Control method of automatic sorting system

An automatic sorting and control method technology, which is applied in the direction of packaging, etc., can solve the problems of slow material sorting speed and poor material stacking ability, and achieve the effect of ensuring the neatness of the arrangement, improving the conveying efficiency and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

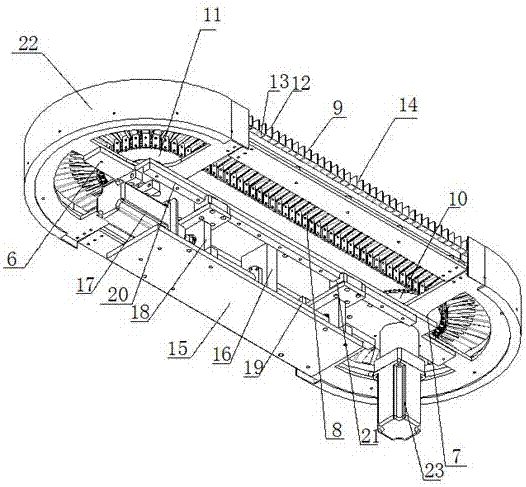

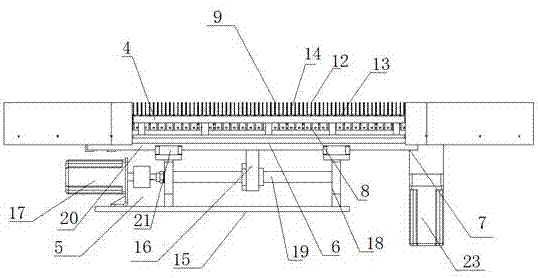

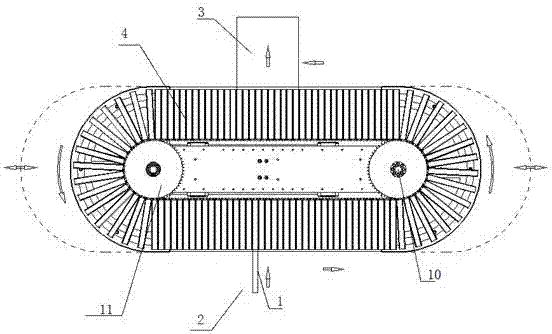

[0024] As a preferred embodiment of the present invention, refer to the appendix Figure 1-3 , This embodiment discloses:

[0025] The control method of the automatic sorting system is characterized in that it includes a control process A, a control process B, and a control process C;

[0026] The control process A specifically refers to cyclically arranging materials from the inlet to the outlet, and arranging a set of materials at the outlet; then entering the control process B;

[0027] The control process B refers to: set the material arrangement direction on the side of the material inlet as the positive direction. When a set of materials are arranged and output, during the output process, the circulating drive motor 23 is controlled to drive the circulating conveying mechanism along The square rotates cyclically, and the translational driving motor 17 is controlled to drive the entire circulating conveying mechanism to move in the positive direction, and then the circulating d...

Embodiment 2

[0030] As another preferred embodiment of the present invention, refer to the appendix of the specification Figure 1-3 , This embodiment discloses:

[0031] The control method of the automatic sorting system is characterized in that it includes a control process A, a control process B, and a control process C;

[0032] The control process A specifically refers to: aligning the trough of the circulating conveying mechanism with the material inlet, and after the material is conveyed to the trough, start the circulating driving motor 23, and the circulating driving motor 23 drives the circulating conveying mechanism to rotate one trough interval and stop Drive the motor 23 cyclically and wait for the next material to enter the trough; repeat until the set number of materials are arranged at the discharge port and enter the control flow B;

[0033] The control process B refers to: set the material arrangement direction on the side of the material inlet as the positive direction. When a...

Embodiment 3

[0036] As another preferred embodiment of the present invention, refer to the appendix of the specification Figure 1-3 , This embodiment discloses:

[0037] The control method of the automatic sorting system is characterized in that it includes a control process A, a control process B, and a control process C;

[0038] The control process A specifically refers to: aligning the trough of the circulating conveying mechanism with the material inlet, and after the material is conveyed to the trough, starting the circulating driving motor 23, and the circulating driving motor 23 drives the circulating conveying mechanism to rotate half a trough interval; Start the translation drive motor 17, and the translation drive motor 17 drives the circulation conveying mechanism to move half a trough interval in the positive direction; stop the circulation drive motor 23 and translation drive motor 17, waiting for the next material to enter the trough, and so on repeatedly receiving the set amoun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com