A fully automatic cotton socks packaging machine

A fully automatic, packaging machine technology, applied in packaging and other directions, can solve the problems of low work efficiency, high labor intensity, easy to make mistakes, etc., and achieve the effect of high work efficiency, low labor intensity, and not easy to make mistakes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

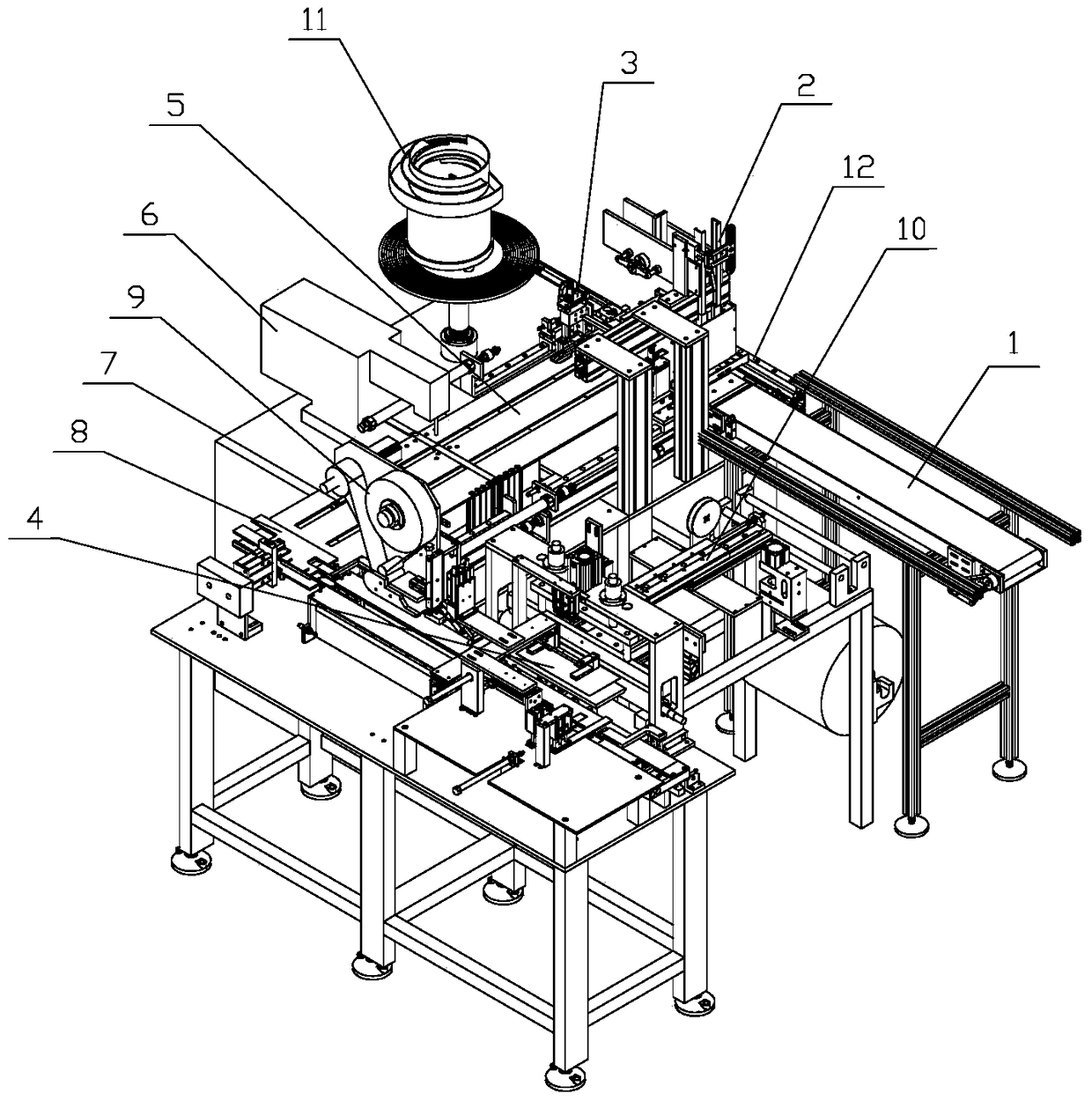

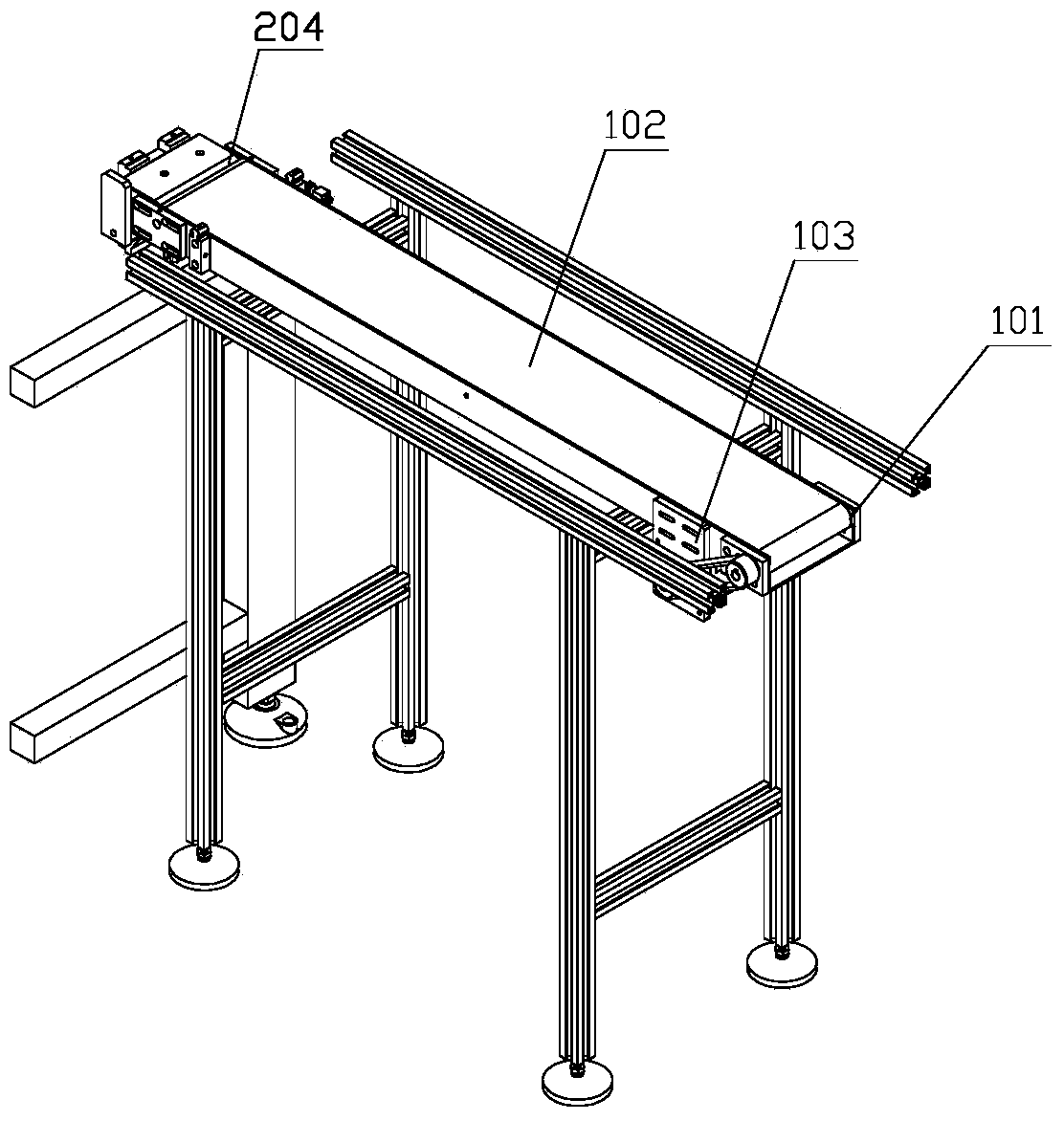

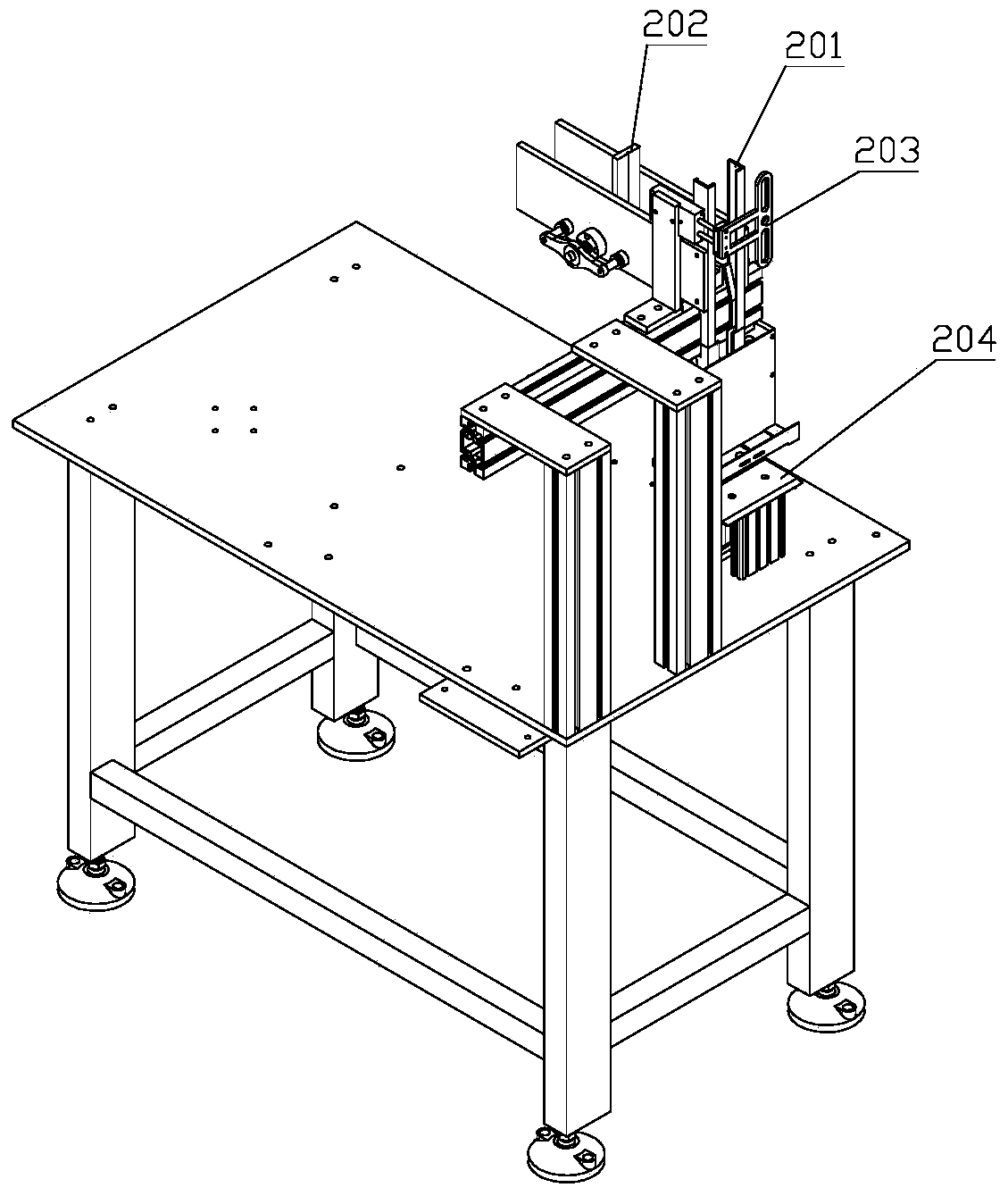

[0023] Example 1: see figure 1 , figure 2 , a fully automatic cotton socks packaging machine, including a sock feeding mechanism 1, a cardboard distribution mechanism 2 docked at the outlet end of the sock feeding mechanism 1, a sock hook insertion mechanism 3 docked on the cardboard distribution mechanism 2, and a sock hook insertion mechanism 3 One side is provided with a sock hook vibration plate 11 docked with it, the sock hook insertion mechanism 3 is docked with a sock conveying platform 5, and one side of the sock conveying platform 5 is provided with a sock cardboard knotting machine distribution mechanism 6, and the sock conveying platform 5 The outlet end of the sock is provided with a sock clamping and pushing mechanism 7 and a sock turning machine 8, and one side of the sock turning machine 8 is provided with a labeling mechanism 9, and a sock bag forming mechanism 10 and a socks bagging mechanism 4 are docked on the labeling mechanism 9. The sock bag forming mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com