Multifunctional robot gripper

A robotic gripper and multi-functional technology, which is applied in the direction of conveyor objects, object stacking, object destacking, etc., can solve the problem of single function of the robot gripper, and achieve the effect of saving time and manpower and good functionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

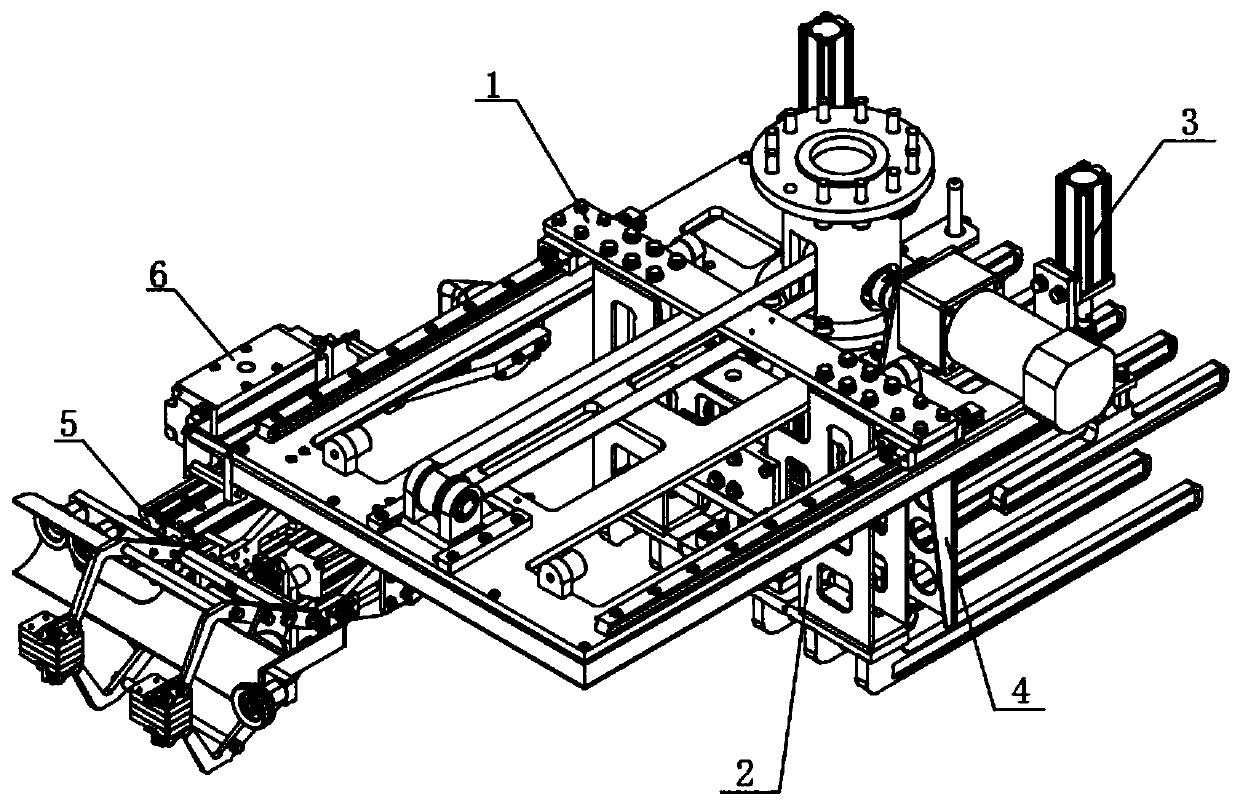

[0027] see figure 1 , in an embodiment of the present invention, a multifunctional robot gripper, including a machine base and a transmission part 1, an insertion claw part 2, a pressure claw part 3, a bag blocking and suction partition part 4, a bag fetching gripper part 5 and a bag The mouth shaping part 6 realizes fully automatic packaging.

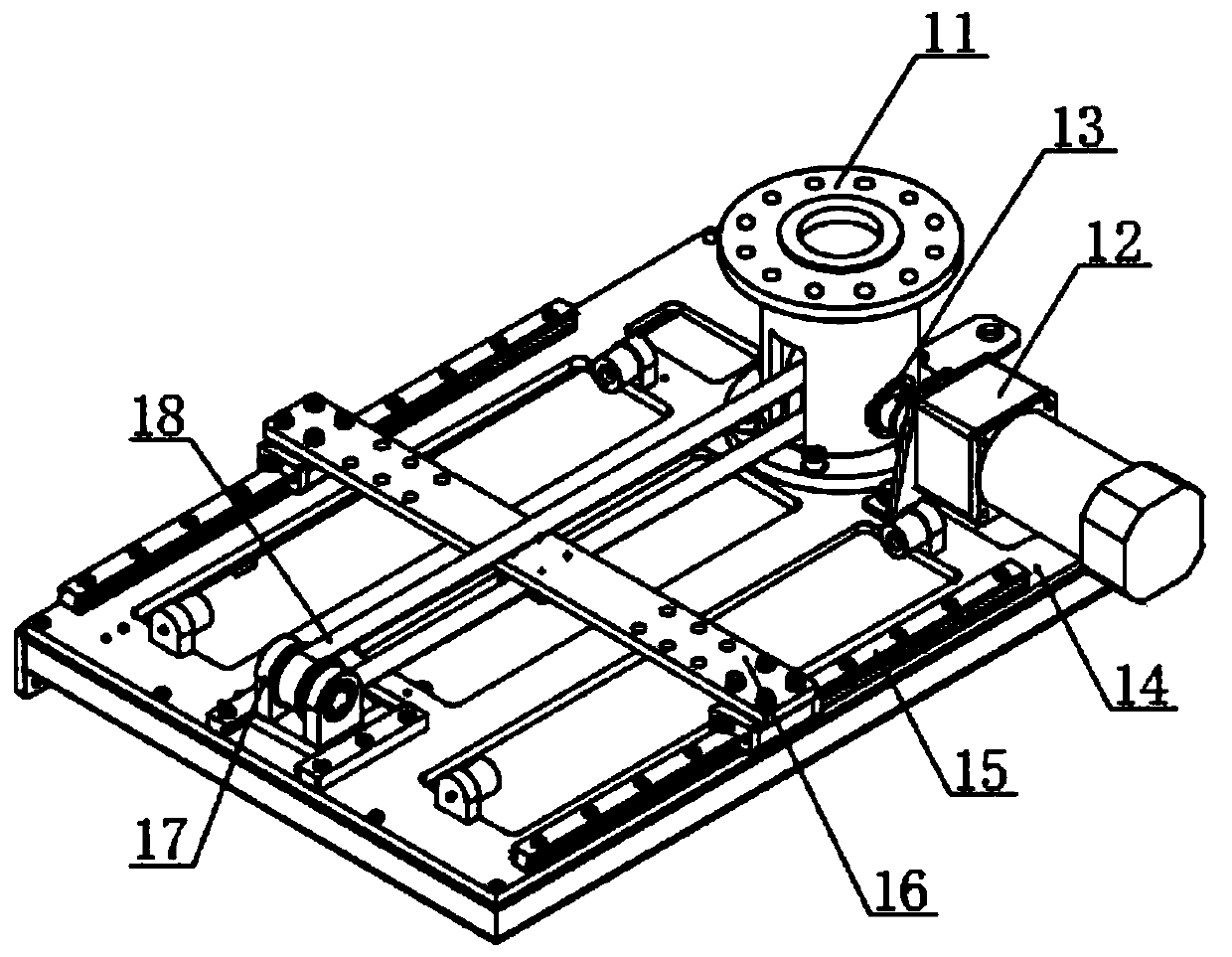

[0028] see figure 2 , the machine base and the transmission part 1 are connected with the six-axis robot, and the automatic bagging and unloading of the valve packaging, the grabbing tray, the cardboard and the palletizing function are realized simultaneously through the six-axis robot, which has very good functions It realizes the automatic working process and saves a lot of manpower; the base and the transmission part 1 include the robot connecting seat 11 connected with the end of the six-axis robot, and the six-axis robot is installed on the robot connecting seat 11, and the robot connecting seat 11 is fixed on the fixed frame 1...

Embodiment 2

[0034] A multi-functional robot gripper, which uses a six-axis robot to simultaneously realize the functions of automatic bagging and unloading, grabbing trays, suction plates, and palletizing of valve bag packaging. It has very good functionality and can be used in limited Fully automatic packaging is realized in the site, which saves a lot of time and manpower.

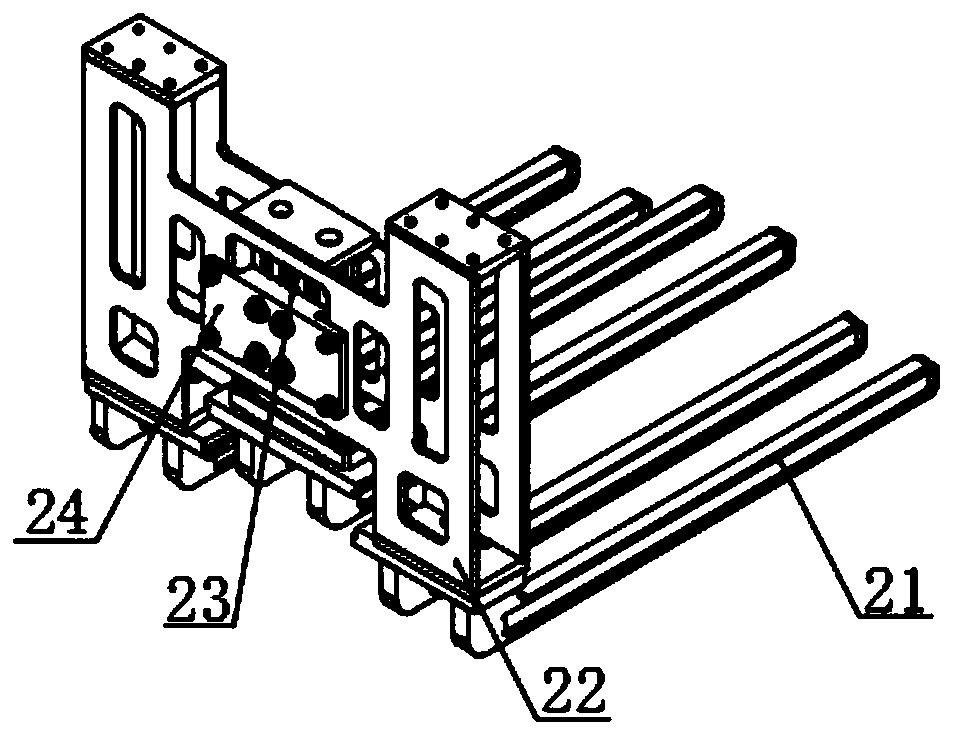

[0035] The working principle of the present invention is as follows: the empty bag is grabbed by the bag-receiving grip part 5, and the shaping is completed by the bag mouth shaping part 6 to complete the automatic bag loading, and the claw part 3 and the claw part 2 cooperate to grab the full bag. The bag blocking and suction partition part 4 is used to absorb cardboard (or film) and pad it on the pallet; the claw part 2 is used to grab the pallet and place it from the pallet warehouse to the palletizing station.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com