Rapid packaging method of strip-shaped articles and packaging line with method

A packaging method and strip technology, applied in the direction of conveyor belt wrapping, etc., can solve the problems of low production efficiency, a large amount of labor input, increased production costs, etc., and achieve the effect of improving production efficiency and saving manpower input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

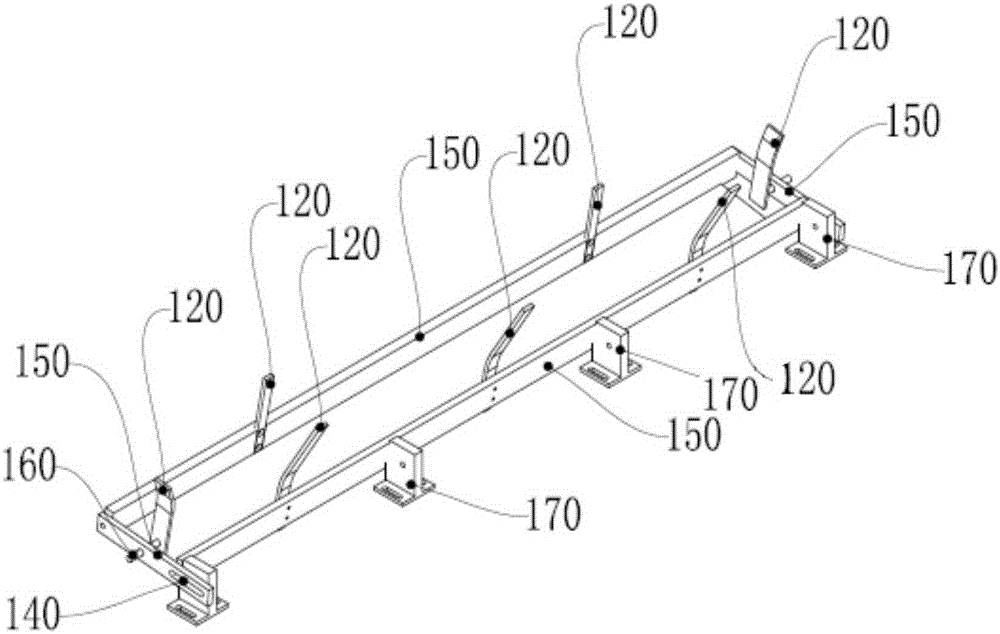

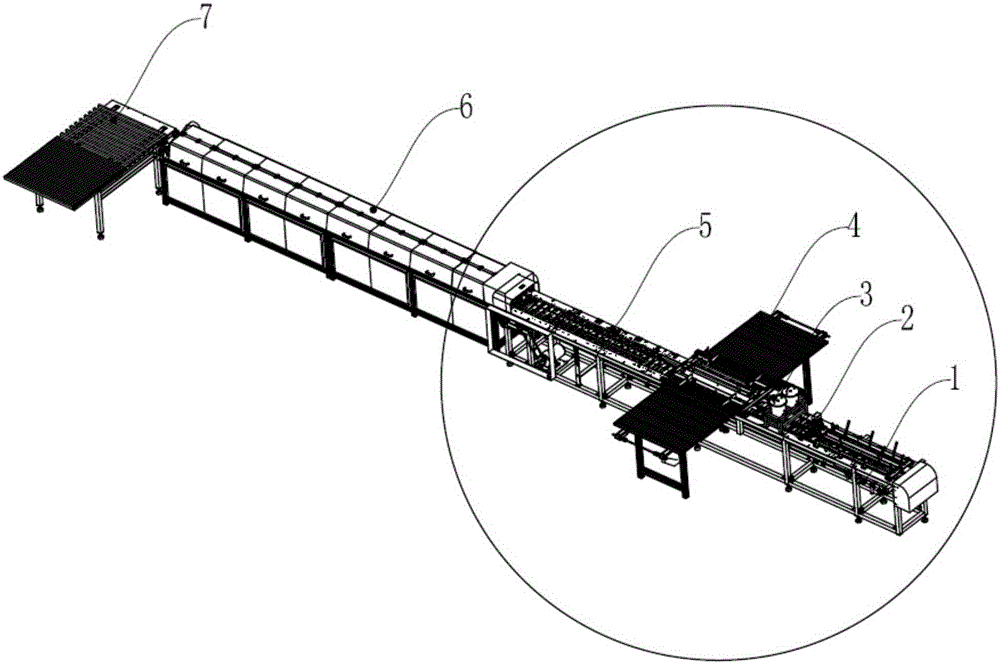

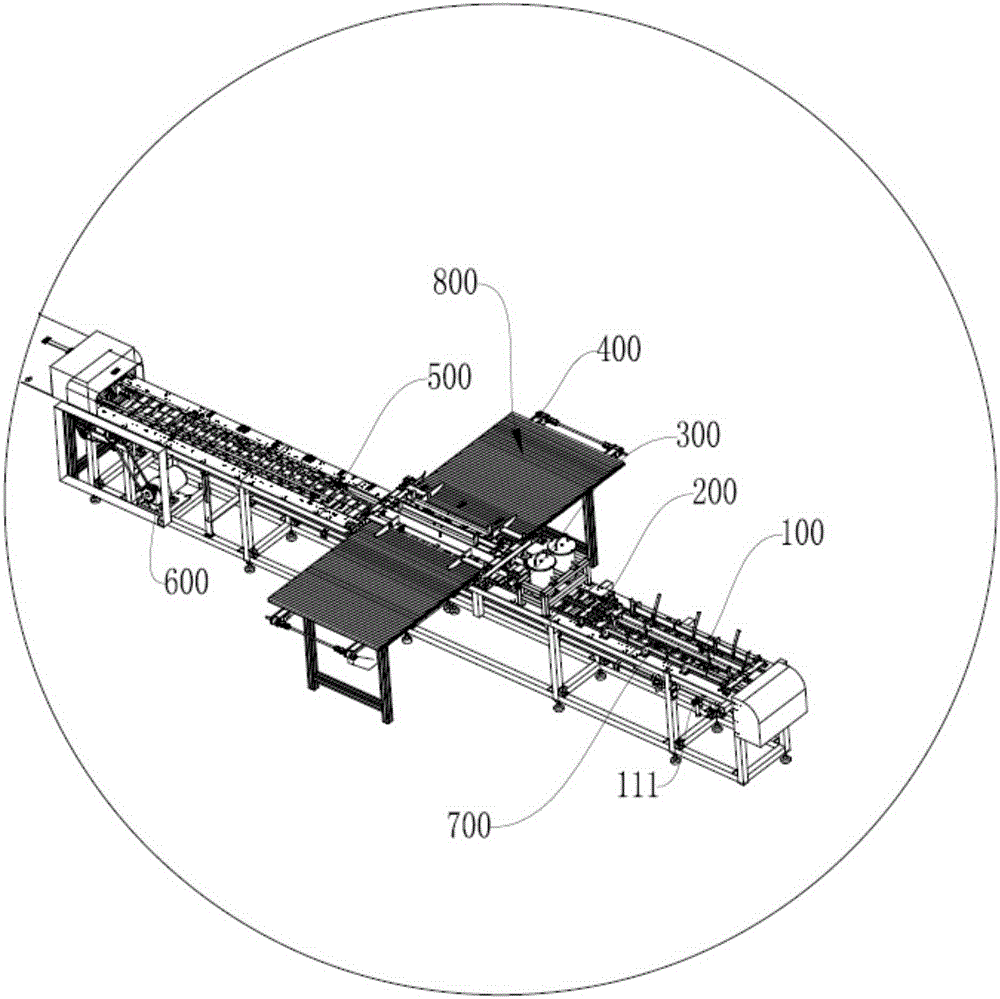

[0037] like figure 1 As shown, a packaging machine is provided with two packaging lines applying the above-mentioned rapid packaging method, and the two packaging lines are symmetrically arranged on the left and right sides, and each of the packaging lines is divided into a paper sheet blanking section 1 sequentially as a whole. , patting paper positioning section 2, kneading paper gluing section 3, strip blanking section 4, folding gluing section 5, shape-preserving transportation section 6, and discharge storage table 7; figure 2 As shown, it includes a bottom frame, a conveying chain 700, a paper sheet unloading device 100, a paper beating device 200, a rubbing paper sheet (marked in the figure), a gluing device 300, a strip unloading device 400, and a folding and gluing device 500 and driving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com