A copy paper packing machine

A paper cartoning machine and copy paper technology, which is applied in the field of improvement and invention of copying paper cartoning machines, can solve the problems of wasting manpower and low efficiency, and achieve the effects of improving production efficiency and saving resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

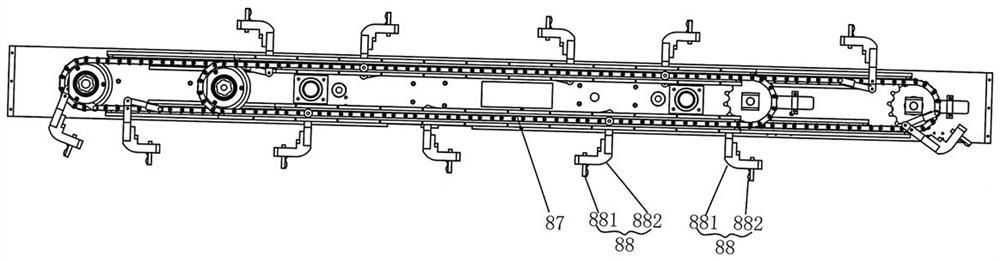

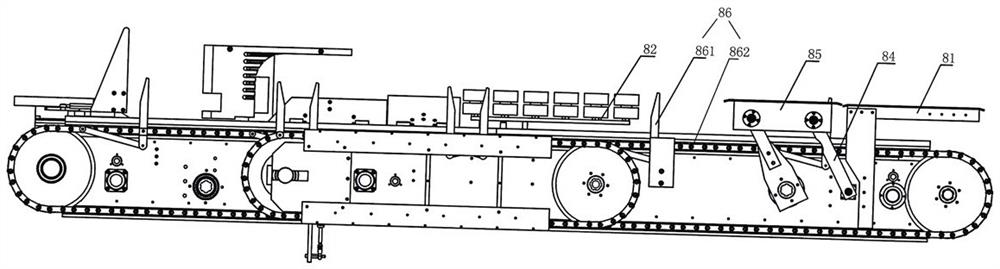

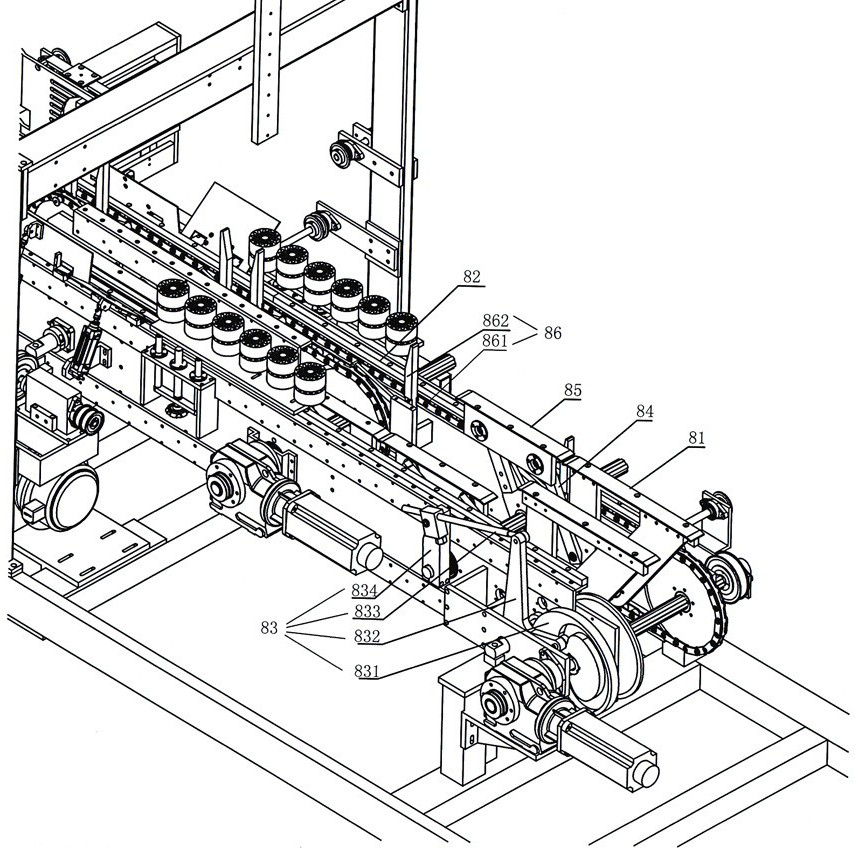

[0050] Referring to the accompanying drawings, the copy paper box packing machine includes a pushing device 101 for pushing the stacked copy paper into the lower cover, a lower cover feeding device 102, a carton lower cover forming device 103, and an upper cover feeding device 104 1. Carton upper cover forming device 105 and conveying channel, said conveying channel includes front and rear high conveying channels and middle low conveying channel, said pushing device 101 is arranged at front high conveying channel 80, said carton upper cover forming device is set At the rear high conveying passage 81, the carton lower cover forming device is arranged at the middle low conveying passage 82, and the front and rear copy paper receiving devices are arranged between the height difference of the high and low conveying passages.

[0051] The pushing device includes a paper conveying path, and both sides of the paper conveying path are provided with a pushing arm 1 that is closed when t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com