Pump type scraper head matched device

A scraper head and pump-type technology, which is applied in the field of pump-type scraper head supporting devices, achieves the effects of weight reduction, simple extrusion and injection, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

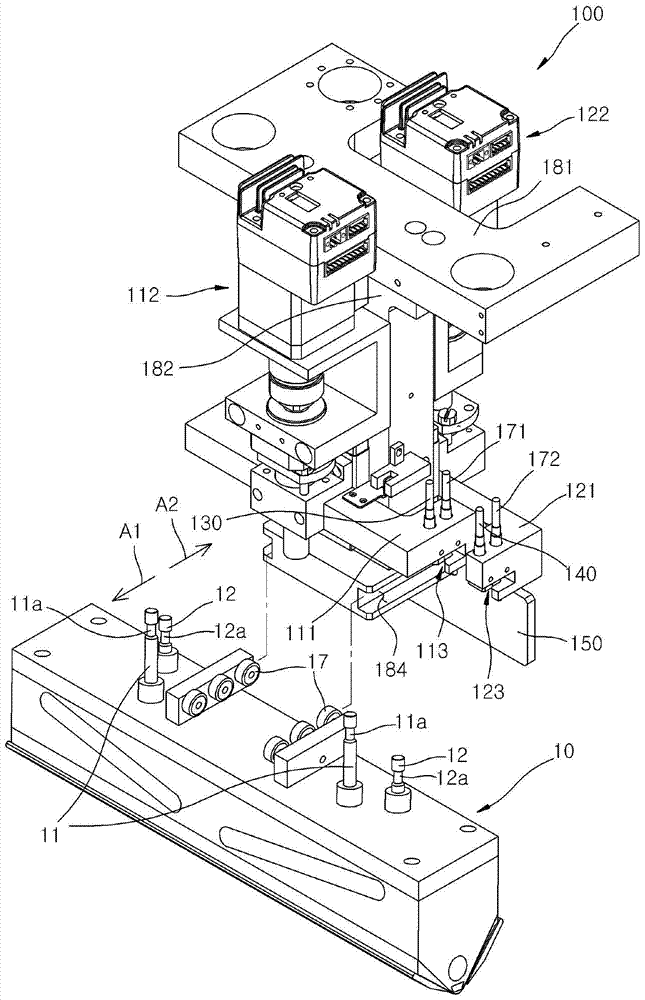

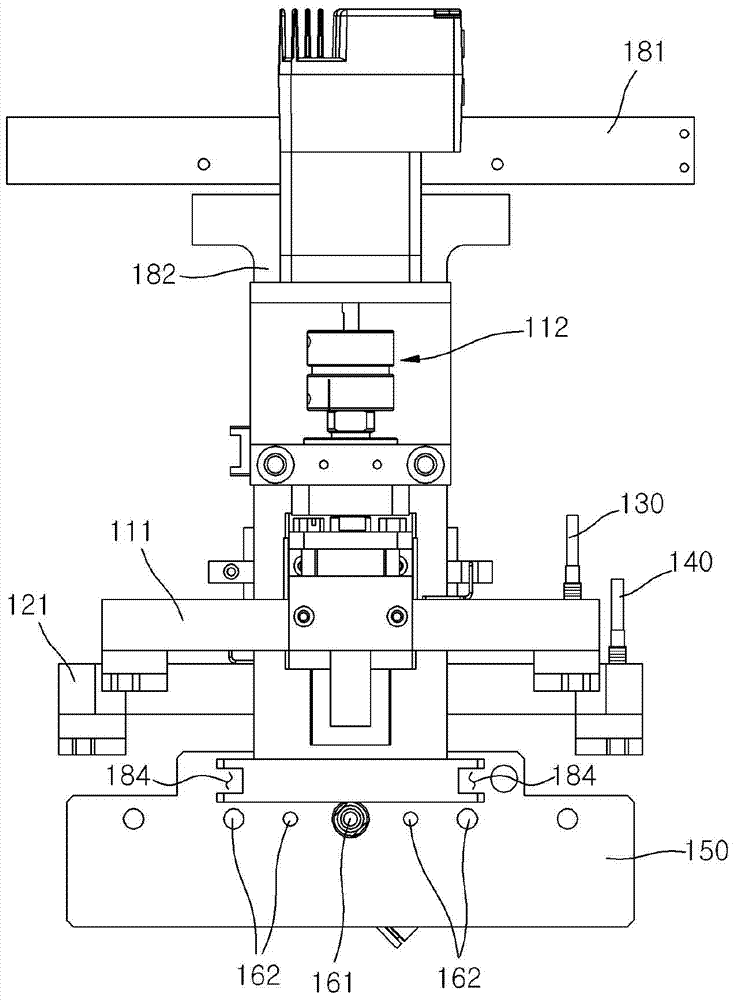

[0047] In order to facilitate the understanding of those skilled in the art, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments:

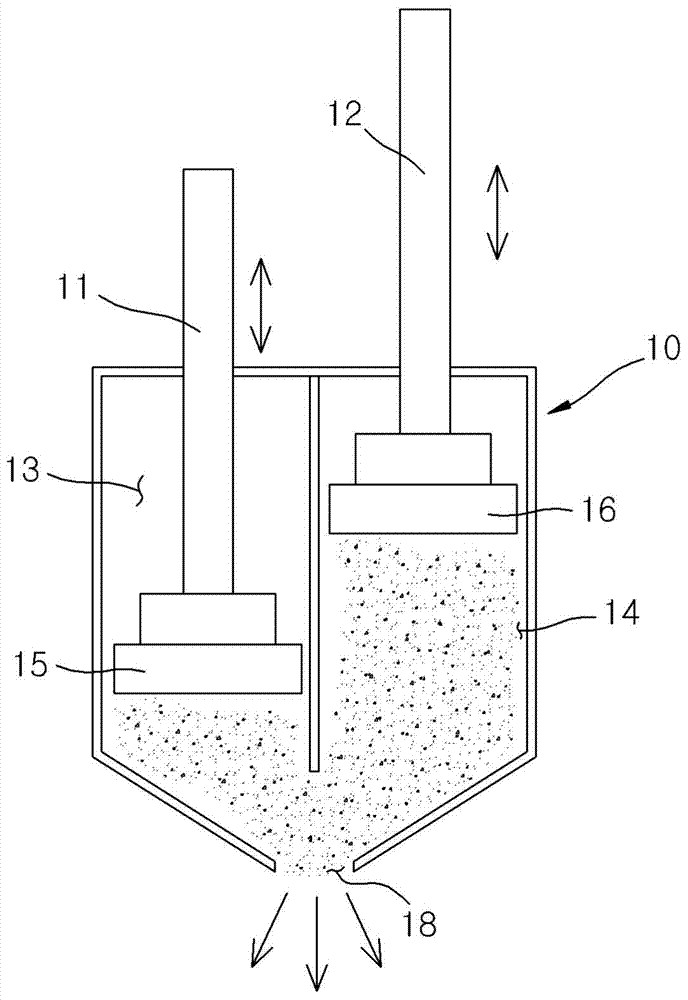

[0048] Such as Figure 2-9 As shown, the present invention discloses a pump-type scraper head matching device capable of accurately and automatically controlling the pump-type scraper head 10 . When applying solder paste to the PCB board, by using this pump-type scraper head matching device, the solder paste can be automatically extruded and sprayed, and filled on the solder pad of the circuit board through the stencil.

[0049] refer to figure 2 , the supporting device of the pump scraper head, including:

[0050] a first driving assembly for driving the lifting movement of the first pressing rod;

[0051] a second driving assembly for driving the lifting movement of the second pressing rod;

[0052] A sensor assembly for sensing the position signals of the first and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com