Telescopic filter element, and filter with replaceable filter element

A filter and filter element technology, which is applied in the field of air purification, can solve the problems of easily disordered air flow, labor-intensive removal of excess glue, and large deformation of filter elements, so as to reduce the generation of hazardous waste and solid waste, prevent operational safety problems, and improve air flow The effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

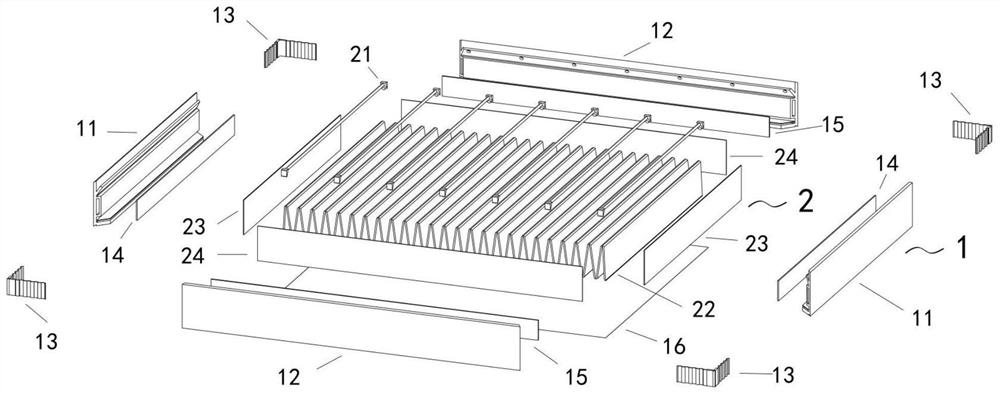

[0055] Such as Figures 6 to 8 As shown, a retractable filter core, the filter core includes a wave-shaped filter element 22, the surrounding of the wave-shaped filter element 22 is provided with a first edge band 23 and a second edge band 24, the first edge band Strip 23 is a hard edge band, which is arranged on both sides of the folded edge of the wave-shaped filter element 22, and the second edge band 24 is a soft elastic edge band, which is arranged on more than one side of the wave-shaped filter element 22. On both sides of the folded edge, and on both sides of the multi-folded edge, there are also fixing pieces 21. The fixing pieces 21 are distributed sequentially along the length direction of the second edge sealing strip 24, and each fixing piece 21 passes through the corrugated filter element. Fold the bottom surface of the peak and the two second edge banding strips 24 .

[0056] In this embodiment, the first edge sealing strip 23 and the second edge sealing strip 2...

Embodiment 2

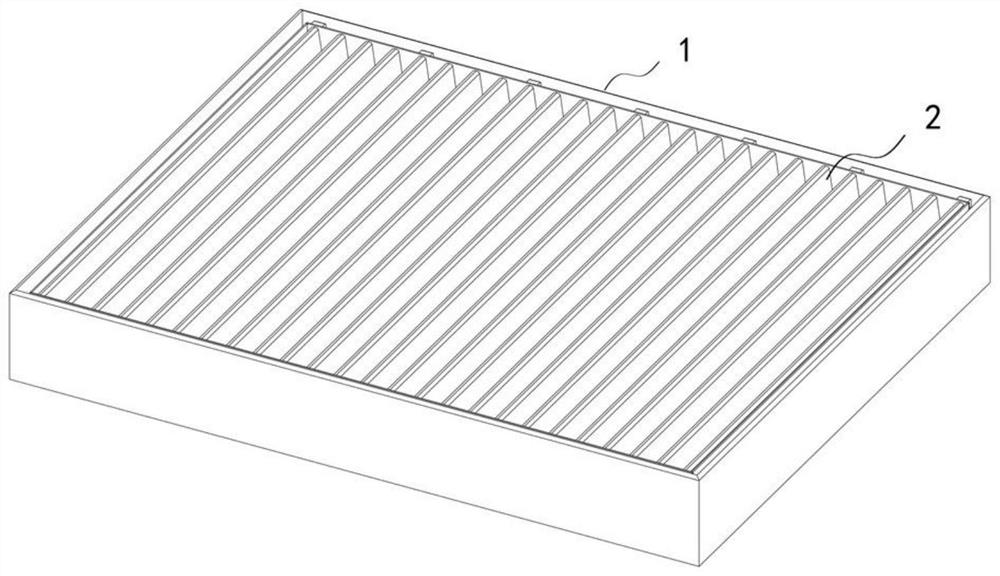

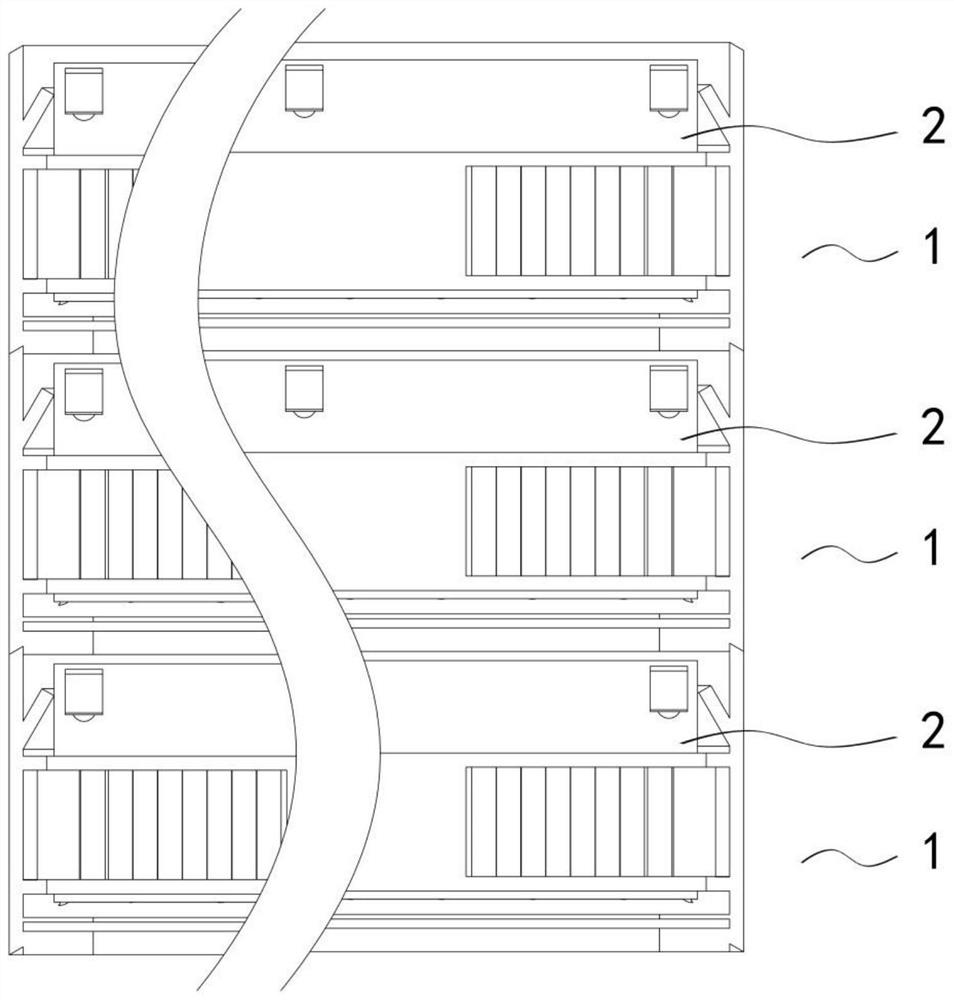

[0061] Such as Figures 1 to 5 As shown, a replaceable filter element filter includes a filter element 2 and a frame 1, the filter element 2 adopts the retractable filter element in Embodiment 1, and the frame 1 is spliced with the first frame piece 11 and the second frame piece 12 The first frame piece 1 and the second frame piece 12 have an L-shaped structure as a whole, and the top edges of the long sides of the first frame piece 11 and the second frame piece 12 are set as inclined surfaces, and along the inside of the long side From top to bottom, inclined convex strips, hollow reinforcing ribs and screen baffles are arranged in sequence. The installation space of the fixing part is formed between the inner wall of the inclined convex strip and the outer wall of the long side. The hollow area of the inner wall of the reinforcing rib is used for The pin 13 is interspersed and installed, and the pin 13 is used to connect the two ends of the first frame piece 11 and the s...

Embodiment 3

[0071] Different from Embodiments 1 and 2, the first frame sheet 11 and the second frame sheet 12 of Embodiment 3 are cut at 90° from both ends, and the second frame sheet 12 is located inside the first frame sheet 11 . One end of the pin 13 connected to the first frame 11 is a closed cuboid, and is connected with the first frame 11 by a rivet; the end of the pin 13 connected to the second frame 12 is wavy. The inclined convex strip 112 of the second frame sheet 12 has an inclination angle of 60°, and the upper surface of the inclined convex strip 122 is treated with a 2mm height zigzag, and the zigzag is cut into a triangular prism shape at an interval of 48mm, and the triangular prism does not wear the inclined convex strip 122. A modified polyurethane sealing strip 14 with a thickness of 4 mm and a Shore A hardness of 14 degrees is arranged on the outer wall 1133 of the cavity. The fixing part 21 of the filter element 2 is made of ABS composite plastic, and the chuck 213 on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com