Metal powder packaging, labeling and boxing integrated device and process

A metal powder, standard packing technology, applied in the directions of packaging, transportation and packaging, the type of packaging items, etc., can solve the problems of troublesome work flow and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

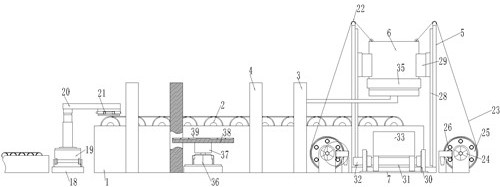

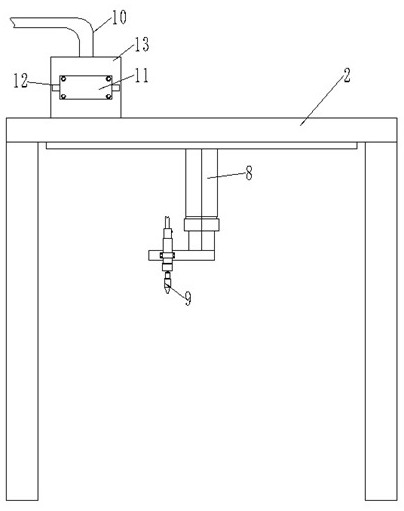

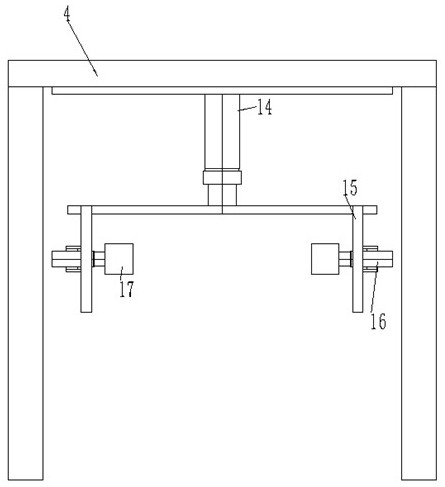

[0047]An integrated equipment for packaging, labeling, and boxing metal powder, including a conveying seat 1, a conveyor 2, a first portal frame 3, a second portal frame 4, a tank frame 5, a container tank 6, and a feeding base 7. The conveyor 2 is set on the transfer seat 1, the first gantry 3 and the second gantry 4 both span the transfer seat 1, the conveyor is located at the transfer seat 1, and there is a material between the conveyor and the transfer seat 1 Take the structure, the feeding base 7 is provided with a feeding structure, the first portal frame 3 is provided with a filling structure, and the second portal frame 4 is provided with a coding structure;

[0048] One side of the second gantry 4 is provided with a third gantry 52 and a fourth gantry 53 in turn, one side of the transfer seat 1 is provided with a bottle cap transmission structure, and the third gantry 52 is provided with a bottle cap placement structure, The fourth gantry 53 is provided with a bottle ...

Embodiment 2

[0075] S1: Pour the metal powder into the feeding structure, and add the metal powder into the container tank 6 through the feeding structure;

[0076] S2: The bottle body is conveyed by the conveyor 2, and reaches the first portal frame 3, and the bottle body is filled by the filling structure;

[0077] S3: the control conveyor 2 continues to transmit, and the bottle body that has been filled is transferred to the bottom of the second portal frame 4, and the coding structure is controlled to code;

[0078] S4: the bottle body arrives at the third portal frame 52 after coding is completed, and the bottle cap is placed on the upper opening of the bottle body by using the bottle cap placement structure;

[0079] S5: the bottle body after the bottle cap is placed reaches the fourth gantry 53, and the bottle cap is clamped and fixed on the bottle body by the bottle cap fastening structure;

[0080] S6: Control the material picking structure to place the packaged and coded product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com