Corner combining production line for aluminum alloy doors and windows

A technology for aluminum alloy doors and windows and production lines, which is applied to assembly machines, metal processing, metal processing equipment, etc., can solve the problems of large load-bearing mass, high labor intensity, and manual single-piece feeding, so as to reduce equipment requirements and labor intensity , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

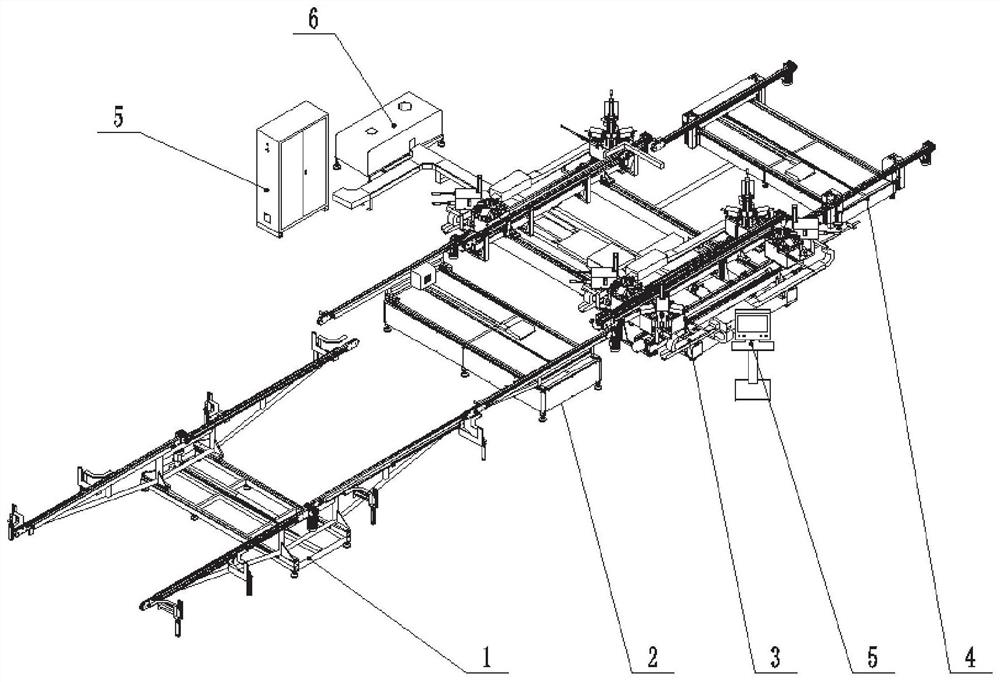

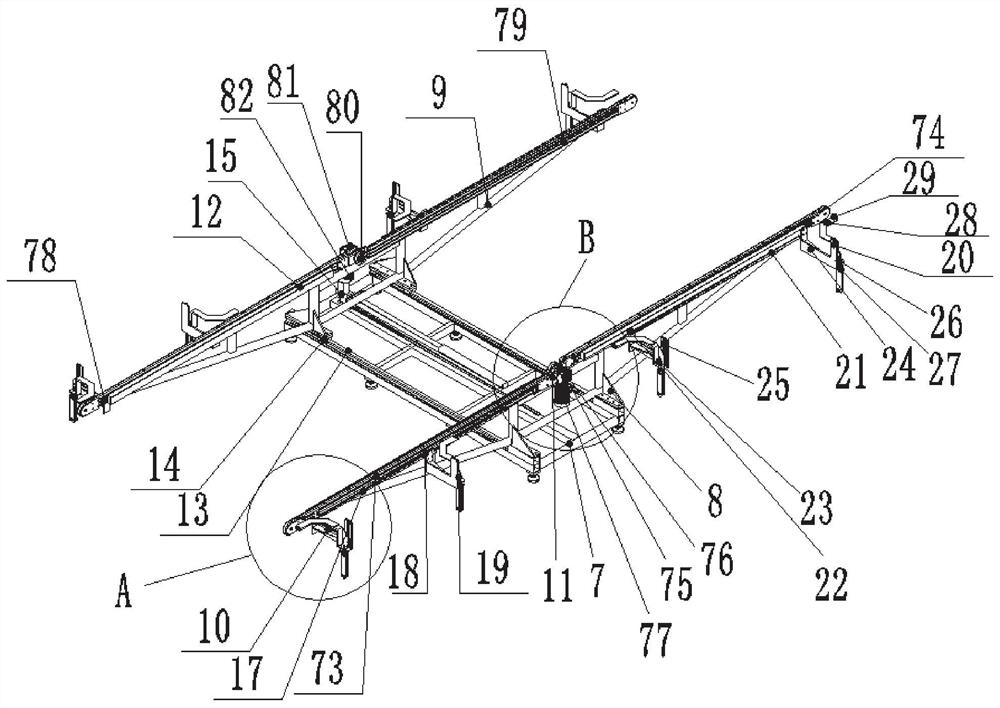

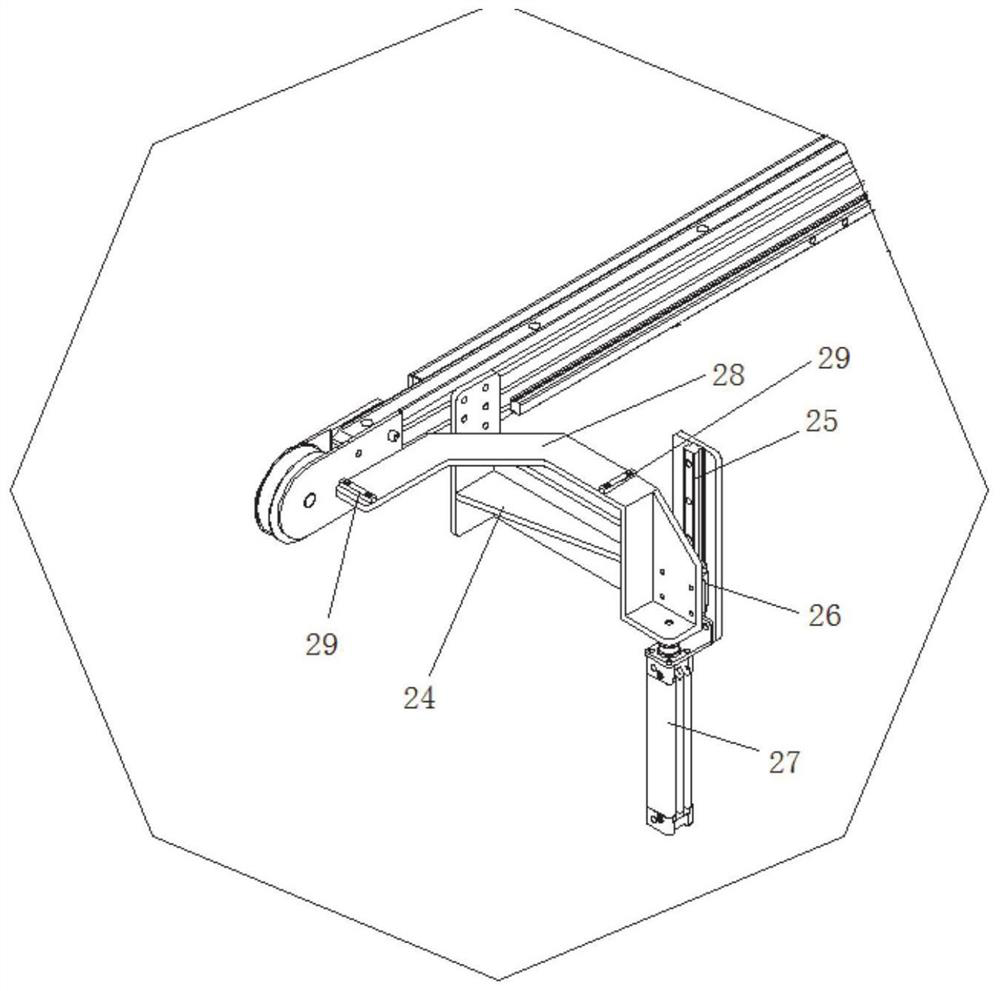

[0041] This embodiment discloses an aluminum alloy door and window assembly corner production line, such as Figure 1-Figure 15 As shown, it includes an assembly device 1 , a waiting device 2 , a corner assembly device 3 and a transmission device 4 arranged in sequence along the first direction. The direction perpendicular to the first direction is the second direction.

[0042] The assembly device is used to assemble the corners of the profile, and the aluminum alloy door and window frame of the profile is then sent to the waiting device. The waiting device is used to wait for the corner assembly device to complete the corner assembly of the previous aluminum alloy door and window frame, and assemble the supported corners The aluminum alloy door and window frame is sent to the corner assembly device. The corner assembly device is used to perform corner assembly operation on the aluminum alloy door and window frame. The transmission device is used to receive the aluminum alloy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com