Ultramicro pulverizer

A technology of ultra-fine pulverizer and box body, which is applied in the direction of grain processing, etc. It can solve the problems of easy powder clogging and difficult powder clogging, and achieve the effects of not easy clogging and clogging, preventing clogging and reducing downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

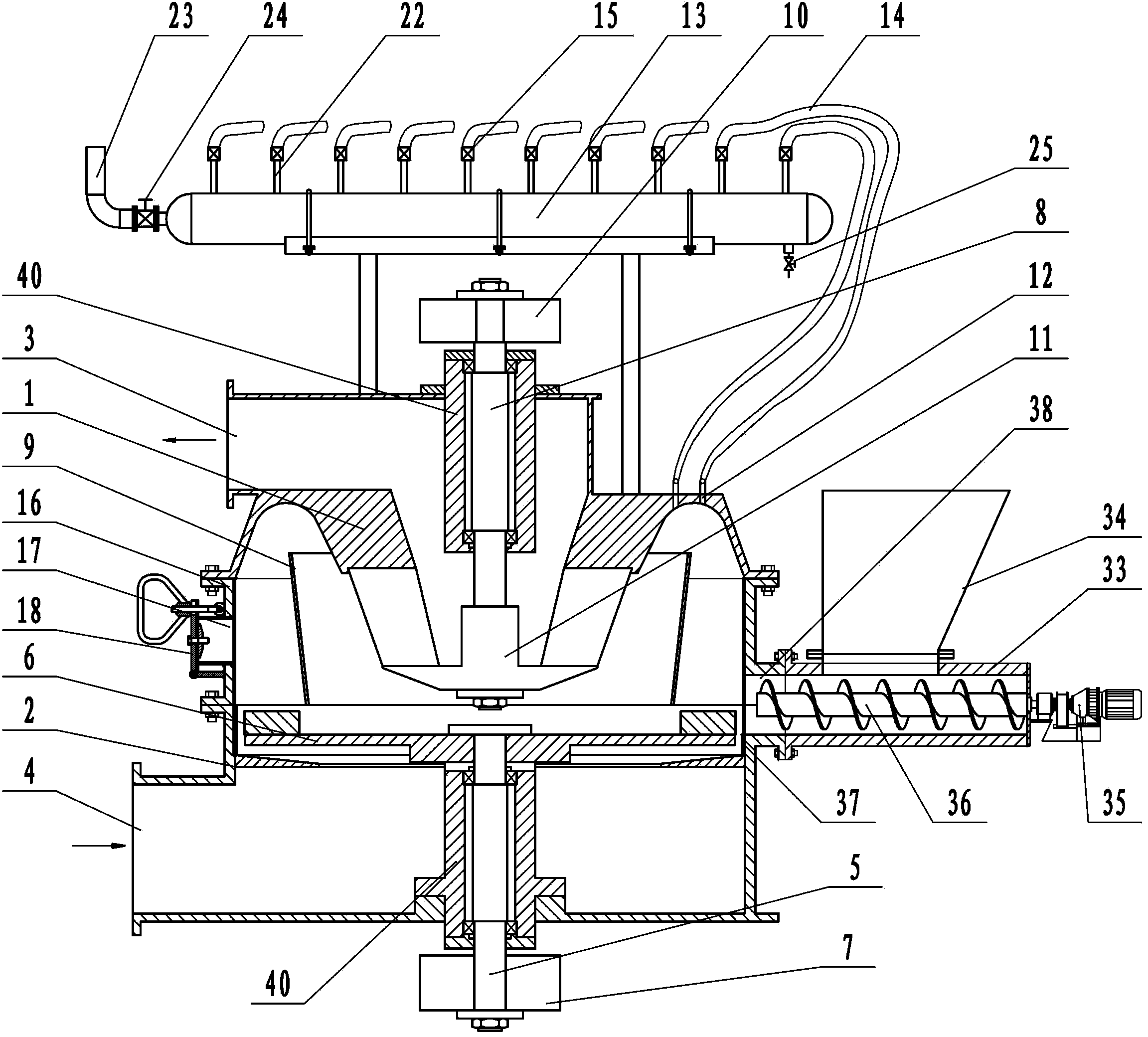

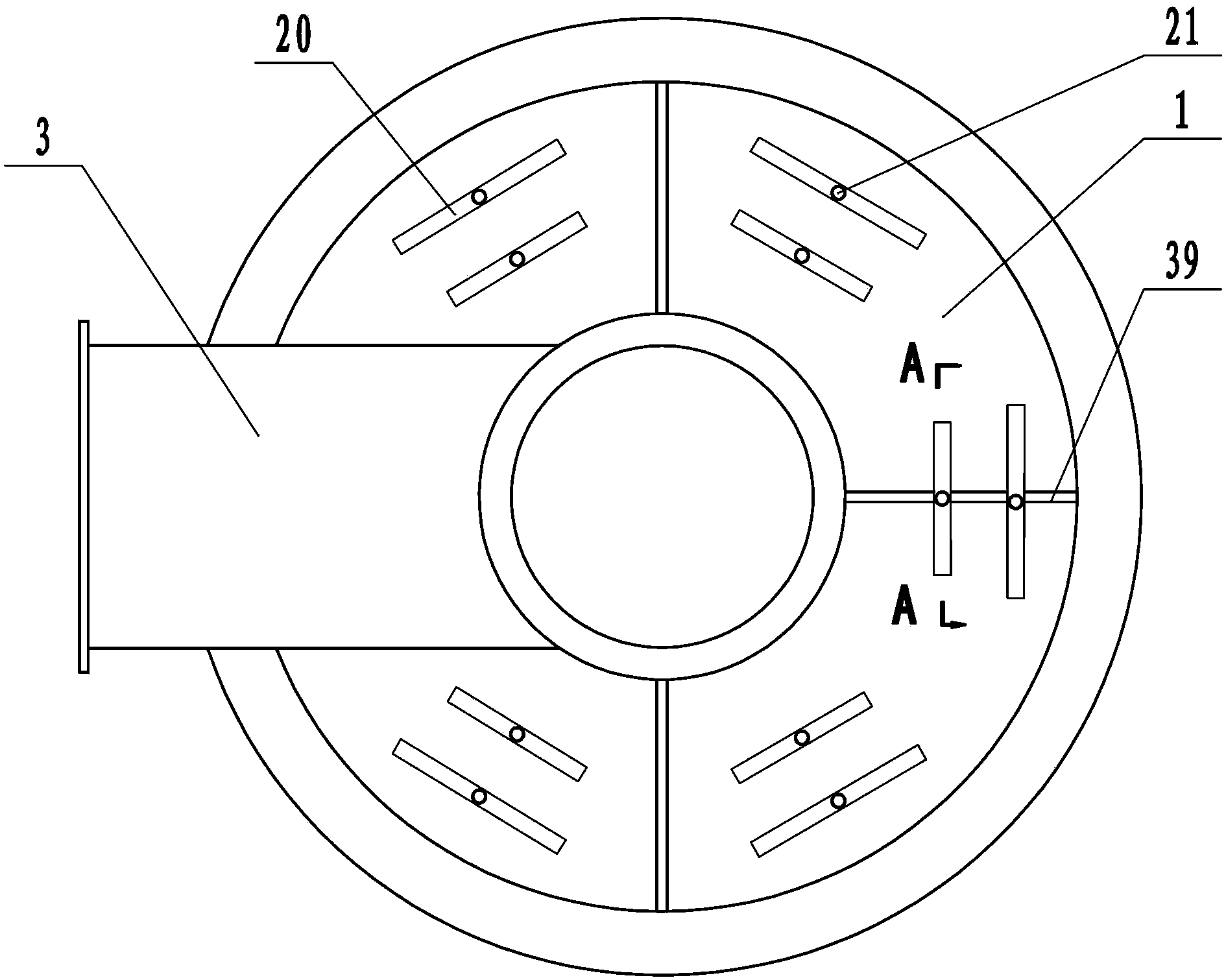

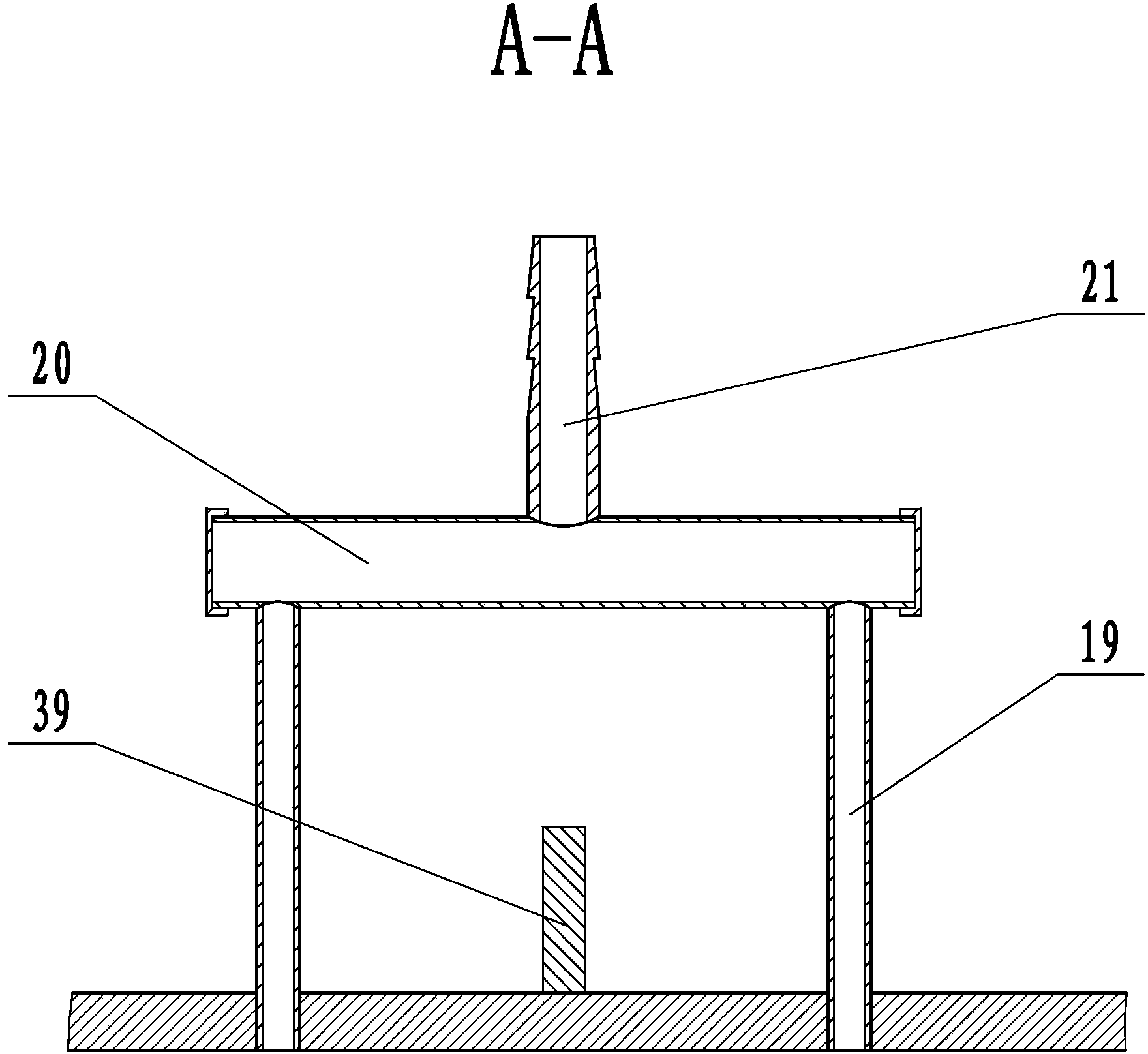

[0024] Example: An ultrafine pulverizer (see attached figure 1 ), including the upper box body 1, the lower box body 2, the upper box body is provided with a discharge port 3, the lower box body is provided with an air inlet 4, the upper box body is provided with an upward cylindrical protrusion, the upper box Between the upper surface of the body and the side wall of the cylindrical protrusion is provided with an upper box body stiffener 39 (see attached figure 2 , Attached image 3 ), the discharge port is set on the cylindrical protrusion. The air inlet is arranged at a position of the lower box body near the lower end side wall. The lower box body is connected to the main shaft 5, the upper end of the main shaft is connected to a crushing disc 6, and grinding blocks are arranged on the edge of the upper surface of the crushing disc. The lower end of the main shaft is connected with the main machine pulley 7, and the motor drives the rotation of the main machine pulley to d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com