Full-automatic carton packing machine

A fully automatic and packing machine technology, which is applied in paper product packaging, packaging, transportation and packaging, etc., can solve the problems of low work efficiency and high labor intensity of workers, and achieve the effect of high packaging efficiency and labor reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

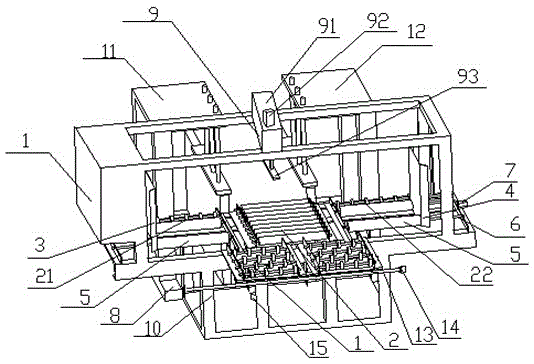

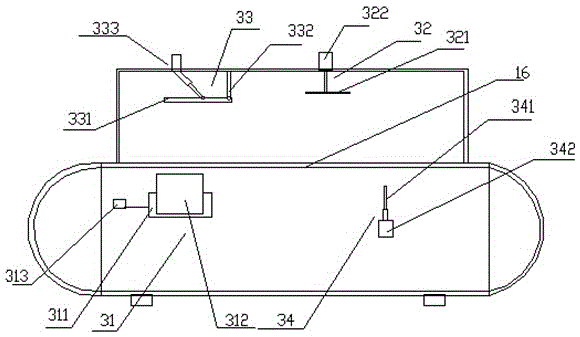

[0020] In this example, if figure 1 , figure 2 , image 3 and Figure 4 As shown, a fully automatic carton packing machine includes a welded first frame 10, a transmission mechanism and a cylinder master valve arranged on the first frame, and the outside of the transmission mechanism includes a compression mechanism and a Control the transmission mechanism, the cylinder master valve 8 and the controller of the compression mechanism. An upper extension device 26 is arranged between the first frame 10 and the compression mechanism. Through the technical scheme designed above, the cartons can be packed and the whole process can be realized. Automatic packaging, high packaging efficiency, reduced labor, in line with the needs of modern social development.

[0021] The transmission mechanism includes a driven roller 1 and a driving roller 2, and a first auxiliary roller 21 and a second auxiliary roller 22 arranged on both sides of the driving roller 2, and the first auxiliary r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com