimal resource configuration scheme; Adding 1to the number of iterations, and judging whether the current number of iterations is smaller than the maximum number of iterations; If yes, repeating the operation; And if not, outputting the currentoptimal resource configuration scheme. The whale algorithm is improved, so that the algorithm convergence speed is higher, the optimal solution is easier to achieve, and a new method is provided forsolving the problem of resource allocation.

Owner:CHANGAN UNIV

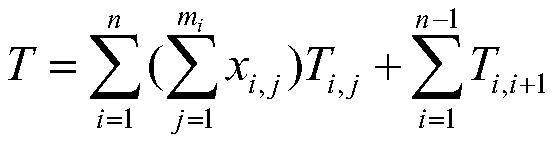

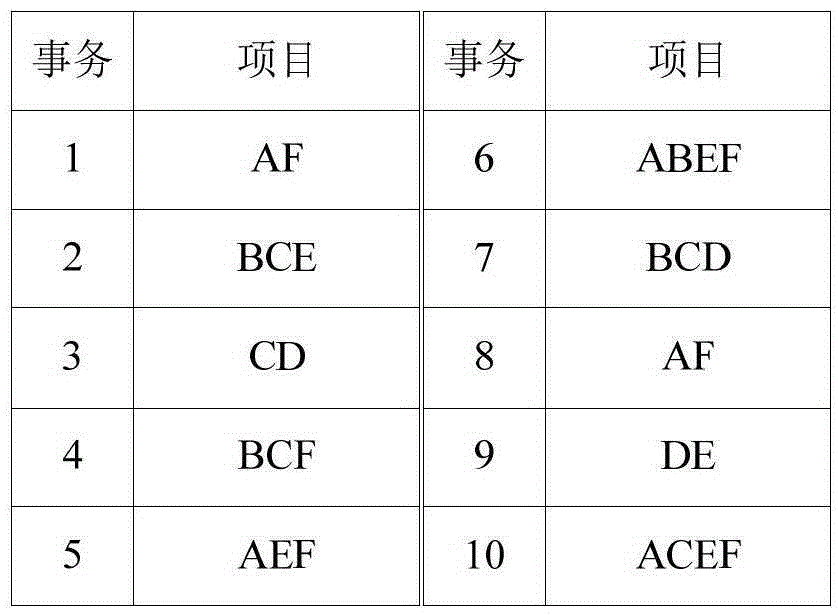

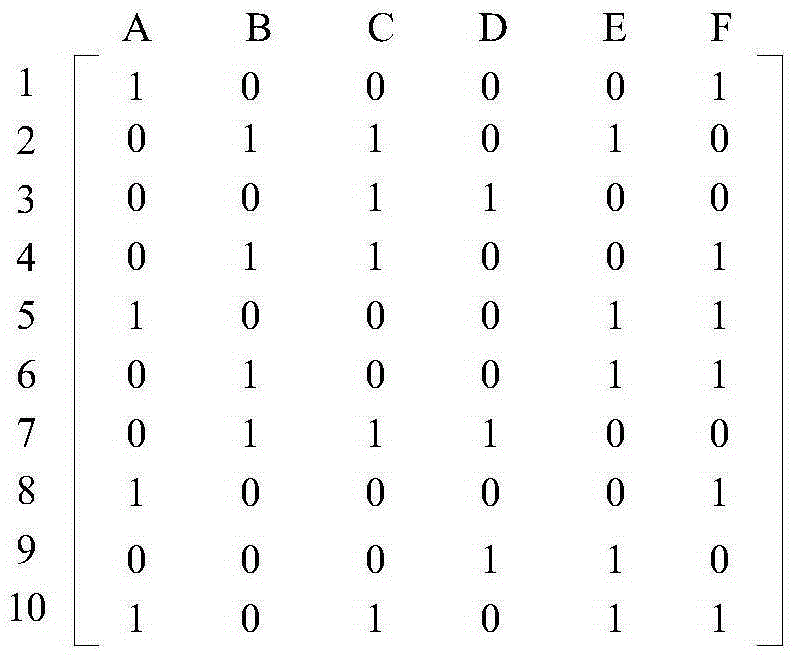

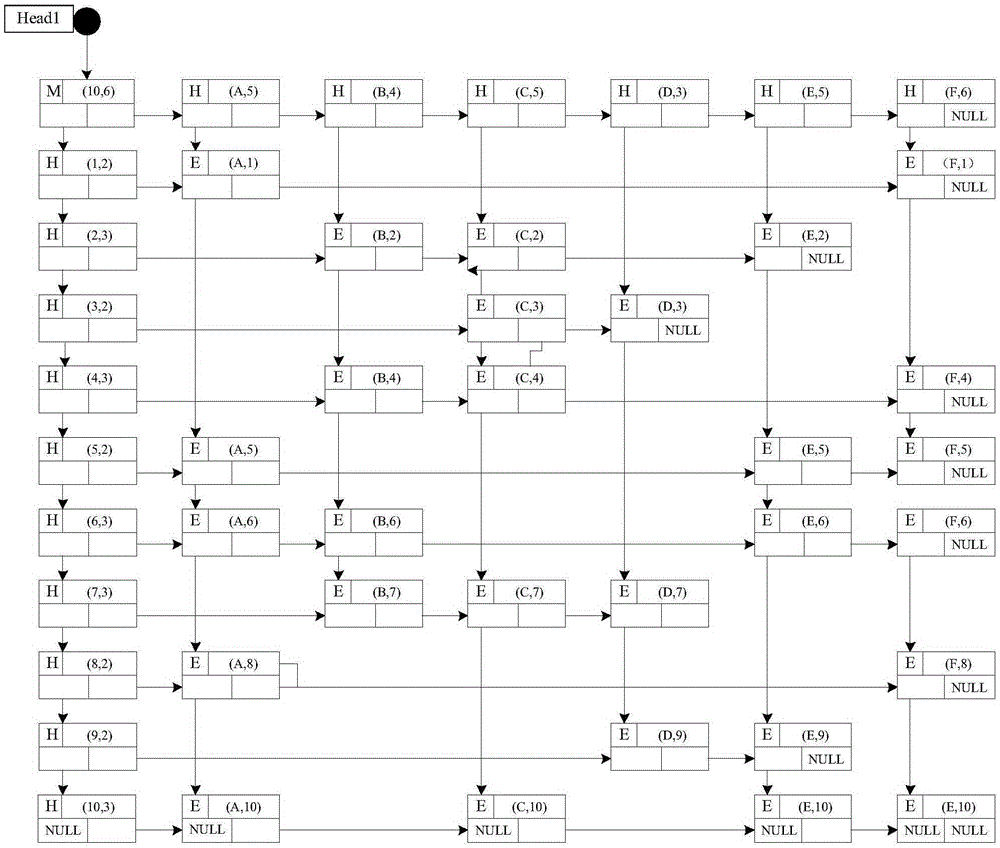

Improved Apriori algorithm based method for mining database association rule

ActiveCN105320756AReduce space complexityReduce demandRelational databasesSpecial data processing applicationsGeneration processRule mining

The present invention proposes an improved Apriori algorithm based method for mining a database association rule. According to the method, a transaction database is converted into a relational matrix, the converted relational matrix is a sparse matrix, and the relational matrix is stored with an orthogonal link list. A generation process of a frequent item set is converted into an operation process of a single link list node set corresponding to items in the corresponding relational matrix. According to the method, a database only needs to be scanned once, so that the shortcomings that Apriori and a related algorithm therefor generate a large amount of candidate sets and need to scan the database for multiple times are overcome, and the time of frequently performing I / O operations is shortened; then, when a frequent 2-item set is generated and found, only an intersection operation of a node set needs to be performed, so that less time is consumed; and a single link list constructed by a generated frequent k-item set is recorded, so that a generation process of a frequent K+1-item set is simplified, and a complex pruning process of the Apriori algorithm is avoided.

Owner:CHINA INFOMRAITON CONSULTING & DESIGNING INST CO LTD

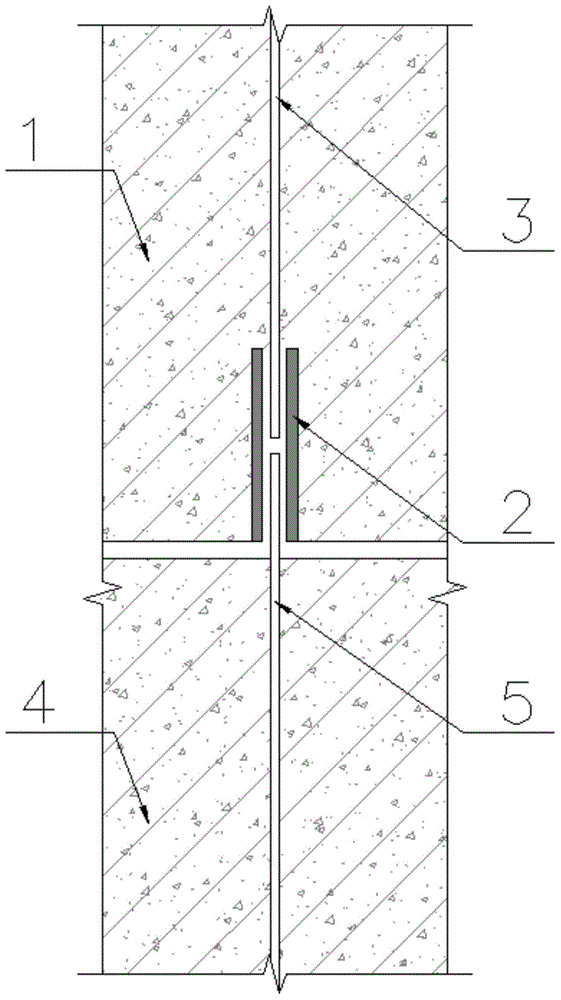

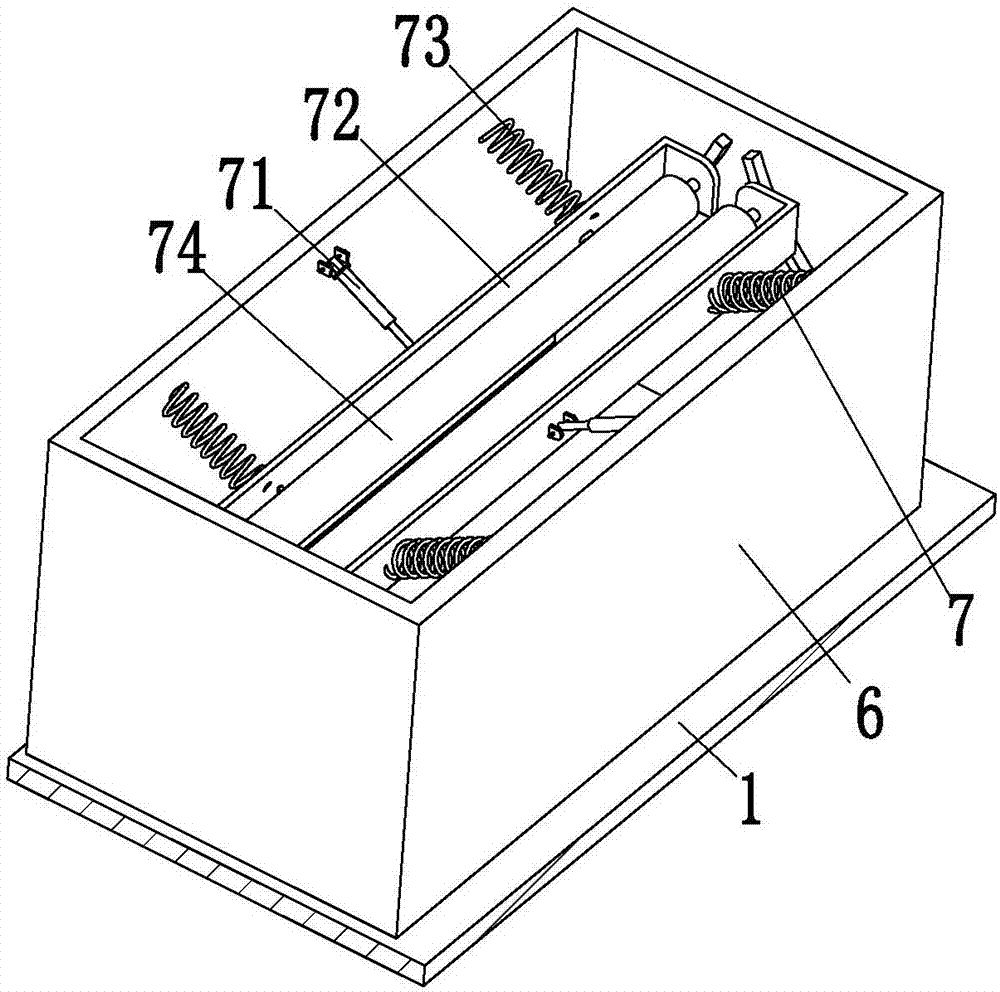

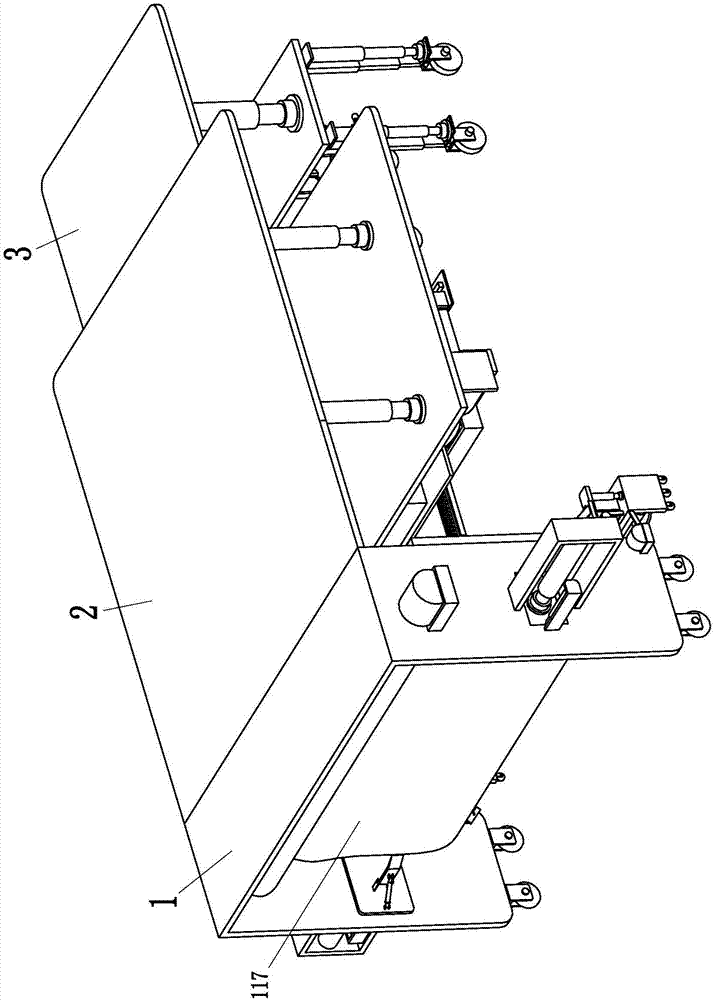

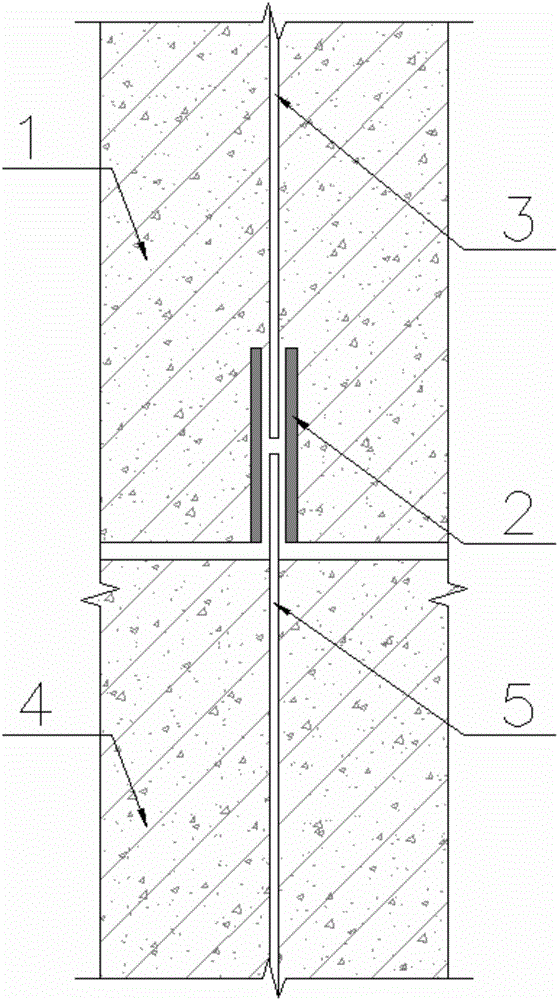

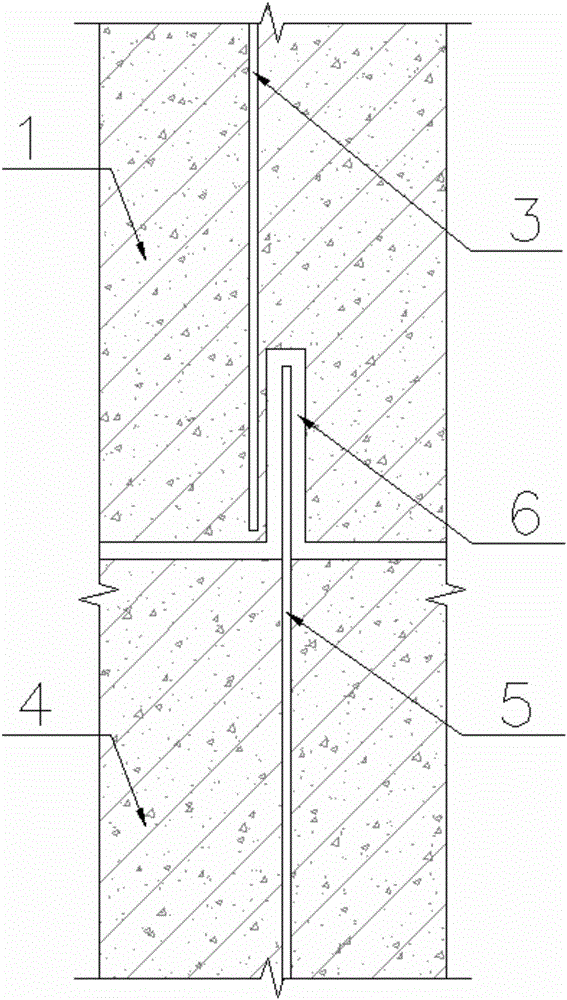

Prefabricated shear wall horizontal abutted seam buckle welding built-up connection device

The invention discloses a prefabricated shear wall horizontal abutted seam buckle welding built-up connection device. An upper anchor plate clings to the bottom surface of an upper prefabricated shear wall, and the top of the upper anchor plate is provided with upper horizontal reinforced bars and connected with bottom ends of upper connecting reinforced bars; the upper connecting reinforced bars are arranged in the upper prefabricated shear wall; the upper portion of a vertical connecting plug pin is located in the upper prefabricated shear wall and connected with the upper connecting reinforced bars, the lower portion of the vertical connecting plug pin protrudes out of the bottom surface of the upper prefabricated shear wall, and the bottom end of the same is an expanded head; a lower anchor plate clings to the top face of a lower prefabricated shear wall and connected with the top ends of lower connecting reinforced bars; connecting blocks are arranged inside a connecting groove box in pairs, opposite protruding snag teeth are arranged at the top ends of the connecting blocks, and the bottom ends of the connecting blocks are connected with the bottom of the connecting groove box through hinges; pressure springs are arranged between the connecting blocks and the inner wall of the connecting groove box. The connecting device can bear shear force, bending moment and tension and pressure, the prefabricated shear wall assembly process is simplified, construction period is shortened, labor cost is reduced, and on-site pollution and material waste are reduced.

Owner:ARCHITECTURAL DESIGN & RES INST OF SOUTH CHINA UNIV OF TECH

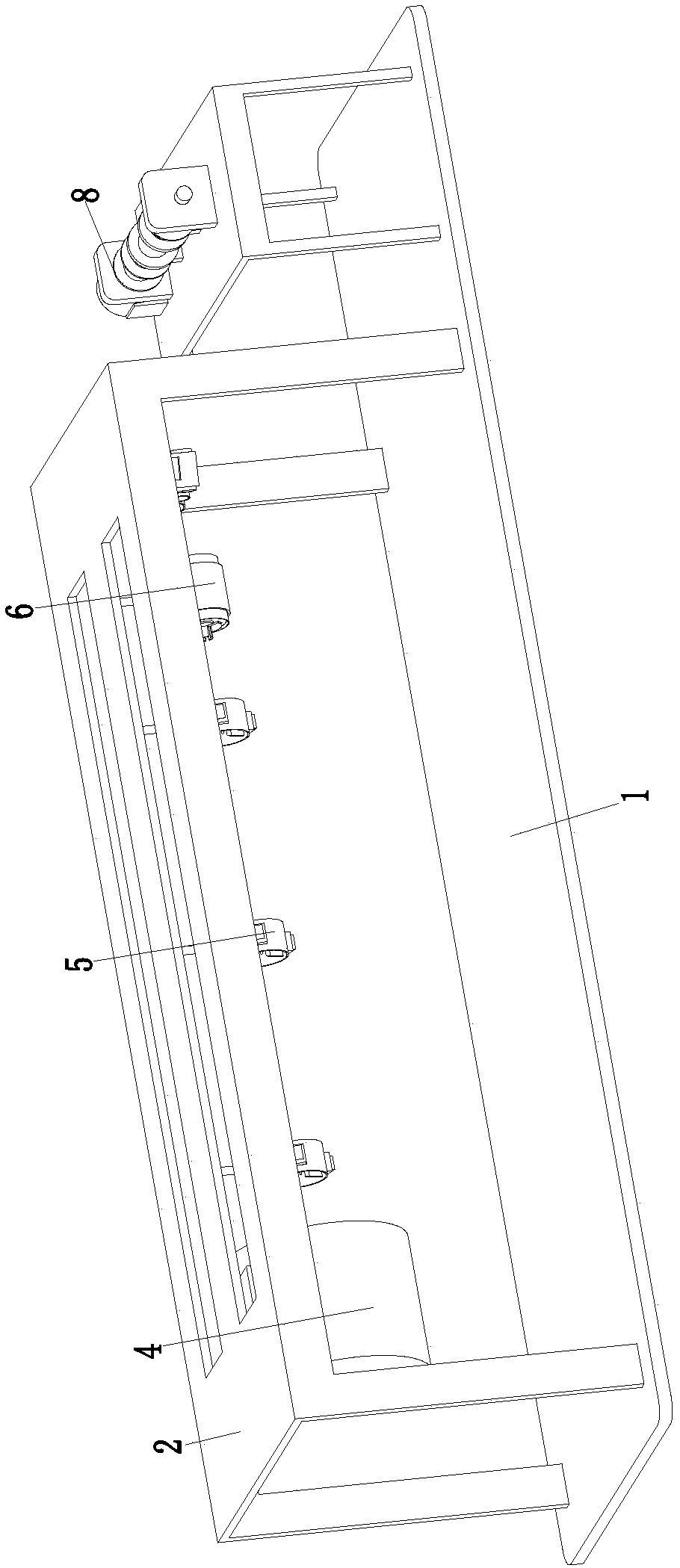

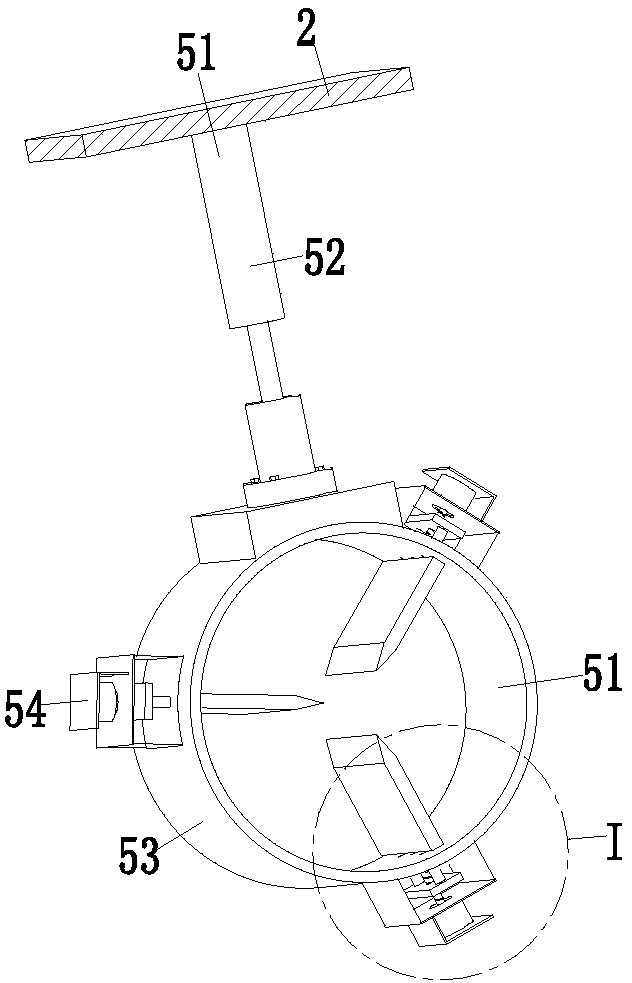

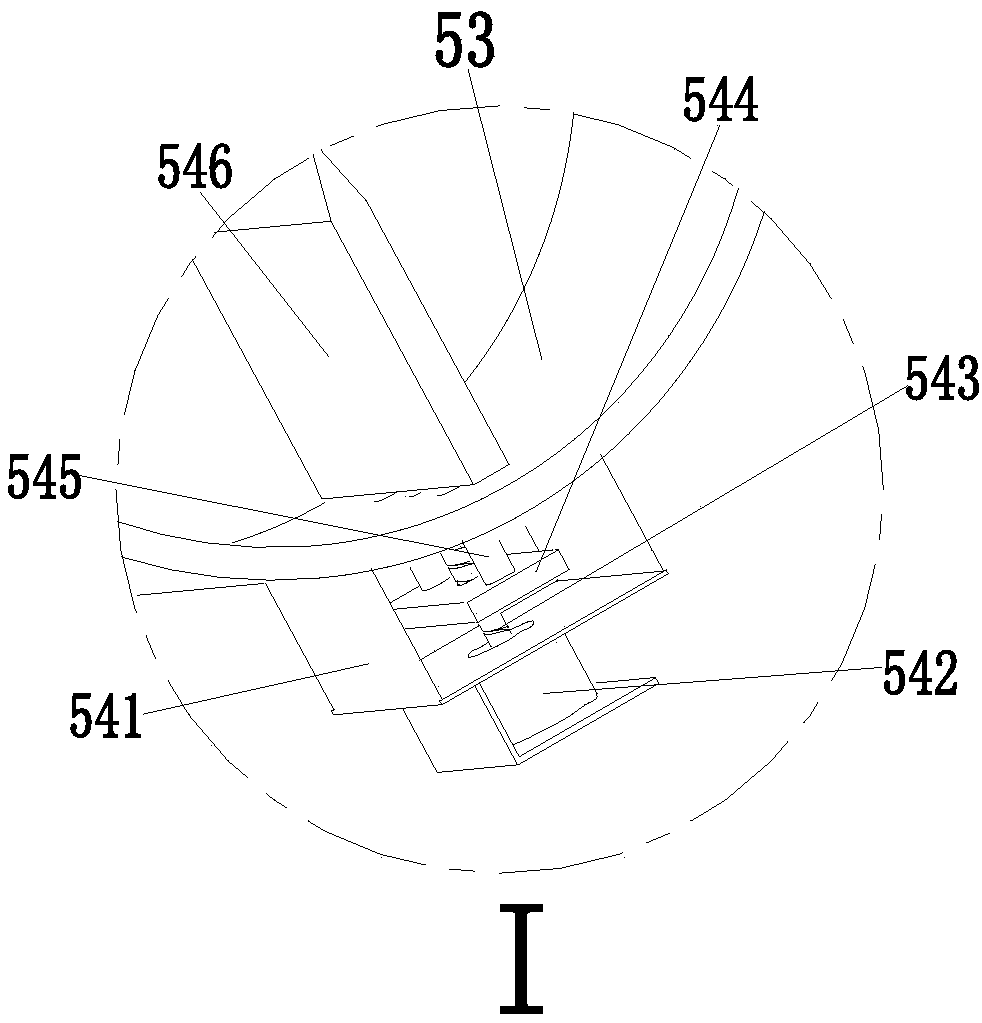

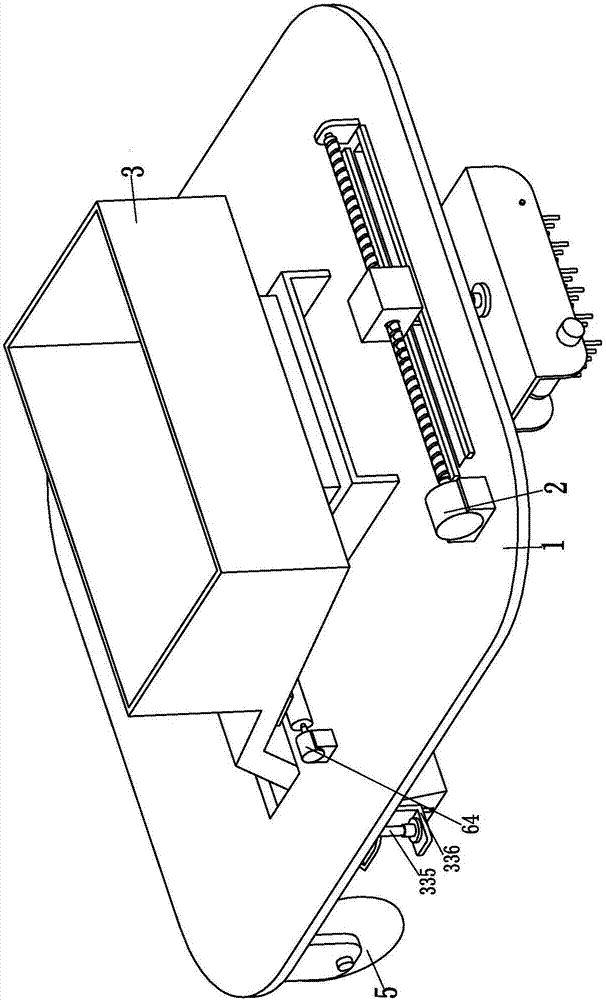

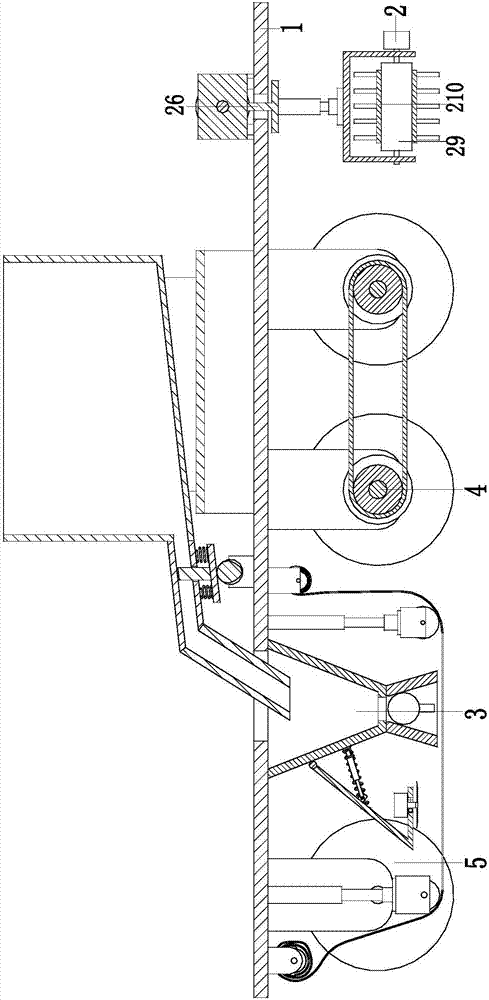

High-efficiency stripping device for insulator of electric power communication cable conductor

InactiveCN107706836AAct as a guideReduce labor intensityApparatus for removing/armouring cablesPower efficientEngineering

The invention relates to a high-efficiency stripping equipment for electric and communication cable insulators, which includes a bottom plate, a cutting support frame is installed on the bottom plate, and the lower end of the cutting support frame is sequentially installed with an adjusting skinning device, a dividing device and a stripping and separating device, and the bottom plate A winding device is installed on the cable, and the present invention can solve the problem that the manual peeling method in the cable recycling process needs to manually peel off the insulator on the cable, and the efficiency of manual stripping of the insulator on the cable is low. The internal structure of the cable insulator cannot be reused, and the gas generated during the incineration process seriously pollutes the environment. The cable is composed of a variety of coils, and different coils need to be wound manually, which takes time. Long length, high labor intensity and low work efficiency, etc., can realize the function of efficient stripping of cable insulation.

Owner:倪菊莲

Fast air drying-type LCD screen automatic cleaning equipment

ActiveCN107030034AReduce labor intensityDecrease productivityDrying gas arrangementsCleaning using toolsEngineeringUltimate tensile strength

The invention relates to fast air drying-type LCD screen automatic cleaning equipment which comprises a base plate. A waterproof isolating device is installed on the base plate. A wiping device is installed at the front end of the base plate. A water tank is installed in the middle of the base plate. Two extrusion water control devices are symmetrically arranged inside the water tank. The waterproof isolating device, the wiping device and the extrusion water control devices are matched for use to complete an automatic cleaning technology of an LCD screen. The fast air drying-type LCD screen automatic cleaning equipment can solve the problems that in an existing LCD screen cleaning process, a waterproof material needs to be manually used to isolate the LCD screen from other mechanisms of liquid crystal equipment, the LCD screen needs to be manually cleaned, water control needs to be conducted on cleaning tools manually, moisture can permeate into the liquid crystal equipment easily to cause damage, time consumption is large by means of manual water controlling, the labor intensity of manual cleaning and wiping is high, the cleaned and wiped LCD screen is dried manually, and working efficiency is low; and the function of automatically cleaning the LCD screen can be achieved.

Owner:南通北外滩建设工程有限公司

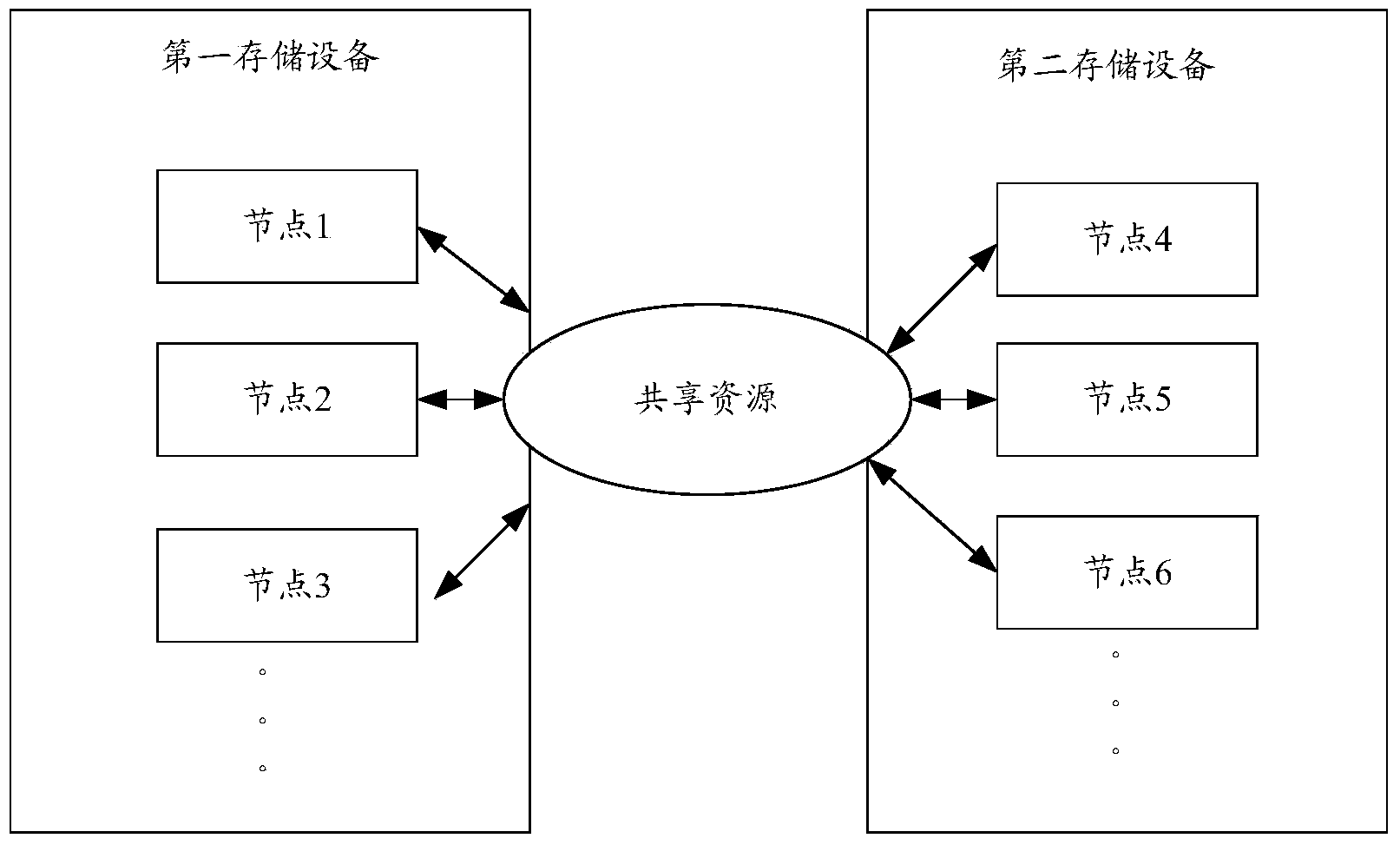

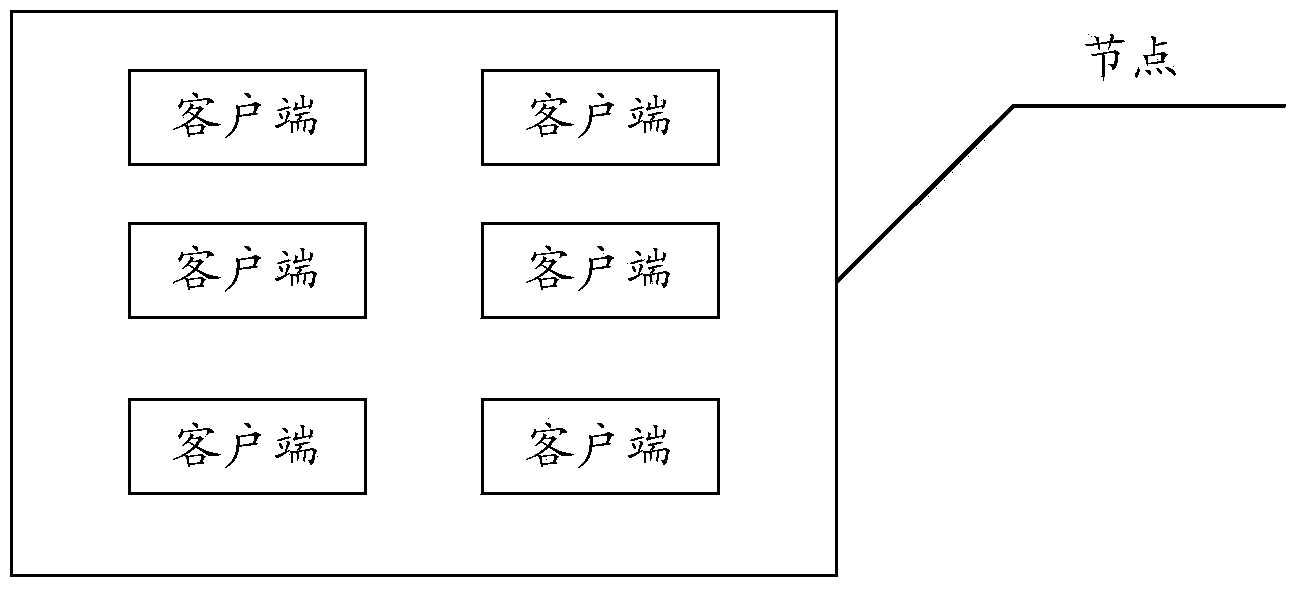

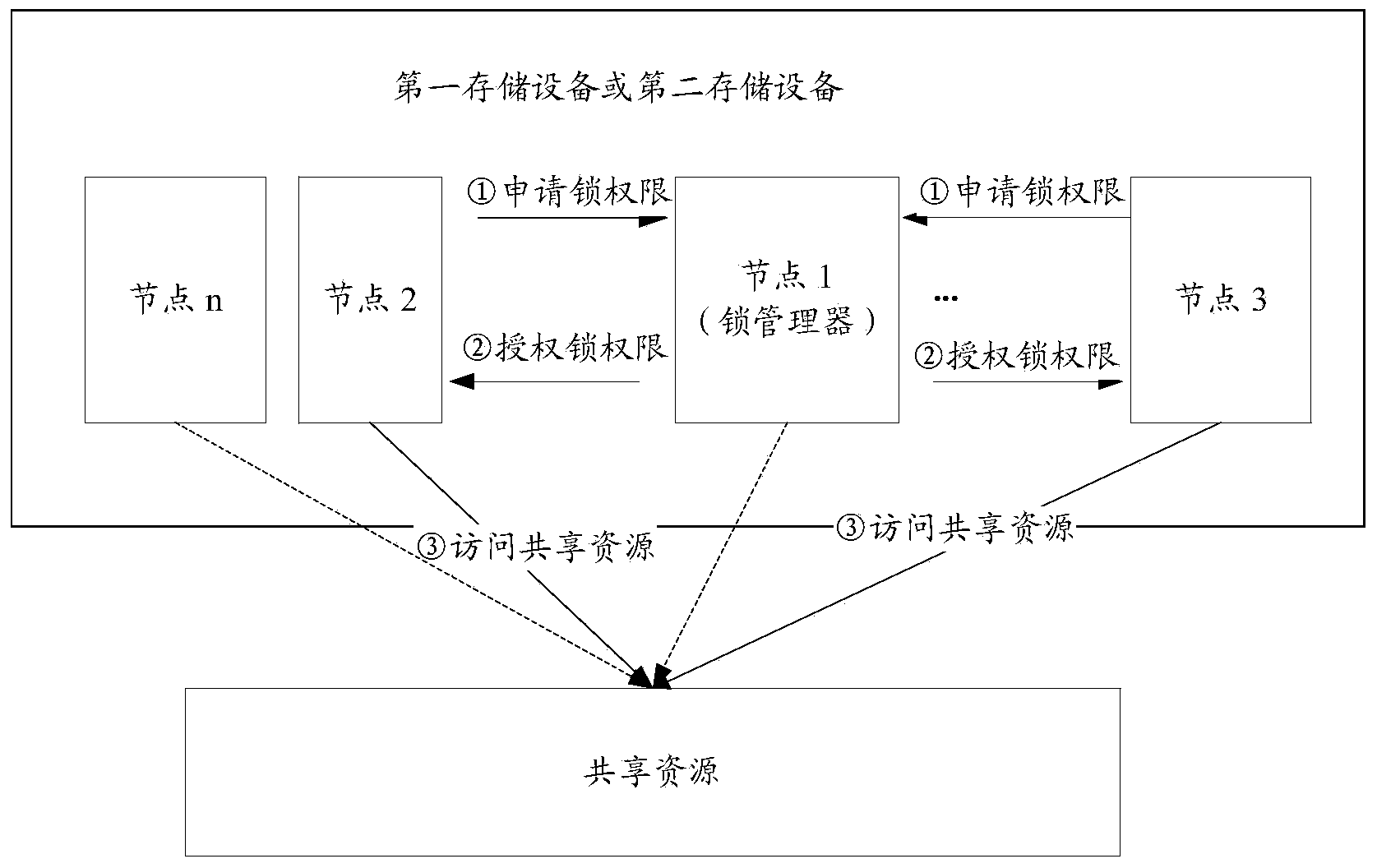

Method and device for accessing shared resources

ActiveCN103716383AReduce time wastedShorten the timeProgram controlTransmissionShared resourceTime-Consuming

The invention relates to the field of data communication and discloses a method and a device for accessing shared resources. According to a scheme described in the embodiment of the invention, after receiving a permission lock request sent by a client of a first node, the first node forwards the permission lock request only when a lock identifier including an identifier of shared resource is not found in the first node, that is to say, whether the lock identifier including the identifier of the shared resource exists in the first node is queried first, the permission lock request is forwarded only when the lock identifier including the identifier of the shared resource does not exist in the first node, and the permission lock request is directly allocated when the lock identifier including the identifier of the shared resource exists in the first node. The time for the client to acquire the lock identifier from the first node is less than the time for the client to acquire the lock identifier from other nodes. Therefore, the problem that the existing method for accessing shared resources is highly time-consuming is solved.

Owner:HUAWEI TECH CO LTD

Architectural decoration device capable of automatically caulking indoor ceramic tile gaps

The invention relates to an architectural decoration device capable of automatically caulking indoor ceramic tile gaps. The architectural decoration device comprises a facing device, a gluing device,and an edge pressing device; the front end of the gluing device is provided with the facing device, and the rear end of the gluing device is installed at the front end of the edge pressing device. Thearchitectural decoration device capable of automatically caulking the indoor ceramic tile gaps solves the problems that when seams are traditionally ornamented, manual work is required to paste masking papers, and personnel need to inject glue and press edges by tools; when the masking papers are pasted, the personnel need to paste the masking papers manually, edges are pasted raggedly, and people may cut their hands during cutting the masking papers by the tools; during working, the papers may be folded, and the personnel need to straighten the folded masking papers to work; during gluing bya seam beauty agent, the personnel need to put a seam beauty agent in a seam ornamenting gun and then glue the gaps, and the personnel may cut the hands due to improper operation during cutting a rubber nozzle laterally; and during edge pressing, the personnel need to vigorously press the gaps after gluing by an edge pressing ball. The architectural decoration device capable of automatically caulking indoor the ceramic tile gaps can achieves the functions of automatic pasting paper, gluing, and edge pressing for ceramic tile gaps.

Owner:吴凡

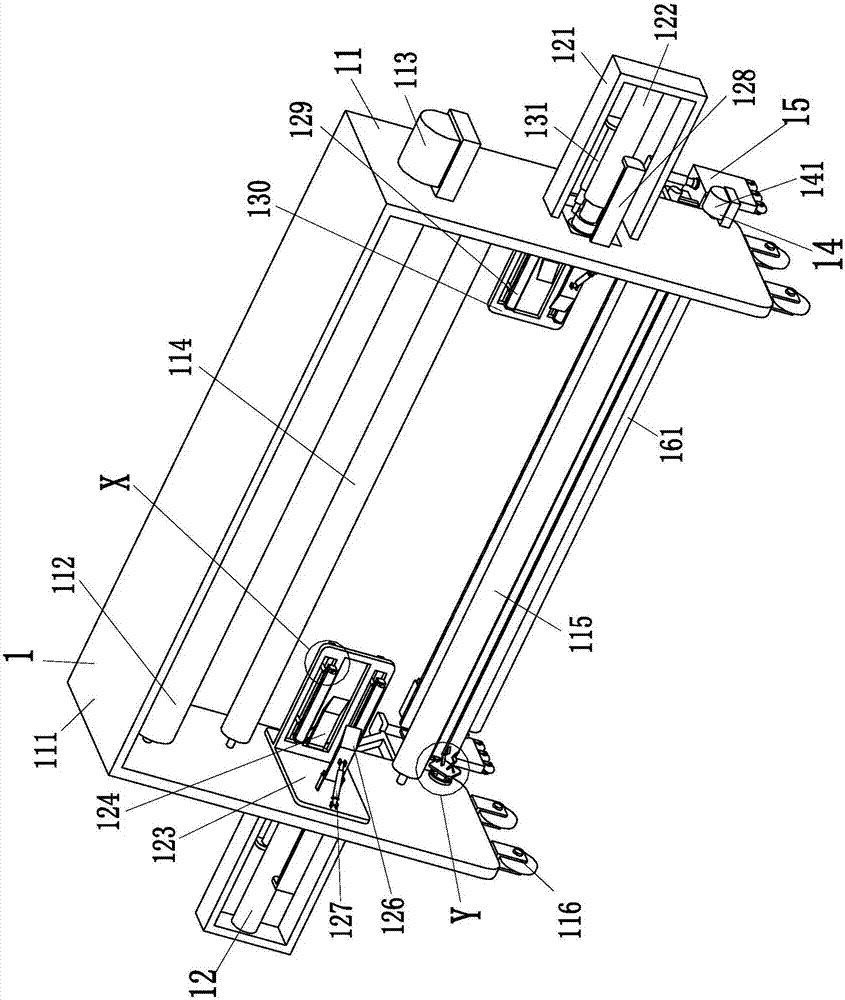

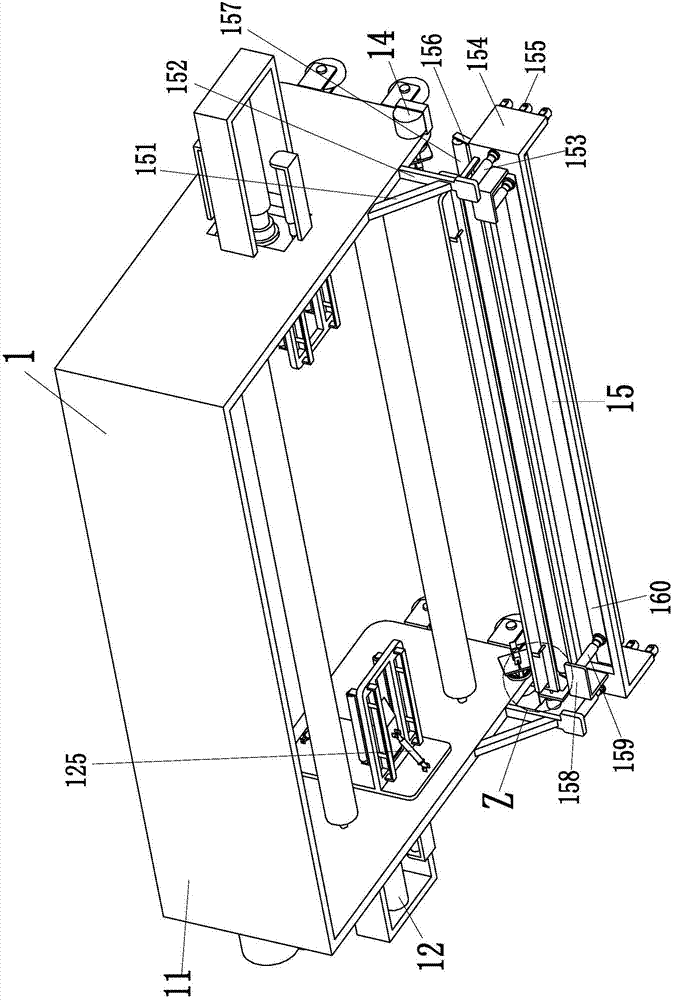

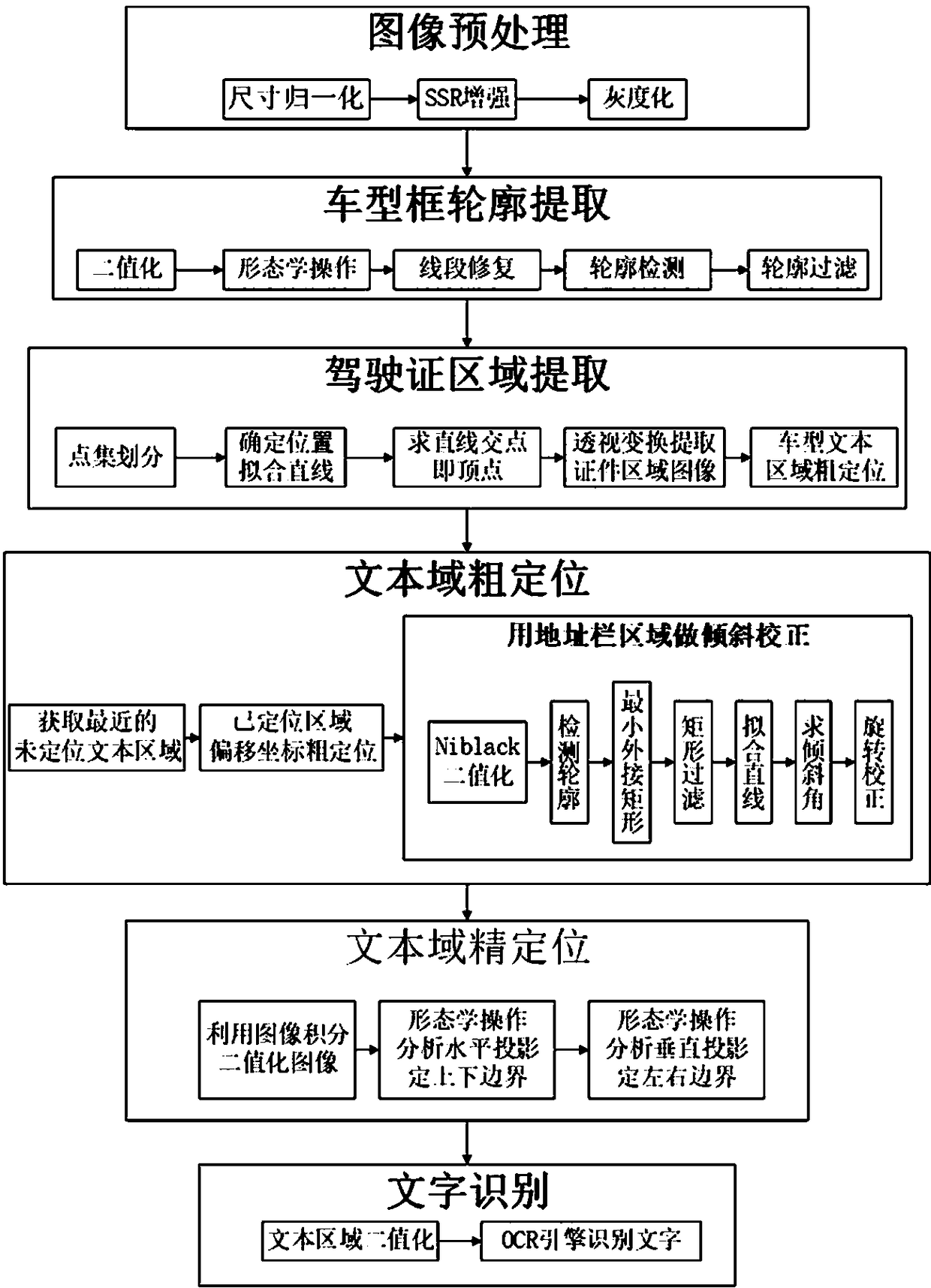

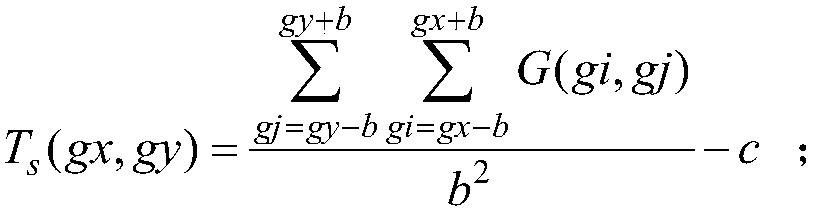

Driver license detection identification method based on internal feature and text field layout in complex scene

ActiveCN108427946AImprove robustnessFast processingCharacter and pattern recognitionCharacter recognitionLine segment

The invention provides a driver license detection identification method based on an internal feature and a text field layout in a complex scene, which comprises the following steps: firstly, preprocessing an image by using a technique of normalization and SSR enhancement and the like, repairing a frame of a vehicle model frame in the certificate by using morphological operation and line segment repair, obtaining the vehicle model frame contour through the contour detection and filtering, solving the intersection point of the fitting straight line to obtain the vehicle model frame vertex, and combining the standard driving license layout to obtain the driving license area image. Then, analyzing the integral projection information to perform accurate positioning on the position of the vehicle model text area, starting from the position, carrying out coarse positioning and fine positioning on the adjacent non-positioning area at each time to obtain a text area image, and performing tilt correction on the area above the address bar. Finally, combining a plurality of methods to binarize the text area, and identifying characters by using a special character recognition engine. The methodis quick and robust, can quickly and rapidly identify the captured images under various complex scenes, and has better practicability and higher application value.

Owner:FUZHOU UNIVERSITY

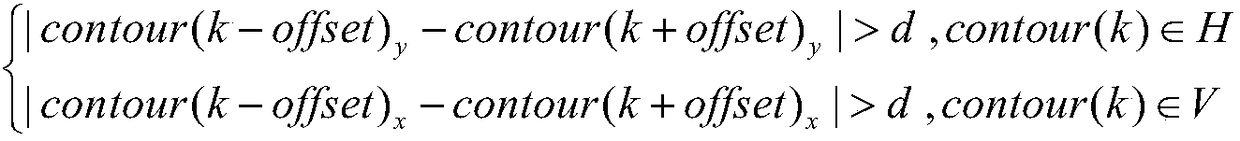

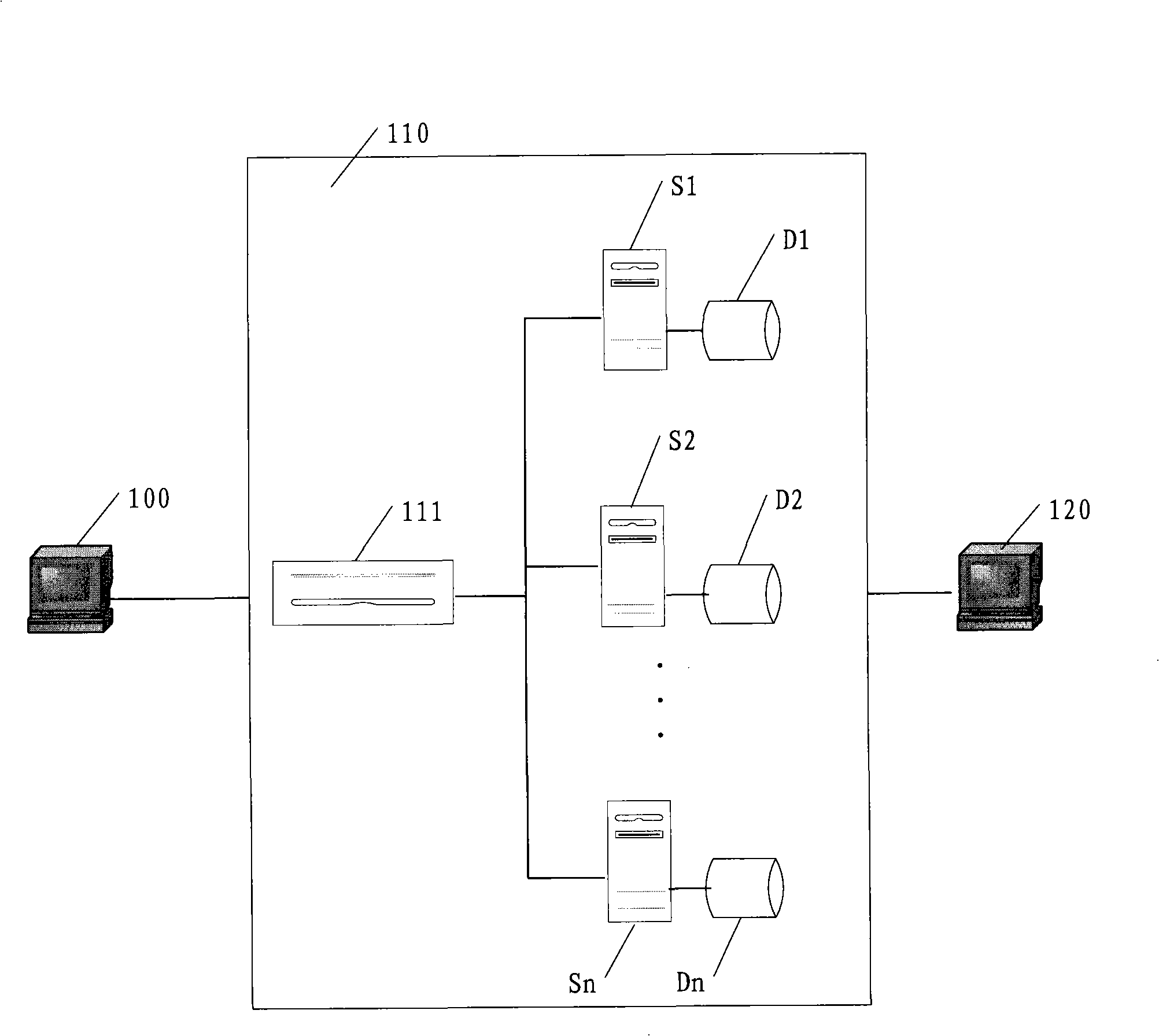

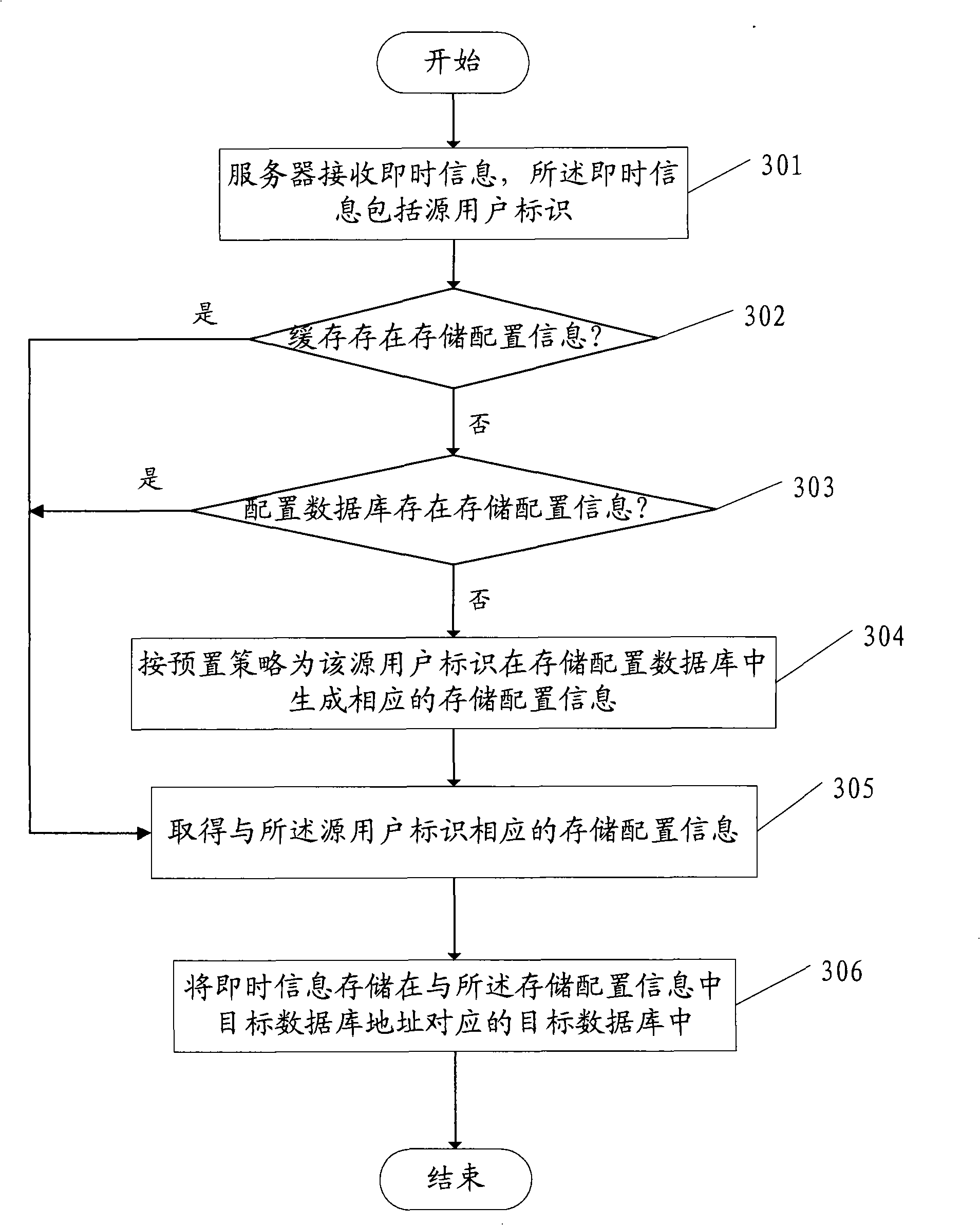

Method and system for storing instant information

InactiveCN101330431ASafety of tradementGood trade creditStore-and-forward switching systemsInformation storageData mining

The invention discloses an instant message storage method and a system thereof. The method comprises the following steps: receiving an instant message comprising user identification; acquiring storage allocation information corresponding to the user identification, which comprises a target database address; storing the instant message in a target database corresponding to the target database address. In this way, instant messaging records related to a user are stored in the target database corresponding to the user identification in a centralized manner, so as to avoid the problems such as low searching efficiency and high cost in the prior art caused by traversing each server in a cluster in order to acquire the instant messaging records of the user, and prevent the server performance from being affected thereby.

Owner:ALIBABA GRP HLDG LTD

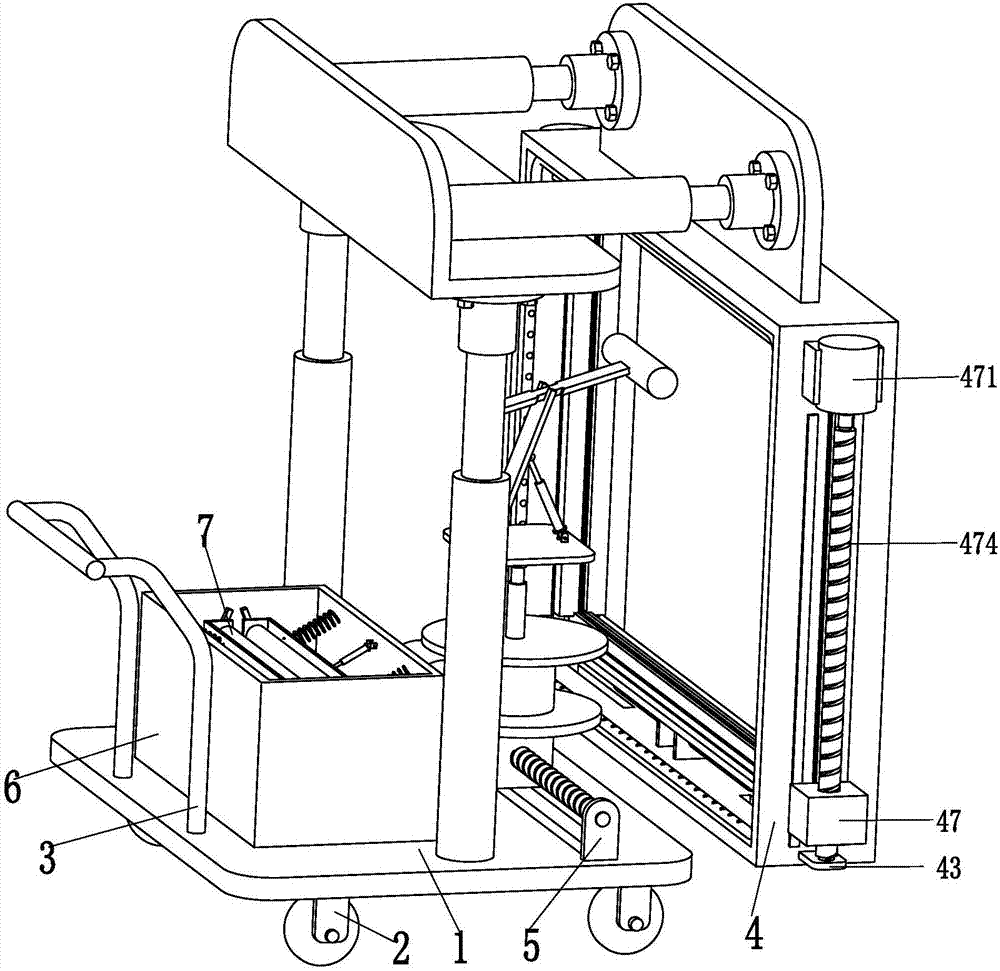

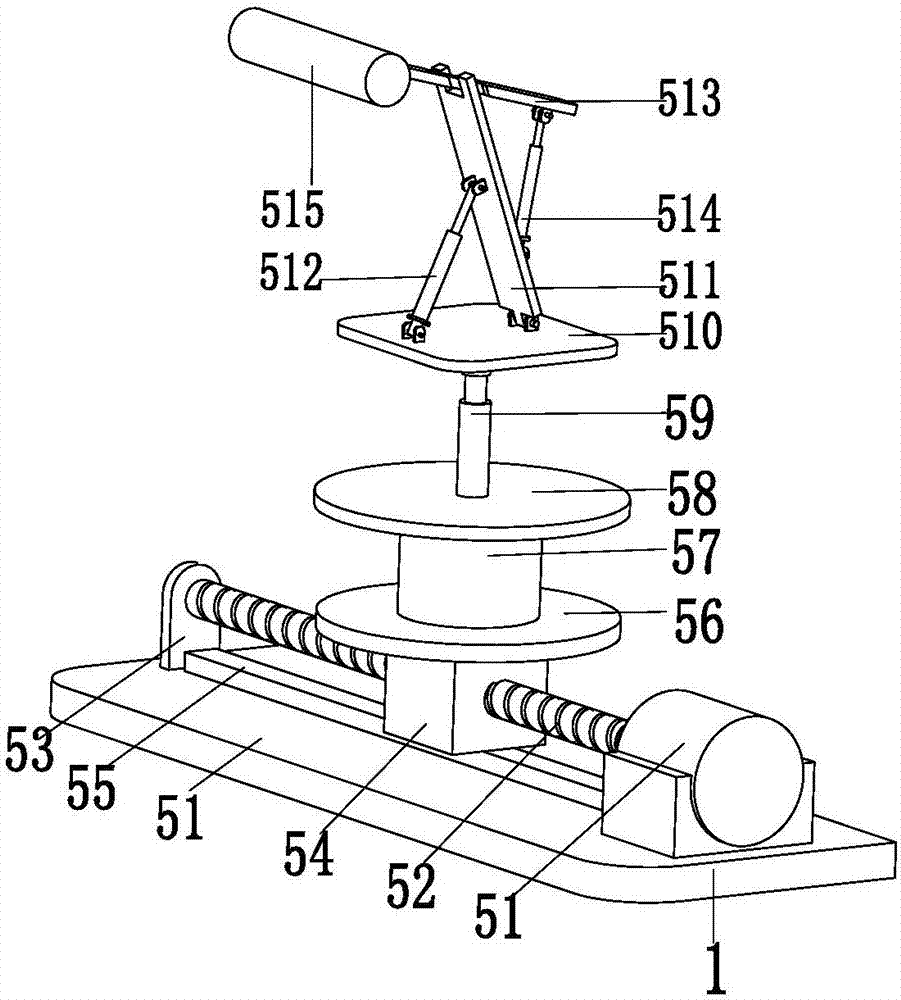

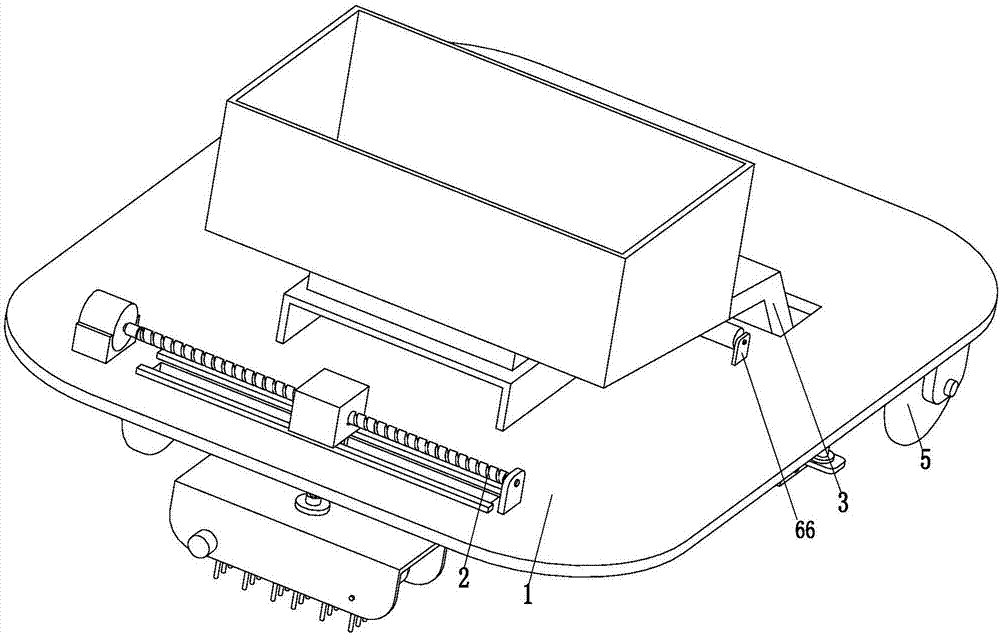

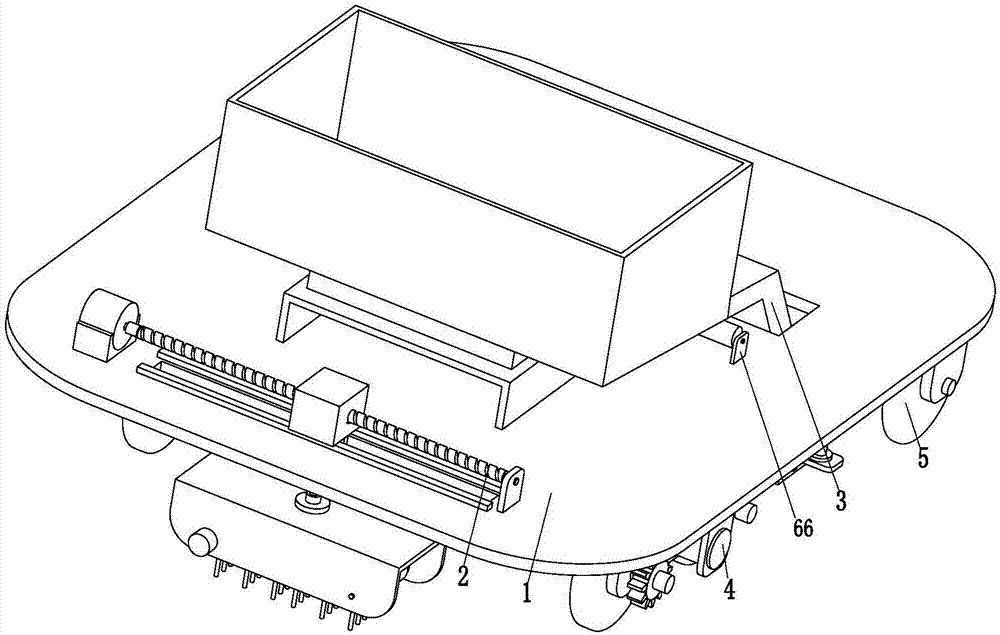

Automatic road line maker used for physical-training environmental-friendly air-permeable plastic runway construction

InactiveCN107326790ASolve the underlineSmooth linesRoad cleaningRoads maintainenceEnvironmental resistanceMachine building

The invention relates to an automatic marking machine for the construction of an environment-friendly and breathable plastic runway for sports training. Wheel, cleaning device and marking device are used in conjunction with each other to complete the automatic marking process of the plastic runway. The present invention can solve the problem of manually cleaning the ground of the plastic runway that needs to be marked in the marking process of the existing plastic runway. The existing marking equipment cannot automatically adjust the output of the marking paint according to the actual marking requirements. Unevenness. In the marking process, it is necessary to manually use isolation tools to isolate the marking paint. The natural air drying of the marking paint takes a long time, and the labor intensity and work efficiency are low. The function of automatic marking of the plastic track can be realized.

Owner:冒俊

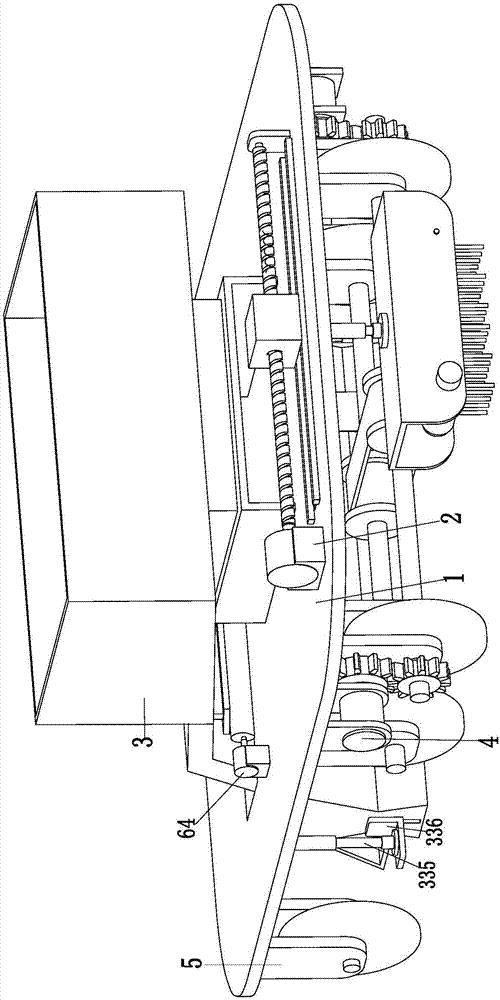

On-site construction road line marker of composite wear-resistant resin plastic runway

InactiveCN107320942ASmooth linesNo manual operationSki bindingsWater-skiingWear resistantEngineering

The invention relates to an on-site construction road line marker of composite wear-resistant resin plastic runway. The on-site construction road line marker of composite wear-resistant resin plastic runway comprises a bottom plate; the front end of the bottom plate is provided with a cleaning device; the middle part of the bottom plate is provided with a line maker; the lower end of the bottom plate is provided with a moving device; two auxiliary wheels are symmetrically arranged on the back side of the lower end of the bottom plate. Plastic runway automatic line drawing is realized via interaction cooperation of the moving device, the cleaning device, and the liner maker. The on-site construction road line marker is capable of solving difficult problems in the prior art that labour is needed by cleaning of plastic runway after line drawing, labour is needed to push conventional line makers to perform line drawing, automatic adjustment of the output quality of line draying paint is impossible to realize by conventional line makers, line drawing is uniform, labour is needed to isolating line drawing paint using isolating tools in line drawing process, natural airing time of line drawing paint is long, labout intensity is high, and working efficiency is low, and is capable of realizing automatic line drawing of plastic runway.

Owner:冒俊

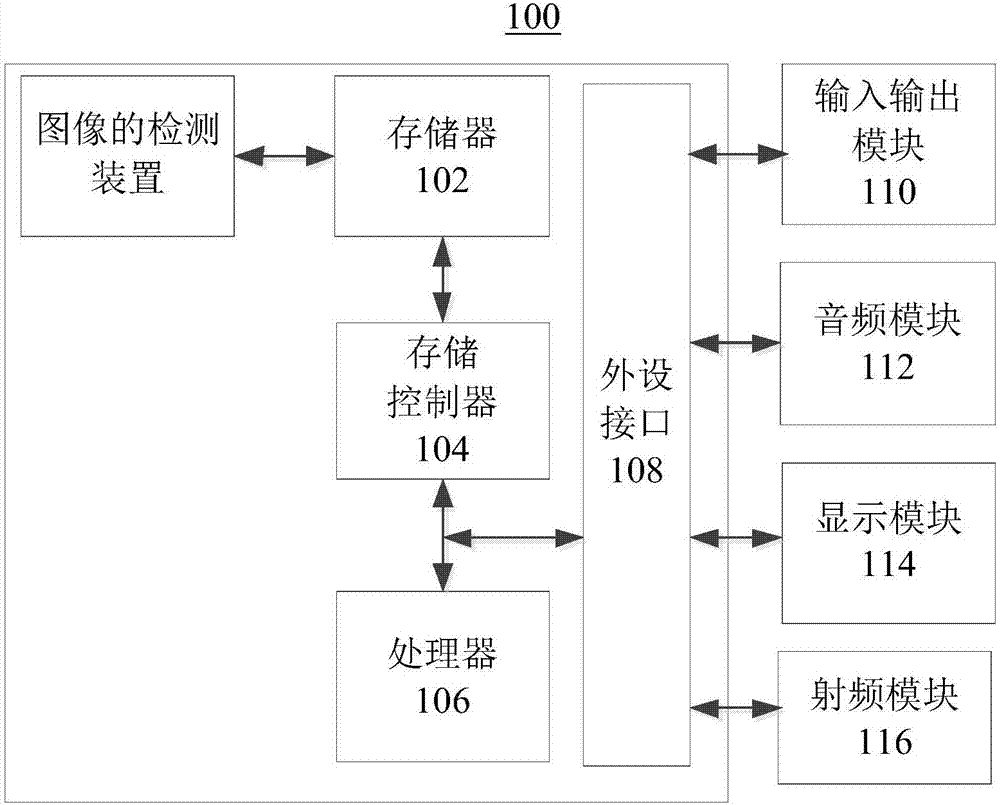

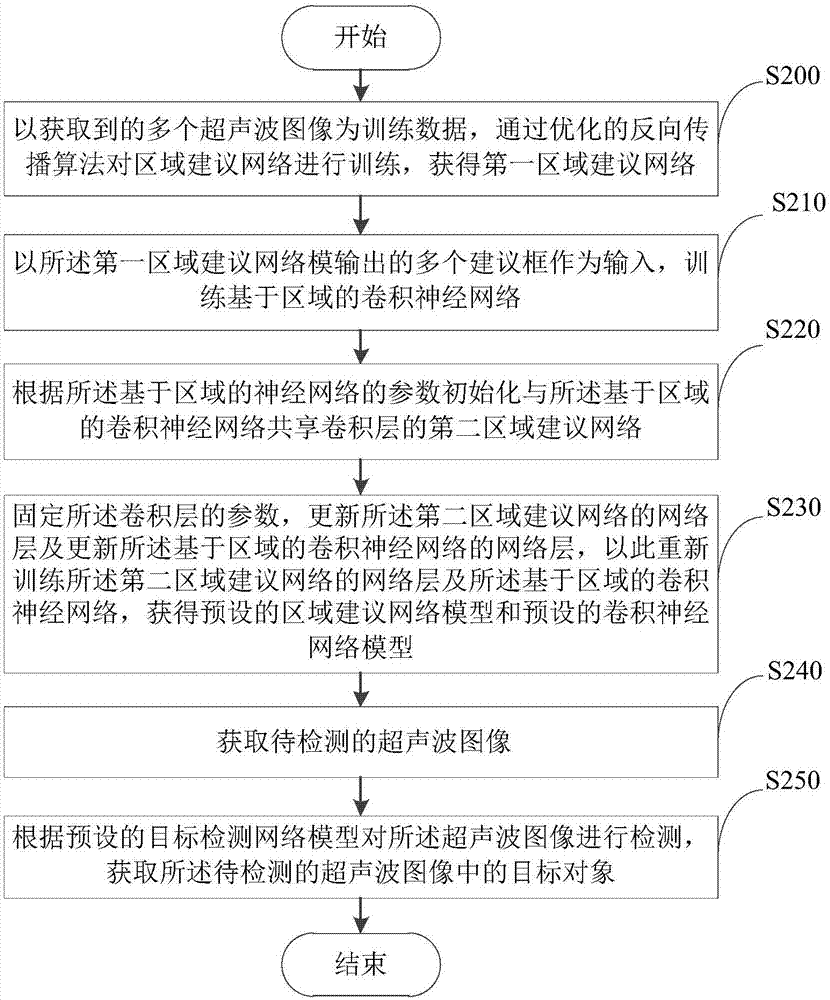

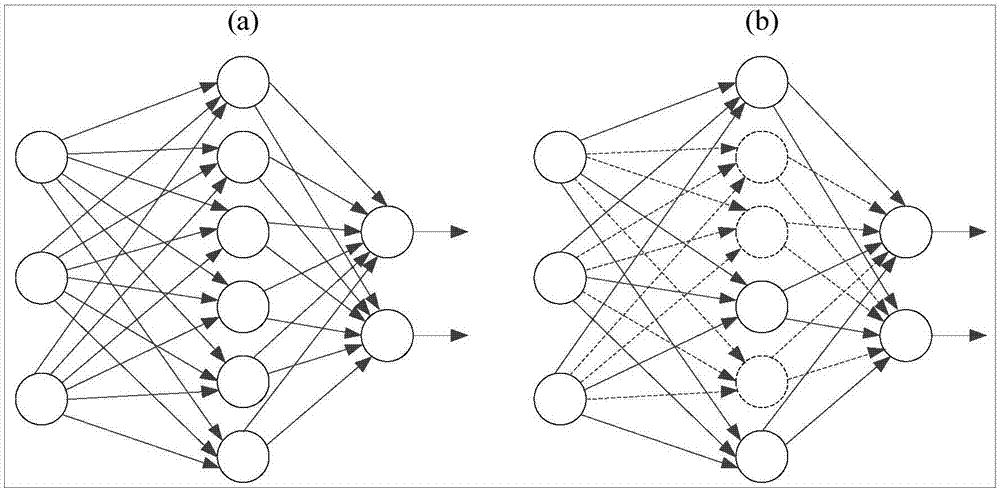

Detection method and device of image

ActiveCN107369154AImplement automatic detectionEasy to operateImage enhancementImage analysisNetwork modelComputer vision

The embodiment of the invention provides a detection method and device of an image, and relates to the field of medical technology. The method includes: acquiring the to-be-detected ultrasound image; and then detecting the to-be-detected ultrasound image according to a preset target detection network model to acquire a target object in the to-be-detected ultrasound image. Therefore, automatically detecting the target object in the ultrasound image is realized, operations are simple, the precision is high, and consumed time is short.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

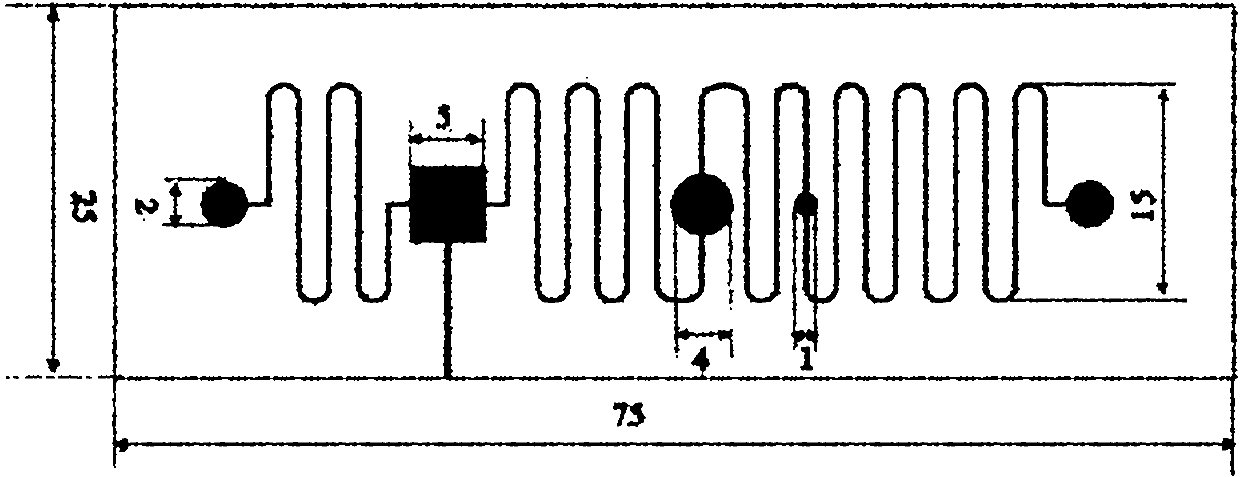

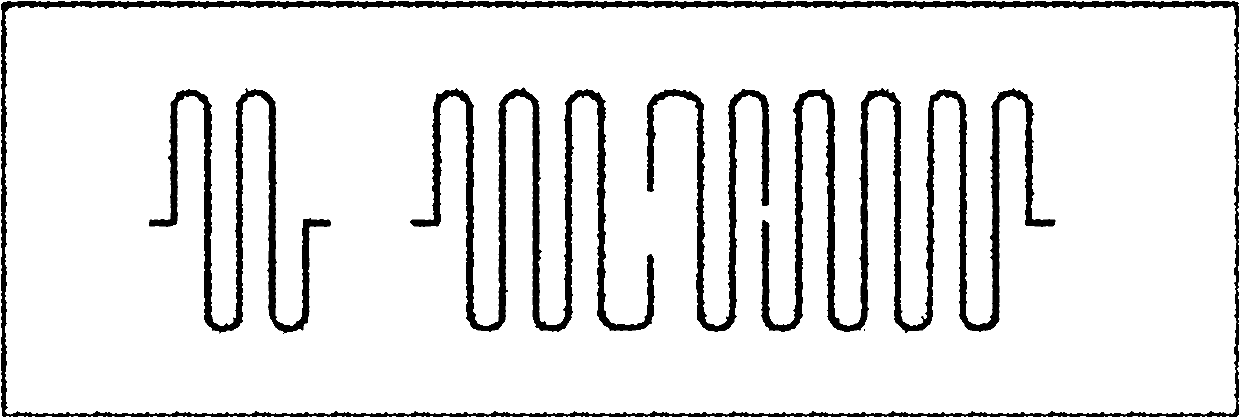

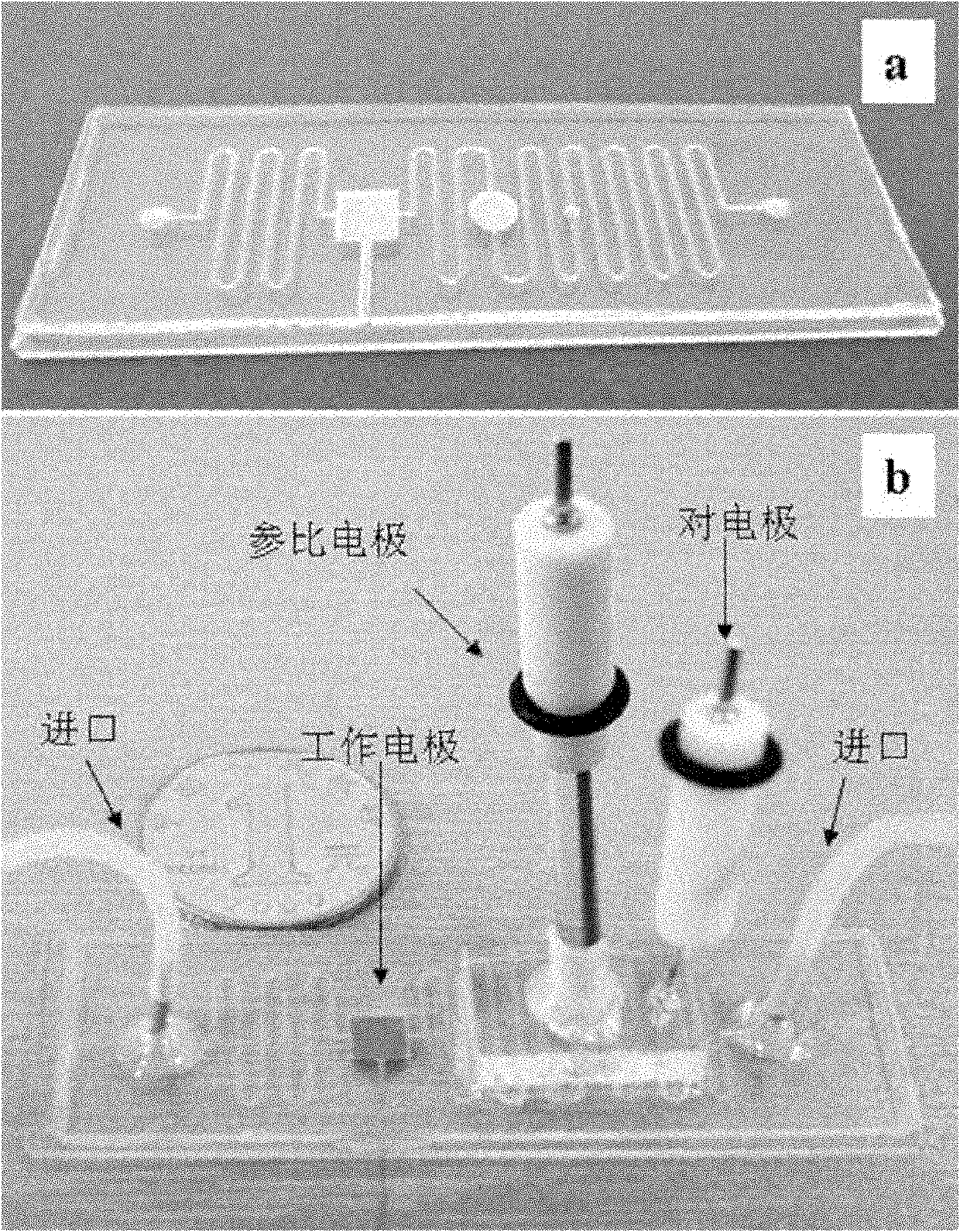

Method for producing photoelectrochemical microfluidic detection chip of three-electrode system

The invention relates to a method for producing a photoelectrochemical microfluidic detection chip of a three-electrode system. The method comprises the following steps: coating liquid polydimethylsiloxane (PDMS) on a glass sheet and curing the PDMS to form a substrate; forming a micro-channel and corresponding work electrode pool, reference electrode pool, counter electrode pool and import / export pool from a pre-designed pattern on the PDMS by using a laser engraving method; placing the work electrodes and connecting with leads; sealing another non-etched PDMS as a cover plate by oxygen plasma processing; and finally integrating the reference electrodes and the counter electrodes to produce the photoelectrochemical microfluidic detection chip of the three-electrode system. The production method is easy to operate; the size of the micro-channel is controllable; the sealing of the microfluidic chip is realized without additional adhesive; after the sealing, the bonding is firm without leakage; and the method is applicable to photoelectrochemical detection and has the advantages of little oxygen consumption, fast detection and high flexibility.

Owner:DONGHUA UNIV

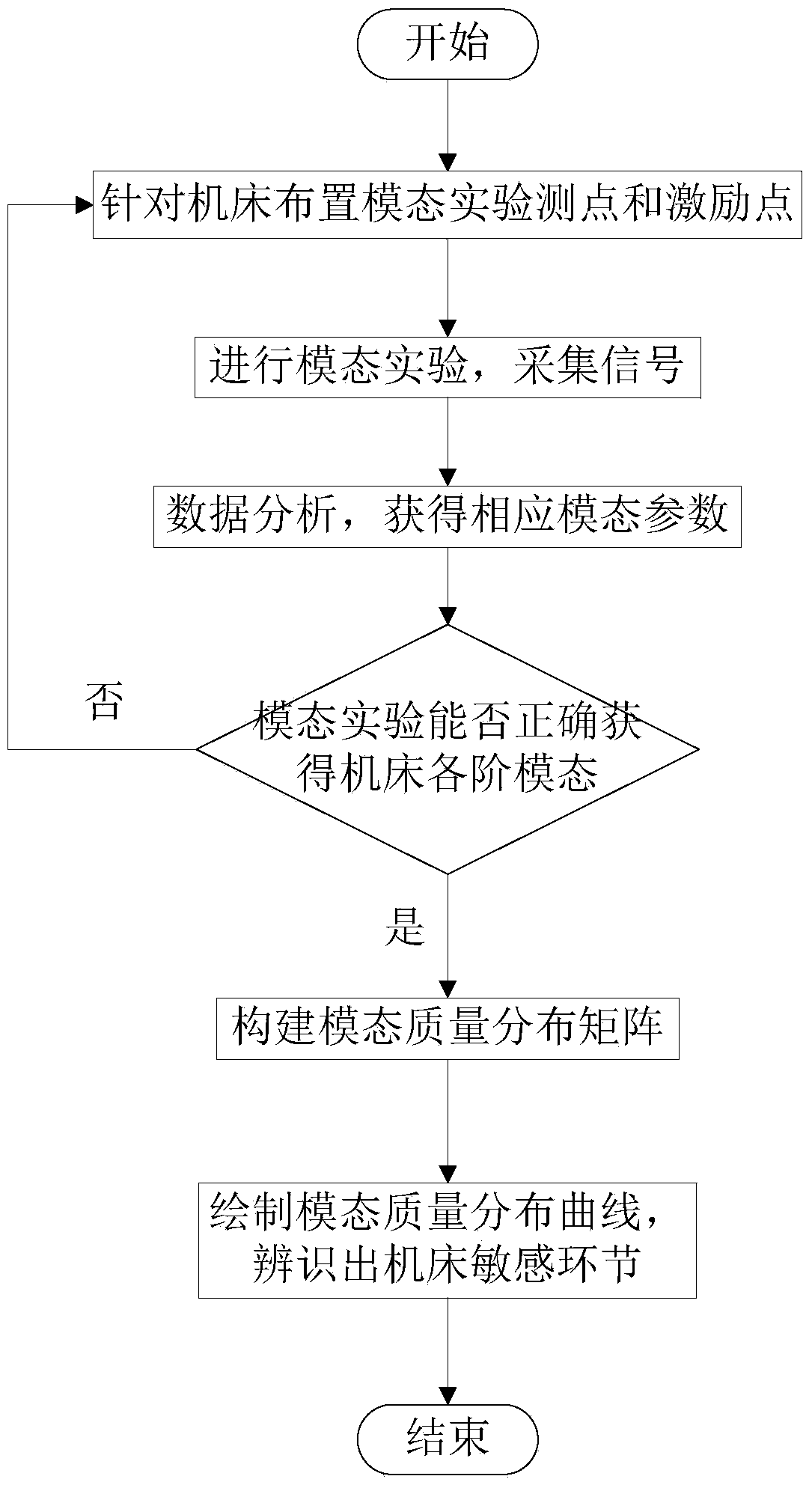

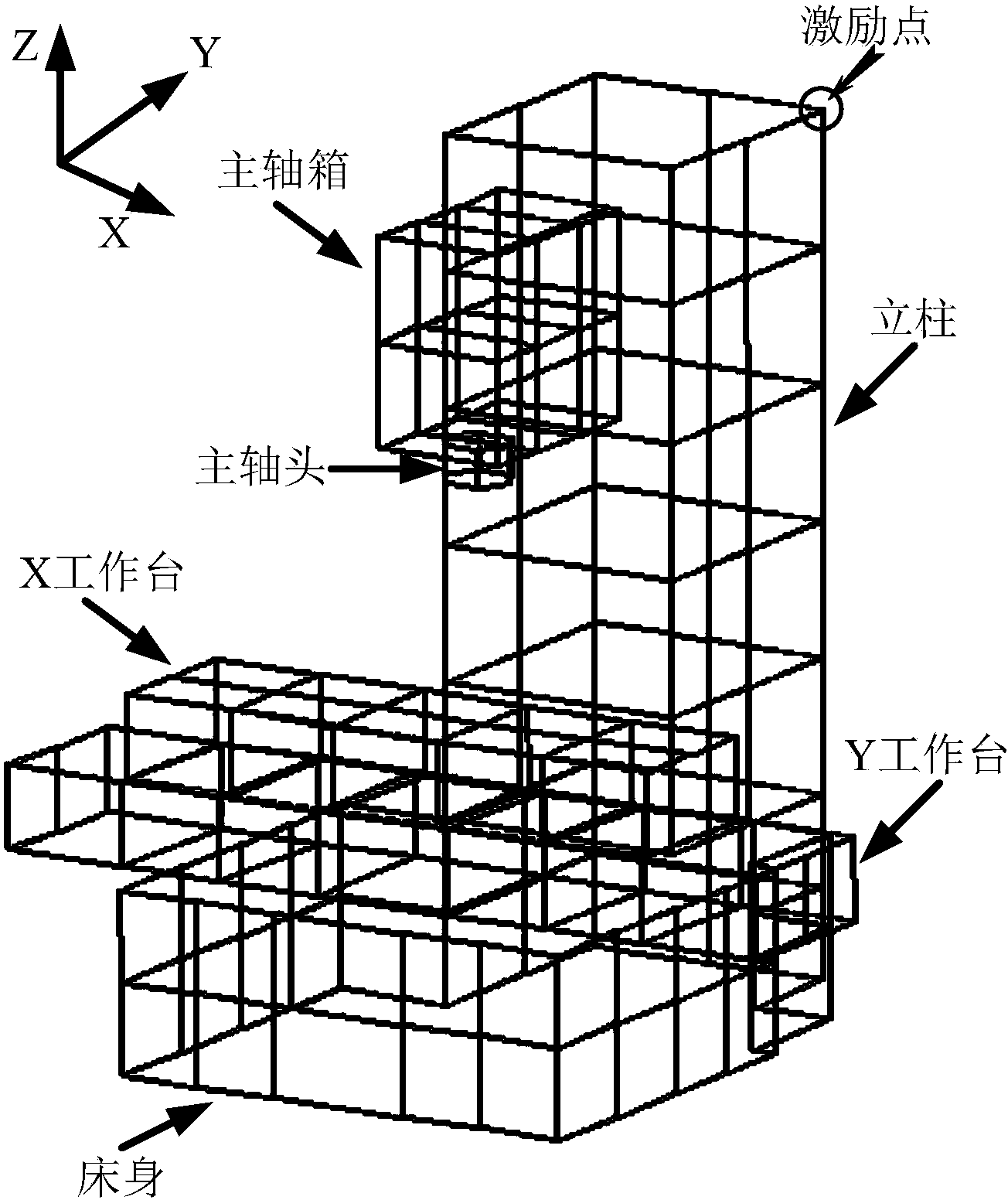

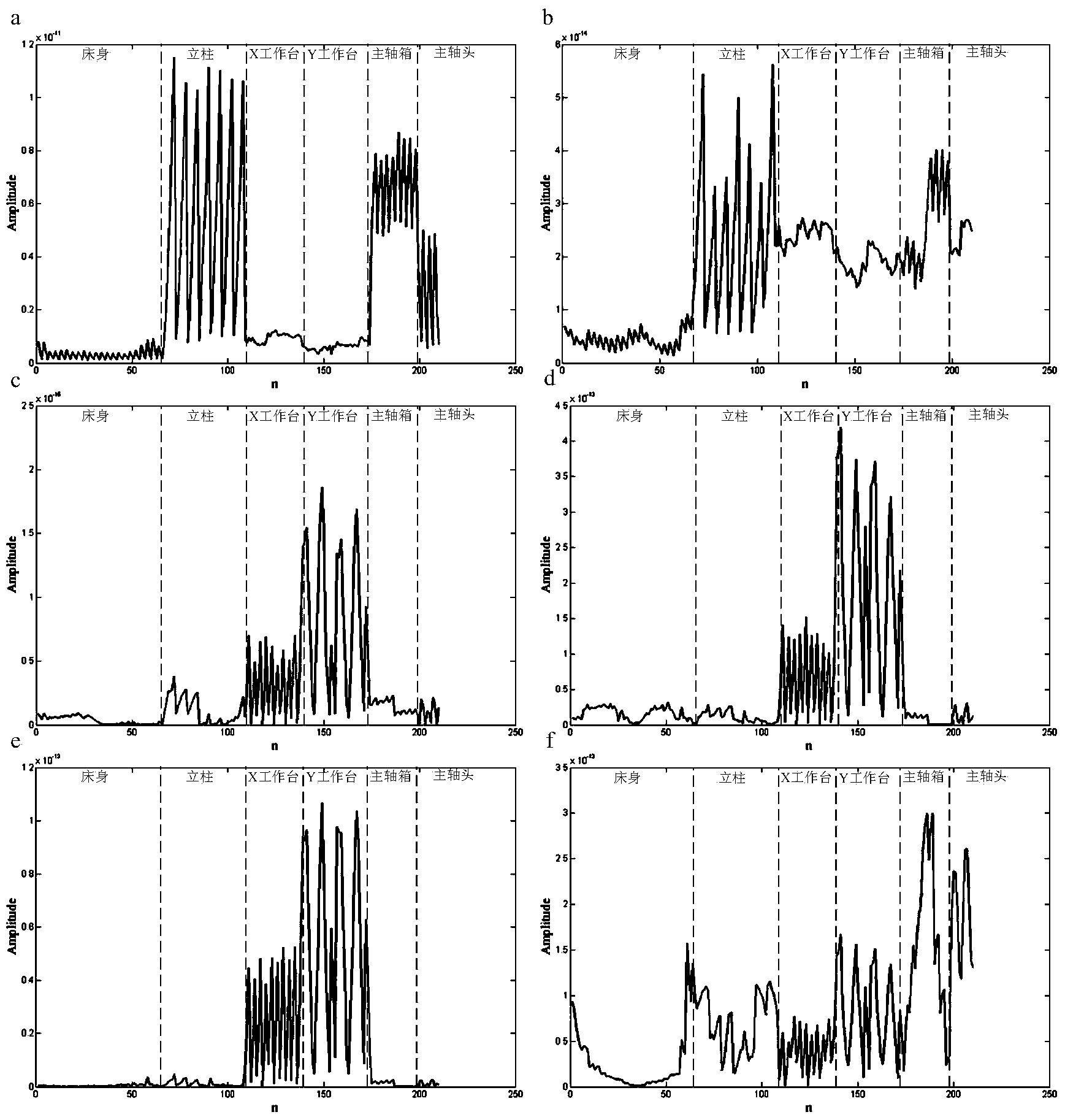

Numerical control machine tool sensitive-link identification method based on modal mass distribution matrix

InactiveCN103823406ALess experience factorGood repeatabilityNumerical controlDistribution matrixNumerical control

The invention discloses a numerical control machine tool sensitive-link identification method based on a modal mass distribution matrix. The modal mass distribution matrix of a numerical control machine tool is constructed with the modal mass of the numerical control machine tool and a modal shape vector, and as a result, the sensitive link of the machine tool structure can be obtained. The method is characterized by comprising the steps of (1) carrying out a modal experiment of the numerical control machine tool to obtain the modal mass of the numerical control machine tool and the modal shape vector, (2) constructing the modal mass distribution matrix of the numerical control machine tool according to the obtained modal mass and the modal shape vector, and (3) obtaining a modal mass distribution curve of all components of the machine tool by virtue of the modal mass distribution matrix, and further identifying the sensitive link of the machine tool. The method is capable of determining the sensitive link of the machine tool structure so that the weak condition of the machine tool structure is quantized, and therefore, the previously mentioned problems encountered in the process of evaluating the sensitive link of the machine tool structure by an existing method are solved.

Owner:HUAZHONG UNIV OF SCI & TECH

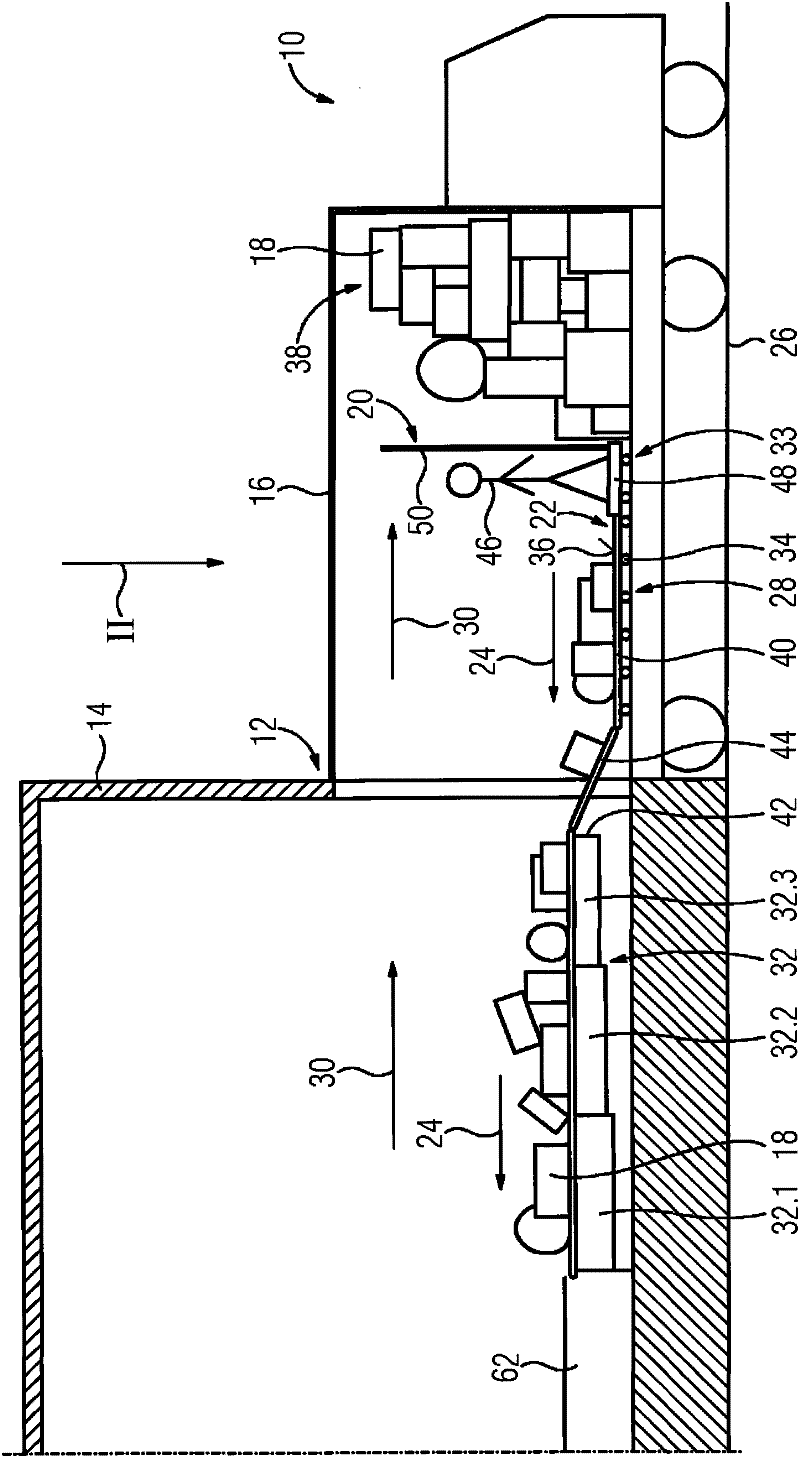

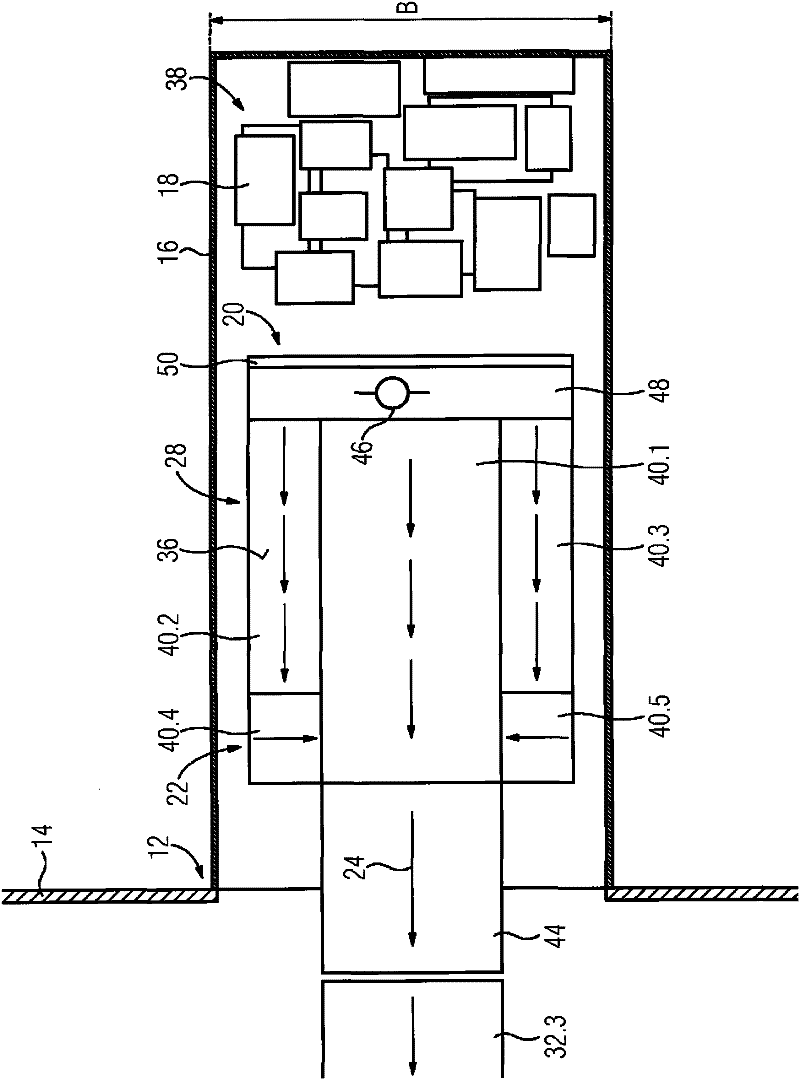

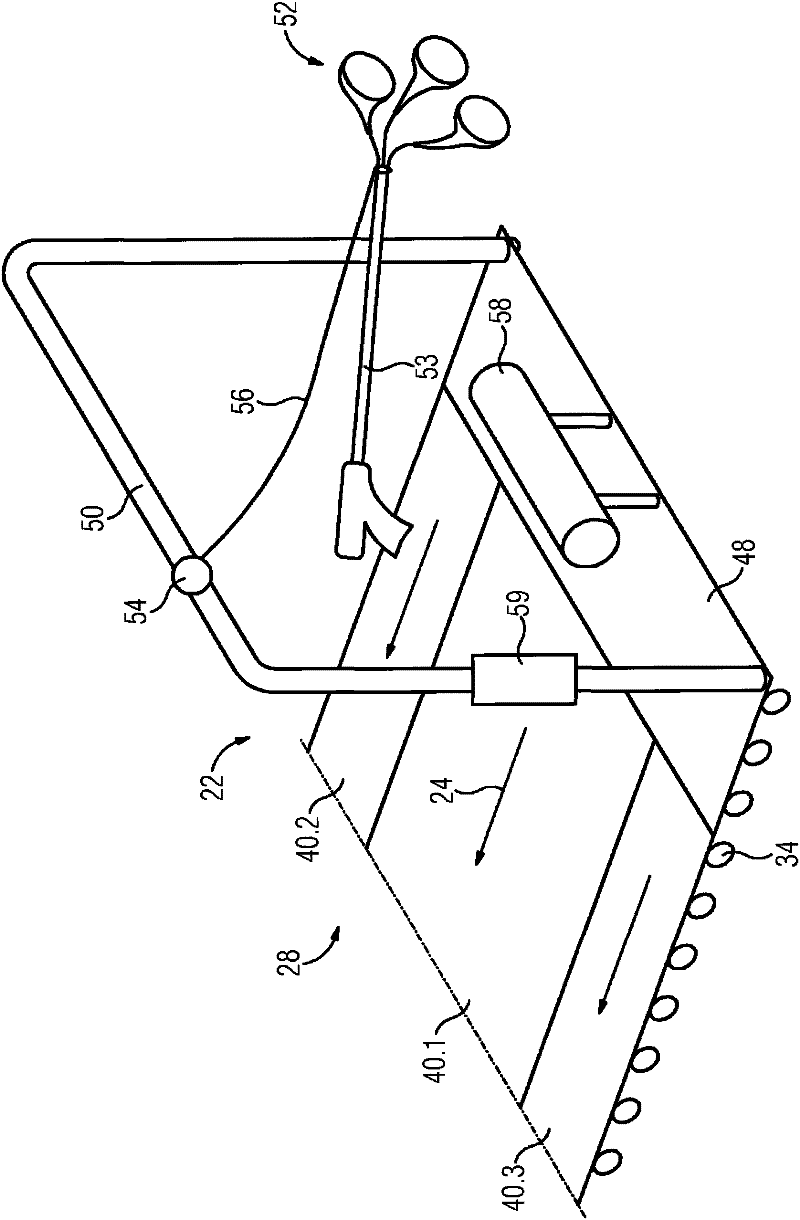

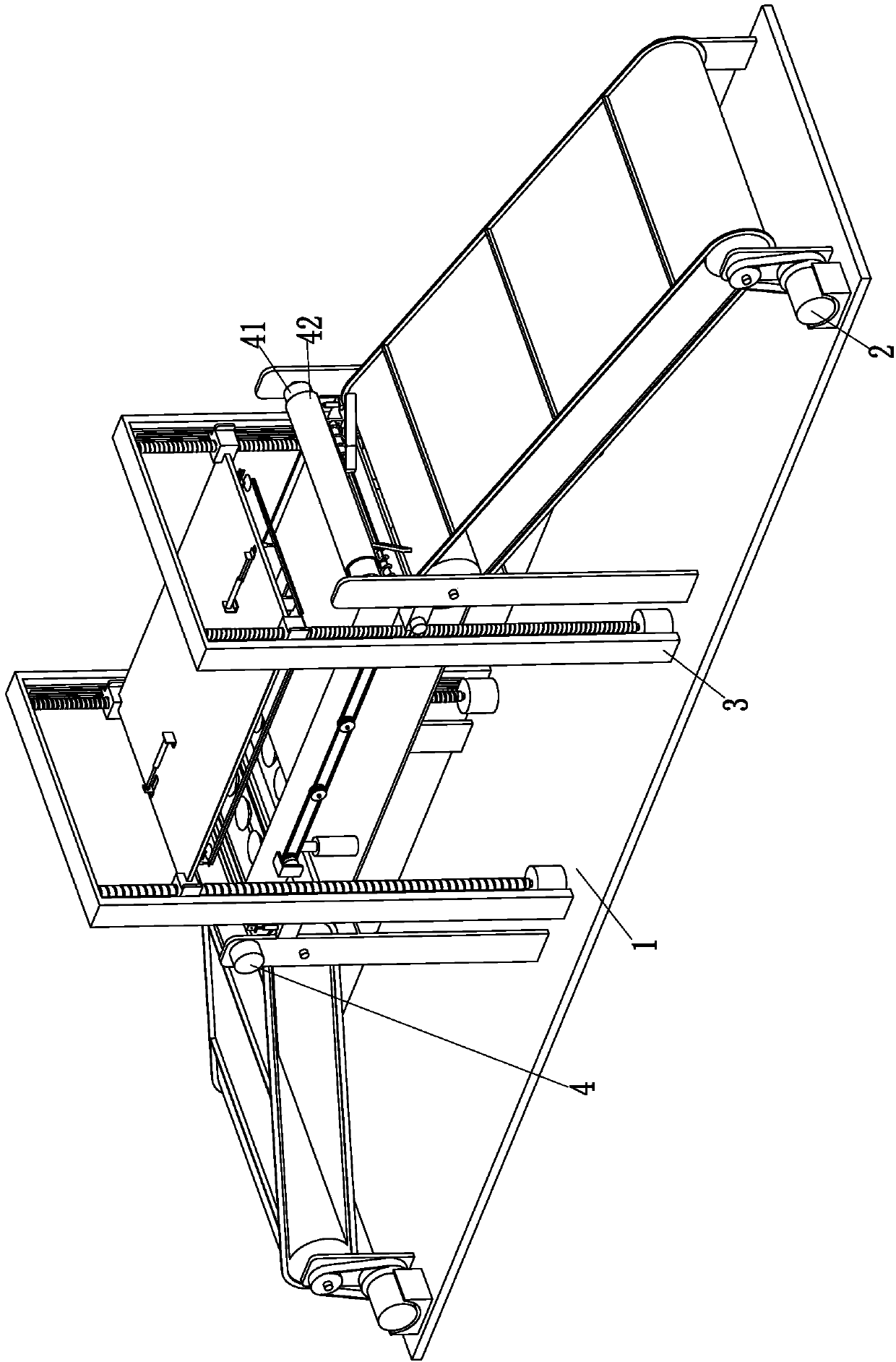

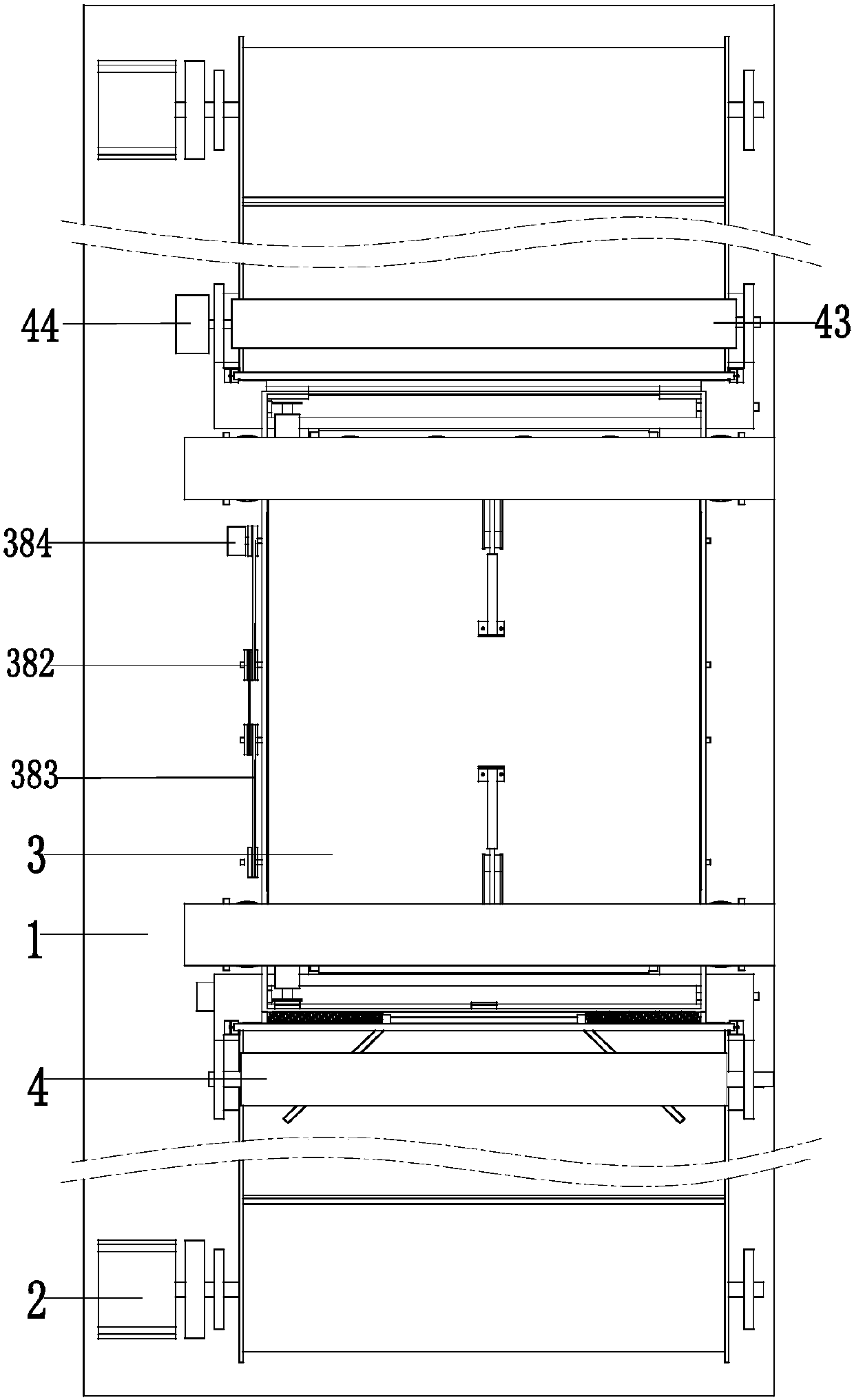

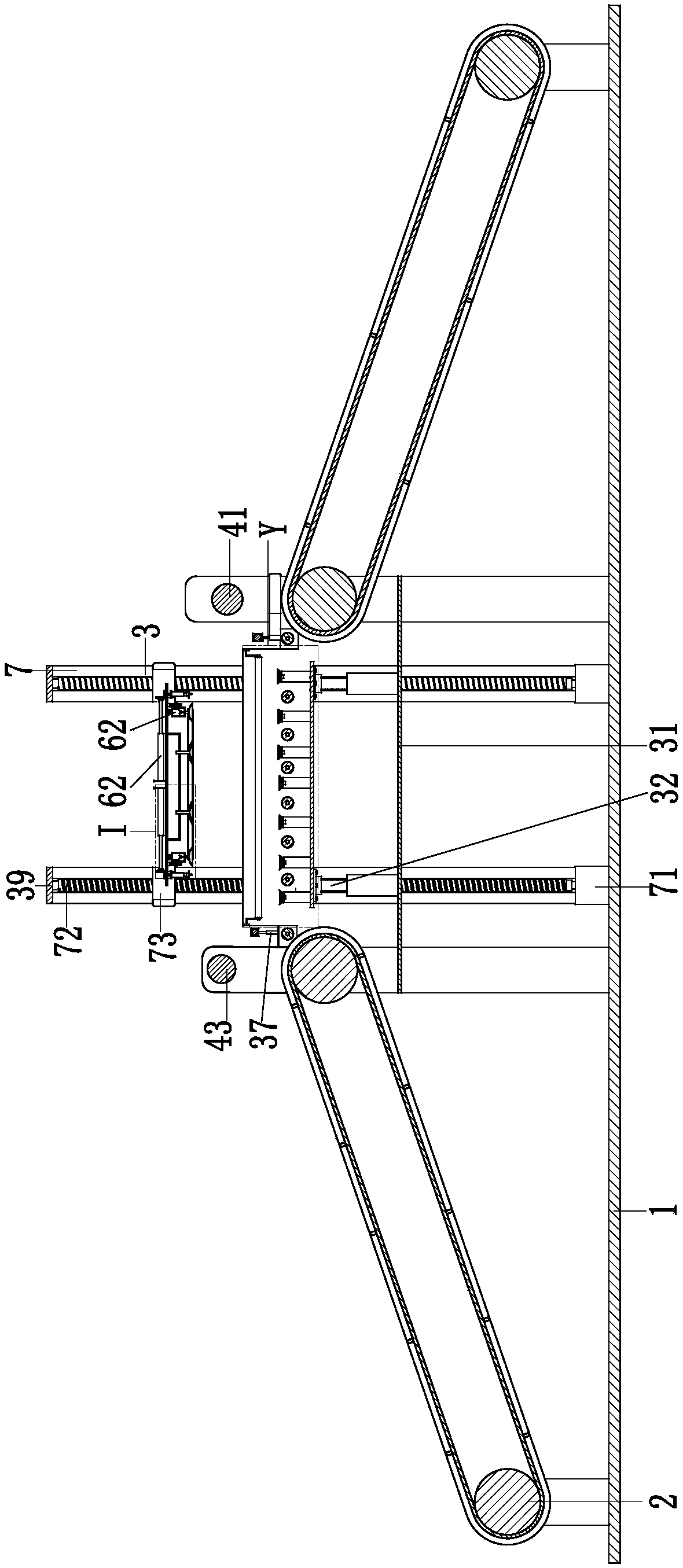

Device for treating piece goods of a transport unit, particularly a swappable container and unloading device

ActiveCN102556688APrevent tippingEliminate height differenceLoading/unloadingExternal fittingsOperational costsMechanical engineering

The invention relates to a device for treating piece goods (18) of a transport unit (16), particularly a swappable container and unloading device. The device has a movable conveyor unit (22), driven into the transport unit so as to unloading the transport unit (16). Under control of an operator (46), piece-goods (18) stacked in the transport unit are received and shipped out from the transport unit (16) in a discharge direction (24) for further processing. In order to provide a device capable of shipping out inconsistently or unclassified stacked piece-goods with low operational cost, the invention provides a conveyor unit (22) comprising a bottom conveyor (28) that conveys the piece goods fallen from a piece-goods stack (38) in a loose arrangement.

Owner:KOERBER SUPPLY CHAIN LOGISTICS GMBH

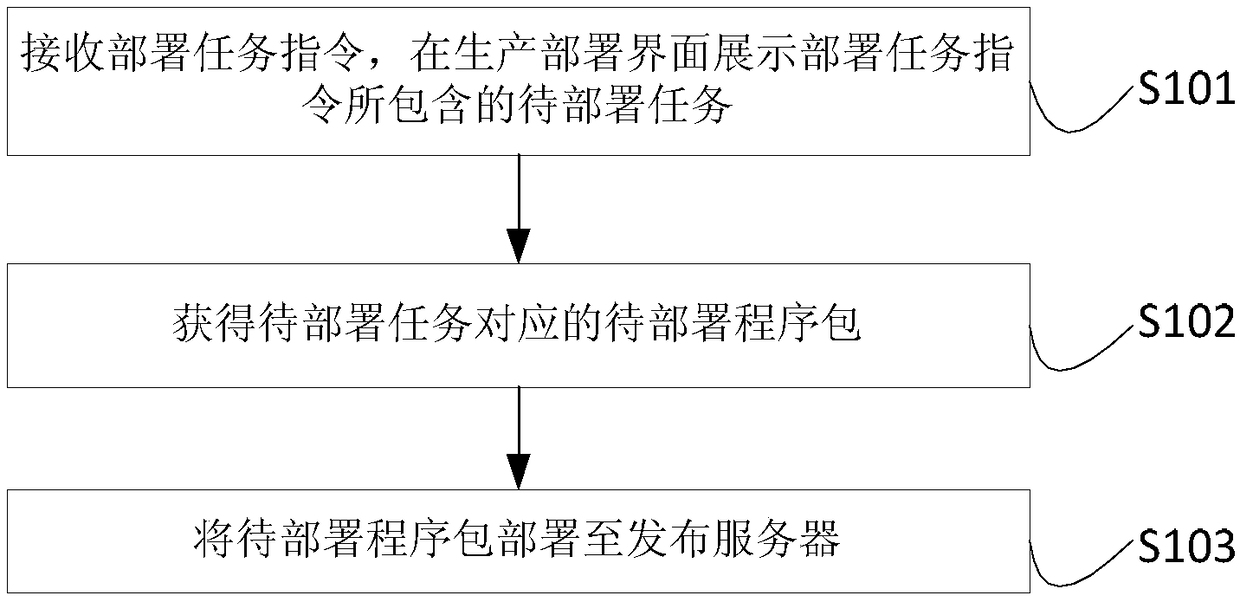

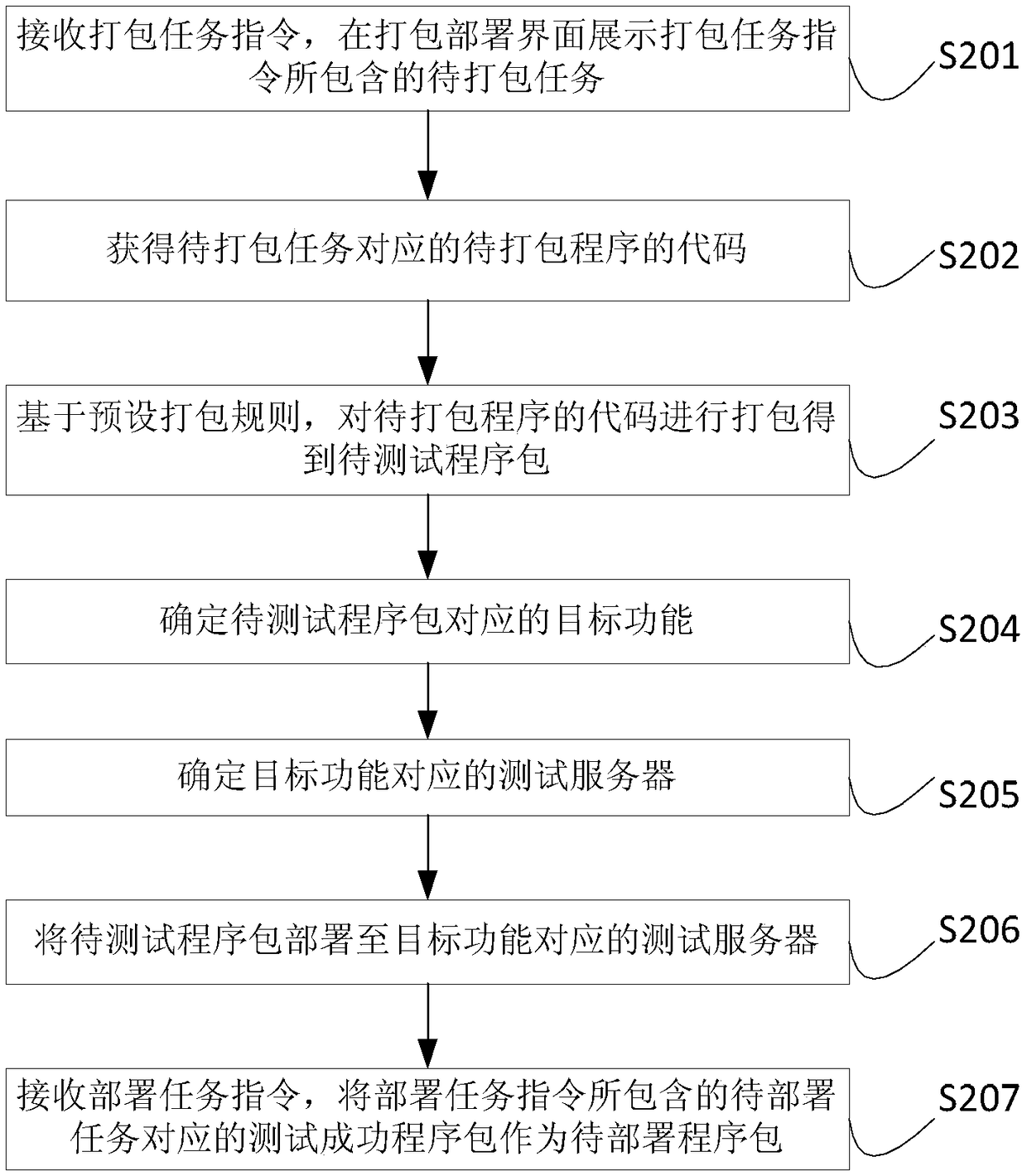

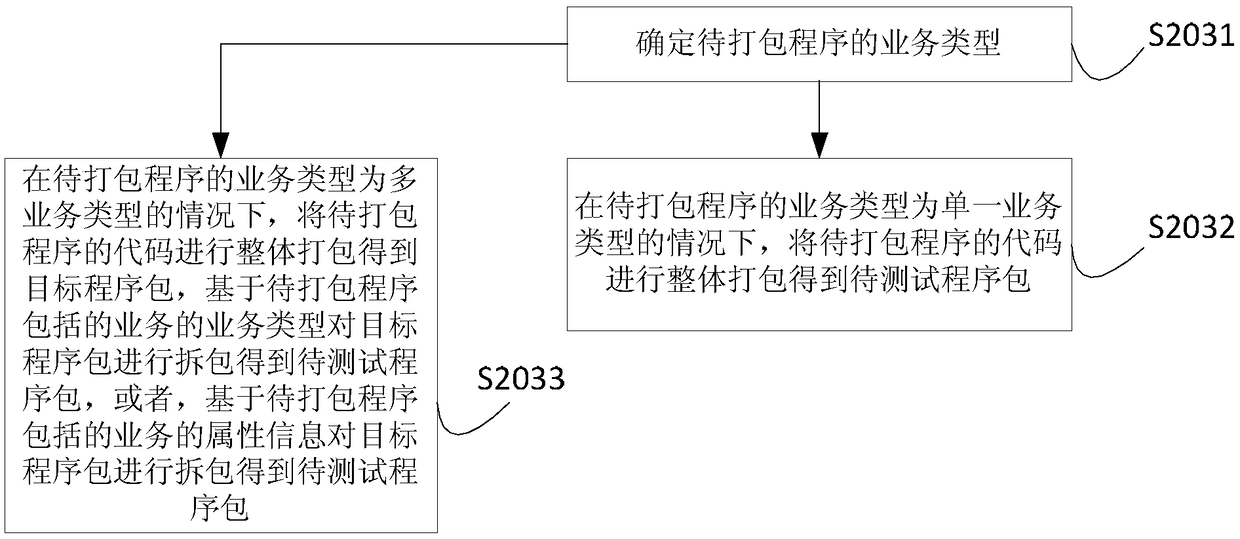

Production deployment method, device, system, electronic equipment and storage media for program package

PendingCN108897548AReduce workloadAchieve the goal of automated production deploymentSoftware deploymentSoftware engineeringWorkload

The invention embodiment provides a production deployment method, device, system, electronic equipment and storage media for a program package. In the production deployment method, a mission instruction is received and deployed. A task to be deployed contained in a deployment task instruction is displayed in a production deployment interface, and the program package of the task to be deployed corresponding to the task to be deployed is obtained, and then the program package of the task to be deployed is deployed to a publish server. The production deployment method, device, system, electronicequipment and storage media for the program package provides the production deployment method based the interface through the method of displaying the task to be deployed on the production deploymentinterface, so as to a non-specialized person can carry the production deployment work based the interface. And the method of deploying the publish server to the program package of the task to be deployed of the production deployment method, device, system, electronic equipment and storage media for the program package achieves the purpose of automated production deployment through obtaining the program package of the task to be deployed corresponding to the task to be deployed. Without manual production deployment, the workload of production deployment is reduced and time consumption is also reduced. As the automatic production deployment, the error rate during deployment is reduced and the efficiency of production deployment is improved.

Owner:BEIJING KINGSOFT DIGITAL ENTERTAINMENT CO LTD +1

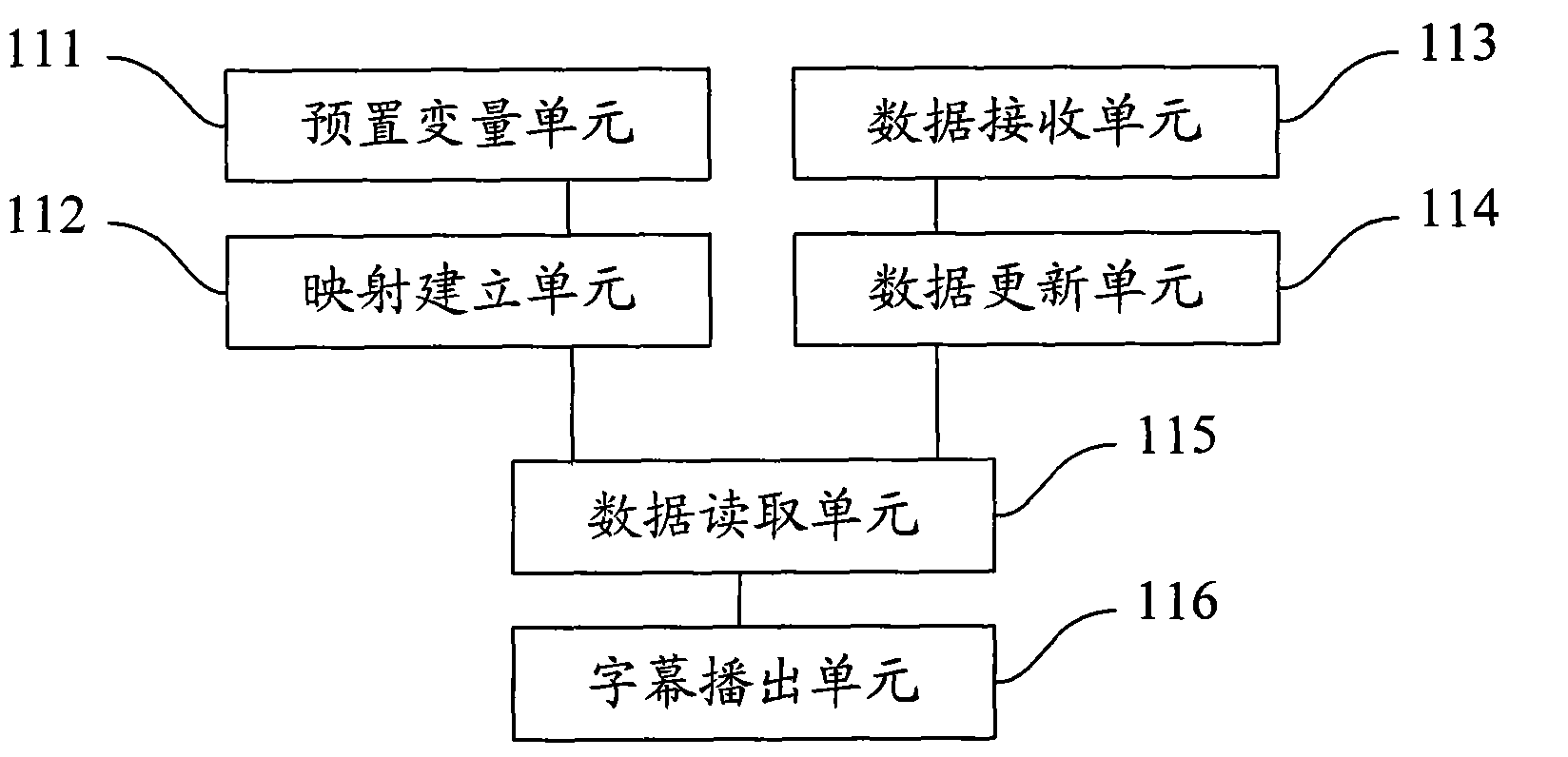

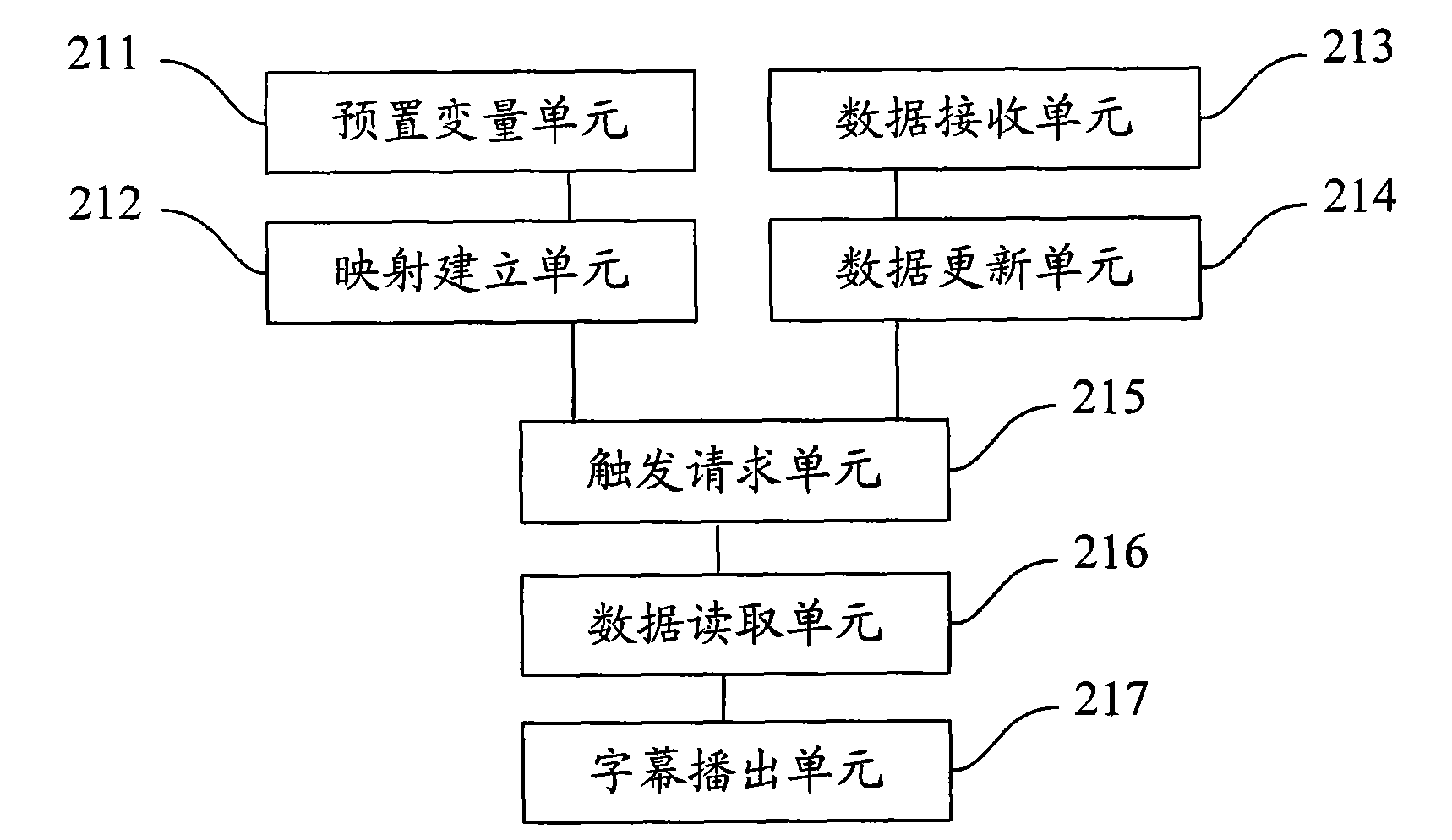

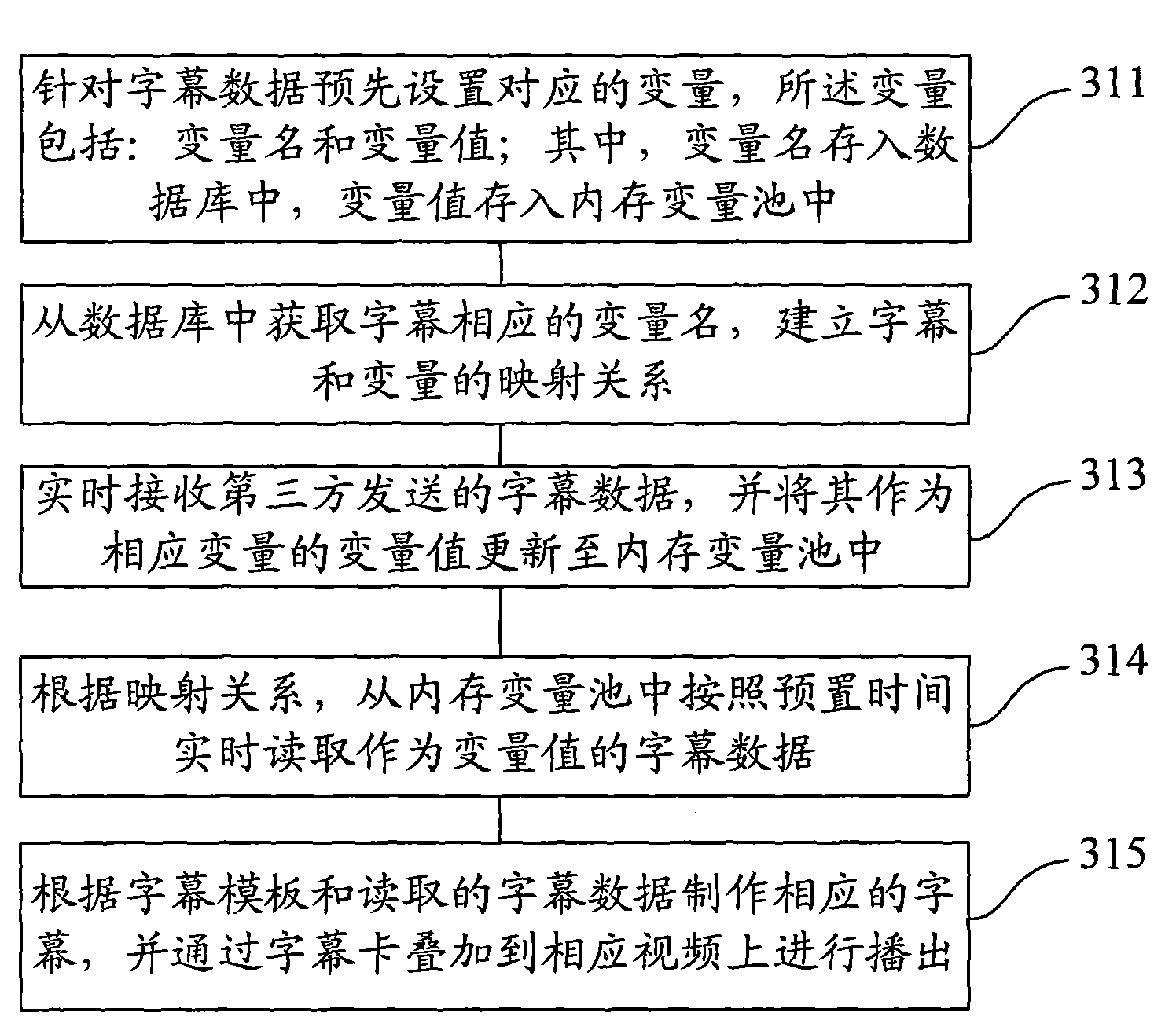

Real-time caption broadcasting system and method

InactiveCN102098454AShort time spentShorten call timeTelevision system detailsColor television detailsThird partyReal-time computing

The invention provides a real-time caption broadcasting system and a real-time caption broadcasting method. The system comprises a variable presetting unit, a mapping establishment unit, a data receiving unit, a data updating unit, a data reading unit and a caption broadcasting unit, wherein the variable presetting unit is used for presetting corresponding variables for caption data; the variable comprises a variable name and a variable value; the variable name is stored into a database, and the variable value is stored into a memory variable pool; the mapping establishment unit is used for acquiring the variable names corresponding to captions from the database, and establishing mapping relationships between the captions and the variables; the data receiving unit is used for receiving the caption data from a third party in real time; the data updating unit is used for updating the received caption data into the memory variable pool as the variable values of the corresponding variables; the data reading unit is used for reading the caption data as the variable values in real time in preset time from the memory variable pool according to the mapping relationships; and the caption broadcasting unit is used for generating corresponding captions according to a caption template and the read caption data, and adding the captions onto corresponding videos for broadcasting by a caption card. The system and the method ensure the real-time broadcasting of the captions.

Owner:CHINA DIGITAL VIDEO BEIJING

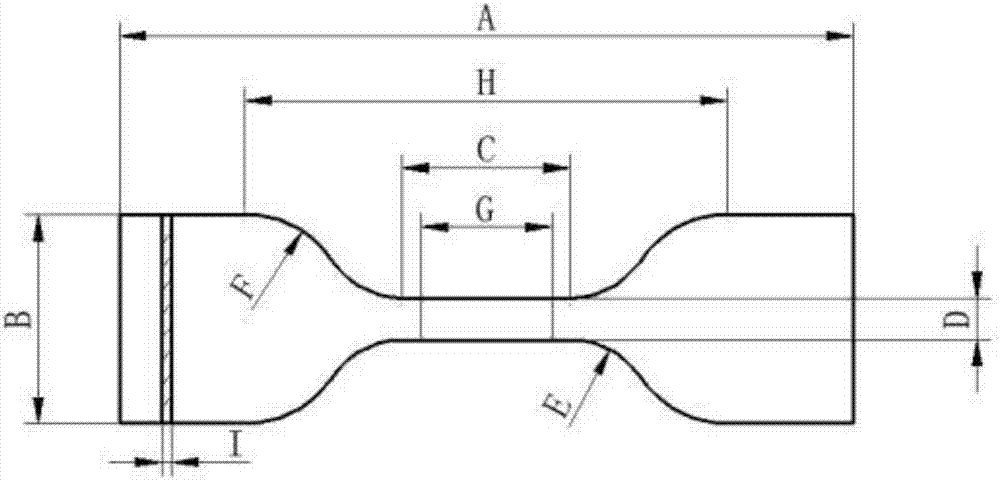

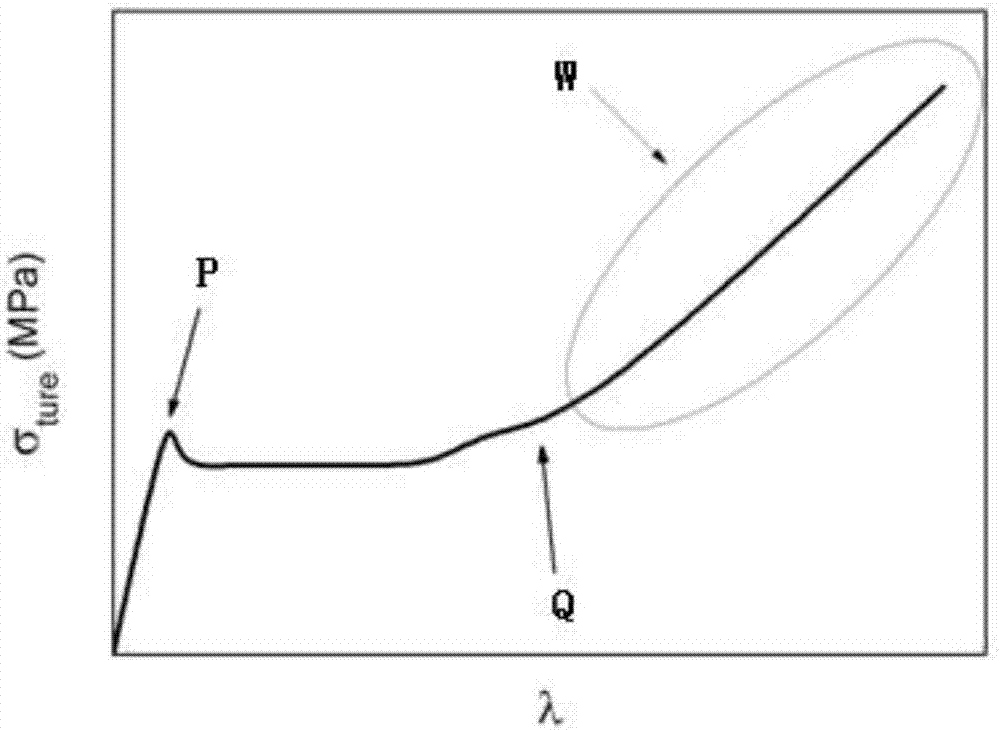

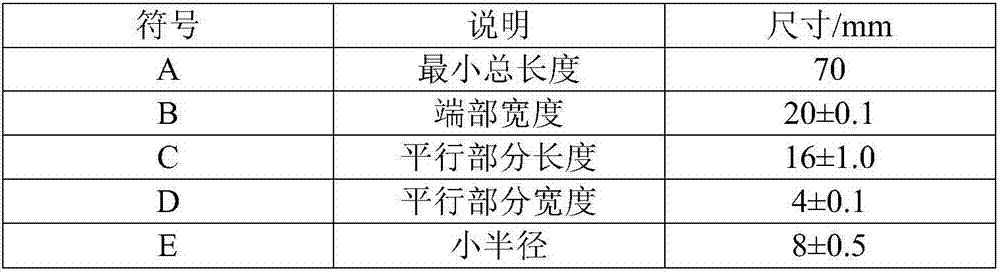

Testing method for accelerating evaluation of slow crack increase resistance of polyethylene tube

InactiveCN107449675AImprove accuracyGood reproducibilityPreparing sample for investigationMaterial strength using tensile/compressive forcesCompression moldingTest sample

The invention relates to a testing method for accelerating evaluation of slow crack increase resistance of a polyethylene tube. The testing method comprises the following two steps: preparing a testing sample, and performing high-temperature tension testing, wherein the testing sample is prepared through procedures of compression molding, annealing and stamping. A relationship curve of stress and strain is obtained through the high-temperature tension testing on the testing sample, a slope of the testing sample is calculated within a strain hardening interval that the stress is suddenly increased on t he relationship curve, then a strain hardening modulus is obtained for representing the slow crack increase resistance of a polyethylene material, and the larger the strain hardening modulus is, the better the slow crack increase resistance is. The testing method provided by the invention has the advantages of short time consumption, low material consumption, simple testing sample preparation step, good result reproducibility and the like.

Owner:GUANGZHOU SPECIAL PRESSURE EQUIP INSPECTION & RES INST

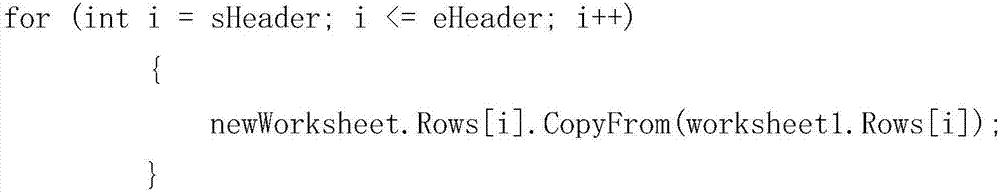

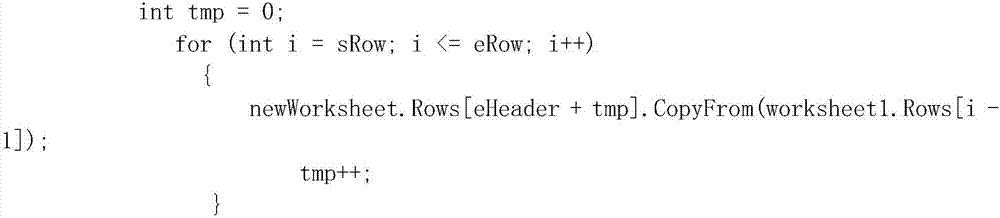

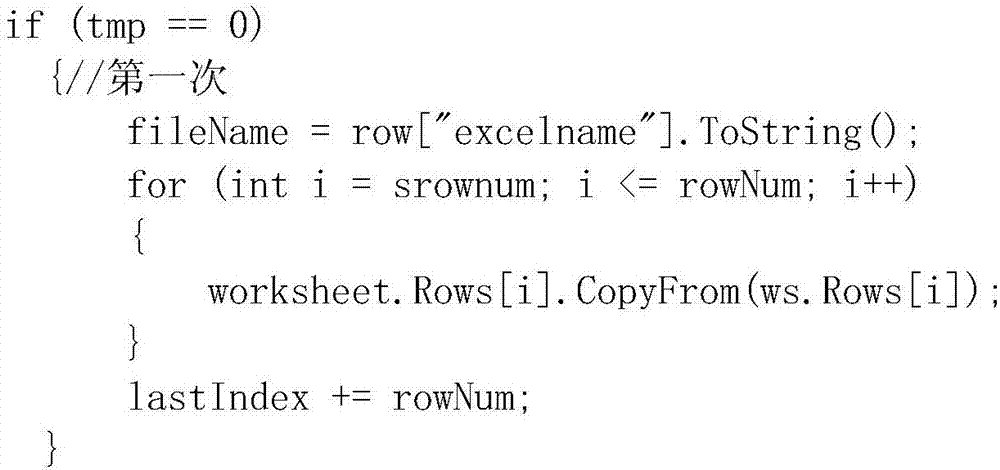

Multi-user synchronous editing processing system for same file, and processing method

ActiveCN108009243AImprove securityEnsure safetyDatabase management systemsVisual data miningData fileDocumentation

The invention discloses a multi-user synchronous editing processing system for the same file, and a processing method. The multi-user synchronous editing processing method comprises steps that a datafile is automatically analyzed and split and analyzed into a plurality of same small files via a template file; a plurality of users edit the file at the same time online, distribute authority for thesplit file for different users, enable all users to online edit file content and hand in the same; the file contents are merged and downloaded; multi-file handing in states are traced; the pluralityof files are merged into a file and contents edit by different users are completely reserved; and then the file is loaded and checked. According to multi-file handing in state trace, and file merge and reservation of contents edit by different users, synchronous edit on various terminals can be achieved; and table contents of each terminal can be checked only by editing users, so safety of important information can be ensured; and the system simplifies a process, reduces work load, shortens reporting time and improves information safety.

Owner:YUNNAN POWER GRID +1

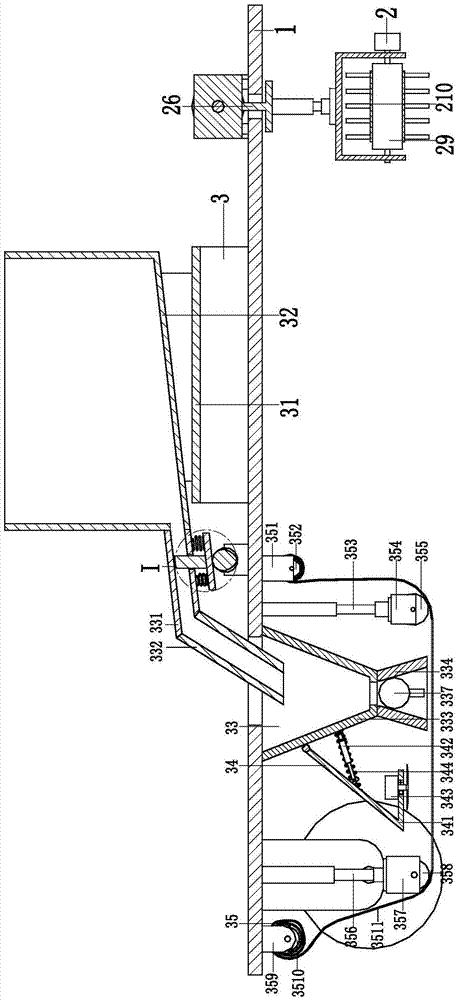

Automatic laminating processing equipment of container house flat color steel plate

ActiveCN107757045AHigh precisionImprove stabilityLamination ancillary operationsLaminationSteel platesEngineering

The invention relates to automatic laminating processing equipment of a container house flat color steel plate. The automatic laminating processing equipment of the container house flat color steel plate comprises a bottom plate; two conveying devices are symmetrically arranged on the bottom plate; a winding device is arranged between the two conveying devices; a conveying and laminating device isarranged between the two conveying devices; and the two conveying devices, the winding device and the conveying and laminating device are cooperatively used to finish the automatic laminating processof the color steel plate. The automatic laminating processing equipment of the container house flat color steel plate can solve the problems that the existing flat color steel plate laminating equipment cannot laminate the upper end and the lower end of the flat color steel plate in the laminating process of the existing flat color steel plate, the flat color steel plate is liable to move under the action of an external force in laminating processing process of the existing laminating processing equipment by the flat color steel plate laminating equipment, the flat color steel plates with different sizes need to be adjusted manually during laminating processing, the precision degree is slow, the labor intensity is large, the time consumption is high, the stability is low, the working efficiency is low and the like, and can realize the function of automatically laminating the container house flat color steel plate.

Owner:新沂市新南环保产业技术研究院有限公司

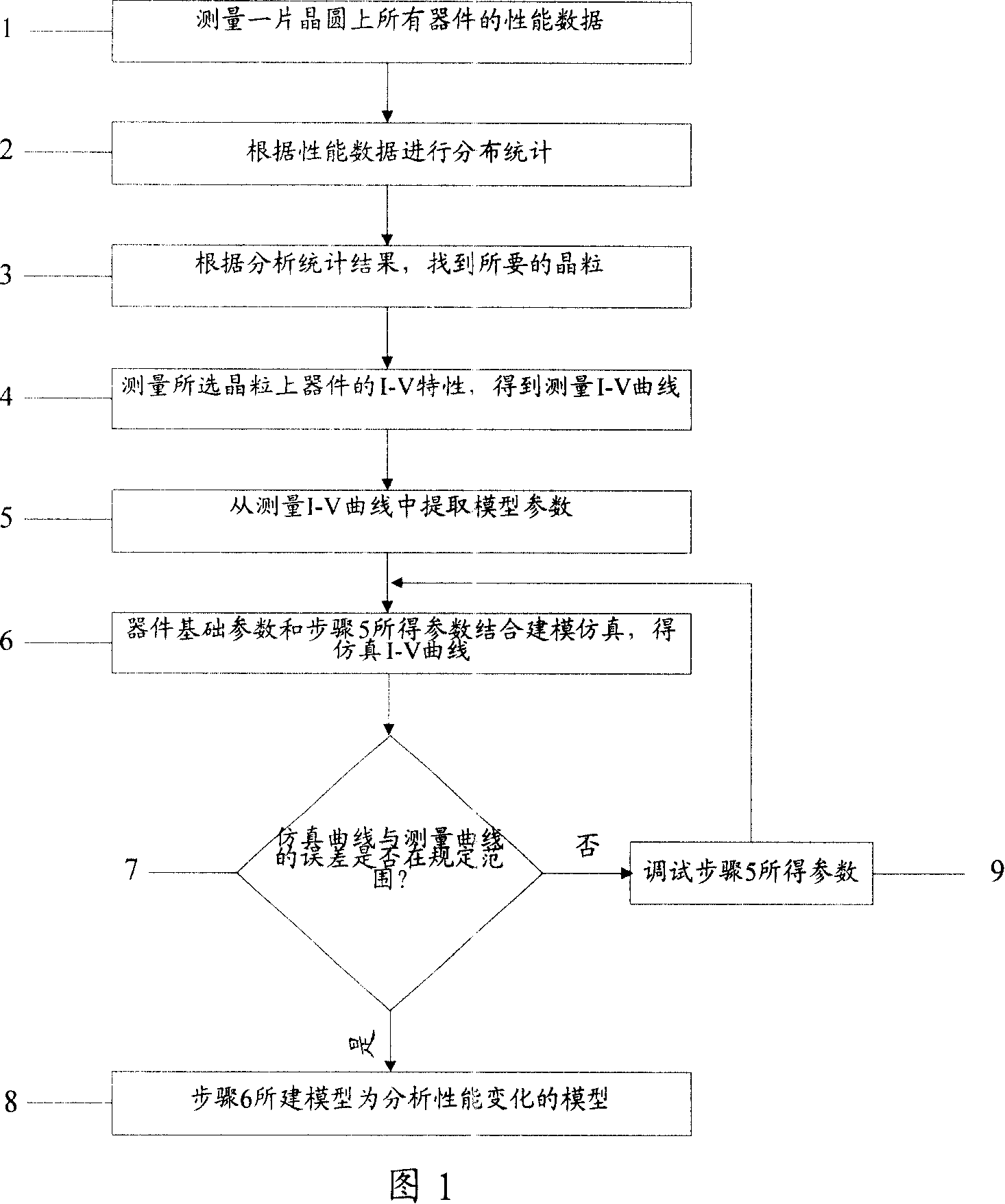

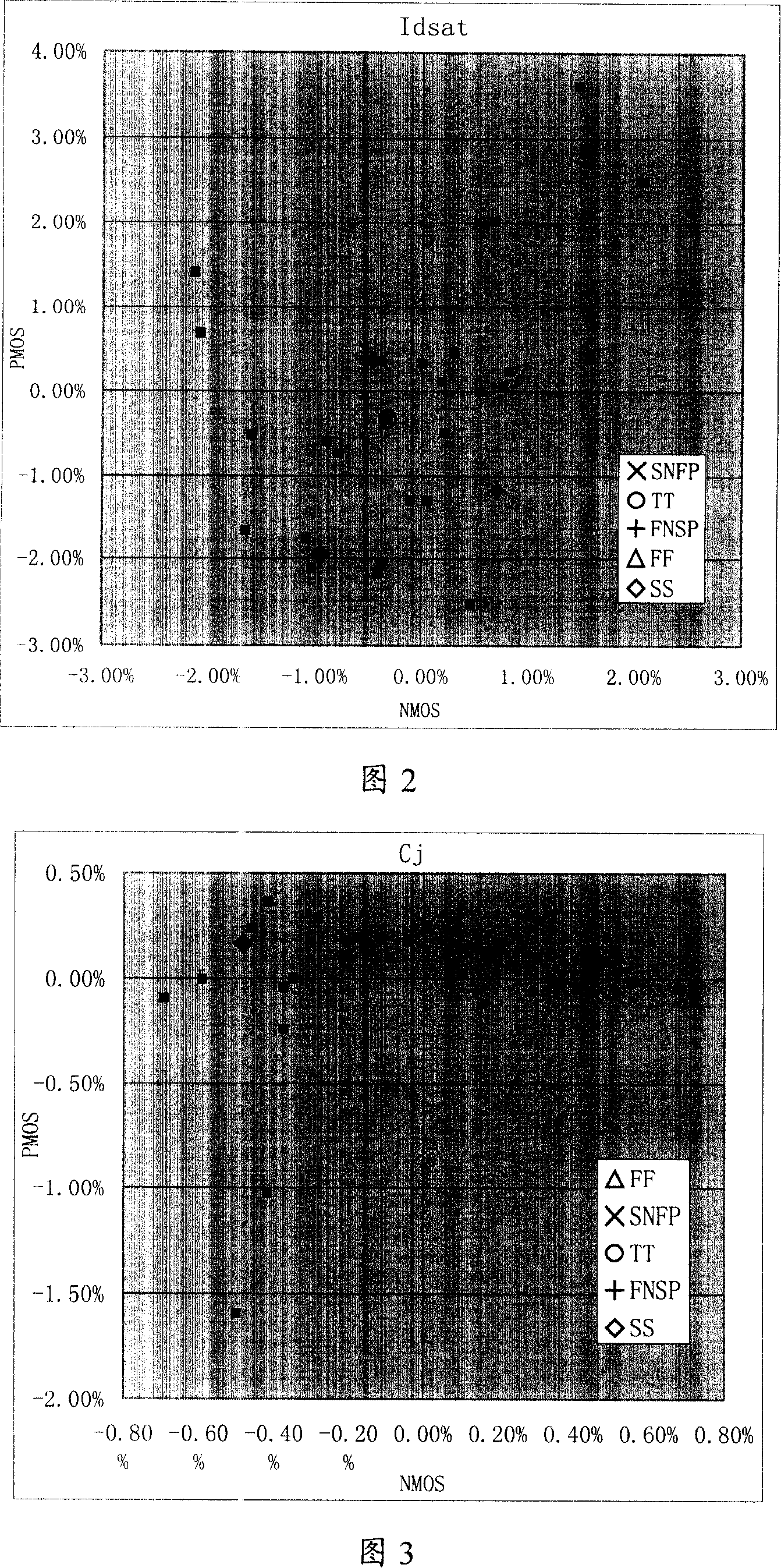

Method for model building based on changes of integrated circuit manufacture process performance

InactiveCN101154242AIntuitive debugging processShort time spentSpecial data processing applicationsAnalysis modelsIntegrated circuit manufacturing

The present invention discloses a building device model method based on the change of integrated circuit manufacturing procedure performance. Firstly, performance data of all transistors on a wafer are measured; crystal grains of a plurality of biggest discrete points are obtained by distributing statistics on the performance data. Then I-V properties of all the transistors of all crystal grains are measured to obtain a measuring I-V curve; model parameters are extracted from the measuring I-V curve. Next, the model parameters combining with the basic parameters of the transistors are input into a simulation software to obtain a simulation I-V curve through model building and simulation; the model parameters are debugged to make errors of the simulation I-V curve and the measuring I-V curve in a specified scope; finally the model satisfying the need of error is used as a performance-analysis model. Models produced by the model building method of the invention can reflect the scope of the device performance on the wafer deviating from a predicated value or a medium value more accurately, thereby helping designers predict the fluctuation of production technique and the deviation of device dimension.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

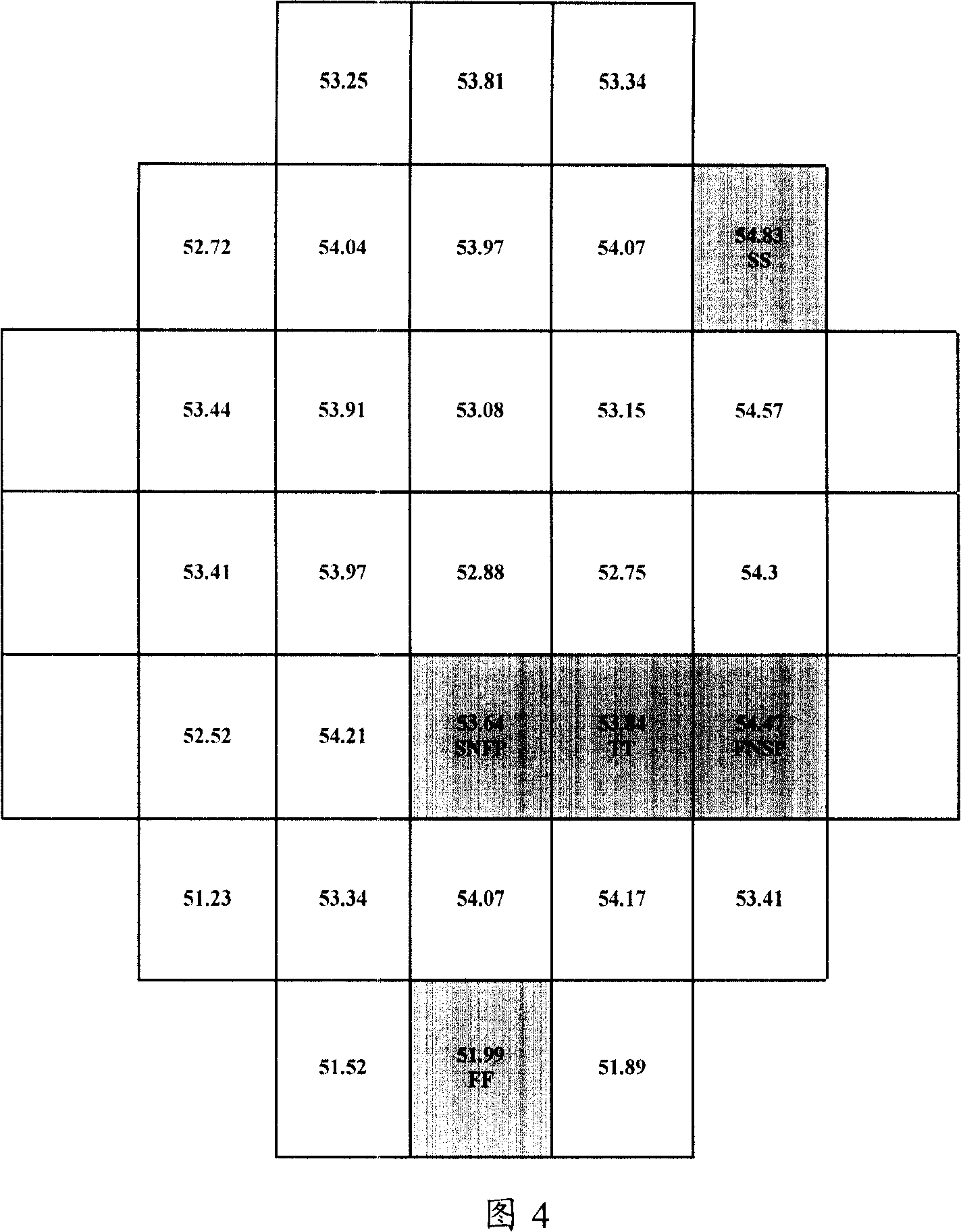

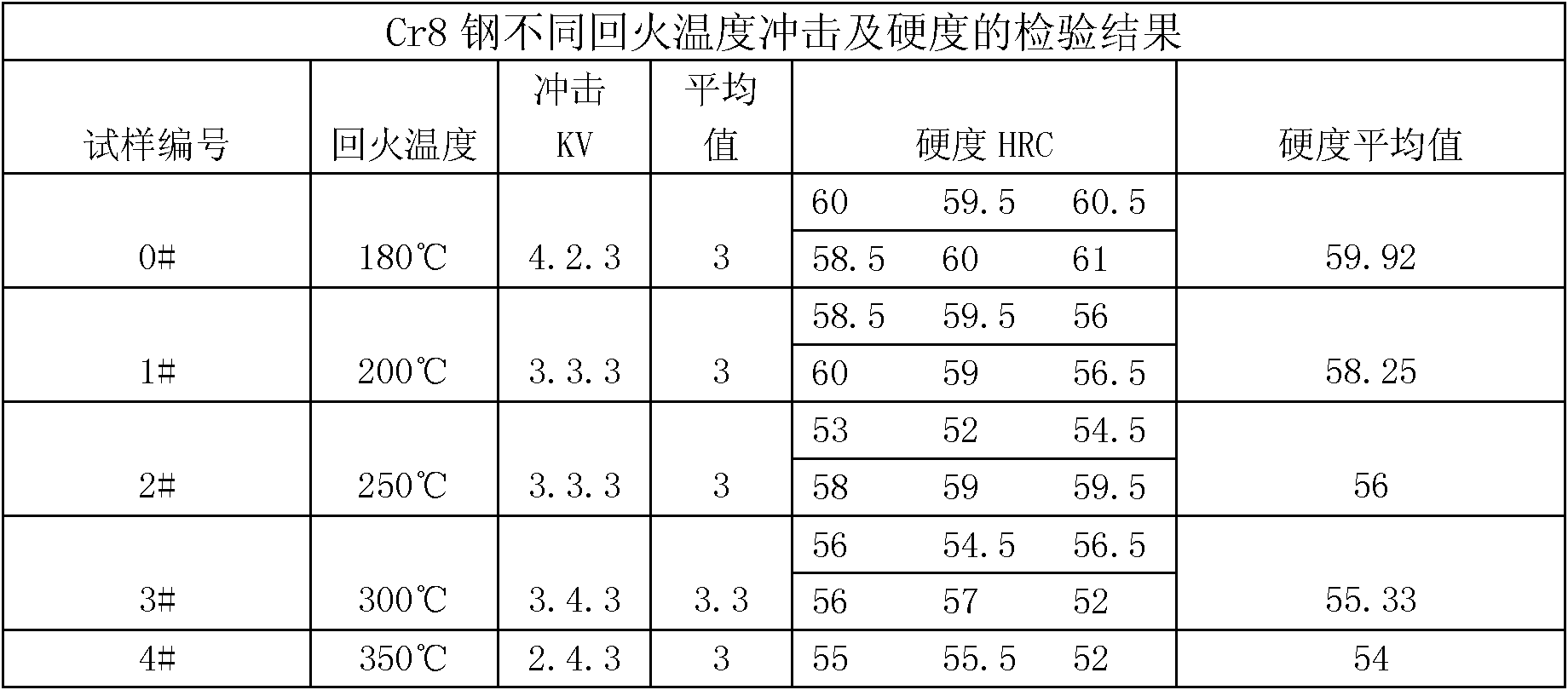

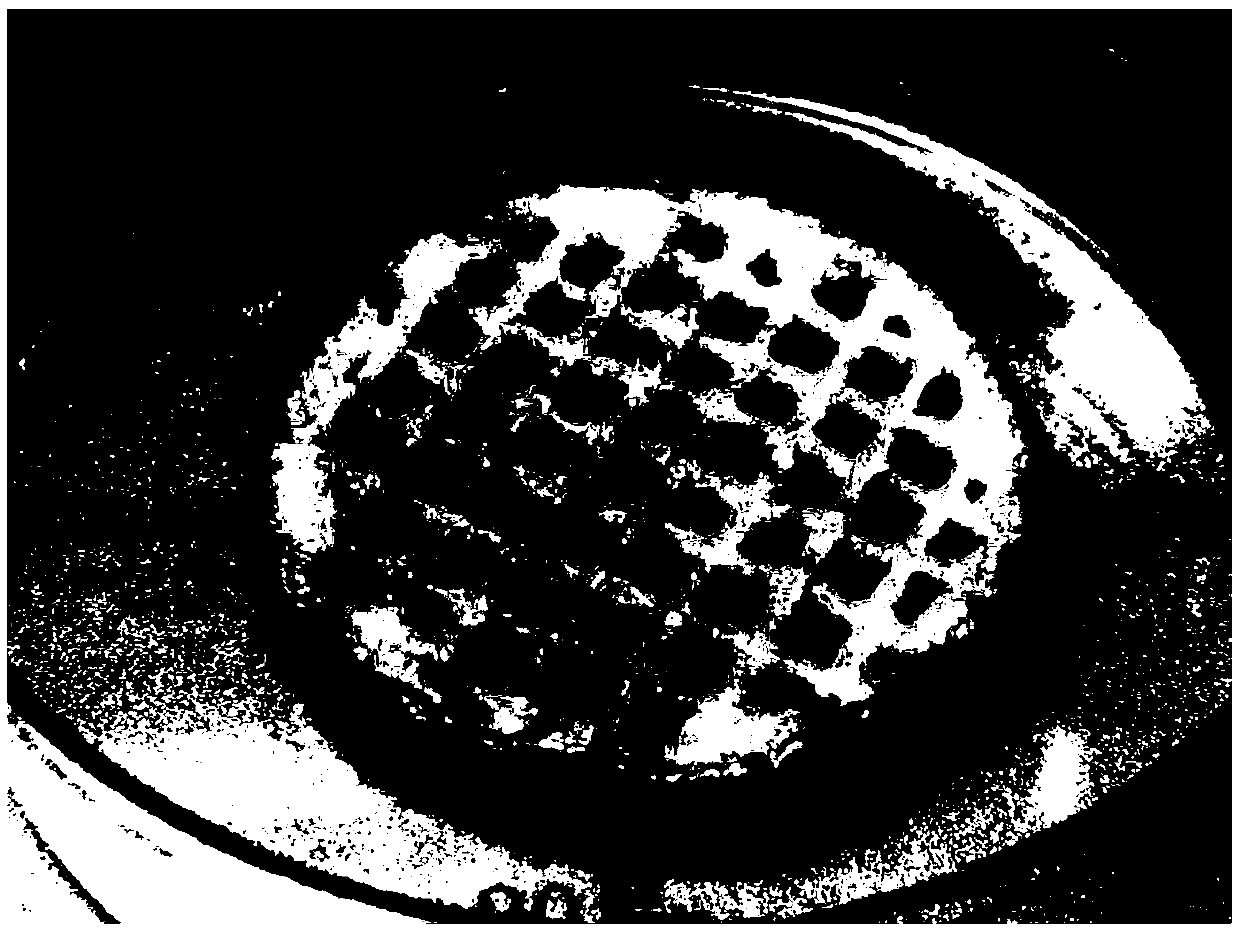

A kind of cold working die steel cr8 and its production method

The invention relates to a cold work die steel Cr8 and a production method thereof. The chemical composition of the cold work die steel Cr8 is as follows according to weight percentage: C: 1.10-1.20%, Mn: 0.30-0.60%, Si≤0.40 %, P≤0.030%, S≤0.030%, Cr: 7.00~8.00%, Cu≤0.25%, and the balance is iron. The production method of cold work die steel Cr8 is carried out according to the following steps: 1) preliminary smelting in an intermediate frequency furnace; 2) tapping; 3) refining in a refining furnace, and then on a continuous casting machine; 4) heating and rolling with heat treatment. The cold working die steel Cr8 of the present invention has the advantages of high hardness, high wear resistance, high hardenability and good toughness, can avoid brittle cracks caused by poor toughness, and has the advantage of low price. The production method has the advantages of simpler process and less time-consuming.

Owner:广东金型重工有限公司

Hydrogel composite material for 3D printing and preparing method and application thereof

ActiveCN109646720AEnsure safetyRich sourcesAdditive manufacturing apparatusTissue regenerationBiocompatibility TestingSodium glycerophosphate

The invention discloses a hydrogel composite material for 3D printing and a preparing method and application thereof. Firstly, the invention discloses the hydrogel composite material for 3D printing.The hydrogel composite material for 3D printing is prepared from, by mass, 10-40% of PEG modified chitosan, 10-40% of gelatin and 30-60% of alpha-cyclodextrin. The invention further discloses the preparing method and application of the hydrogel composite material. When the hydrogel composite material is used for 3D printing, a dual physical crosslinking mode is adopted and involves that before printing, PEG and alpha-cyclodextrin form a supermolecule hydrogel system, and after printing, remaining aminos in chitosan and aminos and beta-sodium glycerophosphate in the gelatin form ironic crosslinking, so that the strength of a hydrogel model structure after printing is improved, and the hydrogel composite material has good printability, biocompatibility and operability.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI +1

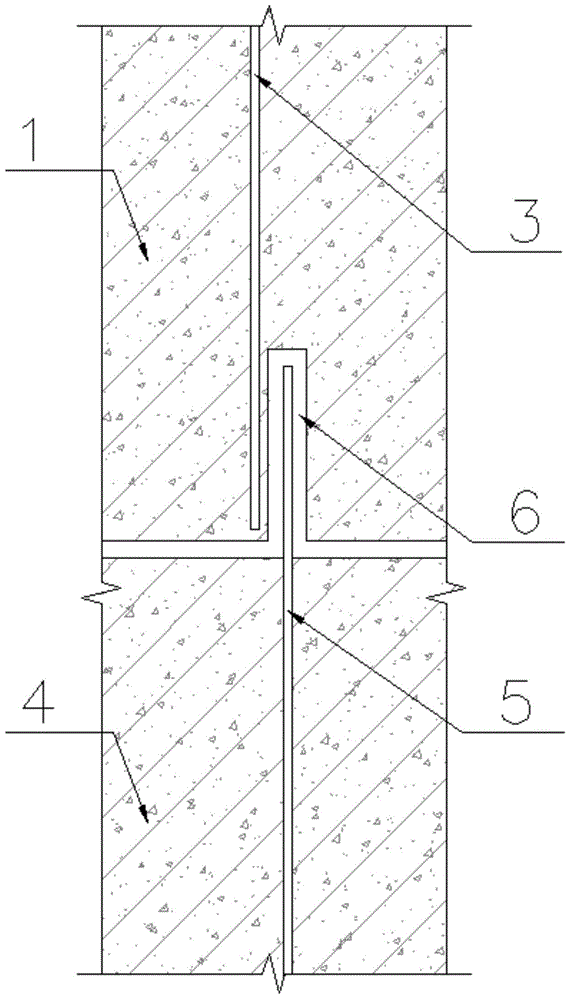

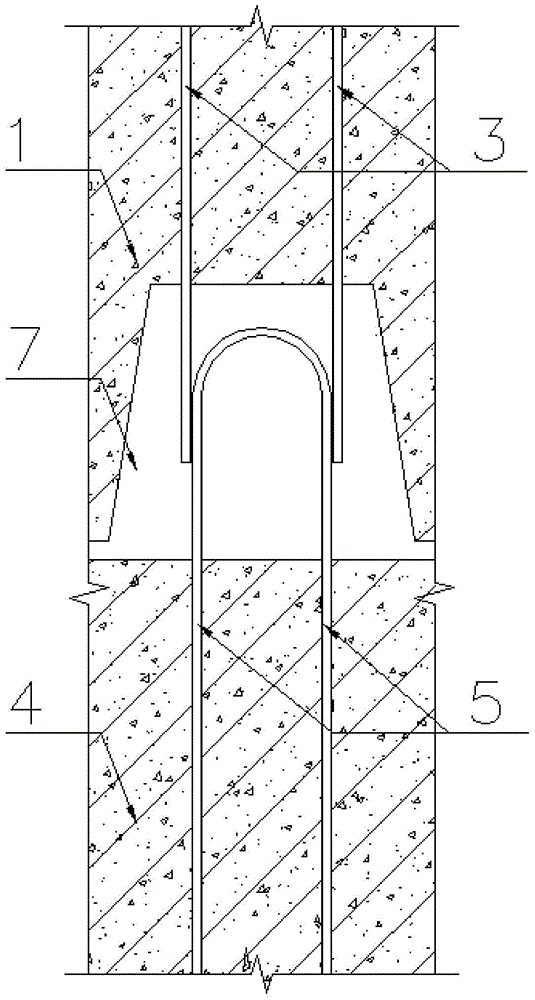

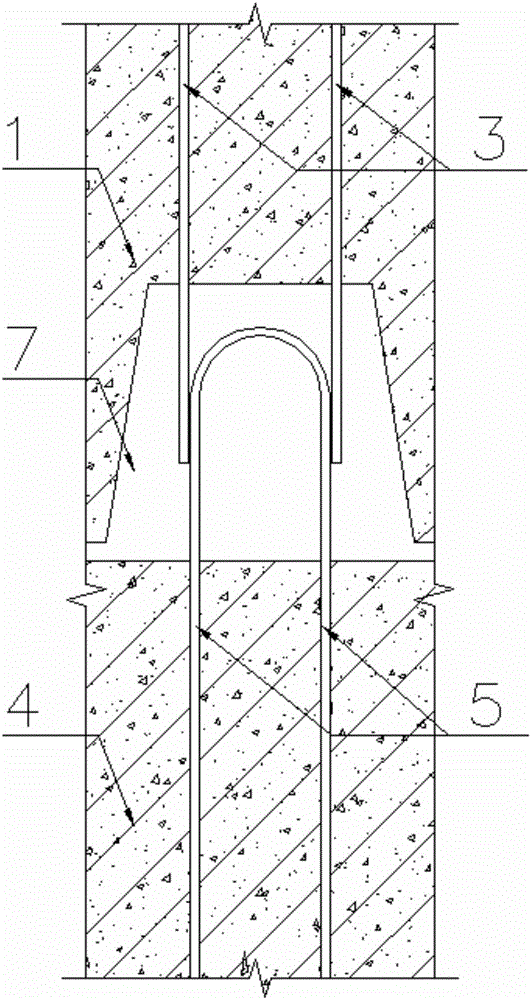

Assembly type prefabricated shear wall horizontal abutted seam steel channel welding and connecting device and connecting method

The invention discloses an assembly type prefabricated shear wall horizontal abutted seam steel channel welding and connecting device and a connecting method. An upper steel channel of the device is composed of a flange and a web, and a lower steel channel of the device is composed of a flange and a web. The web of the upper steel channel is arranged in the mode of being closely attached to the bottom face of an upper prefabricated shear wall. The flange of the upper steel channel is upward and is welded to upper connecting reinforcement. The web of the lower steel channel is arranged in the mode of being closely attached to the top face of a lower prefabricated shear wall. The flange of the lower steel channel is downward and is welded to lower connecting reinforcement. The upper steel channel of the upper prefabricated shear wall and the lower steel channel of the lower prefabricated shear wall are connected through steel channel edge weld seams. The upper connecting reinforcement and the lower connecting reinforcement are connected in an aligned mode. When the upper prefabricated shear wall and the lower prefabricated shear wall are spliced, by connecting a temporary fixing rod with an upper raise ear and a lower raise ear, the upper prefabricated shear wall and the lower prefabricated shear wall are fixed temporarily, and then welding is carried out on side edges of the steel channels to connect the upper steel channel and the lower steel channel. According to the device, the assembly process of the prefabricated shear walls can be simplified, the construction period can be shortened, labor consumption is reduced, and site pollution and material waste are reduced.

Owner:ARCHITECTURAL DESIGN & RES INST OF SOUTH CHINA UNIV OF TECH

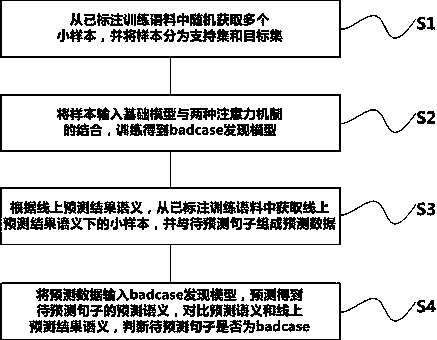

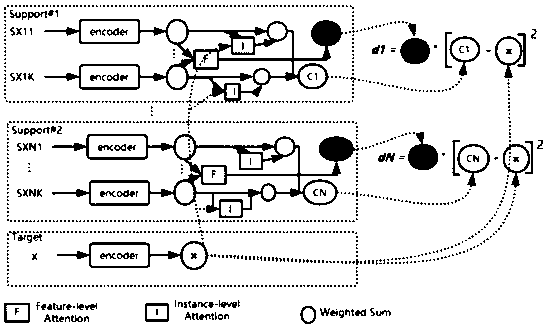

Badcase discovery method and system based on small sample learning

InactiveCN111046979AReduce time wastedReduce learning biasCharacter and pattern recognitionData predictionOutcome predictor

The invention discloses a badcase discovery method and system based on small sample learning, and the system applies the method, and the method comprises the steps: carrying out the data preprocessing, randomly obtaining a plurality of small samples from a labeled training corpus, and dividing the samples into a support set and a target set; pre-training the model, inputting the sample into a basic model, combining the basic model with two attention mechanisms, and performing training to obtain a badcase discovery model; predicting data assembly: according to online prediction result semantics, obtaining small samples under the online prediction result semantics from the labeled training corpus, and forming prediction data by the small samples and the sentence to be predicted; and performing data prediction: inputting the prediction data into the badcase discovery model, performing prediction to obtain prediction semantics of a to-be-predicted sentence, comparing the prediction semantics with online prediction result semantics, and judging whether the to-be-predicted sentence is badcase or not. By adopting the method to discover the badcase, quick positioning can be performed in massive data, and error data can be accurately obtained.

Owner:CHENGDU XIAODUO TECH CO LTD

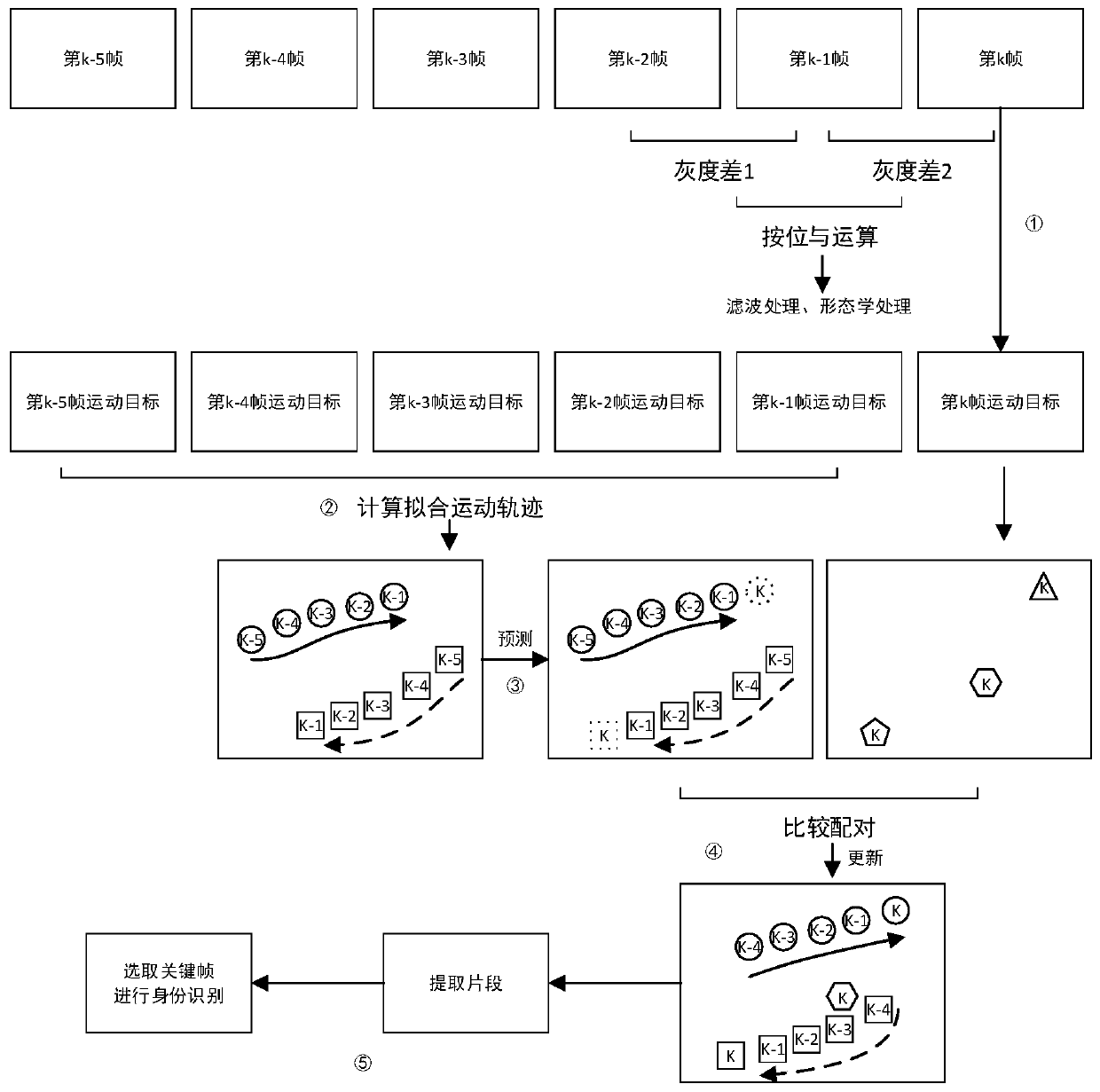

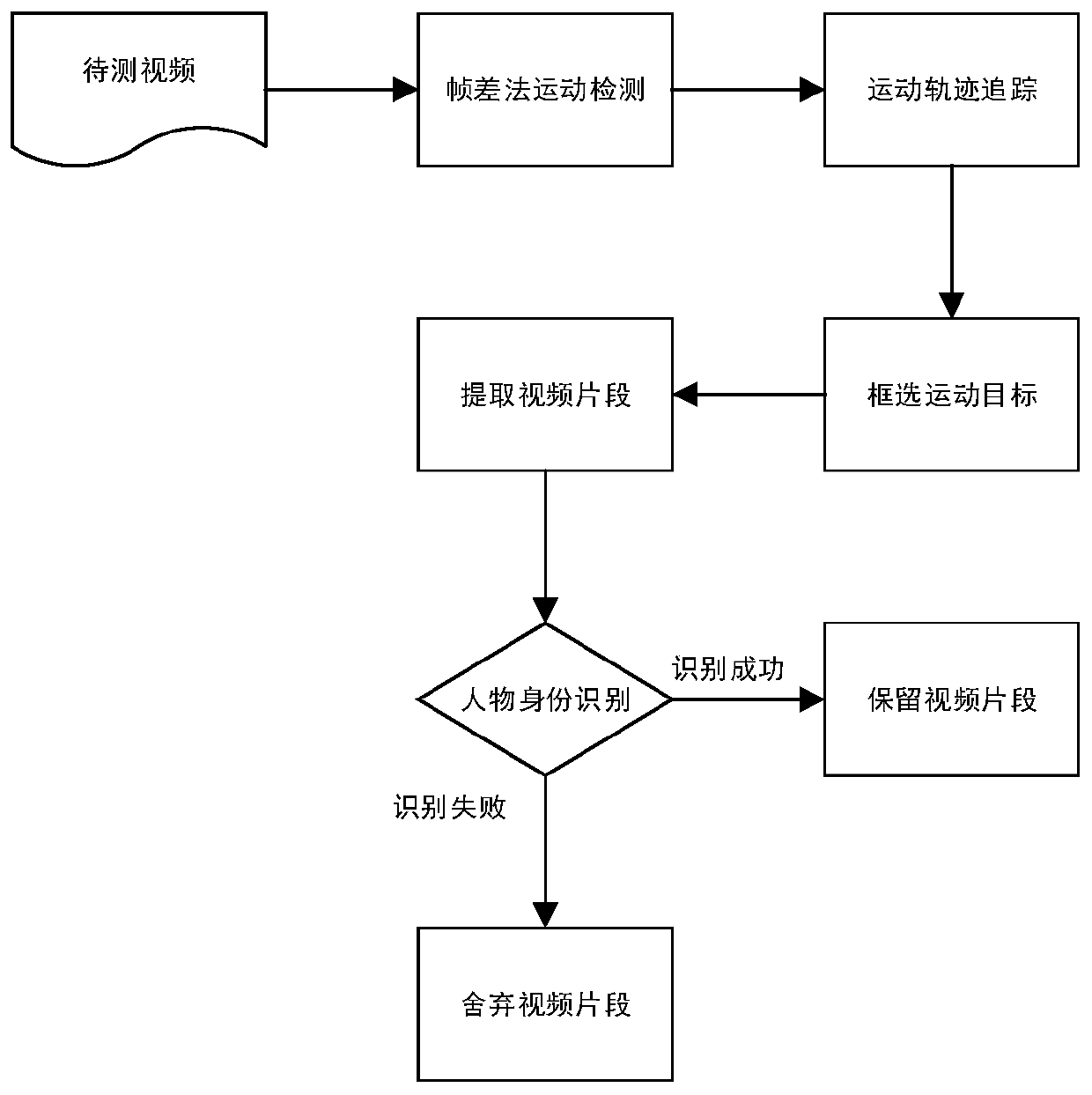

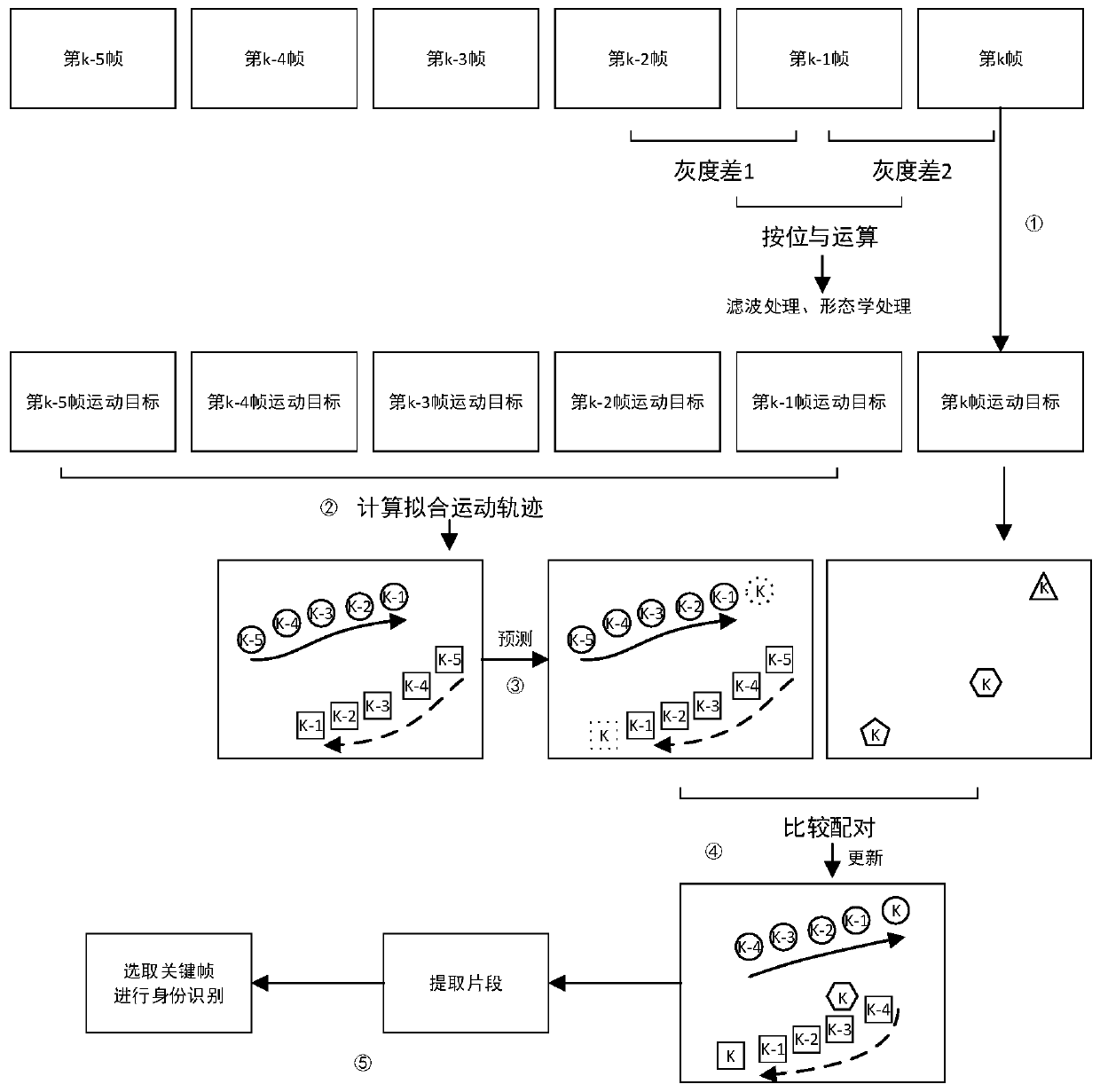

Figure video clip extraction method based on multi-target motion tracking

ActiveCN110009659AReduce time wastedImage enhancementImage analysisIdentity recognitionSurveillance camera

The invention provides a figure video clip extraction method based on multi-target motion tracking, which comprises the following steps: firstly, extracting a video clip in which a moving target appears, and then carrying out figure identity recognition on the extracted video clip. The method is used for monitoring a video shot by a camera, that is, the camera is fixed within a long period of time, a video with no large change in the background of a picture is shot, all moving targets in the video picture can be tracked in real time, the moving targets are identified and distinguished, a videosegment in which a moving object appears is extracted, and the identity of a person in the moving object is identified.

Owner:WUHAN UNIV

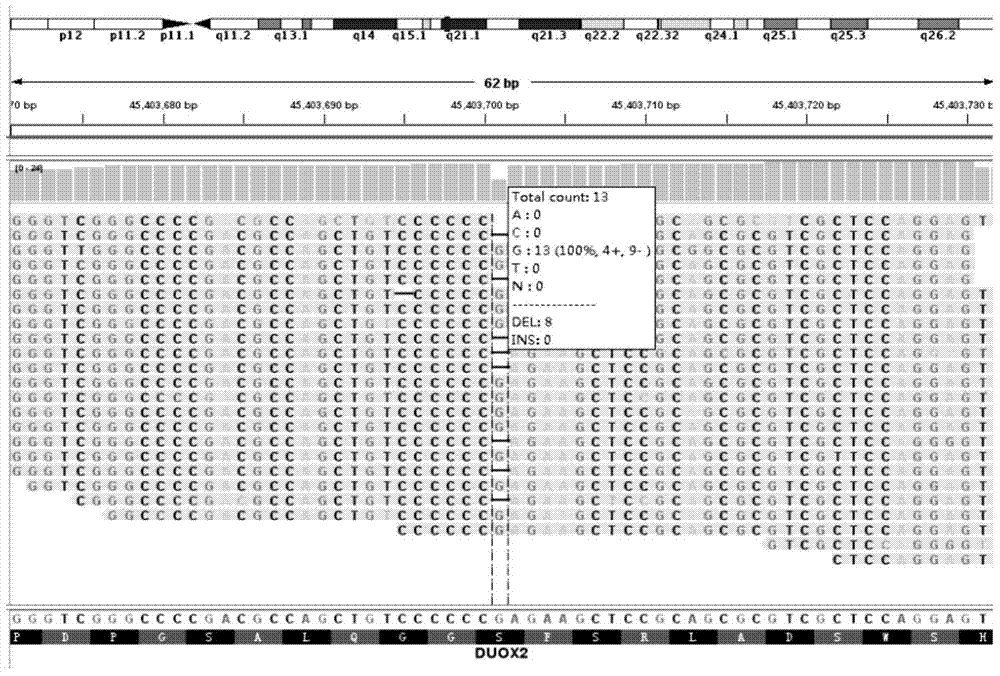

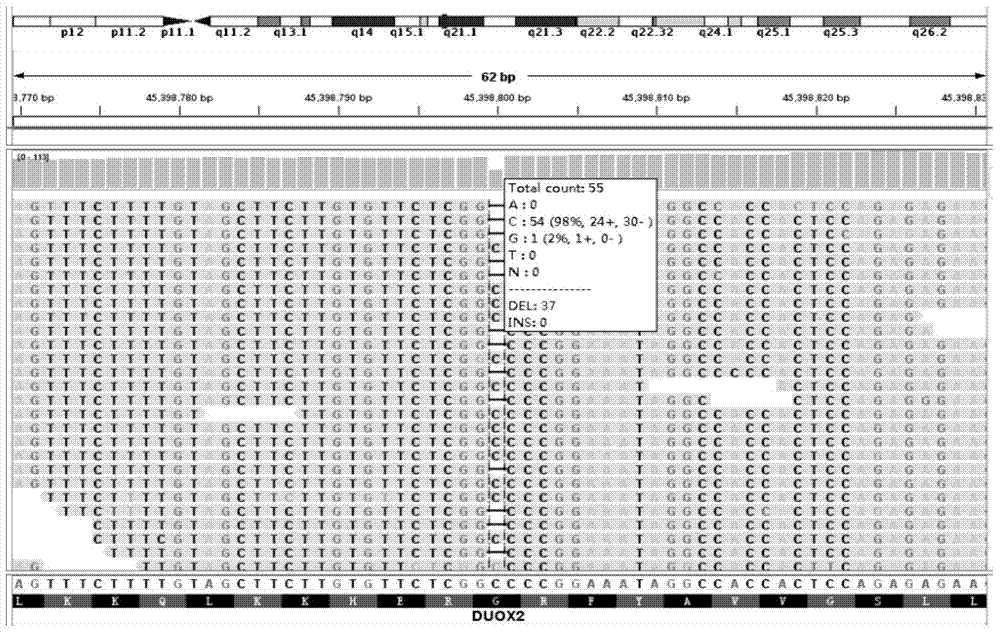

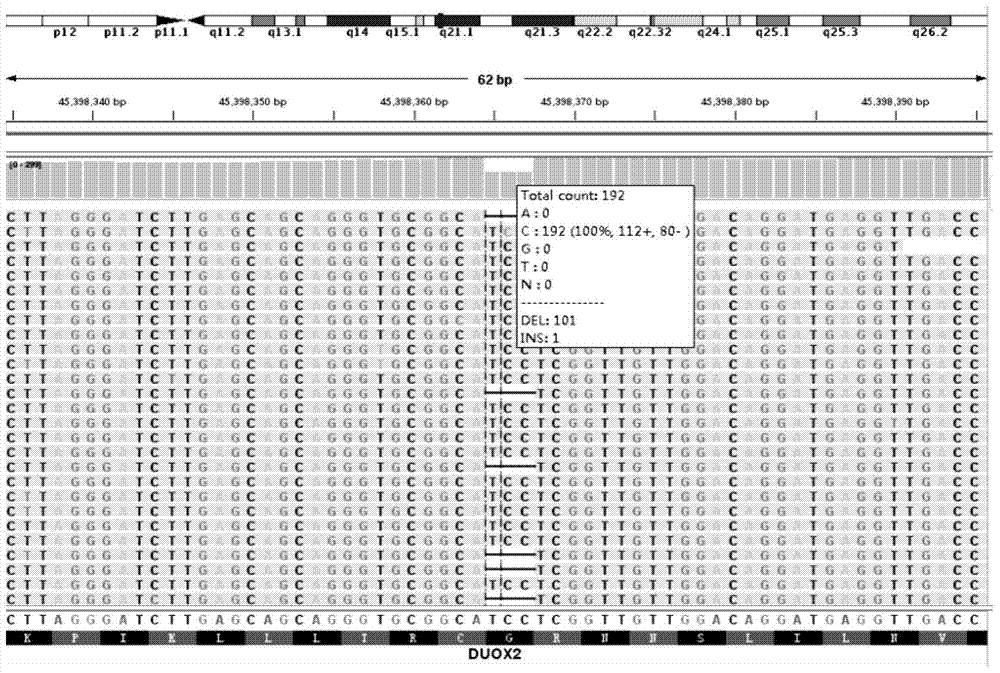

Detection probe for DUOX2 gene mutation and detection method thereof

InactiveCN104120187AQuick checkComprehensive detection effectMicrobiological testing/measurementGenetic material ingredientsDUOX2 geneNew mutation

The invention discloses a detection probe for DUOX2 gene mutation and a detection method thereof, particularly relates to a method for detecting DUOX2 gene mutation related to a congenital hypothyroidism (CH) pathogenic gene, and belongs to the technical field of molecular biology. A PCR primer sequence of a DUOX2 gene for detecting the CH is a nucleotide sequence as shown in SEQ ID No.1-SEQ ID No.18 in the sequence table. The detection probe has the advantages that the DUOX2 gene causing the CH is detected by utilizing new generation sequencing, and 24 new mutation sites which are not yet reported home or abroad are discovered. The detection probe applied to clinical gene mutation detection is beneficial to etiological analysis and diagnosis of CH, further recognition of mutation spectrum of the CH gene and further research on pathogenesis of CH.

Owner:MATERNAL & CHILD HEALTH HOSPITAL OF GUANGXI ZHUANG AUTONOMOUS REGION GUANGXI ZHUANG AUTONOMOUS REGION

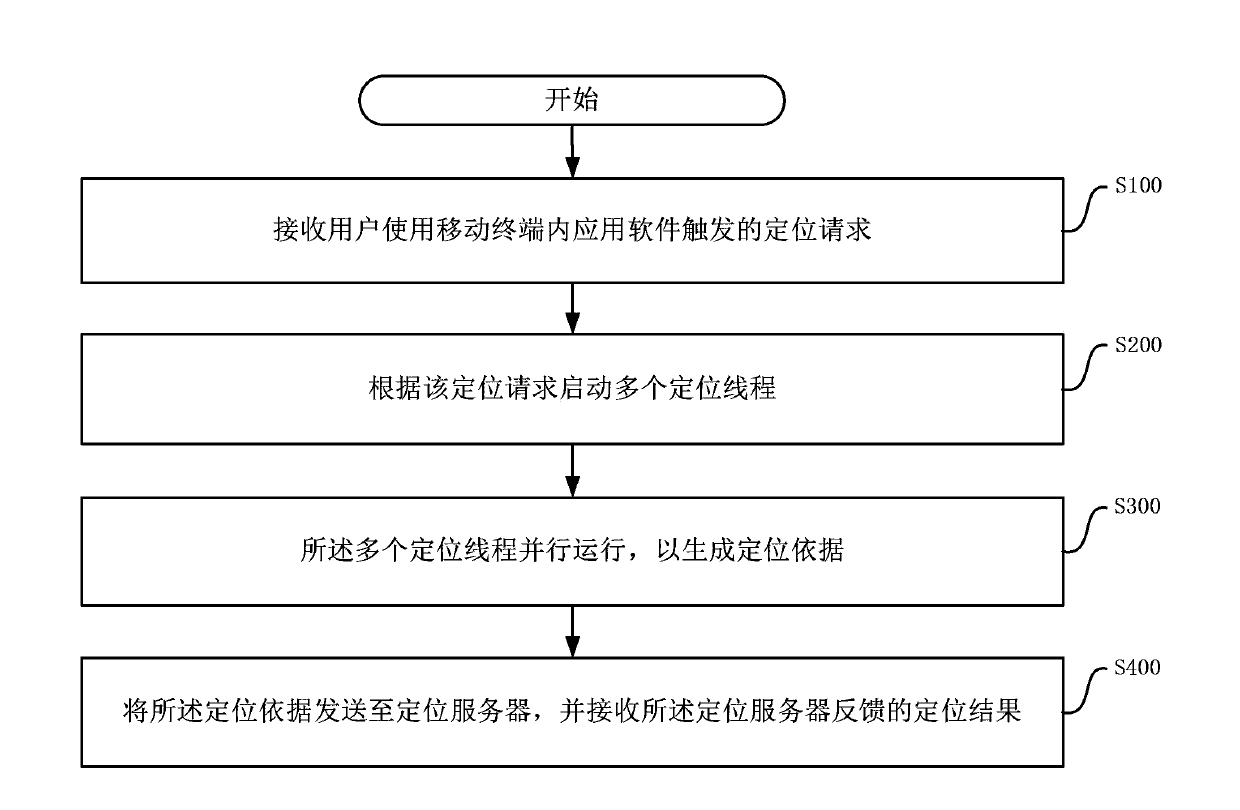

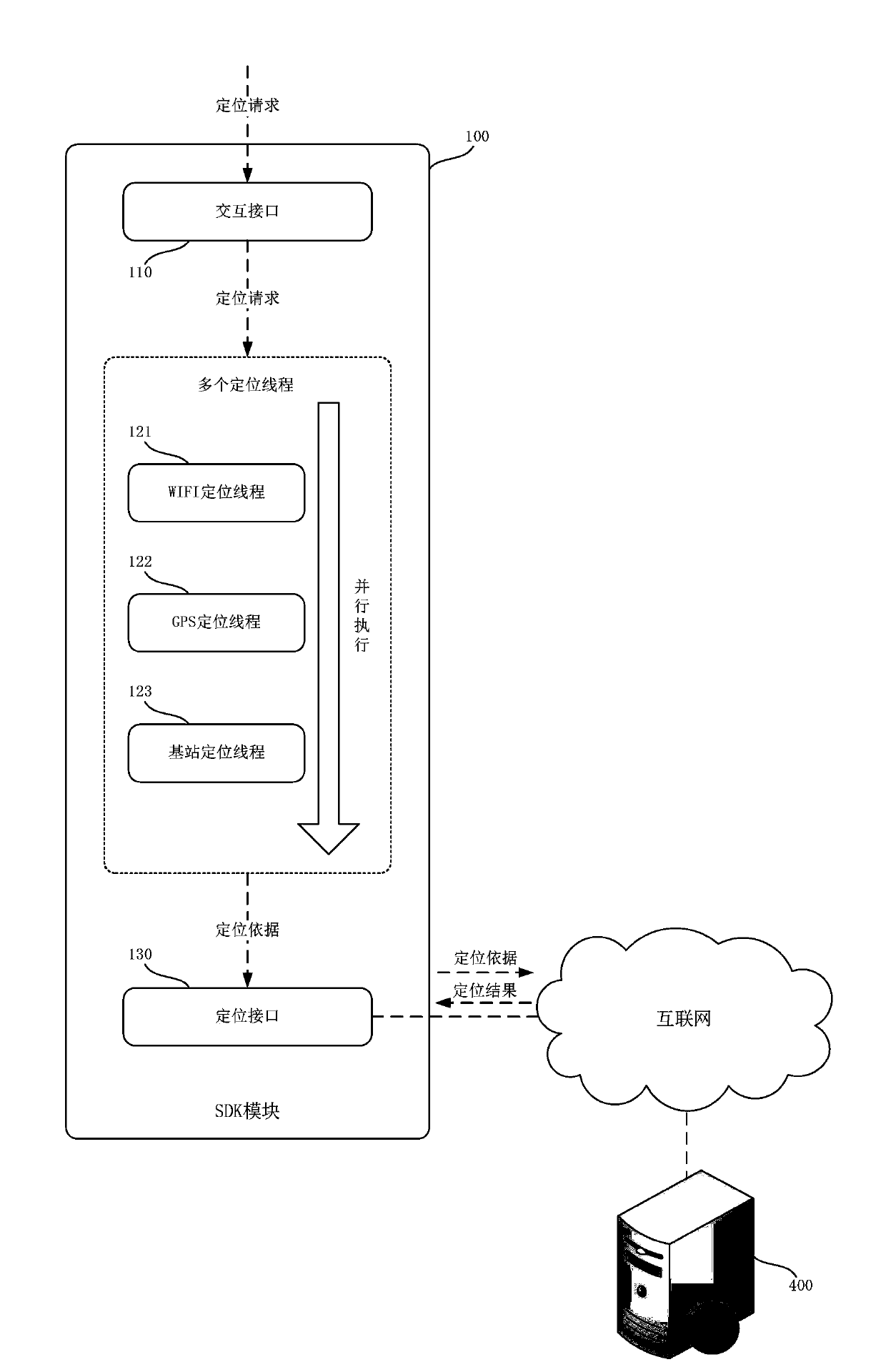

Method for realizing positioning server at mobile terminal and software development kit module

InactiveCN103997711AHigh positioning accuracyImprove power efficiencyLocation information based serviceSoftware engineeringSoftware development

The invention provides a method for realizing positioning service in a program at a mobile terminal. The method comprises the following steps: receiving a positioning request triggered by application software in a mobile terminal by a user; starting a plurality of positioning treads according to the positioning request; carrying out parallel operation of the plurality of positioning threads to generate a positioning basis; and sending the positioning basis to a positioning server and receiving a positioning result fed back by the positioning server. Correspondingly, the invention also provides a software development kit (SDK) module. The provided method or SDK module is applied to the program of the mobile terminal. The positioning precision, the positioning success rate and the positioning efficiency of the program can be improved.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com