Milled composite ram apparatus

A ram, turning and milling technology, which is applied to other manufacturing equipment/tools, large fixed members, metal processing machinery parts, etc., can solve the problems of large space, low degree of automation, and restrictions on the operation capacity of machine tools, and achieve small size, drive The effect of high power and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

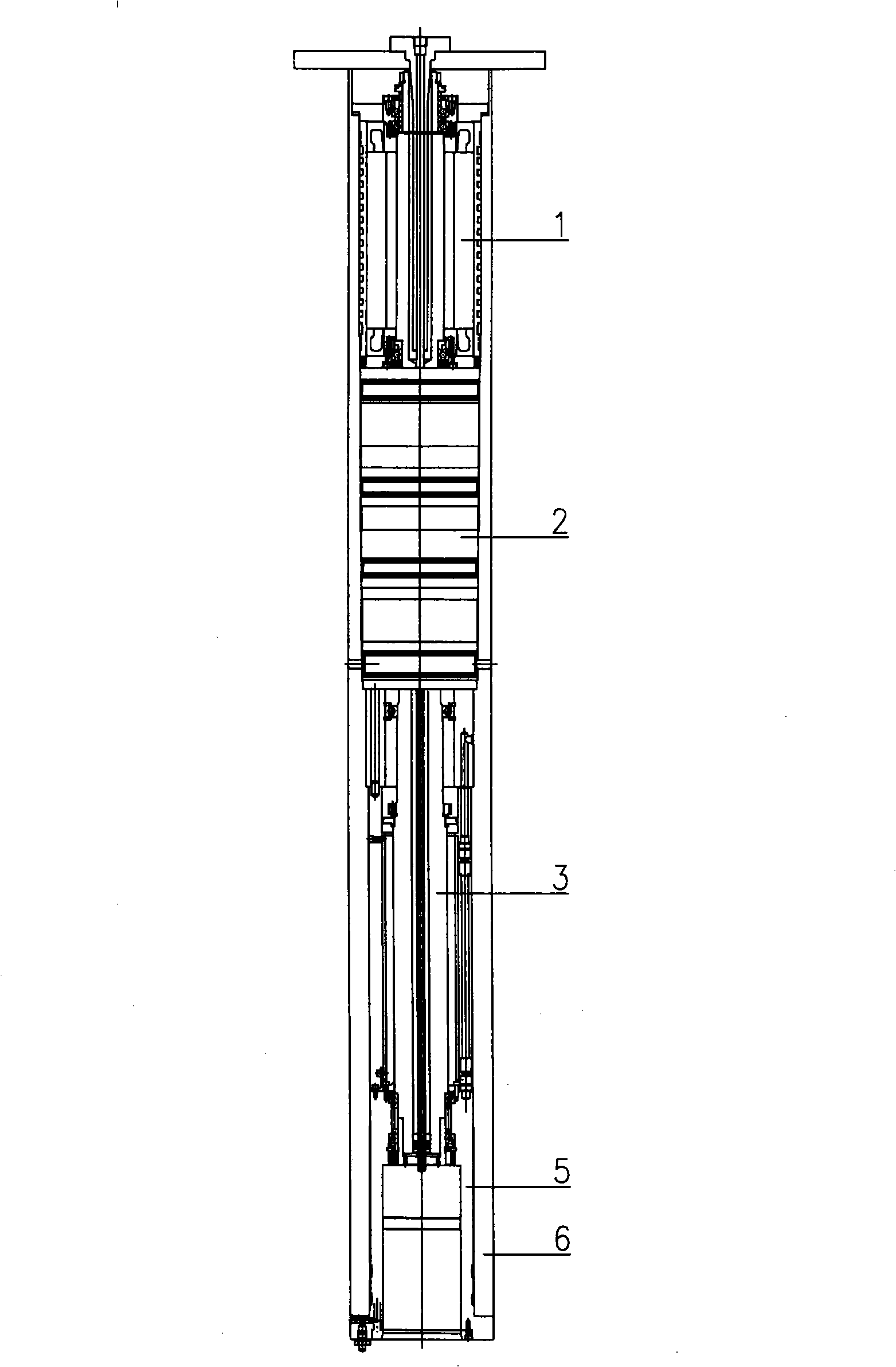

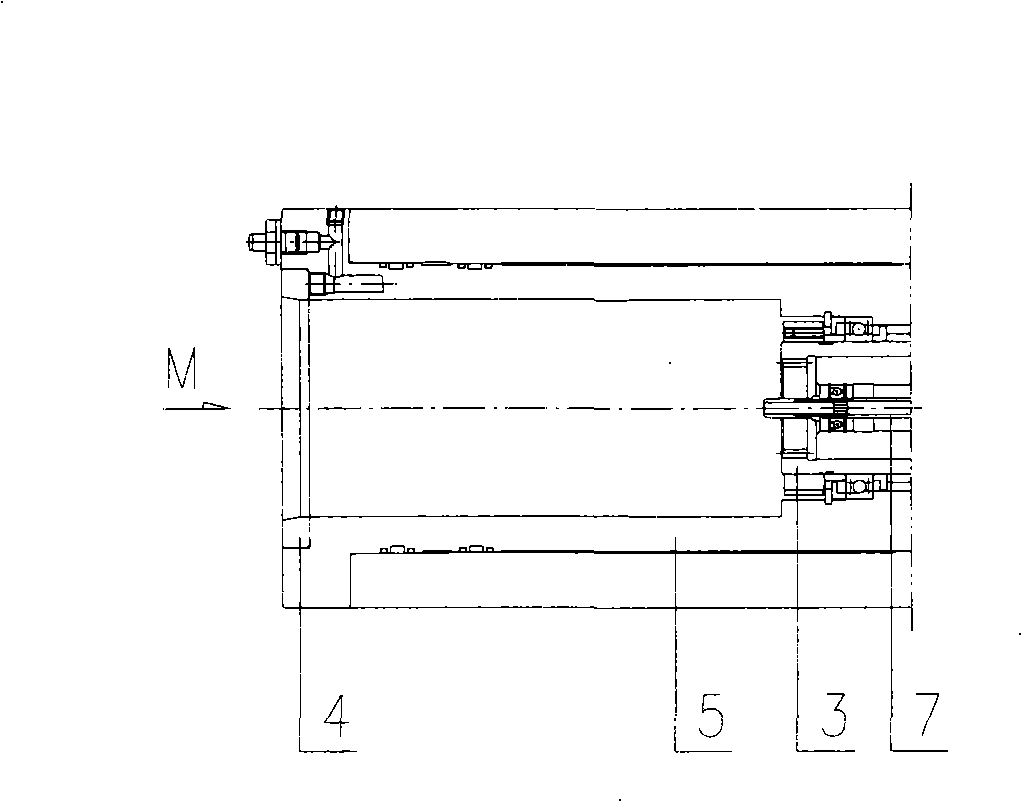

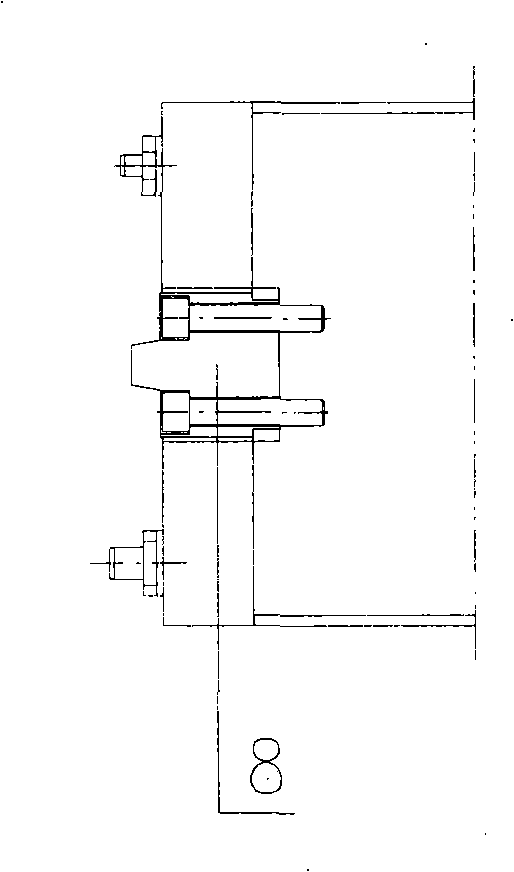

[0014] Turn-mill compound ram device, including motor, gearbox, output shaft and attachment head connection mechanism integrated in the housing, see figure 1 : It is characterized in that the built-in spindle motor integrated in the ram shell 6 is a Siemens wide-speed adjustable AC main servo motor. The main servo motor is mainly composed of a mandrel, a rotor, a stator, and a water jacket. The mandrel and the rotor are through interference fit. connected, and integrated with the stator and the water jacket through the end cover and the supporting bearing to form the AC main servo motor unit 1, and the AC main servo motor unit 1 is matched with the round hole above the ram shell 6 through the outer diameter of the water jacket and The mounting screws on the end cap are connected with the ram housing 6 . The detection of the motor speed is detected by a micro-tooth encoder installed on the motor. The gear sleeve of the encoder is fixed on the core shaft of the motor through a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com