Boxing and packaging machine for medical syringes

A packaging machine and syringe technology, which is applied in the field of automation, can solve the problems of detecting many cartoning steps, consuming a lot of labor resources, low production efficiency, etc., and achieving the effects of good packaging effect, reasonable and ingenious space design, and improved efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

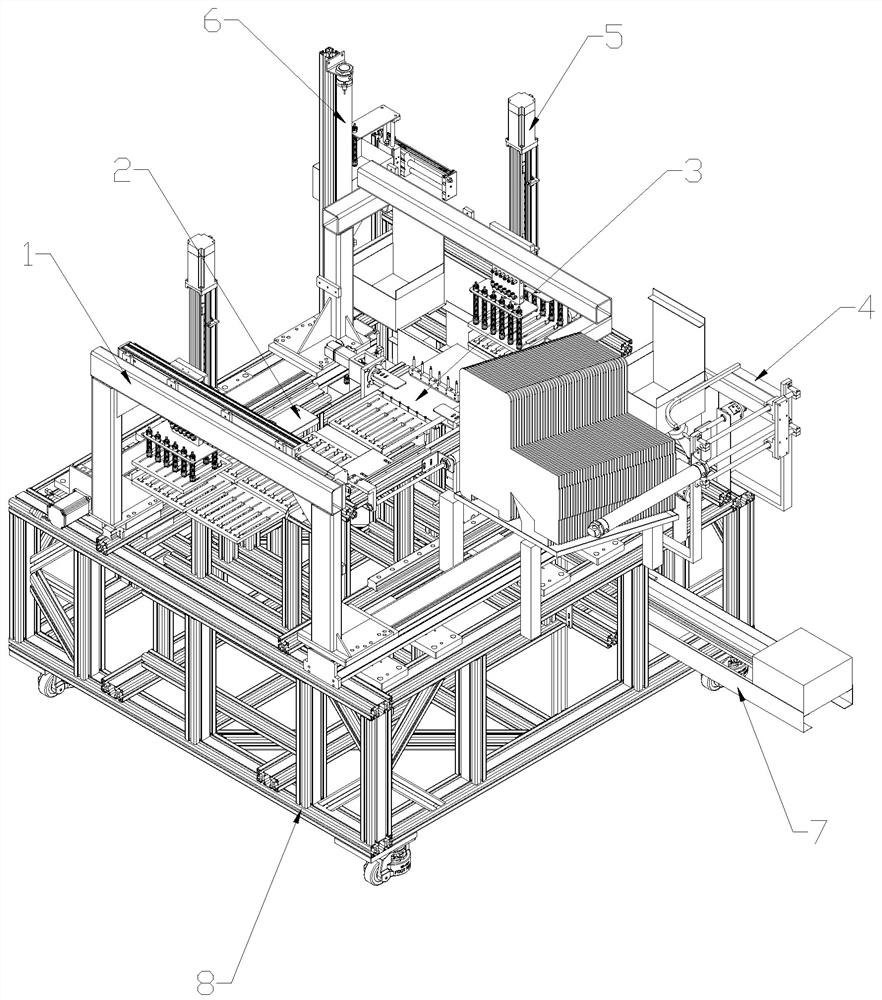

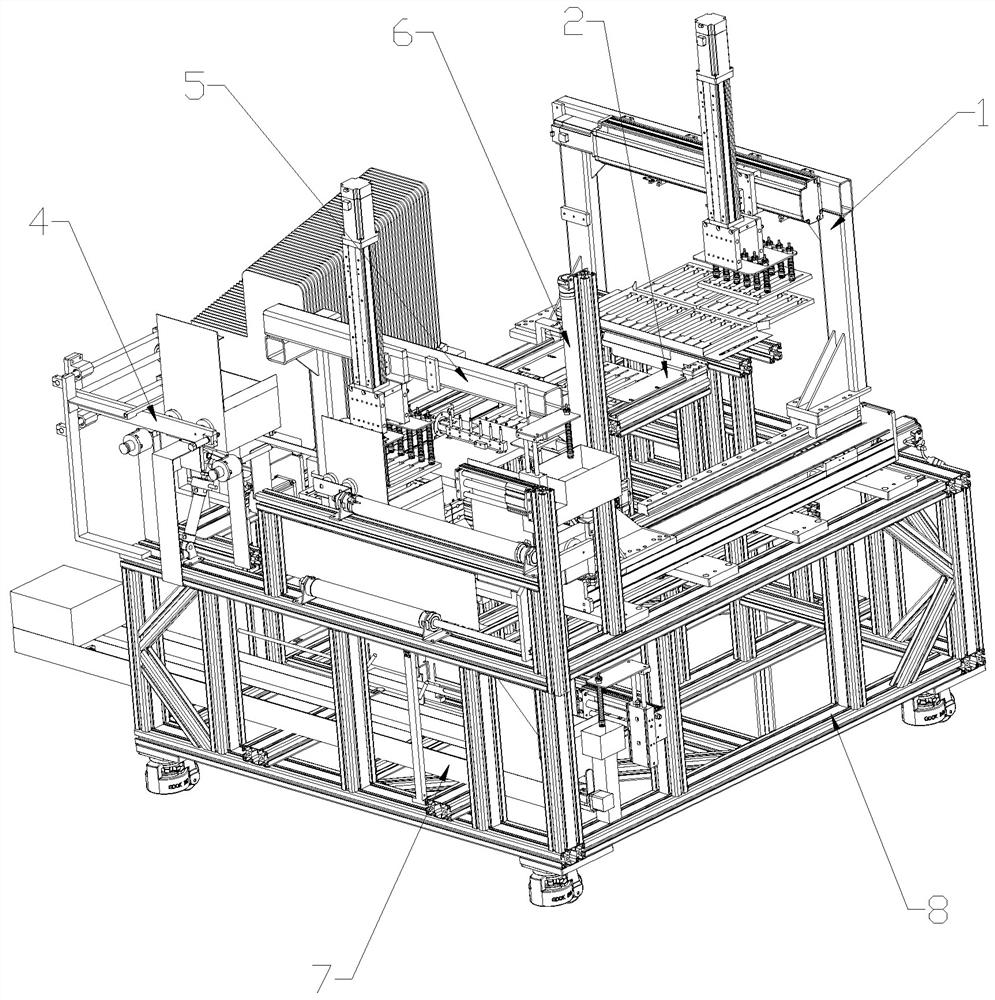

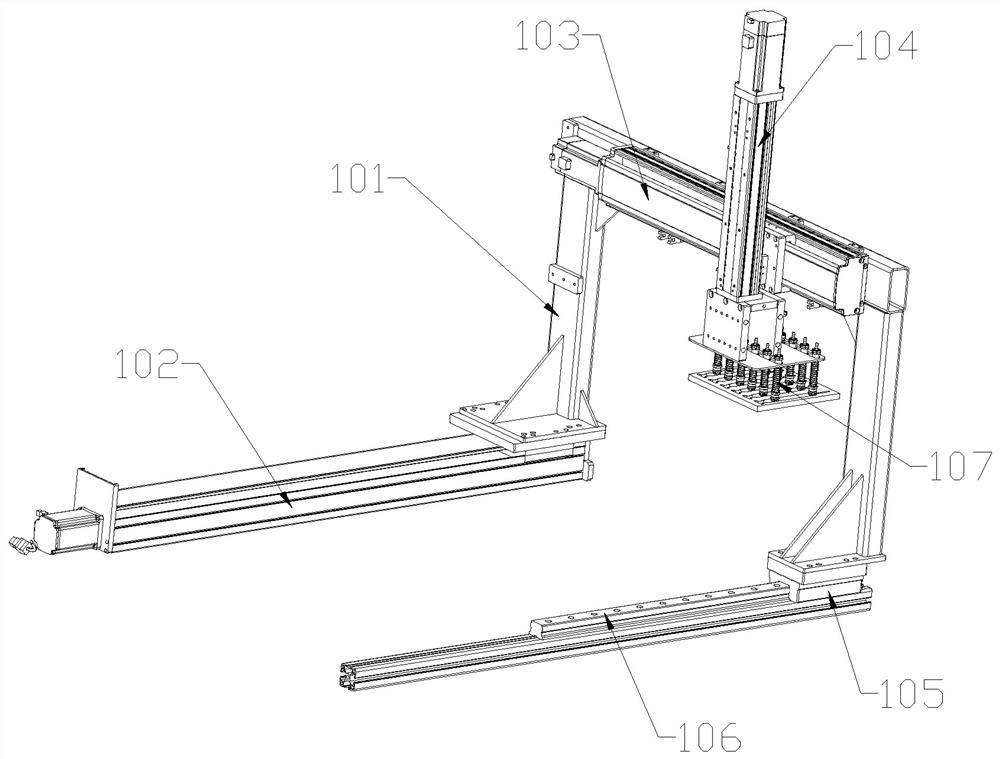

[0043] Such as Figure 1 to Figure 2 As shown, in this embodiment, a medical syringe cartoning and packaging machine includes a main frame 8, an incoming material docking component 1, a detection component 2, a material in-situ turning platform 3, a cartoning component 5, and a box opening component 4. Lifting and replenishing component 6 and box sealing component 7, the incoming material docking component 1 is located in front of the material in-situ turning platform 3, and the detection component 2 is located between the incoming material docking component 1 and the material Between the in-situ turning platforms 3, the box-loading assembly 5 is located above the material in-situ turning platform, and the box-opening component 4 is on one side of the material in-situ turning platform 3 and extends ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com