Testing method for accelerating evaluation of slow crack increase resistance of polyethylene tube

A technology resistant to slow cracks, polyethylene pipes, applied in the direction of applying stable tension/pressure to test material strength, preparation of test samples, measurement devices, etc., can solve the lack of accuracy, poor reproducibility, and lengthy test cycle and other problems, to achieve the effect of high accuracy and reproducibility, overall time-consuming reduction, and less material consumption for testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

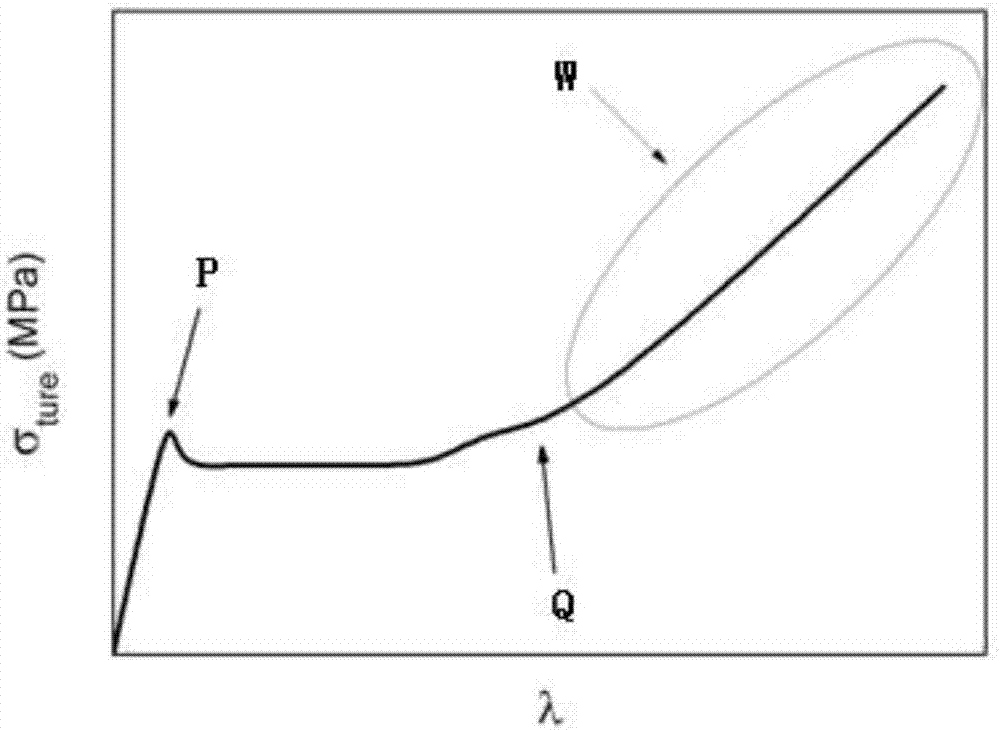

[0029] Based on the inherent strain hardening response characteristics of polyethylene pipes, the present invention defines the slope of the curve whose stress increases suddenly on the tensile curve as the strain hardening modulus, and uses the strain hardening modulus to characterize the slow crack growth resistance of polyethylene pipes. There is a certain positive correlation between them. The present invention will be further described below in conjunction with specific examples.

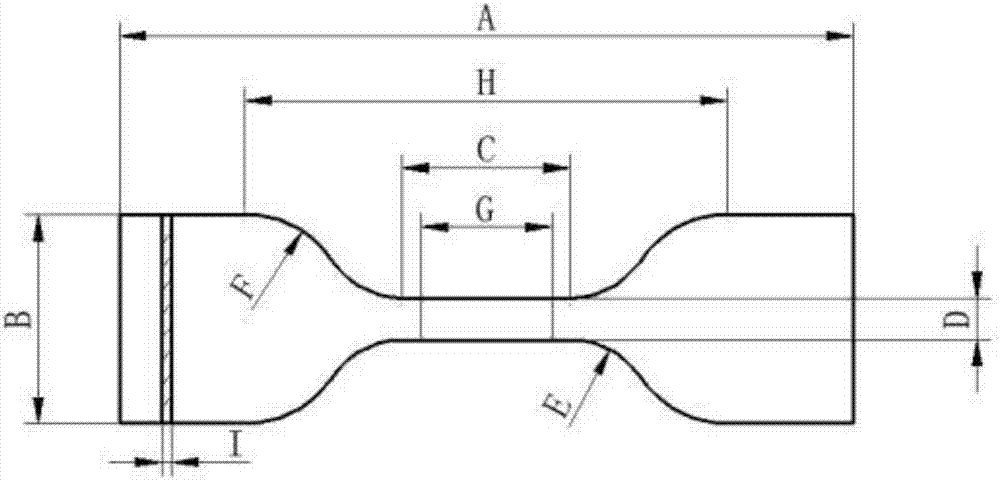

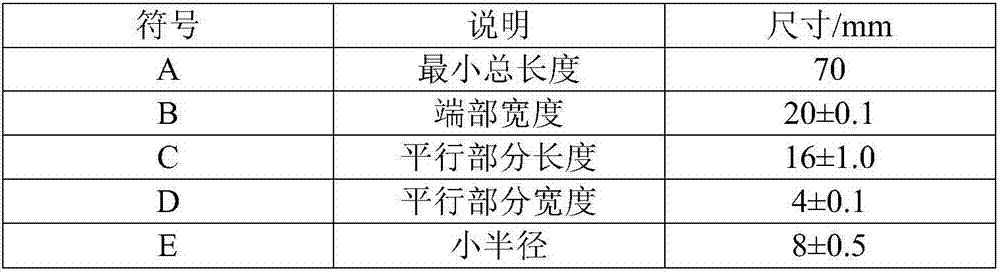

[0030] A test method for accelerated evaluation of slow crack growth resistance of polyethylene pipes in this embodiment includes two steps of test sample preparation and high temperature tensile test.

[0031] Among them, the equipment used for the preparation of the test samples is a four-column electric water-cooled flat vulcanizer, an oven, and a manual or pneumatic punching machine. The specific process is divided into three steps:

[0032] In the first step, the polyethylene raw material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com