Automatic packaging system and packaging method for bagged products

An automatic packaging and product technology, applied in the direction of packaging automatic control, packaging, transportation and packaging, etc., can solve the problems of low equipment utilization rate, increase enterprise production and operating costs, etc., achieve high utilization rate, improve production and packaging efficiency, and adaptability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

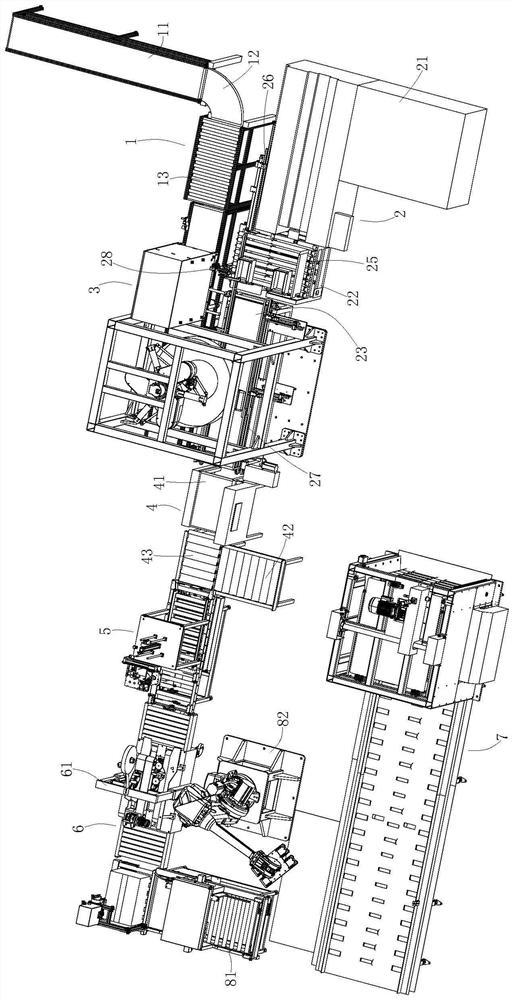

[0024] The invention provides an automatic packaging system for bagged products, which mainly realizes automatic boxing, unpacking, weighing, vibration sorting of products in bags, labeling, box sealing, coding, stamping and palletizing for flexible bagged products The function of blanking can effectively solve the problem of high labor intensity, low packaging efficiency, and unguaranteed food safety in the packaging industry of flexible bagged products. Moreover, the automatic packaging system for bagged products has a high production capacity, and the bagged products can be packed up to 50 bags. per minute, it can also realize the packaging production of products of different sizes and packing boxes of different sizes.

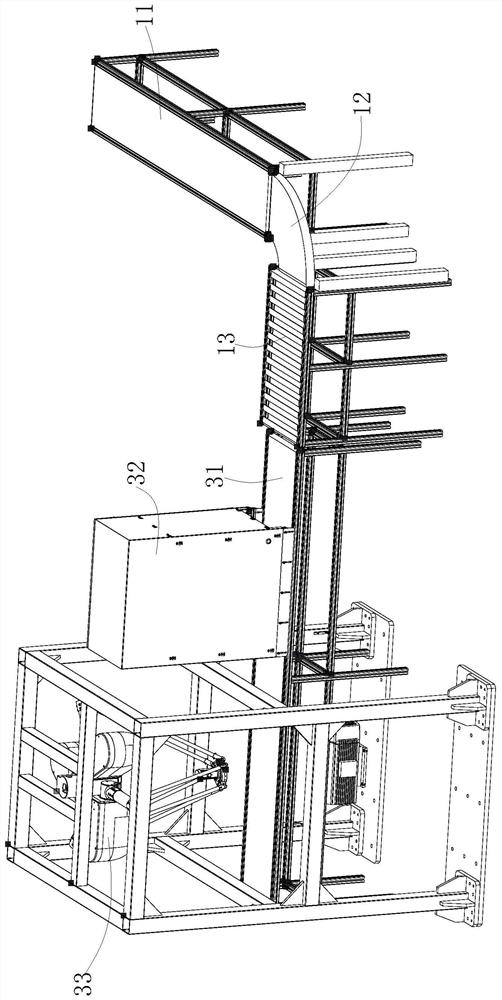

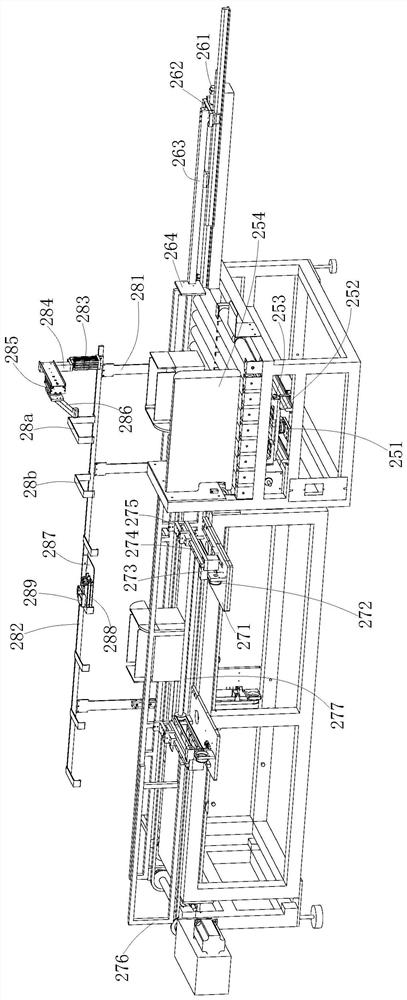

[0025] In o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com