Grout sealing device of advance strengthening and grout sealing device and advance strengthening and grout sealing device

An advance reinforcement and sealing technology, applied in shaft equipment, wellbore lining, tunnel lining, etc., can solve problems such as small overflow area, increased manufacturing and installation costs, and blockage of the slurry port, and achieve a simple structure of the slurry sealer , reduce the probability of blocking, reduce the effect of flipping angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

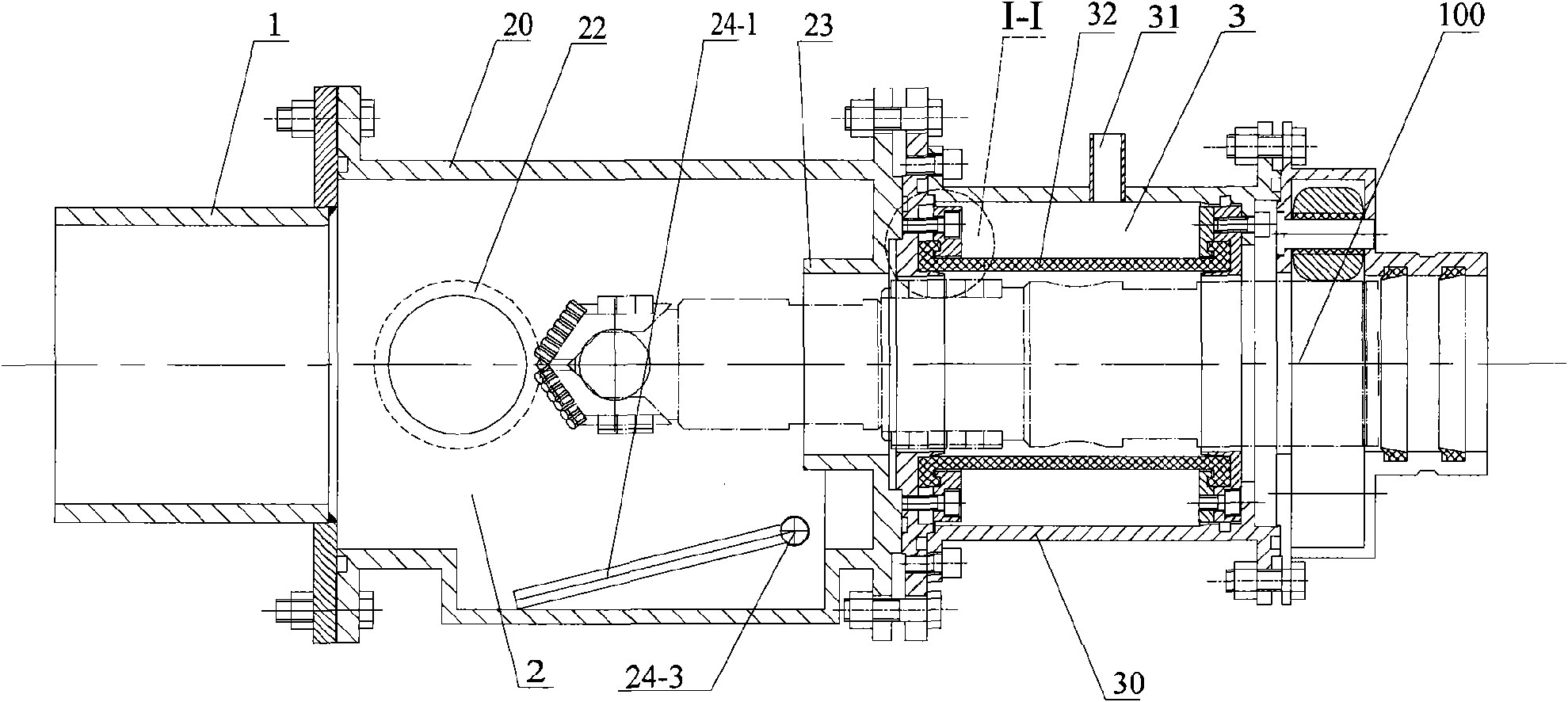

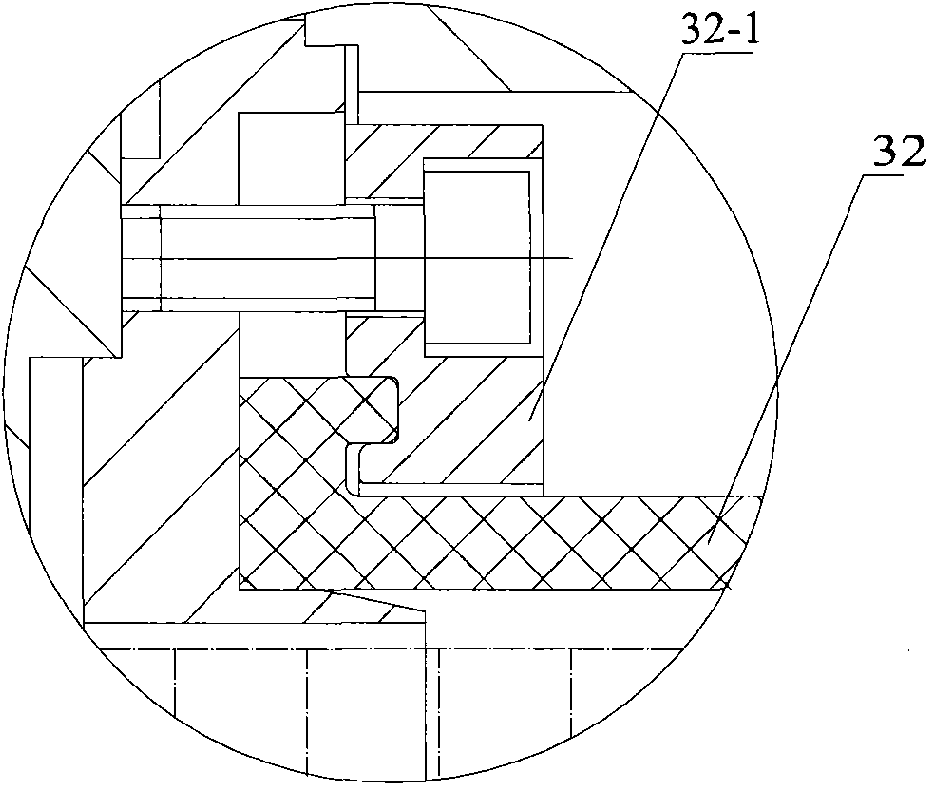

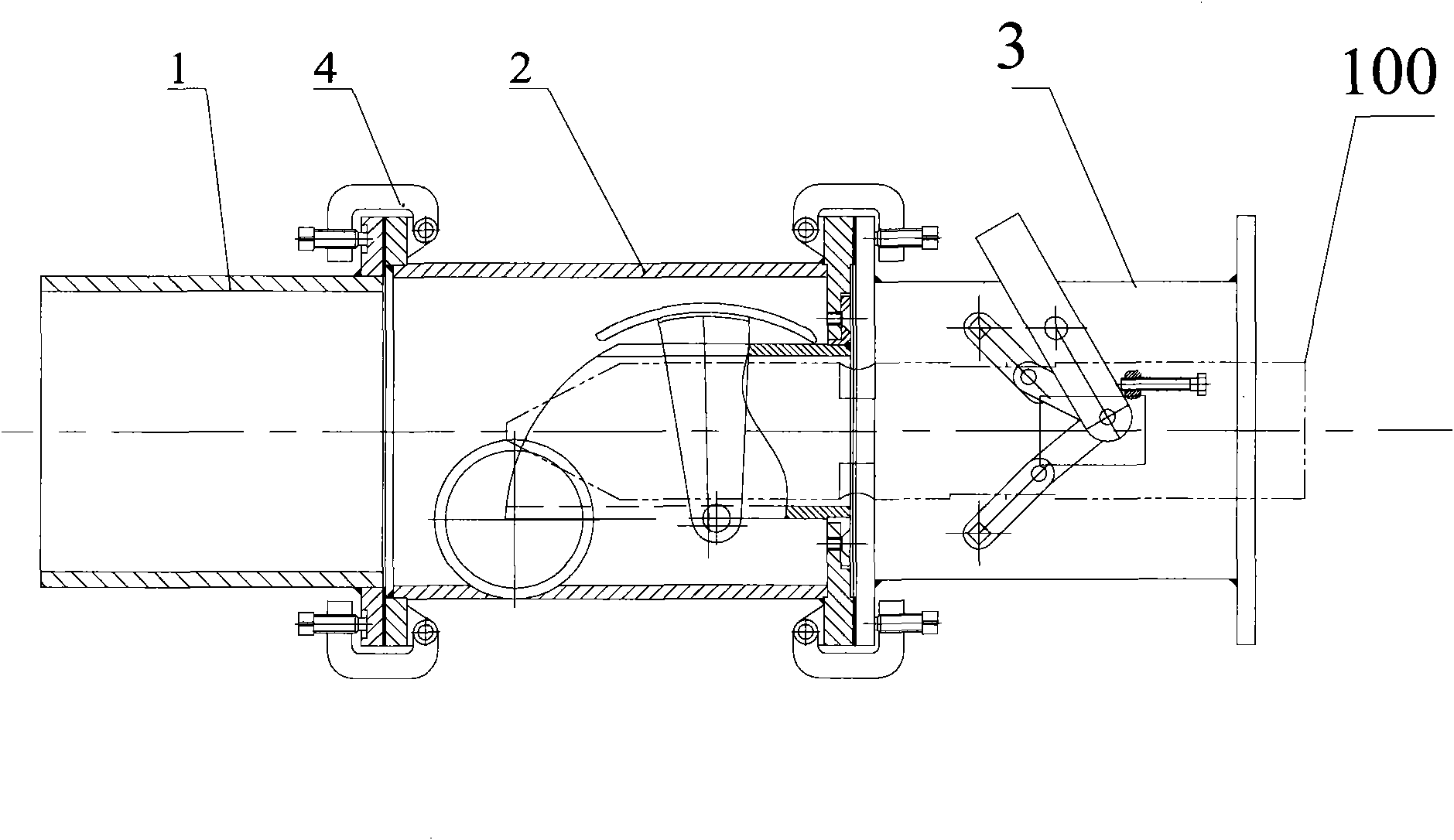

[0055] The content of the present invention will be described in detail below in conjunction with the accompanying drawings. In this part, while the overall description of the advanced reinforcement sealing device is given, the structure and working principle of the sealing device are described, so the structure of the sealing device will not be described separately. described separately. The description in this section is only explanatory and exemplary, and unless otherwise specified, the specific description sequence and language should not have any limiting effect on the protection scope of the present invention.

[0056] like image 3 As shown, the advance reinforcement sealing device includes three parts: face pipe 1, overflow device 2 and sealer 3, between face pipe 1 and overflow device 2, and overflow device 2 and sealer 3 are connected by matching flanges, and the corresponding flanges are fixed together by fastening device 4. Each part is explained separately below...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com